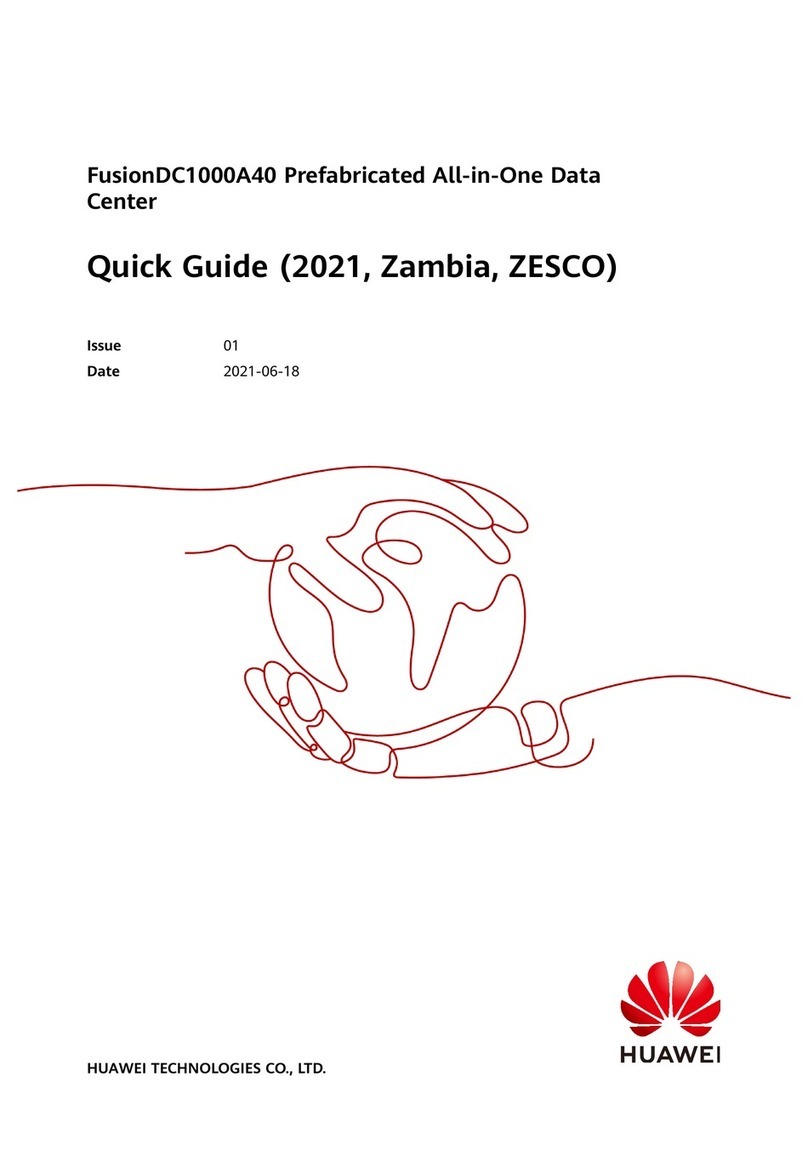

Delfin LYRA User manual

DELFIN S.r.l. –Via Keplero, 18 C.F. e P.IVA 02528290246

36034 MALO (VI) Italy REG.IMPR.VICENZA N. 186653/1996

Tel.: +39 0445 580688 Fax: +39 0445 580766 R.E.A. N. 237768

e-mail: info@delfin.it http://www.delfin.it Cap. Soc. Є100.000,00 i.v.

