10 Part Number: 9295040 07/17

Installation Section 2

Electrical Service

DANGER

Check all wiring connections, including factory terminals,

before operation. Connections can become loose during

shipment and installation.

nWarning

This appliance must be grounded and all field wiring must

conform to all applicable local and national codes. Refer

to rating plate for proper voltage. It is the responsibility of

the end user to provide the disconnect means to satisfy

the authority having jurisdiction.

VOLTAGE

All electrical work, including wire routing and grounding,

must conform to local, state and national electrical codes.

The following precautions must be observed:

• The equipment must be grounded.

• A separate fuse/circuit breaker must be provided for each

unit.

• Check all green ground screws, cables and wire

connections to verify they are tight before start-up.

GROUND FAULT CIRCUIT INTERRUPTER

Ground Fault Circuit Interrupter (GFCI/GFI) protection is a

system that shuts down the electric circuit (opens it) when it

senses an unexpected loss of power, presumably to ground.

Welbilt does not recommend the use of GFCI/GFI circuit

protection to energize our equipment. If code requires the

use of a GFCI/GFI then you must follow the local code. The

circuit must be dedicated, sized properly and there must

be a panel GFCI/GFI breaker. We do not recommend the

use of GFCI/GFI outlets to energize our equipment as they

are known for more intermittent nuisance trips than panel

breakers.

Maximum 10ft (3m) cord with plug.

