STM REVOLUTION 2.0 User manual

MATERIALS

ASSEMBLY

POWER

MOTOR

WEIGHT &

DIMENSIONS

HOPPER

THROUGHPUT

DUAL-BLADE SYSTEM

Encased in 100% Food-Grade Material

SAE 304/316, Dent-Resistant Stainless Steel

Handle & Heavy Duty Castor Wheels for Easy Mobility

Designed, Manufactured, & Assembled in the USA

Standard 220V | 17.1 Load Amps

Single Phase | 5-1/2 ft. Cord Length

Requires L6-30 Plug

Seek Certified Electrician for Installation Needs

3HP |UL Listed | Long Life Cycle

Small Footprint

Approx. 220 lbs

30" L x 65" H x 22-1/4" W

Holds 21 Liquid Gallons

(Four 5-Gallon Buckets of Material)

Up to 50 lbs +/- Hourly

Up to 400 lbs +/- Daily

Varies with Different Material Types

Custom-made Stainless Steel Serrated Blades

Proprietary Angle for Optimized Cutting of Material

REVOLUTION 2.0™

USER MANUAL

CHUTE &

CHAMBER

SOFTWARE &

UPGRADES

TOUCH

SCREEN

COMPLIANCE

CLEANING

LIFE CYCLE &

WARRANTY

SAFETY

FEATURES

Chute with Vibrating Agitator (non-stick, food-grade)

Blade Area Chamber (food-grade)

Revolution OS V1.2

Upgradable System Software Included for

Lifetime of the Machine

Manual and Automatic Operation

Ergonomic 3.5" Resistive Touch Control Panel

Low, Med, High Speed | Start/Stop

Auger On/Off Time Delay

Pop-Up Error Messages

Standard Service Data for Clogs or E-Stop Conditions

OSHA Compliant

Sliding Back Door for Easy Access

Quick Release Bolts | Dishwasher Friendly

1-Year Parts and Labor Warranty

Motor 10-Year LIfe Cycle

Machine is Fully Enclosed

2 Quick Access Emergency Stop Buttons

Lock-Out Tag-Out Power Switch

Multiple Automatic Internal Safety Limit Switches

PARTICLE SCREENS Fine Particle Screen (food grade, stainless material)

Coarse Particle Screen (food grade, stainless material)

1

TABLE OF CONTENTS

Components ....................................................... 2

Getting Started ................................................... 4

Best Practices & Tips ......................................... 5

Emergency Procedures ..................................... 6

Quick Start Guide ............................................... 7

Touch Screen Operation ....................................... 8

Powering Down ...................................................... 9

Preventative Maintenance .................................. 10

Troubleshooting ................................................. 15

Terms of Business ................................................ 23

2

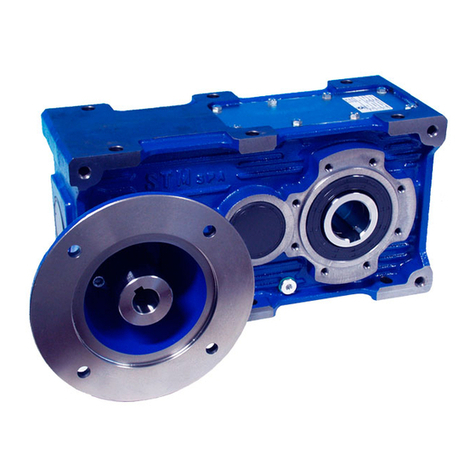

5. Auger Motor

7. Chute

Hopper1.

1. Hopper - The area your material is

stored as it feed into your

2. Auger Bearing - Provides smooth

rotation as it feeds material into the throat

3. Belt Drive- provides the momentum

and power that spins the blades.

4. Casters- Swiveling caster wheels for

easy mobility.

5. Auger Motor - Powers the auger

6. E-Stop Button- Turns the machine

off in case of an emergency.

7. Chute- After the grinding process

exits out of the machine here.

2. Auger Bearings

COMPONENTS

6. E-Stop Button

4. Casters

3. Belt Drive

Revolution Grinder Components - bit.ly/revolution-components

FRONT

13. Power/Lockout Button

3

8. Lid

12. Touch Screen Control

9. E-Stop Button

10. Top of Back Door Panel

11. Lower Back Door Panel

8. Lid - Open to introduce material into

the hopper

9. E-Stop Button - Turns the machine off

in case of an emergency.

