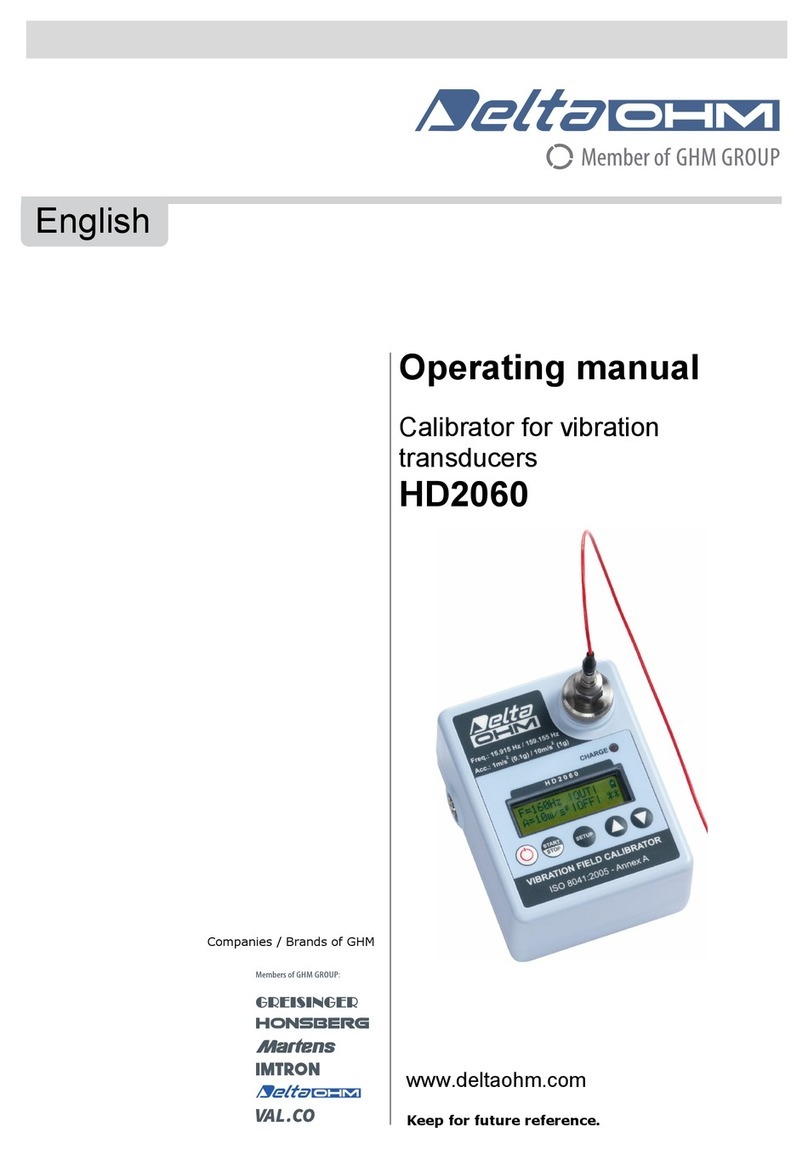

Delta OHM HD2024 User manual

Operating manual

Acoustic calibrator

HD2024

www.deltaohm.com

English

Keep for future reference.

Companies

/

Brands of

GHM

HD2024 - 2 - V1.0

TABLE OF CONTENTS

1INTRODUCTION.................................................................................................... 3

2DESCRIPTION....................................................................................................... 4

3CALIBRATION PROCEDURE................................................................................... 5

3.1CORRECTION DEPENDING ON THE TYPE OF MICROPHONE ................................................... 5

4BATTERY............................................................................................................... 6

4.1LOW BATTERY INDICATION ...................................................................................... 6

4.2BATTERY REPLACEMENT ......................................................................................... 6

4.3CAUTIONS ON USING THE BATTERY ............................................................................ 6

5CONSTRUCTION AND FUNCTIONING .................................................................... 7

6TECHNICAL SPECIFICATIONS ............................................................................... 8

7INSTRUMENT STORAGE ........................................................................................ 9

8SAFETY INSTRUCTIONS ........................................................................................ 9

9ORDERING CODES .............................................................................................. 10

HD2024 - 3 - V1.0

1INTRODUCTION

The HD2024 sound level calibrator is a portable, battery operated sound source,

suitable for sound level meters (portable and laboratory) and acoustic stations.