“LYRA”

Order DELFIN:

Year of construction: 2017

Instruction Manual

ORIGINAL INSTRUCTIONS

Pag 2 / 154

Manuale Lyra 600 sx elettr eng

Summary:

1General information ............................................................................ 7

1.1 List of documents ...............................................................................................7

1.2 This instruction manual .......................................................................................7

1.3 Information property ..........................................................................................8

1.4 Meanings and symbols ........................................................................................9

1.5 Identification data of the manufacturer .................................................................9

1.6 Machine identification data ................................................................................ 10

1.7 EC conformity declaration.................................................................................. 10

1.8 Warranty......................................................................................................... 11

1.9 Technical assistance ......................................................................................... 12

1.10 Use of the manual.......................................................................................... 12

2Operators’ safety and protective devices........................................... 14

2.1 Safety requirements ......................................................................................... 14

2.2 Classification of machine operators..................................................................... 14

2.3 Machine work zones.......................................................................................... 17

2.4 Description of the command/control and work stations.......................................... 19

2.5 Designed use and prohibited use ........................................................................ 21

2.6 Protective devices, signs and PPE. ...................................................................... 24

2.7 Residual risks................................................................................................... 34

2.8 General Instructions for safety and prevention ..................................................... 45

3Technical data ................................................................................... 48

4Installation........................................................................................ 50

4.1 Positioning and levelling of the machine .............................................................. 50

4.2 Electrical connection ......................................................................................... 54

4.3 Compressed air treatment group (optional) ......................................................... 55

5Controls............................................................................................. 57

5.1 Touch screen control panel ................................................................................ 57

6Film roll holder shaft and calander assembly .................................... 60

6.1 General instructions.......................................................................................... 60

6.2 Description of the components ........................................................................... 61

6.3 Reel assembly and disassembly.......................................................................... 62

6.4 Film dragging device......................................................................................... 63

6.5 Automatic film junction ..................................................................................... 64

6.6 Film editing ..................................................................................................... 67

7Fin wheel assembly's pulling/sealing set .......................................... 70

7.1 General instructions.......................................................................................... 70

7.2 Description of the components ........................................................................... 71

Pag 3 / 154

Manuale Lyra 600 sx elettr eng

7.3 Adjustment of the fin wheel pressure.................................................................. 72

7.4 Replacement of a resistance/probe ..................................................................... 73

7.5 Adjustments of the motorized reel (optional) ....................................................... 75

8Transverse sealing jaw assembly ...................................................... 77

8.1 General instructions.......................................................................................... 77

8.2 Jaw teeth adjustments ...................................................................................... 78

8.3 Jaw teeth adjustment on a sealing jaw with longitudinal sealing pattern .................. 79

8.4 Jaw teeth adjustment on a sealing jaw with transverse sealing pattern ................... 83

8.5 Assembly and adjustment of the knife ................................................................. 86

8.6 Replacement of the brushes on the slip ring holders .............................................. 87

8.7 Heat adjustment and replacement of the heaters ................................................. 88

9Torque limit (safety clutch) on the sealing jaws (only for mechanical

torque limiter).......................................................................................... 91

11 Bag length adjustment with neutral film (not film registered film), on an

electronic machine ................................................................................... 94

