Delta Controls CON-768 User guide

Document Edition 1.4 Page 1 of 7

INSTALLATION & APPLICATION GUIDE

RS-232/485 Converter

CON-768 (Rev 3.3)

Document Edition 1.4

Product Description

The Delta Controls RS-232/485 Converter converts RS-

232 signals to/from RS-485 signals. It connects to Delta

Controllers through a service tool port using a RJ11 quick

connect cable. The Service Tool Port is built onto many

of Delta’s ORCA controllers, including the BACstat II

(DNS-24/DNT-Txxx) and most of the Application

Controllers.

The Delta Controls RS-232/485 Converter allows Service

Personnel or Building Operators to connect directly to

any BACnet MS/TP network through their PC or

Laptop’s RS-232 Serial Port. Once connected they have

access to the entire network of controllers. The converter

can also be used when flash loading Delta’s BACnet

MSTP controllers to a new version of firmware.

Contents

MODEL NUMBERS & ACCESSORIES............................................................................ 2

PACKAGE CONTENTS ...................................................................................................... 2

OTHER RELEVANT DOCUMENTS................................................................................. 2

IMPORTANT INFORMATION.......................................................................................... 2

PRODUCT SPECIFICATIONS .......................................................................................... 3

BOARD LAYOUT................................................................................................................. 3

INDICATORS ....................................................................................................................... 4

MOUNTING .......................................................................................................................... 4

POWER.................................................................................................................................. 4

COMMUNICATIONS SETUP ............................................................................................ 4

COMPLIANCE DECLARATIONS .................................................................................... 6

RS-232/485 Converter CON-768 (Rev 3.3) Installation & Application Guide

Page 2 of 7 Document Edition 1.4

Model Numbers

Features CON-768

RS-232/485 Converter 9

Accessories

• Spare RJ11 Cable part# CON-CBL

Package Contents

• RS-232/485 Converter Board, CON-768 (Rev 3.3)

• RJ11 cable

• RS-232/485 Converter CON-768 (Rev 3.3) Installation & Application Guide

Other Relevant Documents

• RS-485 Network Installation Guide (DOC818-11)

• CON-768 Release Notes

• Release Notes for V3.22 and/or V3.30 Firmware/Software

Important Information

The RS-232/485 Converter can be used with any BACnet MS/TP network.

NOTE:While the CON-768 can be used on any BACnet MS/TP network it is designed to connect

through a Delta proprietary RJ11 service port connection. This means that in order to connect a

CON-768 to a BACnet MS/TP network requires at least one Delta controller with a service port, or

an RTS-20J sensor. (The RTS-20J is a wall thermistor that has had a service port added to it’s

enclosure with termination points to attach it to the MS/TP daisy chain and 24Vac to power the

converter.)

Delta Controls

Document Edition 1.4 Page 3 of 7

Product Specifications

Power Requirements

• 24VAC (supplied by the RJ11 Service Tool Port)

• Class II

Ambient Ratings

• 32º to 131º F (0º to 55º C)

• 10 to 90% RH (non-condensing)

Communication Ports

RS-232 Port

• Communications Speed @ 1,200 or 2,400 or 4,800 or 9,600 or 19,200 or 38,400 or 76,800 or 115,200

baud

RS-485 Port

• Communications Speed @ 1,200 or 2,400 or 4,800 or 9,600 or 19,200 or 38,400 or 76,800 baud

Technology

• 8-bit Processor

• Internal A/D, Flash, and RAM

Size (c/w Enclosure)

• 3.5” x 1.7” x 1.0” (8.88 cm x 4.31 cm x 2.57 cm)

Weight (c/w Enclosure)

• 0.15 lb. (65 g.)