10. Top of Back Door Panel - Easy access

to your blade chamber and chute

11. Lower Back Door Panel - Contains

your electrical components. DO NOT

access this portion as it will VOID your

warranty.

12. Touch Screen Control - Used for

the operation of machine.

13. Power/Lockout Button - Turns on

the power and locks machine.

COMPONENTS

BACK

4

GETTING STARTED

UNPACKING YOUR MACHINE

Carefully unpack your machine and inspect it to

ensure it has not been damaged during shipping.

Make sure all the correct parts are included and

match your invoice. Please contact us if you have

missing or damaged items.

Revolution Grinder Machine

(1) Screen for 3/16" (4.76mm) particles (pre-installed)

(1) Screen for 5/32" (3.96mm) particles

(1) Set of Dual Stainless Steel Blades (pre-installed)

Extra Screens and Blade Sets Available for Additional Cost

IMPORTANT! Always wear cut-proof gloves when handling anything inside the blade chamber.

INCLUDED ITEMS

3/16th Coarse 5/32nd Extraction

Floater Blade

4 Arm Blade

PARTICLE SCREENS

(coarse screen is pre-installed on your machine)

STAINLESS STEEL DUAL BLADE SYSTEM

(both blades are pre-installed in your machine)

5

BEST PRACTICES & TIPS

Inspect your material prior to grinding

Optimal moisture can range between 7-10%

Lab certified optimal moisture is 8.8%

Do not overfill hopper

The Revolution grinder can

handle up to 10% moisture.

IMPORTANT! Always turn off and unplug machine before cleaning or servicing.

Always start motor on the

highest speed setting speed

Auger on 3-seconds run time and 3-seconds

off time to prevent clogging. If material is too

dry, auger can run for longer, but can remain

at 3-seconds of run time.

If product bends without a snap, it's too moist.

It product snaps and keif falls, it's too dry.

Optimal product will bend, then snap.

Preventative Maintenance on Page 10

6

E-STOP BUTTON

LIMIT SWITCHES

EMERGENCY PROCEDURES

If there is a sudden emergency or need to shut off

the machine quickly, press either of the two E-STOP

buttons.

One is located on top of the plate on the rear side

of the machine. The other is located just to the left

of the touch screen.

"Emergency Stop" will display on the touch screen.

NOTE: the machine will not operate in this mode.

To clear the "Emergency Stop", pull the red E-STOP

near the touch screen ensuring the yellow ring

under the bottom is exposed.

If the "Emergency Stop" message is still displayed

and both E-STOP buttons are not pressed, it is likely

a trigger of the limit safety switch. (refer to page 20)

Press in case of an emergency

There are four safety switches located

in the machine that will display the

emergency stop as well. The screen will

tell you which e-stop or limit switch is

tripped. These switches will prevent

the machine from running if not

depressed properly.

Hopper Lid - Under Handle

Behind the Drop Down Chute - Back Left Corner

Slide Panel Door - Top Right Corner

Components Slide Panel Door - Top Right Corner

LIMIT SWITCH LOCATIONS

IMPORTANT! Do not alter limit switches in any way.

8

TOUCH SCREEN OPERATION

START/STOP

Pressthe START button to start

the operation and STOP to stop

the operation of the grinder.

HIGH: 100% of motor speed (1750RPM)

MEDIUM: 50% of full power (875RPM)

LOW: 10% of full power (175RPM)

The Revolution has three speeds for operation.

High, Medium, and Low, indicated by the largest

to smallest icons on the touch screen:

1.

2.

3.

MOTOR SPEEDS The amp meter is located in the lower right corner.

When in higher amperage, the machine will read that

and delay the auger. This allows for the blade chamber

to clear before introducing more material. If the meter

remains high, you may have a clog that needs clearing.

AMP METER

The Revolution has one auger speed that comes pre-set

into the machine. The auger comes pre-set with ON

times and OFF times. This prevents the clogging of

materials and overfeeding the blade. These times may

be changed, but we do not recommend going below 3

seconds off or more than 15 seconds on. If you wish to

alter this please contact Client Services.

AUGER SPEEDS

7

QUICKSTART GUIDE

Prepare your material. This prevents clogs

and potential damage to your grinder.

Buck and clean off big fan leaves and large

stems. Remove as many seeds and remaining

bud stems as possible to ensure an even grind.

