being worked on. Once deployed properly, service parts can be removed from the ESD bag and placed directly on the mat. ESD-

sensitive items are safe in your hand, on the ESD mat, in the system, or inside a bag.

•Wrist Strap and Bonding Wire – The wrist strap and bonding wire can be either directly connected between your wrist and bare

metal on the hardware if the ESD mat is not required, or connected to the anti-static mat to protect hardware that is temporarily

placed on the mat. The physical connection of the wrist strap and bonding wire between your skin, the ESD mat, and the hardware is

known as bonding. Use only Field Service kits with a wrist strap, mat, and bonding wire. Never use wireless wrist straps. Always be

aware that the internal wires of a wrist strap are prone to damage from normal wear and tear, and must be checked regularly with a

wrist strap tester in order to avoid accidental ESD hardware damage. It is recommended to test the wrist strap and bonding wire at

least once per week.

•ESD Wrist Strap Tester – The wires inside of an ESD strap are prone to damage over time. When using an unmonitored kit, it is a

best practice to regularly test the strap prior to each service call, and at a minimum, test once per week. A wrist strap tester is the

best method for doing this test. If you do not have your own wrist strap tester, check with your regional office to find out if they have

one. To perform the test, plug the wrist-strap's bonding-wire into the tester while it is strapped to your wrist and push the button to

test. A green LED is lit if the test is successful; a red LED is lit and an alarm sounds if the test fails.

•Insulator Elements – It is critical to keep ESD sensitive devices, such as plastic heat sink casings, away from internal parts that are

insulators and often highly charged.

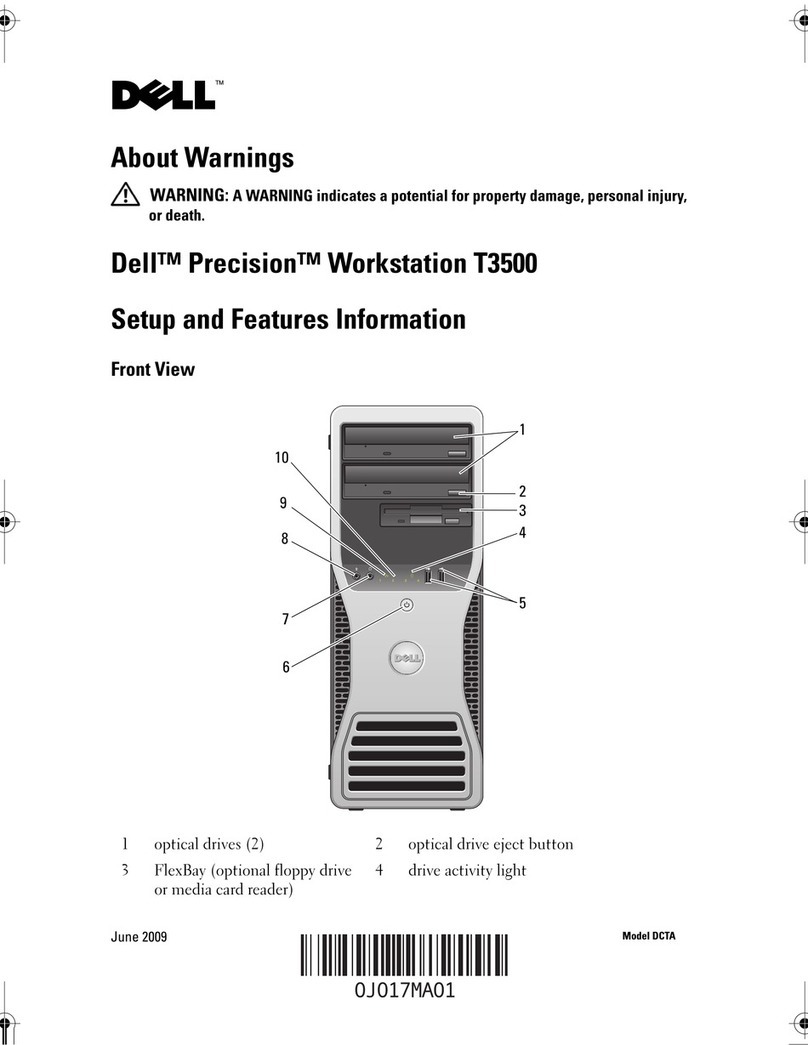

•Working Environment – Before deploying the ESD Field Service kit, assess the situation at the customer location. For example,

deploying the kit for a server environment is different than for a desktop or portable environment. Servers are typically installed in a

rack within a data center; desktops or portables are typically placed on office desks or cubicles. Always look for a large open flat work

area that is free of clutter and large enough to deploy the ESD kit with additional space to accommodate the type of system that is

being repaired. The workspace should also be free of insulators that can cause an ESD event. On the work area, insulators such as

Styrofoam and other plastics should always be moved at least 12 inches or 30 centimeters away from sensitive parts before physically

handling any hardware components

•ESD Packaging – All ESD-sensitive devices must be shipped and received in static-safe packaging. Metal, static-shielded bags are

preferred. However, you should always return the damaged part using the same ESD bag and packaging that the new part arrived in.

The ESD bag should be folded over and taped shut and all the same foam packing material should be used in the original box that the

new part arrived in. ESD-sensitive devices should be removed from packaging only at an ESD-protected work surface, and parts

should never be placed on top of the ESD bag because only the inside of the bag is shielded. Always place parts in your hand, on the

ESD mat, in the system, or inside an anti-static bag.

•Transporting Sensitive Components – When transporting ESD sensitive components such as replacement parts or parts to be

returned to Dell, it is critical to place these parts in anti-static bags for safe transport.

ESD protection summary

It is recommended that all field service technicians use the traditional wired ESD grounding wrist strap and protective anti-static mat at all

times when servicing Dell products. In addition, it is critical that technicians keep sensitive parts separate from all insulator parts while

performing service and that they use anti-static bags for transporting sensitive components.

Identifier GUID-0332D293-B3CC-4042-8A0D-795B07BE277E

Status Released

Transporting sensitive components

When transporting ESD sensitive components such as replacement parts or parts to be returned to Dell, it is critical to place these parts in

anti-static bags for safe transport.

Lifting equipment

Adhere to the following guidelines when lifting heavy weight equipment:

CAUTION: Do not lift greater than 50 pounds. Always obtain additional resources or use a mechanical lifting device.

1. Get a firm balanced footing. Keep your feet apart for a stable base, and point your toes out.

2. Tighten stomach muscles. Abdominal muscles support your spine when you lift, offsetting the force of the load.

3. Lift with your legs, not your back.

4. Keep the load close. The closer it is to your spine, the less force it exerts on your back.

5. Keep your back upright, whether lifting or setting down the load. Do not add the weight of your body to the load. Avoid twisting your

body and back.

6. Follow the same techniques in reverse to set the load down.

8Working inside your computer