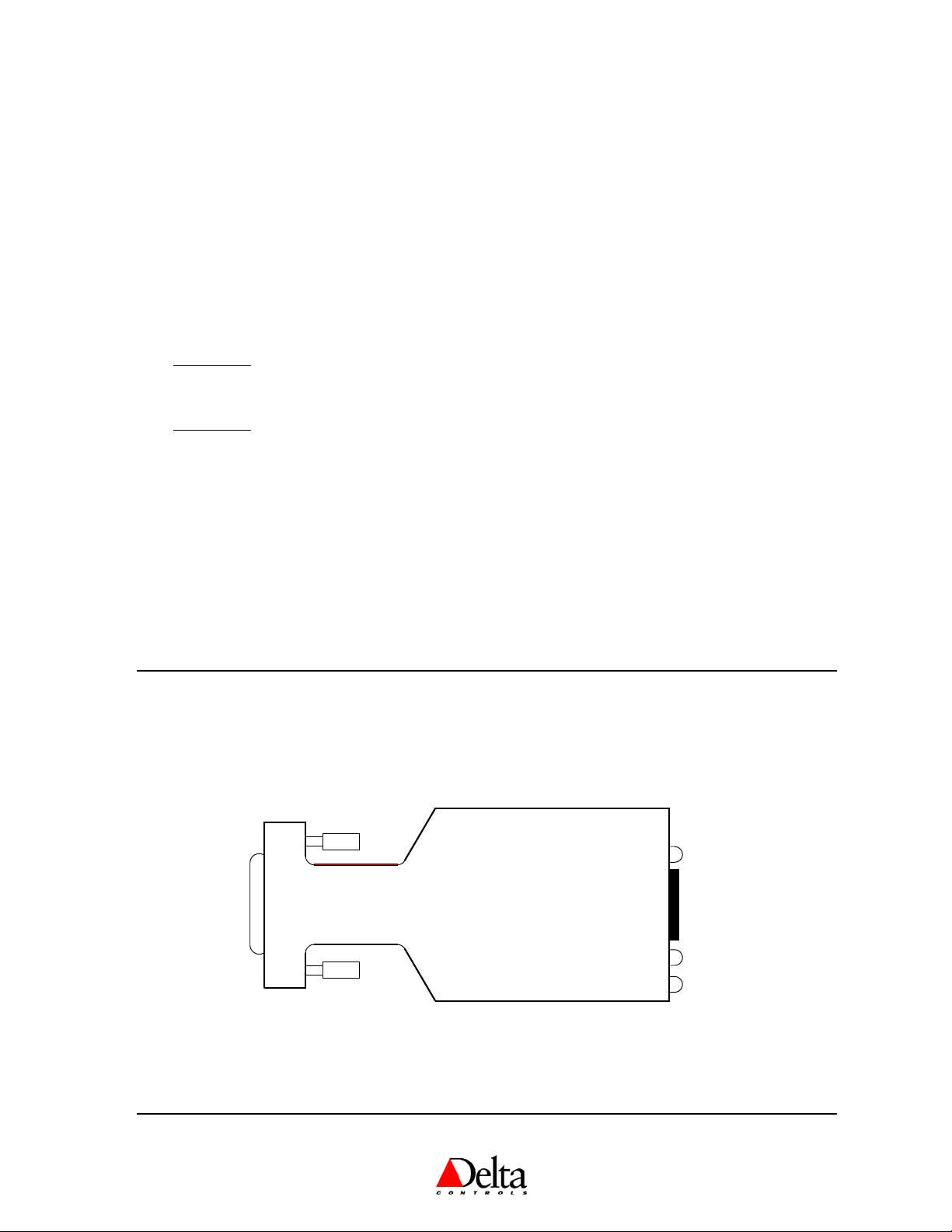

Board Layout (CON-768)