13 Setting to work the photocell group .................................................. 96

14 Adjustment of the bag length with print

‐

registered film (optional) ... 98

15 Infeed conveyor .............................................................................. 101

15.1 General instructions ..................................................................................... 101

15.1 Pusher dismantling and assembly .................................................................. 103

15.2 Pusher support dismantling and assembly....................................................... 104

15.3 Adjustment of the infeed conveyor side guides ................................................ 105

15.4 Infeed conveyor chain tensioning................................................................... 106

16 Forming box adjustments................................................................ 108

16.1 General instructions ..................................................................................... 108

16.2 Fixed forming box ........................................................................................ 109

16.3 Adjustable forming box................................................................................. 109

16.4 Fixed adjustable forming box ........................................................................ 113

17 Discharge belt conveyor .................................................................. 116

17.1 General instructions ..................................................................................... 116

17.2 Maintenance................................................................................................ 117

18 Use and maintenance of machinery ................................................. 120

18.1 Checking efficiency protection devices ............................................................ 120

18.2 Use and Maintenance ................................................................................... 121

18.3 Scheduled maintenance................................................................................ 122

18.4 Replacement of sealing jaw supply wires ........................................................ 123

18.5 Check of belts/chain conditions and tension .................................................... 124

18.6 Periodically lubrication.................................................................................. 125

19 Packaging problems and solutions .................................................. 128

20 Touch Screen panel ......................................................................... 131

20.1 Home page ................................................................................................. 133

Pag 4 / 154

Manuale Lyra 600 sx elettr eng

20.2 Alarm page 1/2 ........................................................................................... 134

20.3 Alarm page 2/2 .......................................................................................... 135

20.4 Temperature control page............................................................................. 136

20.5 Block notes –Setting page 1/2...................................................................... 137

20.6 Block notes –Setting page 2/2...................................................................... 138

20.7 Block notes page ......................................................................................... 139

20.8 Product counter page ................................................................................... 140

20.9 Photocell for print-registered film page (optional) ............................................ 141

20.10 Product phase page ................................................................................... 142

20.11 Transversal sealing unit slowdown page ....................................................... 143

20.12 Printing unit page (optional) ....................................................................... 144

20.13 No product no bag page (optional) .............................................................. 145

20.14 Automatic film junction (optional) ............................................................... 146

20.15 Gusseting page (optional) .......................................................................... 147

20.16 Manual mode page .................................................................................... 148

20.17 Outfeed conveyor page (optional) ............................................................... 149

20.18 Electronic clutch limiter page ...................................................................... 150

20.30 Recipes page ............................................................................................ 151

20.31 List of recipes page ................................................................................... 152

99 Attached list of documents .............................................................. 154

Pag 5 / 154

Manuale Lyra 600 sx elettr eng

This page has been intentionally left blank

Pag 6 / 154

Manuale Lyra 600 sx elettr eng

Dear Customer,

Thank you for having chosen our machine. We take the pleasure to supply you with

this instruction manual, with the objective to help you operate our machine efficiently

and safely. We invite you to read the contents with utmost care and make sure that

all the personnel that operate, maintain, repair and eventually dismantle the machine

fully understand the contents.

We are at your disposal for any further information that you may require on the

machine or on any idea to improve the machine functions, safety and manual.

We remind you that we have at your disposal our technical assistance office for any

questions you may have for repairs and maintenance, this to ensure the maximum

security to the personnel and to ensure a long machine life.

Kind regards

The manufacturer

Pag 7 / 154

Manuale Lyra 600 sx elettr eng

1 General information

1.1 List of documents

Instruction manual (this instruction manual).

1.2 This instruction manual

Documents data

Instruction manual:

Edition 1.0

Year and month it was printed :

The manual is to be read and understood by :

Loading and unloading personnel

Installation personnel

Machine operator

Maintenance personnel

Pag 8 / 154

Manuale Lyra 600 sx elettr eng

1.3 Information property

The information in this manual is reserved property, all rights are reserved.

This manual cannot be reproduced or photocopied in any of its parts without having

requested written permission to the manufacturer.

This instruction manual is addressed to the owner, user of the machine, to managers or

employees with appointed responsibility, to personnel in charge of handling, installing,

operating, watching, maintaining, dismantling ext. the machine.

This manual must be considered an integral part of the machine, however it can never

replace the proper training and work experience of the user, who should read this manual

before starting to work on the machine.

This manual must be kept for future reference until dismantling of the machine.

We suggest you keep this manual in a sheltered, dry and dust free area, preferably near to

the machine. Should this manual be lost or damaged, contact the manufacturer.

The manufacturer declares that the information contained in this manual are relative to the

technical specifications and safety devices of this machine.

Her manufacturer is not responsible for direct or indirect injury to persons, things or

domestic animals subsequent to the incorrect use of the machine or due to conditions other

than recommended in this manual.

The manufacturer reserves the right to update this manual and the machines of the same

model but with different serial numbers without any prior notice.

The information contained in this manual refer to the machine specified in Machine

identification data of the machine page 5.

We invite the customer to advise the manufacturer in case the machine changes ownership

or address.

The manufacturer reminds the client of his obligations to respect local laws regarding safety

and hygiene in the work place.

Pag 9 / 154

Manuale Lyra 600 sx elettr eng

1.4 Meanings and symbols

Conventional terminology

Left, right: refers to the operators position when standing in front of the operating panel.