It allows calibrating 1/2” (1/4” with HD2020MA adapter) microphones with mechanical

dimensions compliant with IEC 61094-1 (“Measurement microphones. Part 1:

Specifications for laboratory standard microphones”) and IEC 61094-4 (“Measurement

microphones. Part 4: Specifications for working standard microphones”).

The generated sound pressure level is equal to 94 dB at 1000 Hz frequency.

A LED signals the low battery condition.

Advantages of the HD2024 calibrator:

•The 1000 Hz frequency allows calibrating sound level meters with any frequency

weighting (LIN, A, B, ...), without applying any correction factor.

•The generated sound pressure level is indipendent of atmospheric pressure: you

don’t need to adjust the value according to static pressure over a wide range of

values.

•Its simplicity of use allows even unskilled staff to use it.

HD2024 - 4 - V1.0

2DESCRIPTION

1. ON-OFF key: turns on and off the instrument.

2. LED indicating the calibrator status.

3. Calibrator cavity for 1/2” microphones.

4. LOW BATT LED: indicates that the battery is low and needs to be replaced.

5. Battery lid.

HD2024 - 5 - V1.0

3CALIBRATION PROCEDURE

The HD2024 can calibrate standard 1/2” (and 1/4” with HD2020MA adapter) micro-

phones compliant with IEC 61094-1 and IEC61094-2.

To calibrate the microphone, insert it deep into the cavity. The O-ring will offer some

resistance.

The calibrator can be held in vertical position or placed on a flat surface.

While measuring, you should move neither the microphone nor the calibrator; make

sure that the worktable doesn’t transmit vibrations.

A small misalignment of the microphone and calibrator axes is allowed.

•Switch on the calibrator by pressing the ON/OFF key.

•Calibrate the sound level meter as per the procedure shown in the instrument

manual.

•Apply the correction to the pressure level depending on the type of microphone

(see the following paragraph).

•Once calibration is complete, switch off the sound level meter and the calibrator

and remove the microphone from the cavity.

The HD2024 calibrator allows calibrating any sound level meter provided that it is

equipped with a laboratory or working standard 1/2” microphone compliant with IEC

61094-1 and IEC 61094-4 standards.

3.1 CORRECTION DEPENDING ON THE TYPE OF MICROPHONE

The calibrator generates a 94 dB sound pressure level referred to 20 μPa. Working

standard 1/2” microphones for sound level meters are manufactured to achieve flat

frequency response in free or diffuse field, i.e. in a field of progressive plane waves

propagating in the same direction as the microphone axis and in a field of sound

waves coming from every direction, respectively. These propagation conditions are

different from those in the calibrator cavity.

In free field, reflections due to the microphone alter the sound level by increasing the

actual high-frequency capsule sensitivity. Microphones optimized for free field meas-

urements exploit this phenomenon to achieve flat frequency response even at very

high frequencies. In these microphones, the sound level increase at 1 kHz corre-

sponds to approximately 0.05 dB ÷ 0.20 dB. Therefore, when you calibrate a free field

microphone, you must take into account for this difference by setting in the sound

level meter a sound level 0.1 dB or 0.2 dB lower than the calibrator nominal one.

Microphones optimized for diffuse field measurements don’t require corrections when

calibrated in a closed cavity at 1 kHz instead.

HD2024 - 6 - V1.0

4BATTERY

The calibrator is provided with a 9 V alkaline battery that can be replaced by the user.

The battery charge is constantly monitored.

4.1 LOW BATTERY INDICATION

If the battery is charged, the LOW BATT LED is off.

