Delta OHM HD2060 User manual

Operating manual

Calibrator for vibration

transducers

HD2060

www.deltaohm.com

English

Keep for future reference.

Companies

/

Brands of

GHM

HD2060 - 2 - V1.0

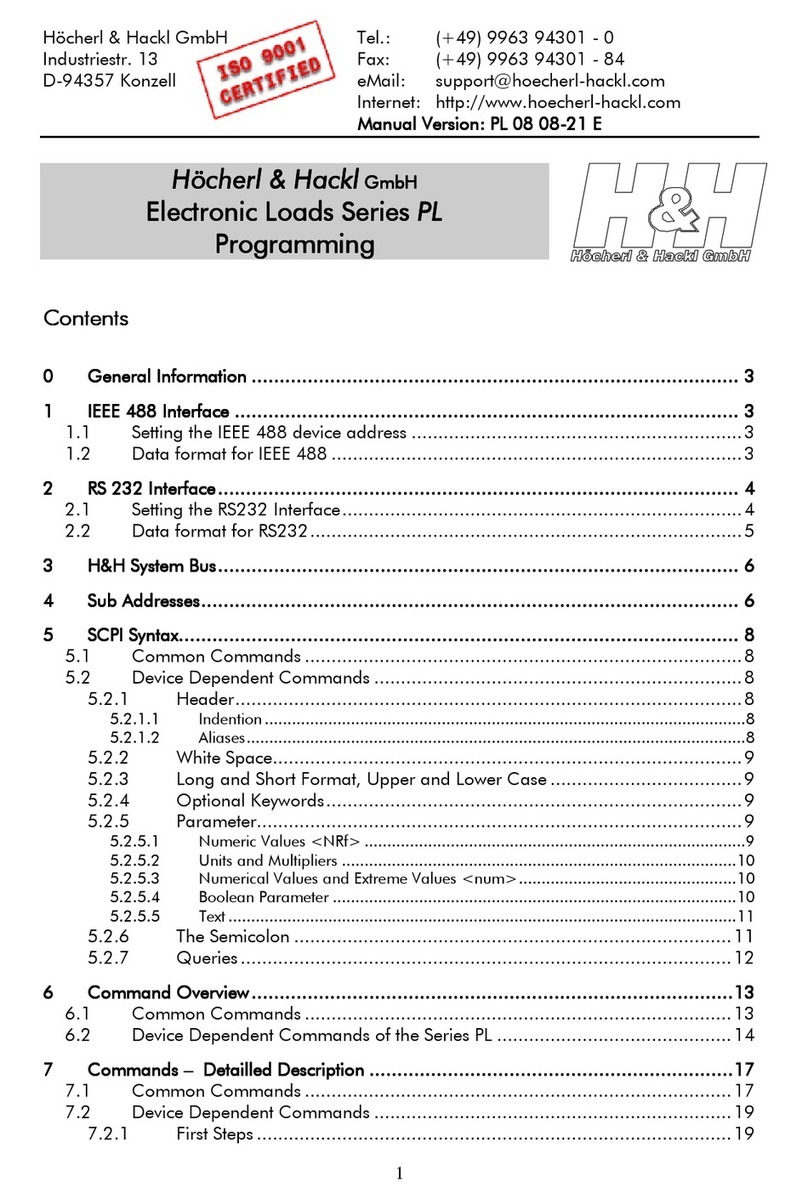

INDEX

1INTRODUCTION.................................................................................................... 3

2TECHNICAL CHARACTERISTICS ............................................................................ 4

3DESCRIPTION AND MOUNTING OF TRANSDUCER ................................................. 5

4TRANSDUCER CALIBRATION................................................................................. 8

5CALIBRATOR CONFIGURATION........................................................................... 10

6BATTERY............................................................................................................. 12

7STORAGE OF INSTRUMENTS ............................................................................... 13

8SAFETY INSTRUCTIONS...................................................................................... 13

9ORDERING CODES .............................................................................................. 14

HD2060 - 3 - V1.0

1INTRODUCTION

The calibrator HD2060 generates mechanical vibration amplitude controlled with pre-