Qualified personnel: people with experience, and specific training, in depth knowledge of

the safety regulations and all the relative instructions of how to avoid injury to people, or

any other danger.

Conventional typography

Writings with big characters and dark black characters: Indicates the title of a chapter or a

paragraph of a chapter, or a table or a drawing identification.

DPI: Individual protection devices.

N: Represents a number, for example.

3: Indicates the start button on the control panel.

L: Represents a letter, for example.

B: indicates a part on the machine.

NOTE

The notes contain very important information, evidenced in a separate paragraph

and in dark letters.

ATTENTION

Is important information that help avoid damage to the machine or other

equipment connected to the machine.

DANGER

Is important information the can avoid injury to the personnel responsible for the

machine in all its life span

1.5 Identification data of the manufacturer

DELFIN S.r.l.

Via Keplero, 18

36034 Malo (VI) ITALY

Tel. 039/0445/580688

Fax. 039/0445/580766

E-mail: info@delfin.it

Internet: http://www.delfin.it

Pag 10 / 154

Manuale Lyra 600 sx elettr eng

1.6 Machine identification data

Type:

Model:

Serial number:

Year of construction:

Fig. 1.6.1 Identification plate

Machine type _______________________________ Volt ______________

Model ______________________________________ Hz _______________

Serial number _______________________________ Kw _______________

Year of construction _________________________ Phase ____________

Certificate of origin __________________________ Weight ____________

1.7 EC conformity declaration

See attached 1 EC conformity declaration.

Pag 11 / 154

Manuale Lyra 600 sx elettr eng

1.8 Warranty

General conditions

The warranty is 12 months (8 hour shift) from the effective delivery date of the machine.

Any defects are to be notified in writing to the manufacturer within 8 days from there being,

and approval of the manufacturer.

If during this period structural defects or faults on material appear, the defected parts will

be replaced or repaired free of charge. The electrical components, dismantling, assembling

and our technicians time is excluded from the warranty.

The parts replaced are not subject to a further 12 months warranty period on the entire

machine.

We do not acknowledge damages due to overloads, improper use, wear or tear due to

climatic conditions.

All transport charges, costs and custom taxes due to the replacement of defected parts are

at the buyers expense.

Replacement and repairs are subject to the execution of the payment terms by the buyer.

In no case we accept responsibility for paid out salaries, wages, decrease in profit, loss of

time and claims by third parties.

Our warranty does not include worn out parts, replacement or repairs due to improper use,

bad maintenance or lack of expertise. We will in no way be considered responsible for direct

or indirect damages.

For parts assembled on this machine, but not manufactured by us, such as

electrical/electronic equipment ext. are not included in the warranty. The warranty does not

cover parts subject to wear and tear.

Any returns of goods must be previously authorized by us in writing. The goods must be

perfectly packed and returned CIF to our company.

NOTE

In case of repairs on the machine installation site, the guarantee slip must be

shown to a maintenance technician: warranty is valid only if this is filled in all its

parts.

Any particular warranty terms are to be specifically expressed in writing in the

buyers/sellers contract.

The following conditions will cause the warranty to be invalid

Unforeseen use of the machine

Use of tools other than those specified in chapter 18 Use and Maintenance.

Assembly of the machine in conditions other than those specified in chapter 18 Use and

Maintenance.

Electrical and pneumatic connections other than those specified in chapter 18 Use and

Maintenance.

Use of not original parts or parts not specified by the manufacturer.

Request for spare parts, or request for maintenance for machine under warranty must be

made in writing to the manufacturer or the nearest authorized agent, immediately after the

defect or problem has come to being General conditions.

When requesting spare parts always inform the manufacturer or agent the machine serial

number and model, this data is written on the identification plate fixed to the machine.

NOTE

The inobservance of the information in this manual will exclude manufacturer

from any responsibility in case of accidents to persons and or property or

malfunctioning of the machine.

Pag 12 / 154

Manuale Lyra 600 sx elettr eng

1.9 Technical assistance

This manual must be considered an integral part of the machine, however it can never

replace the proper training and work experience of the user, who should read this manual

before starting to work on the machine.