DB9

Serial Port

Connector

Status LED

Transmit LED

Receive LED

RJ-11

RS-485 Connection

RS-232/485 Converter CON-768 (Rev 3.3) Installation & Application Guide

Page 4 of 7 Document Edition 1.4

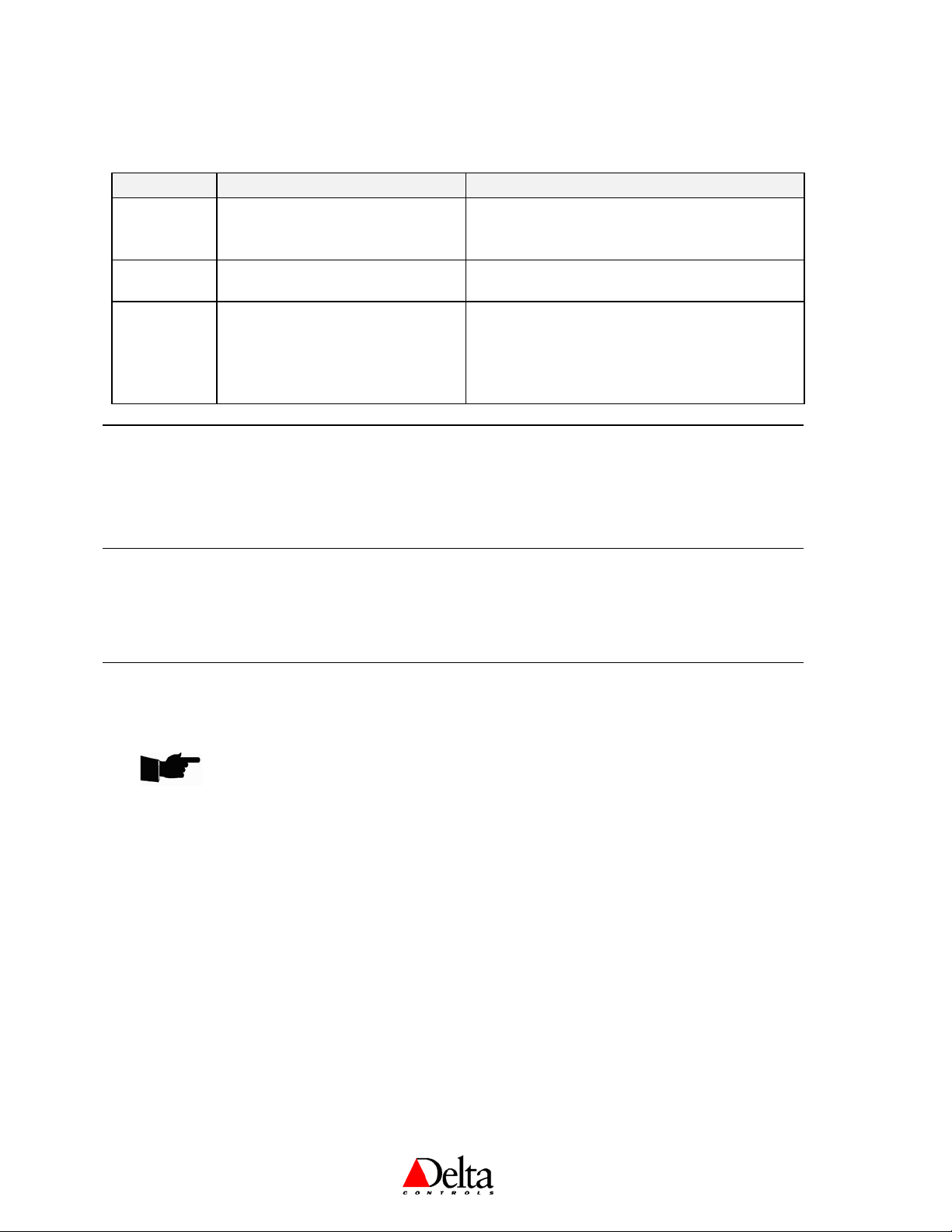

Indicators

LED Function Description

POWER/

STATUS

Indicates that the RS-485/232

Network Converter (CON-768) has

power applied.

This green LED is on steady for normal operation

and blinks during auto configuration.

Tx

(RS-485)

Indicates that the RS-485 port is

broadcasting on the RS-485 network.