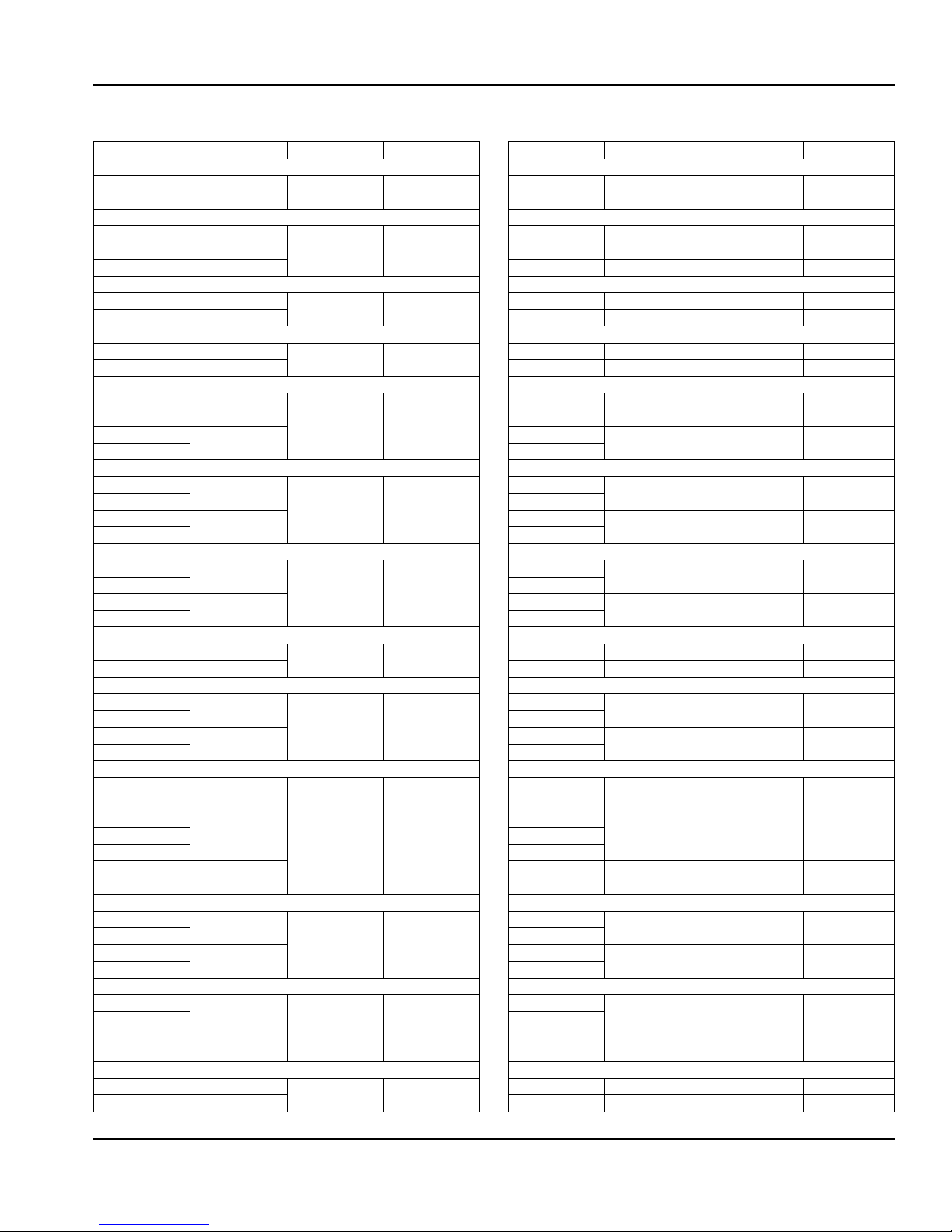

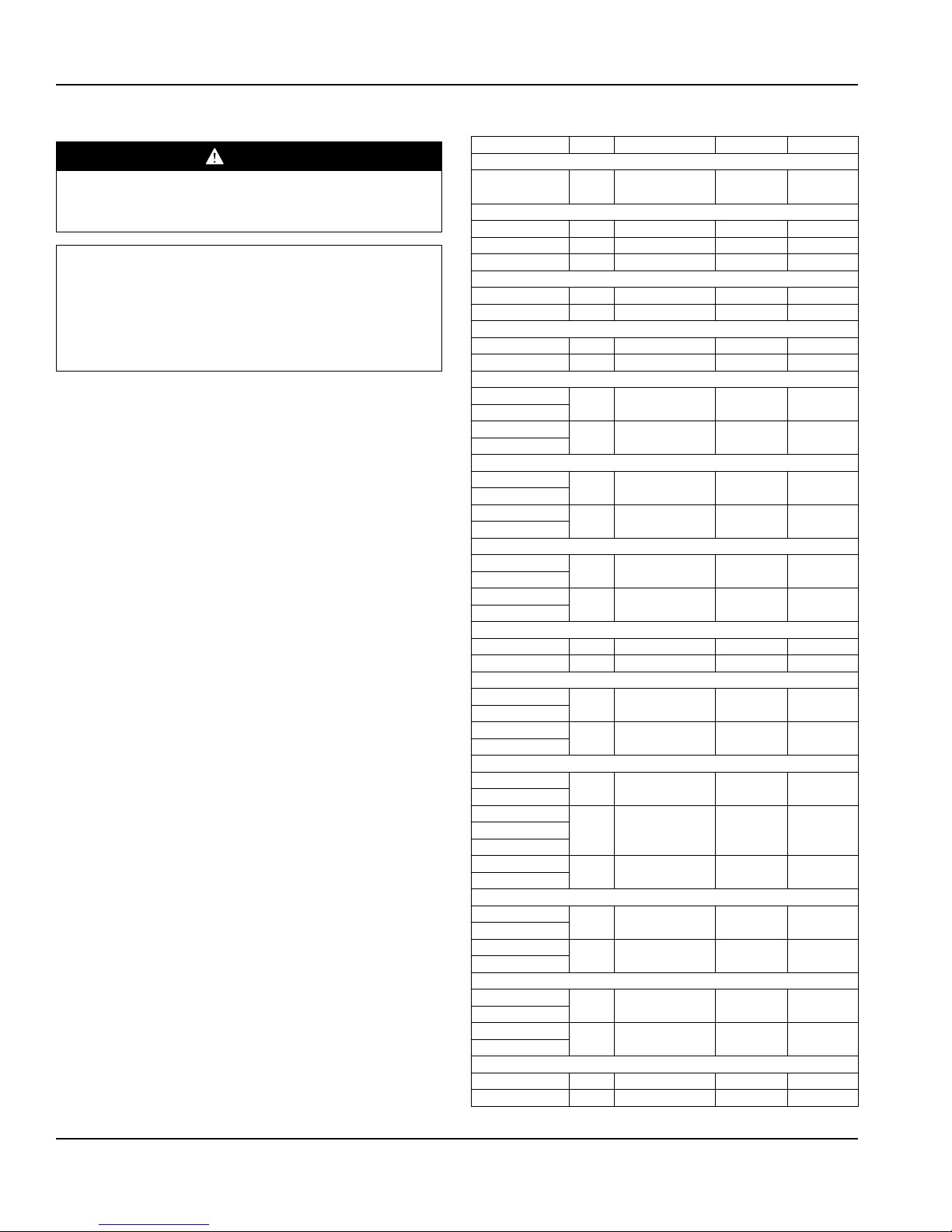

Model Amps V, Hz, Ph H.P. Nema Plug

Reach-In Dual Temperature

CSDBR1P-SH

CSDTR1P-SH

5.8 115, 60, 1 Ref. 0.20

Frzr. 0.315

5-15P

Reach-In Freezers

CSF1P-S (H) 7.2 115, 60, 1 0.55 5-15P

CSF2P-S (H) 10.0 115, 60, 1 0.68 5-15P

CSF3P-S (H) 14.7 115, 60, 1 (2X)0.55 5-20P

Pass-Thru Freezers

CSFPT1P-S (H) 10.0 115, 60, 1 0.55 5-15P

CSFPT2P-S (H) 14.6 115, 60, 1 (2X)0.55 5-20P

Roll-In Freezers

CSFRI1P-S 10.0 115, 60, 1 0.68 5-15P

CSFRI2P-S TBD 115, 60, 1 (2X)0.55 5-20P

Reach-In Heated Cabinets

CSH1-G (H) 6.0 208-240, 60, 1 NA 6-20P

CSH1-S (H)

CSH2-G (H) 10.5 208-240, 60, 1 NA 6-20P

CSH2-S (H)

Pass-Thru Heated Cabinets

CSHPT1-G (H) 6.0 208-240, 60, 1 NA 6-20P

CSHPT1-S (H)

CSHPT2-G (H) 10.5 208-240, 60, 1 NA 6-20P

CSHPT2-S (H)

Roll-In Heated Cabinets