Requests for assistance operations

Technical assistance service

You can contact our technical assistance office by contacting us at the following address:

DELFIN S.r.l.

Via Keplero, 18

36034 Malo (VI) ITALY

Tel. 039/0445/580688

Fax. 039/0445/580766

E-mail: info@delfin.it

Internet: http://www.delfin.it

Request for spare parts

When requesting assistance or spare parts, you must specify the following:

machine model

serial number

year of construction.

1.10 Use of the manual

Read the manual carefully, Chapter 1 “General information”, Chapter 2 “Safety

information“, Chapter 3 “Technical data“, Chapter 4 “Installation“, Chapter 5 “Controls“.

Pag 13 / 154

Manuale Lyra 600 sx elettr eng

This page has been intentionally left blank

Pag 14 / 154

Manuale Lyra 600 sx elettr eng

2 Operators’ safety and protective devices

2.1 Safety requirements

This machine was designed and manufactured according to the appropriate criteria and

expedients that comply with the essential safety requirements pursuant to Machine

Directive 2006/42/EC and the Directive on Electromagnetic Compatibility 2004/108/EC as

amended.

As specified on p. 1.5.1 of Attachment I on Machine Directives, the electrical equipment

complies with the safety objectives established by the Directive on Low Voltage 2006/95/EC

but the evaluation of conformity in relation to hazards caused by electric energy is regulated

only by the Machine Directive itself, and consequently, the machine is not certified with

respect to the Low Voltage Directive.

Pursuant to Attachment I of Directive 2006/42/EC as amended, the definition of terms are

as follows:

«danger», a potential source of health injury or damage;

«dangerous zone», any zone within and/or in proximity with a machine, wherein the presence of a

person may imply a risk for the safety and health of said person;

«exposed person», any person stationing completely or partly within a dangerous

zone;

«operator», the person/s assigned to install, start up machine functions, adjust, clean,

repair and move a machine or to carry out maintenance.

«risk», combination of the probability and the gravity of an injury or danger to health

that may arise in a dangerous situation;

«guard», machine element used specifically to ensure protection through a material

barrier;

«protective device», device (different from a guard) that reduces the risk, by itself or

associated with a guard;

«designed use», the use of the machine complying with the information given in the

instructions for use ;

«reasonable foreseen incorrect use», using the machine in a way other than that

indicated in the instructions for use, but which may arise from easily foreseen human

behavior.

2.2 Classification of machine operators

ATTENTION

The machine was designed for professional use and the operator must possess the

proven qualifications and be able to read and understand the instructions for use. Since

the reader supposedly possesses the experience with regard to maintenance of industrial

machinery, the basic maintenance instructions have been omitted..

The number of operators indicated and the related intervention procedures should ensure

the safety and health of the assigned workers and allow excellent production.

The use of a lower or greater number of operators, with inferior or divergent

qualifications, or the use of intervention procedures differing from those indicated in this

document, seriously jeopardizes the safety of the operators themselves and/or may

impede the achievement of an excellent production.

Pag 15 / 154

Manuale Lyra 600 sx elettr eng

Qualified technician

Technically qualified and skilled staff member assigned to transporting, moving and

installing the machine.

Machine operator

Qualified operator who has been properly trained to run the machine, able to operate on the

machine and is able to carry out the following operations:

- Verify the protective devices before starting up the machine;

- Effect controls, verifications and prepare the machine to execute the programmed

work cycles, only with the machine stopped in safe conditions;

- Start up and stop the machine through the use of the command elements on the

command panel with the protective devices closed and active and always remaining

outside the work zone;

- Run the machine to carry out work cycles with the protective devices closed and -

active and always remaining outside the work zone;

- Use the machine’s PLC, create, recall and/or edit and send work programs to be

executed;

- Restart the machine after a sudden stop or an emergency arrest;

- Load the product to be pace on the infeed conveyor (only on machines not equipped

with automatic loading systems);

- Do the machine cleaning operations with the electric and pneumatic power feed cut

off.