This green LED will blink quickly in a regular

repeating pattern.

Rx

(RS-485)

Indicates that the RS-485 port has

received information from a

controller on the RS-485 network.

This red LED will blink quickly in the same

regular repeating pattern as the Tx LED provided

all controllers are communicating. The blinking of

the Rx LED will lag slightly behind the blinking of

the Tx LED.

Mounting

The RS-232 (9-pin connector) port on the CON-768 plugs directly into the PC 9-pin serial port. The RS-485

(RJ11) port plugs directly into the RJ11 connector of the Service Tool Port on the ORCA controller.

Power

The CON-768 is powered by24Vac supplied through the service tool port of the Delta controller it is connected

to.

Communications Setup

ORCAview Login through the Service Port

NOTE:In order to use the new converter with ORCAview on a 3.22 site you require 3.22a OWS

Build 556 (or newer) and on a 3.30 site you require 3.30 OWS Build 1063 (or newer). In these

builds of OWS the V2 Micronet protocol is no longer supported so you cannot use the CON-768 to

login to a V2 Micronet Network of controllers.

Run ORCAview and when the login dialog is displayed on the screen enter your Username and Password, then

click on the Advanced tab. Ensure the connection method is properly configured by verifying these settings:

• CONNECT USING: Serial (BACnet MS/TP)

• COM PORT: COM1 (or whichever port the converter is connected to)

• BAUD RATE: Set the Baud Rate to match the network speed the device with the Service Port jack is

communicating at on its network. LINKnet networks should be set to 76800 bps, and MS/TP

networks default to 76800 bps (but could be set to something else as required).

• ADDRESS: The address field on the MS/TP login dialog is the MS/TP Mac address that the CON-

768/OWS will use to identify itself on the network. This number defaults to 127 and typically will not

need to be changed. It must be a value between 1-127 and unique on the MS/TP network segment the

converter is connected to. Since Delta typically only uses Mac address ranges 1-99 for panel

addresses using the 100-127 range for the OWS/converter will help reduce the possibility of creating

duplicate network addresses for a site.

Delta Controls

Document Edition 1.4 Page 5 of 7

Once you have verified the connection settings, click on OK to login and begin communicating freely as

configured and as defined by your System User Access (SUA) object settings. Devices should begin to show

up in the Navigator network tree and you should have system-wide access to all BACnet devices and their

objects across the network.

NOTE:If you have some of the earlier version 3.22 controllers they may not accept 127 as a valid

MAC address. This is because on earlier versions the address ranges were limited as follows:

• For controllers configured to reside on a MS/TP network segment the valid address range

was set from 1-99.

• For controllers configured to reside on a Linknet network segment the valid address range

was set from 1-13.

For more detailed information on the logging into panels through the service tool port refer to Appendix H of

the ORCAview Technical Reference manual.

Flashing a Panel Using the CON-768

Flash upgrading a panel’s firmware using a CON-768 requires a PC with 3.30 Version of Delta Flashloader

(Build 1063 or higher).

NOTE:Only the Toshiba based DSC/DAC products can be flash upgraded using the CON-768

over RS-485. The DCU must still be flashed using a serial cable over RS-232.

Preparing to Run Flash Loader

1. Ensure that the panel database is backed up.

2. Place the controller into loader mode by powering off the controller then turning all of its address dip

switches to the on position and powering it back up.

3. Use a CON-768 and RJ11 cable to connect the PC COM port to the service port on the controller.

(The controller should not be connected to any other controllers over the NET 1 MS/TP port while

being flashed in loader mode.)

Running the Flash Loader

• Click on the Windows Start button and select Program\Delta Controls\ORCAview Flash Loader or

click on the ORCAview Flash Loader icon on the desktop.

Selecting an Upgrade File

• In the Filename dropdown list, select the required file. The Upgrade File Details field shows the

details of the selected upgrade file. For a DAC look for a filename similar to: DAC V3 322

Bxxxxx.fls.