Plug in your machine. Insert the three-prong

L6-30 plug into a standard 220v/30 amp

single-phase wall outlet.

If it does not turn on, check the power

connection.

If “Emergency Stop” is displayed on the

screen, check the emergency procedures on

the previous page.

Power on your machine. Turn the red lock-out

power switch to the vertical position on the

right side of the machine for ON. Turn

horizontal for OFF.

Open the hopper. With the machine on the

highest speed setting open the hopper to

reveal the Auger and throat to the grinder.

Begin loading your material. Load material

starting at the end opposite the throat. This

allows the Auger to pull the material into the

throat and prevents clogging.

Collect your material. The material will run

from the throat of the hopper down into the

blade chamber and ground material will

move down the chute to vibrate out of the

grinder.

9

POWERING DOWN

Ensure all material has been run through the machine.

Never leave material in your machine overnight. Your

material can dry out, reducing your final product quality.

Clean the machine entirely to prevent any material built

up from the previous run from drying onto your machine

causing buildup and possibly degrading your equipment

over time.

Turn your red lockout power switch to the horizontal

position - OFF

10

Lube the auger bearing once a month by using any

food-grade bearing grease.

Cure and prep your material properly.

Clean your inside blade chamber regularly

between runs and the hopper area as needed.

Keeping your machine clean and maintained will

guarantee longevity and optimal operating conditions.

The key things to note are:

PREVENTATIVE MAINTENANCE

Run all material through the Revolution to ensure it is empty.

Turn the Power/Lockout button to the OFF position and unplug the power.

ALWAYS work with diamond cut-proof gloves when handling anything in

the blade chamber

BEFORE CLEANING

11

Remove the Auger

On side of the hopper without the motor, loosen Auger Shaft Bolts that are around the Auger Drive Shaft with

⅛” Allen Wrench.

Slide-out the now loosened Auger Drive Shaft from the center of the bearing. Located right below the Auger

Shaft Bolt that has now been loosened.

Inside the Hopper, the (2) sections of Auger may now be removed. Remove the first section of Auger that is

located next to Auger Drive Shaft that was just removed.

Remove the Backing Trough Plate

Using isopropyl alcohol to spray and wipe off material from the Auger

Use a soft-bristle paintbrush/nylon brush to move all dry material down to the 2 ½" drop tube to the blade

chamber.

Spray down the inside of the hopper with isopropyl alcohol once the chute has been removed and all material

has been removed and collected. Wipe down the inside of the Hopper with paper towels or microfiber rags

1.

a.

b.

c.

2.

3.

4.

5.

PREVENTATIVE MAINTENANCE

HOPPER & AUGER - CLEANING

12

Place the bottom hopper base back in the hopper.

Attach the short piece of flighting with the open end on the Hex rod.

Put the long piece of flighting with the cut out onto the short piece of flighting.

Slide the 16" piece of Hex Rod back into the flighting through the outside of the Hopper.

Secure the 2 Allen set screws located on the bearing, opposite of the chain guard side (using a 1/8" Allen wrench)

Replace the removable baffle above the throat leading into the grinder.

Close the lid.

Plug the Revolution back in (Revolution is clean and ready for the next use!)

1.

2.

3.

4.

5.

6.

7.

8.

PREVENTATIVE MAINTENANCE

REASSEMBLY OF THE AUGER

ALWAYS UNPLUG MACHINE PRIOR TO ANY MAINTENANCE.

Video: Removing & Reinstalling Auger - bit.ly/removing-auger

13

Remove the upper back panel by removing the four Allen head screws using a 3/16" Allen wrench.

Slide the back door straight up to expose the upper inside of the Revolution.

First, release the quick-clamp from the top of the black elbow and drop the output tube onto the midplate

Second, remove the hitch pins from the buckle latches and then open the buckles and the chute will then pull

out.

Do this in reverse order to get the unit put back together

After the chute has been lowered, loosen the 4 tabs with the 5/16" Allen.

Swing the tabs away from the surface to allow the screen to drop.

Replace screen and reverse steps above to secure screen.

Reverse sections 1 and 2, ensuring all quick-release tabs and bolts are secure.

Use isopropyl alcohol to clean the inside of the chute, particle screen, and blade chamber. Do not scrape, this

may cause damage.

Reverse sections 1 and 2, ensuring all quick-release tabs and bolts are secure.