Mechanical maintenance technician

Qualified technician who is able to conduct the machine in normal conditions and with the

protective devices open and/or deactivated, and effect all the interventions of mechanical

nature for the adjustment, maintenance and repairs. He is not qualified to carry out

electrical interventions on energized parts.

Electrician

Qualified technician who is able to conduct the machine under normal conditions and with

the protective devices open and/or deactivated, and perform all the interventions of

electrical nature for adjustment, maintenance and repairs. He is qualified to perform

electrical intervention in the presence of voltage in the electric cabin.

Manufacturer’s technician

Qualified technician that the manufacturer places at the disposition of clients to carry out

complex repairs in particular situations, as agreed with the client

Pag 16 / 154

Manuale Lyra 600 sx elettr eng

2.2.1 Operators assigned to use the machine

ATTENTION

1 OPERATOR will be assigned to use the machine.

2.2.2 Training of operators

The user/employer will take charge of instructing and training the operators assigned to use

the machine in order to:

Use the machine correctly.

Know the type and the localization of residual risks.

Be sensitive to problems regarding safety, and notify the employer on time with

regard to eventual malfunctions, dangerous situations.

Know and respect the plates and signs prescribed.

Execute scrupulously the controls, preparation and cleaning operations assigned,

according to the instructions in this manual

Not intervene with actions that they are not authorized or qualified to do.

The training will be done by the manufacturer’s specialized staff and a report will be drafted

regarding the training performed.

2.2.3 Subjects of the operator training course

The minimum subjects the employer/user will have to train the operators on are

the following:

General training.

Safety norms (L. Decree 81/2008 and succeeding amendments).

Workplace Hygiene.

Specific training:

Technical characteristics of the machine.

Machine preparations including replacement of film spools.

Startup and arrest of the machine.

Loading of product to be packed on the infeed conveyor.

Intervening on and restoring the protective devices on the machine.

Machine safety measures.

Functioning modes of the machine.

Restarting the machine after a sudden or emergency arrest.

Machine cleaning operations.

Pag 17 / 154

Manuale Lyra 600 sx elettr eng

2.3 Machine work zones

The machine’s work zone (zone Z fig. 2.3.1) is composed of sub-zones and specifically (Z =

ZA+ZB+ZC+ZD+ZE):

1. Spool holder shaft, and film unwinding rollers (zone ZA fig. 2.3.1).

2. Product infeed conveyor (zone ZB fig. 2.3.1).

3. Longitudinal sealing group (zone ZC fig. 2.3.1).

4. Transversal seal/cut group (zone ZD fig. 2.3.1).

5. Product outfeed conveyor (zone ZE fig. 2.3.1).

6. Motorized reel above longitudinal sealing group (zone ZF fig. 2.3.1).

Fig. 2.3.1 Machine’s work zones

DANGER

Some of the sub-zones of the machine’s work zone are dangerous and it is

prohibited to enter these zones when the machine is running or on standby while

awaiting commands.

The machine executes the packaging cycle in a totally automatic manner. The operator

loads the product to be packaged onto the infeed conveyor (zone ZB) only on machines that

are not equipped with the automatic load system; this operation must be done in safe

conditions since the load zone of the infeed conveyor may be hazardous. The operator is

allowed to enter the other dangerous work sub-zones (ZC-ZD-ZE-ZF) only under safety

conditions, that is, with the machine at a standstill and when there is no possibility of the

machine getting started suddenly without the operator being informed.

Entering the machine is allowed only for the following operations:

Preparations (with the machine at a standstill or in active IMPULSE mode);

Loading of product on the infeed conveyor (with machine running);

cleaning (only with machine at a standstill and power feeds cut off);

maintenance (only with machine at a standstill and power feeds cut off).

ZE

ZB

ZA

ZC

ZD

ZF

Pag 18 / 154

Manuale Lyra 600 sx elettr eng

2.3.1 Dangers present in the machine’s work zone

DANGER

The sub-zones of the machine’s work zone (ZB-ZC-ZD-ZE-ZF fig. 2.3.1) are

dangerous due to the presence of mechanical hazards:

moving elements approaching fixed parts;

moving elements;

rotating elements;

sharp edges.