If the battery charge is insufficient to ensure the normal operation of the instrument,

the LOW BATT LED lights up.

4.2 BATTERY REPLACEMENT

To replace the 9 V battery:

•Switch off the instrument.

•Open the lid at the bottom of the instrument.

•Replace the battery.

•Close the lid.

4.3 CAUTIONS ON USING THE BATTERY

•Remove the battery if the instrument is not to be used for an extended period.

•If the battery is low, replace it as soon as possible.

•Make sure that there is no liquid leakage from the battery.

•Use good quality sealed batteries (alkaline if possible).

HD2024 - 7 - V1.0

5CONSTRUCTION AND FUNCTIONING

Calibrator mechanical construction (section)

The figure schematizes the HD2024 calibrator structure (in section). The battery com-

partment is on the right side of the case. The printed circuits with the electronics are

over and under the battery compartment. The electro-acoustic transduction system is

on the left and it consists of a wide cavity with a piezoceramic generator and a feed-

back sensor. The system emits the signal through the 1/2” microphone cavity. An

outer capillary hole balances the chamber static pressure protecting microphones from

overpressure due to their insertion.

The electronics consist mainly of an oscillator combining high stability and low distor-

tion, as well as an RMS converter, the automatic gain control (AGC), the driver for the

ceramic resonator and the electronics for conditioning the signal from the feedback

sensor.

The RMS level of the signal provided by the sensor is compared with the factory set

reference level; the difference adjusts the width, through the automatic gain control,

of the signal generated by the oscillator and thus the acoustic signal generated by the

piezoelectric transducer.

The signal provided by the sensor has minimal changes with the ambient temperature

and the static pressure; the frequency of the signal provided by the oscillator is also

stable in relation to ambient parameters.

HD2024 - 8 - V1.0

6TECHNICAL SPECIFICATIONS

The HD2024 calibrator complies with IEC 60942-2003 Class 1 and ANSI S1.40-

1984.

Coupling cavity For standard ½” (12.7 ± 0.03 mm) microphones

according to IEC 61094-1 and IEC 61094-4

Optional adapter HD2020MA for ¼” microphones

Frequency 1000 Hz

Frequency tolerance 1% in the range -10 ÷ +50 °C and 10 ÷ 90%RH

Sound pressure level 94.0 dB ± 0.3 dB at 1 kHz

(referred to 101.3 kPa, 23 °C ± 3 °C and 65%RH)

Reference conditions 23 °C, 50%RH, 101.3 kPa, microphone capsule

with 10 mm3equivalent volume

Stabilization time 10 s

Total distortion < 1%

Ambient condition influence

Temperature and humidity influence

Static pressure influence

< 0.3 dB in the range -10 ÷ 50 °C and 10 ÷ 90%RH

< 0.1 dB in the range 65…108 kPa

Stability levels

Short-term stability

Stability after 1 year with normal use

±0.05 dB

±0.15 dB

Operating conditions -10 ÷ +50 °C / ≤90%RH

Storage temperature -25 ÷ +70 °C

Microphone equivalent volume From 5 to 250 mm3

Power supply 9 V alkaline battery IEC type 6LR61

9 V rechargeable batteries can also be used

Battery autonomy 48 hours of continuous use with good quality al-

kaline batteries

Case material ABS

Dimensions 53 x 43 x 83 mm

Weight 160 g

Protection degree IP 64

Effects of electromagnetic fields < 0.3 dB

HD2024 - 9 - V1.0

7INSTRUMENT STORAGE

Instrument storage conditions:

•Temperature: -25...+55 °C.

•Humidity: less than 90 %RH no condensation.

•In storage, avoid places where:

•humidity is high;

•the instrument is exposed to direct sun radiation;

•the instrument is exposed to a high temperature source;

•high vibration levels are present;

•the instrument may be exposed to vapor, salt and/or corrosive gas.

The housing of the instrument is in ABS plastic material: do not use solvents not com-

patible for cleaning.