Remove the Back Panel

1.

2.

Drop the Chute

1.

2.

3.

Changing the Particle Screen

1.

2.

3.

4.

5.

6.

PREVENTATIVE MAINTENANCE

CHANGING & CLEANING THE PARTICLE SCREEN

Video: Changing Particle Screensbit.ly/particle-screens

14

First, remove the cotter pin from the bottom of the shaft where it goes through the castle nut

Second use a screwdriver to hold the blades from spinning while you a 9/16 open-end wrench to remove the

castle nut being careful as the blades will fall at this point.

The hat washer goes in between the two blades.

When putting the S blade the bearing is pressed flush on one side of the S blade. This is the side that goes up

toward the 4 arm blade.

Ensure the blades have been put back on and secured into place.

Replace the screen.

Replace the chute and plug back in the small internal motor that is attached to the chute (if removed)

Slide the back panel in place and secure it with the 4 screws.

Replacing the Blades

1.

2.

3.

4.

Putting the Machine Back Together

1.

2.

3.

4.

PREVENTATIVE MAINTENANCE

CHANGING THE BLADES

Video: Changing the Blades - bit.ly/changing-blades

Please watch our how-to video for this crucial step

in maintaining your grinder.

15

Prepare your material before introducing it into your grinder

BUCK your buds completely off of the main stem

REMOVE all big stems and fan leaves

CURE your material! This is one of the most important steps. Our lab-tested and certified results state 8.8% is

the optimal moisture content for most cannabis and hemp plants. Ultimately you will need to work with your

material to lock in the perfect cure for your company. This moisture content can be between 7% - 10%

Load the hopper from the end opposite the throat of your grinder. This allows the auger to pull material into the

throat at the set speed

Adding material directly over the throat can potentially clog it

Preparing Your Material Properly

1.

a.

b.

c.

2.

a.

TROUBLESHOOTING

CLOG PREVENTION

ALWAYS UNPLUG MACHINE PRIOR TO ANY MAINTENANCE.

USE CUT-PROOF GLOVES WHEN CHANGING THE BLADES.

16

Have a lab test your moisture content

Test the moisture content yourself with a reliable moisture reader.

Cure your material in an open bin for a few hours. If your material bends without a snap - TOO MOIST! If your material

snaps and kief is seen falling after the snap - TOO DRY!

Cure your material in an open bin overnight if high moisture content is present.

Honing in your material's moisture content is the only way to resolve this issue. As with grinding material in a hand

grinder. The more live and wet your bud is the harder it is to twist and grind that material. The same goes for your

industrial grinder. Wet material naturally sticks and stacks causing buildup and potentially clogging or damage to your

grinder.

MOISTURE CONTENT IS TOO HIGHT - The most common cause of clogs

Our lab-certified results state the optimal moisture level is 8.8% but please note your material may require slightly different

moisture levels. Stay within 7% - 10% range. Anything higher will result in possible damage to your machine by gunking up

and clogging the blade chamber. This can result in blade breakage or burning out the motor.

TO TEST THIS

TO RESOLVE THIS

TROUBLESHOOTING

WHAT CAUSES CLOGS?

ALWAYS UNPLUG MACHINE PRIOR TO ANY MAINTENANCE. USE CUT-PROOF GLOVES WHEN CHANGING THE BLADES.

17

You loaded too much material into the hopper

You loaded material into the machine directly over the throat.

Please see the "HOPPER & AUGER - CLEANING" section to access the throat to clear debris.

You loaded material with a moisture content higher than recommended.

CURE your material longer

These clogs can occur when the material is either introduced into your machine incorrectly:

TROUBLESHOOTING

HOPPE & THROAT CLOGS

ALWAYS UNPLUG MACHINE PRIOR TO ANY MAINTENANCE.

USE CUT-PROOF GLOVES WHEN CHANGING THE BLADES.

Table of contents

Other STM Industrial Equipment manuals

STM

STM ROCKETBOX User manual

STM

STM ROCKETBOX 2.0 User manual

STM

STM NGN-8100 User manual

STM

STM RX Series Instruction Manual

STM

STM ROCKETBOX Installation guide

STM

STM ATOMIC CLOSER User manual

STM

STM MINI-ROCKETBOX CANNA User manual

STM

STM MINI-ROCKETBOX PLUS+ User manual

STM

STM RFA Series Instruction Manual