2.3.2 Specific warnings for the operator

ATTENTION

The operator must not for any reason whatsoever:

try to introduce parts of his body into the machine’s work zones (Z fig. 2.3.1) when this

is started up or running;

start up the machine when there are people exposed in proximity with the work zone (Z

fig. 2.3.1);

tamper with the interlock devices applied on the mobile guards or dismantle the fixed

guards.

ATTENTION

Before starting up the machine, the operator will have to make sure that there is nobody

or no foreign objects in the work zone (Z fig. 2.3.1) and that all the guards (fixed or

moveable) are correctly positioned.

Access to the machine’s work zone (Z fig. 2.3.1) for machine preparations is allowed

only for the assigned staff, with the machine at a standstill or in IMPULSE active mode.

Access to the machine’s work zone (Z fig. 2.3.1) for machine cleaning and maintenance

is allowed only for the assigned staff, with the machine at a standstill and with the

electrical and pneumatic power feeds cut off.

Pag 19 / 154

Manuale Lyra 600 sx elettr eng

2.4 Description of the command/control and work stations

2.4.1 Control station

Il control station (PC fig. 2.4.1.1) is located on the front side of the machine, in front of

the control panel (1 fig. 2.4.1.1). From this position the operator commands and

controls the entire machine, sets the work parameters, recalls or edits the programs,

prepares the machine, and starts up the packaging cycle. The control panel is located

outside the machine work zone (Z fig. 2.3.1), therefore in a safe area, easily reached

and very much in view.

From the control station the operator has a complete view of the machine’s work zone (Z

fig. 2.3.1); and therefore can easily check whether or not there are people stationing

nearby or exposed at the time of startup and when the machine is working.

In case of danger, the operator may stop the machine through the emergency stop

button (2 fig. 2.4.1.1).

Fig. 2.4.1.1 Control and work stations

PL2

PL1

PC

PL3

1

2

4

3

PL2

PL1

Pag 20 / 154

Manuale Lyra 600 sx elettr eng

2.4.2 Work stations

There are two work stations, on the front side (PL1 fig. 2.4.1.1) and one at the rear

end (PL2 fig. 2-2) of the machine’s infeed conveyor. From these stations the operator

can load the product to be packed on the infeed conveyor (3 fig. 2.4.1.1), paying

attention to the pusher or other product pushing devices found on the conveyor.

From the work station the operator has a full view of the machine’s work zone (Z fig.

2.3.1); therefore he can easily check whether or not there are persons exposed while the

product is being loaded.

In case of danger, the operator may stop the machine through the emergency stop

button located on the infeed conveyor (4 fig. 2.4.1.1).

ATTENTION

Loading of the product in manual mode must be done only if the machine is not

equipped with the automatic load system.

2.4.3 Machine preparation stations

There are four preparation stations (PC-PL1-PL2-PL3 fig. 2.4.1.1) since the operator or

maintenance technician to prepare the machine will have to enter almost all the work sub-

zones (ZA-ZC-ZD-ZE fig. 2.3.1).

1. In zone ZA the film spool is mounted and the film inserted through the unwinding roller

and the forming tunnel, with the probable adjustment of the tunnel itself according to the

dimensions of the product (operator, PC or PL1 station).

2. In zone ZB adjustment of the product pusher rods according to pace of the product itself

(maintenance technician, PL1 or PL2 stations).

3. In zone ZC insertion of the film between the wheels of the longitudinal sealing group

(operator, PC station) and eventual adjustment of wheel pressure (maintenance

technician, PC station).

4. In zone ZD insertion of the film between the wheels of the transversal sealing group

(operator, PC station) and eventual adjustment of the sealing teeth, pressure of the

sealing and knives (maintenance technician, PC station).

5. In zone ZE no preparation interventions are done but is normally used to gain access to

the transversal sealing group (PL3 station fig. 2.4.1.1).

6. In zone ZF adjustment of the product brushes according to pace of the product itself

(maintenance technician, PC station).

Table of contents