8SAFETY INSTRUCTIONS

General safety instructions

The instrument has been manufactured and tested in accordance with the safety

standard EN61010-1:2010 “Safety requirements for electrical equipment for mea-

surement, control and laboratory use” and has left the factory in perfect safety tech-

nical conditions.

The instrument proper operation and operating safety can be ensured only if all stan-

dard safety measures as well as the specific measures described in this manual are

followed.

The instrument proper operation and operating safety can be ensured only in the cli-

matic conditions specified in this manual.

Do not use the instruments in places where there are:

•Rapid ambient temperature variations that may cause condensation.

•Corrosive or flammable gases.

•Direct vibrations or shocks to the instrument.

•High-intensity electromagnetic fields, static electricity.

If the instrument is moved from a cold environment to a hot one or vice versa, the

formation of condensation might cause problems to its operation. In this case you

need to wait for the instrument temperature to reach ambient temperature before op-

eration.

User obligations

The instrument operator shall follow the directives and regulations below that refer to

the treatment of dangerous materials:

•EEC directives on workplace safety.

•National law regulations on workplace safety.

•Accident prevention regulations.

HD2024 - 10 - V1.0

9ORDERING CODES

HD2024 Acoustic calibrator. Supplied with: 9 V alkaline battery and instruction

manual.

HD2020MA Microphone adapter for 1/4” capsules.

DELTA OHM metrology laboratories LAT N° 124 are ISO/IEC 17025 accredited by

ACCREDIA for Temperature, Humidity, Pressure, Photometry / Radiometry, Acous-

tics and Air Velocity. They can supply calibration certificates for the accredited

quantities.

GUARANTEE

TERMS OF GUARANTEE

All DELTA OHM instruments are subject to accurate testing, and are guaranteed for 24 months from the

date of purchase. DELTA OHM will repair or replace free of charge the parts that, within the warranty

period, shall be deemed non efficient according to its own judgement. Complete replacement is excluded

and no damage claims are accepted. The DELTA OHM guarantee only covers instrument repair. The

guarantee is void in case of incidental breakage during transport, negligence, misuse, connection to a

different voltage than that required for the appliance by the operator. Finally, a product repaired or

tampered by unauthorized third parties is excluded from the guarantee. The instrument shall be returned

FREE OF SHIPMENT CHARGES to your dealer. The jurisdiction of Padua applies in any dispute.

The electrical and electronic equipment marked with this symbol cannot be disposed of in public

landfills. According to the Directive 2011/65/EU, the european users of electrical and electronic

equipment can return it to the dealer or manufacturer upon purchase of a new one. The illegal

disposal of electrical and electronic equipment is punished with an administrative fine.

This guarantee must be sent together with the instrument to our service centre.

IMPORTANT: Guarantee is valid only if coupon has been correctly filled in all details.

Instrument Code: HD2024

Serial Number

RENEWALS

Date Date

Inspector Inspector

Date Date

Inspector Inspector

Date Date

Inspector Inspector

GHM GROUP – Delta OHM | Delta Ohm S.r.l. a socio unico

Via Marconi 5 | 35030 Caselle di Selvazzano | Padova | ITALY

Phone +39 049 8977150 | Fax +39 049 635596

www.deltaohm.com | info@deltaohm.com

The quality level of our instruments is the result of the constant development of the product. This may

produce some differences between the information written in this manual and the instrument you have

purchased. We cannot completely exclude the possibility of errors in the manual, for which we apologize.

The data, images and descriptions included in this manual cannot be legally asserted. We reserve the

right to make changes and corrections with no prior notice.

GHM GROUP – Delta OHM | Delta Ohm S.r.l. a socio unico

Via Marconi 5 | 35030 Caselle di Selvazzano | Padova | ITALY

Phone +39 049 8977150 | Fax +39 049 635596

www.deltaohm.com | info@deltaohm.com

V1.0

04/06/2018

Table of contents

Other Delta OHM Test Equipment manuals