CSHRI1-G 6.0 208-240, 60, 1 NA 6-20P

CSHRI1-S

CSHRI2-G 10.5 208-240, 60, 1 NA 6-20P

CSHRI2-S

Roll-Thru Heated Cabinets

CSHRT1-S 6.0 208-240, 60, 1 NA 6-20P

CSHRT2-S 10.5 208-240, 60, 1 NA 6-20P

Narrow Reach-In Refrigerators

CSR1NP-G (H) 4.2 115, 60, 1 0.22 5-15P

CSR1NP-S (H)

CSR2NP-G (H) 6.0 115, 60, 1 0.33 5-15P

CSR2NP-S (H)

Reach-In Refrigerators

CSR1P-G (H) 4.2 115, 60, 1 0.22 5-15P

CSR1P-S (H)

CSR2P-G (H)

6.0 115, 60, 1 0.33 5-15PCSR2P-GL

CSR2P-S (H)

CSR3P-G (H) 6.5 115, 60, 1 0.355 5-15P

CSR3P-S (H)

Pass-Thru Refrigerators

CSRPT1P-G (H) 4.5 115, 60, 1 0.22 5-15P

CSRPT1P-S (H)

CSRPT2P-G (H) 6.2 115, 60, 1 0.33 5-15P

CSRPT2P-S (H)

Roll-In Refrigerators

CSRRI1P-G 6.0 115, 60, 1 0.33 5-15P

CSRRI1P-S

CSRRI2P-G 6.2 115, 60, 1 0.355 5-15P

CSRRI2P-S

Roll-Thru Refrigerators

CSRRT1P-S 6.0 115, 60, 1 0.33 5-15P

CSRRT2P-S TBD 115, 60, 1 0.355 5-15P