Changing the Connection Settings

1. Click the Settings button.

2. On the Setting dialog, set the Protocol to Micronet RS-485 (DAC25x)

3. From the Port drop-down list, select the PC COM Port that the converter is connected to.

4. Click OK. The settings are saved and the dialog closes.

RS-232/485 Converter CON-768 (Rev 3.3) Installation & Application Guide

Page 6 of 7 Document Edition 1.4

Transmitting the Upgrade File

1. Click the Query button to confirm communications with the controller and determine the current

firmware in the device.

2. Click the Program button. (Depending the version you are upgrading to/from a flash lock with

sufficient upgrade counts may be required before Flashloader will allow you to upgrade the panel.)

3. The Flash Loader transmits the new firmware. The Status and Progress fields indicate the current

upgrade operation. Once the upgrade is complete the Status field will show Upgrade Completed.

For more detailed information on the Delta Flash Loader refer to the Flash Loader Users Guide.

Compliance Declarations

FCC Compliance Information

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be required to correct the interference at his

own expense.

Industry Canada Compliance Statement

ICES-003 This Class A digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations

Cet appareil numérique de la Classe A Respecte toutes les exigences du Règlement sur le matérial

brouiller du Canada.

UL Compliance Information

This product conforms to the following UL requirements:

• UL916: Energy Management Equipment

• CAUTION – Risk of Electric Shock – More than one disconnect switch may

be required to de-energize the equipment before servicing

• All terminals are acceptable for Class 2 circuit connection only

• CAUTION – Input Class 2 Power Supplies are interconnected. To Reduce

the Risk of Fire or Electric Shock, Use only Class 2 sources Suitable for

Interconnection

• Use Copper Conductor Only

• Select an external power supply that is certified for safety for the correct

destination country and that has an output rating, which is considered an NEC

Class 2 or Limited Power Source with the rating not to exceed 30 V rms, 42.4

V peak, 100 VA.

Delta Controls

Document Edition 1.4 Page 7 of 7

CE - DECLARATION OF CONFORMITY

according to ISO/IEC Guide 22 and EN 45014

Manufacturer's Name: Delta Controls

Manufacturer's Address: 17850 56th Avenue

Surrey, British Columbia

Canada

V3S 1C7

declares that the product (s):

Product Name: RS-232/485 Converter

Model Numbers: CON-768

Product Options: All

conforms to the following Product Specifications:

EMC:

EN 55022:1998 Radiated and Conducted Emissions Class A

EN 50082-1:1997 Generic Immunity Standard

EN 61000-3-2:1999 Harmonic Current Emissions Class A

EN 61000-3-3:1998 Voltage Fluctuations and Flicker

EN 61000-4-2:1995 + A1:1998 ESD Immunity Level B

EN 61000-4-3:1996 RF Electromagnetic Field Immunity Level A

ENV 50204:1995 RF Electromagnetic Field Immunity (Keyed) Level A

EN 61000-4-4:1995 EFT/Burst Immunity Level B

EN 61000-4-5:1995 Surge Immunity Level B

EN 61000-4-6:1996 Conducted RF Disturbances Immunity Level A

EN 61000-4-11:1994 Voltage Dips / Interruptions Level B/C

Supplementary Information:

The product(s) herewith comply with the requirements of the EMC Directive

89/336/EEC. The product(s) were tested in a typical configuration.

Lee Dickson

Quality Assurance Manager

Table of contents

Other Delta Controls Media Converter manuals

Popular Media Converter manuals by other brands

Kramer

Kramer KDS-EN7 user manual

Extron electronics

Extron electronics VLD 50 user guide

American Lighting

American Lighting 120-CTRL-4CH installation instructions

Assun

Assun AM-EN2211-S003 Series product manual

ACTEON Equipment

ACTEON Equipment SATELEC P MAX Newtron XS user manual

AJA

AJA FS-HDR quick start guide