cision and frequency stabilized by a quartz. Coupling a transducer to the vibrating

base of the calibrator it is possible to check its sensitivity to acceleration, velocity or

displacement. The presence of a rechargeable internal battery, the weight and the

small dimensions as well as the low sensitivity to environmental parameters make it

easy to use the calibrator in the field. The calibrator is equipped with a feedback sys-

tem capable of accurately maintaining the amplitude level set, regardless of the load

associated with the mass of the transducer (within the limits stated in the technical

specifications).

The mechanical vibrations generated by the calibrator are very stable over the time,

with a typical drift of 1% per year. In order to maintain the accuracy, we recommend

the annual calibration at DELTA OHM metrological laboratories. The calibrator notifies

the user about the need to make the periodic check by displaying alternately the signs

"cal" and "exp" on the display.

The backlit display provides a clear indication of acceleration, frequency and the

reaching of the set level. In case of exceeding the maximum permissible load or in

case of low battery, the calibrator alerts the user by displaying an error message and

the operation of the vibrating base is turned off. The automatic stop of the vibration

after the set time and the automatic shutdown function prevent the discharge of the

battery.

The calibrator is equipped with screws and accessories for mounting the transducers,

with external power supply for charging the battery and with calibration report.

Applications:

•In-the-field calibration of acceleration, velocity and displacement transducers.

•Calibration of acceleration sensors used for the measurement of vibrations

transmitted to men in the workplace, according to the standard ISO 8041:2005.

•Calibration of acceleration sensors used to evaluate buildings vibration.

Main specifications:

•Two frequencies of emission: 15.915 Hz at 1 m/s2and 0,1 g

159.155 Hz at 10 m/s2and 1 g

•Low distortion accelerations, independent from the mass of the transducer

•Absence of dispersed magnetic field.

•Backlit display with the indication of the acceleration level stabilization.

•Internal rechargeable battery which allows 2 hours of continuous operation at

15.915 Hz and 7 hours of continuous operation at 159.155 Hz.

HD2060 - 4 - V1.0

2TECHNICAL CHARACTERISTICS

Maximum load of the

vibrating base

Traction force: 10 N

Pressure: 30 N

Transverse: 2 N

Mass of the transducer Maximum 150 g at 15.915 Hz

Maximum 30 g at 159.155 Hz

Emission frequency

tolerance

± 0.1%

Emission amplitude

tolerance

± 3%

Distortion Less than 3% at 15.915 Hz

Less than 0.5% at 159.155 Hz

Duration of individual

emission

Settable from 120 seconds to 10 minutes. Automatic turn OFF

Transverse acceleration Less than 10% at 15.915 Hz

Less than 20% at 159.155 Hz

Mounting of the

transducer

Threaded hole UNF 10-32 at 90° ±1°

Working temperature/RH 0…+40 °C / 0…85 %RH not condensing

Stabilization time Less than 30 s

Display Backlit with indication of:

Frequency generated

Acceleration generated

Stabilization of the vibration

Remaining battery charge

Calibration deadline

Power supply Rechargeable NiMH battery pack 1.2V x 4, capacity 1600

mA/h (BAT-40)

100-240 Vac / 12 Vdc 1 A stabilized power supply (SWD10)

Authonomy with full

charged battery

2 hours of continuous use at 15.915 Hz

7 hours of continuous use at 159.155 Hz

Battery charging time 4 hours at 12 Vdc 1A

Auto power off After an inactive period of time equal to 3 times the time of

solicitation set

Dimensions 115 x 93 x 63 mm

Weight 930 g including battery

The exceeding of the limits ma

y

permanently damage the vibrating base

HD2060 - 5 - V1.0

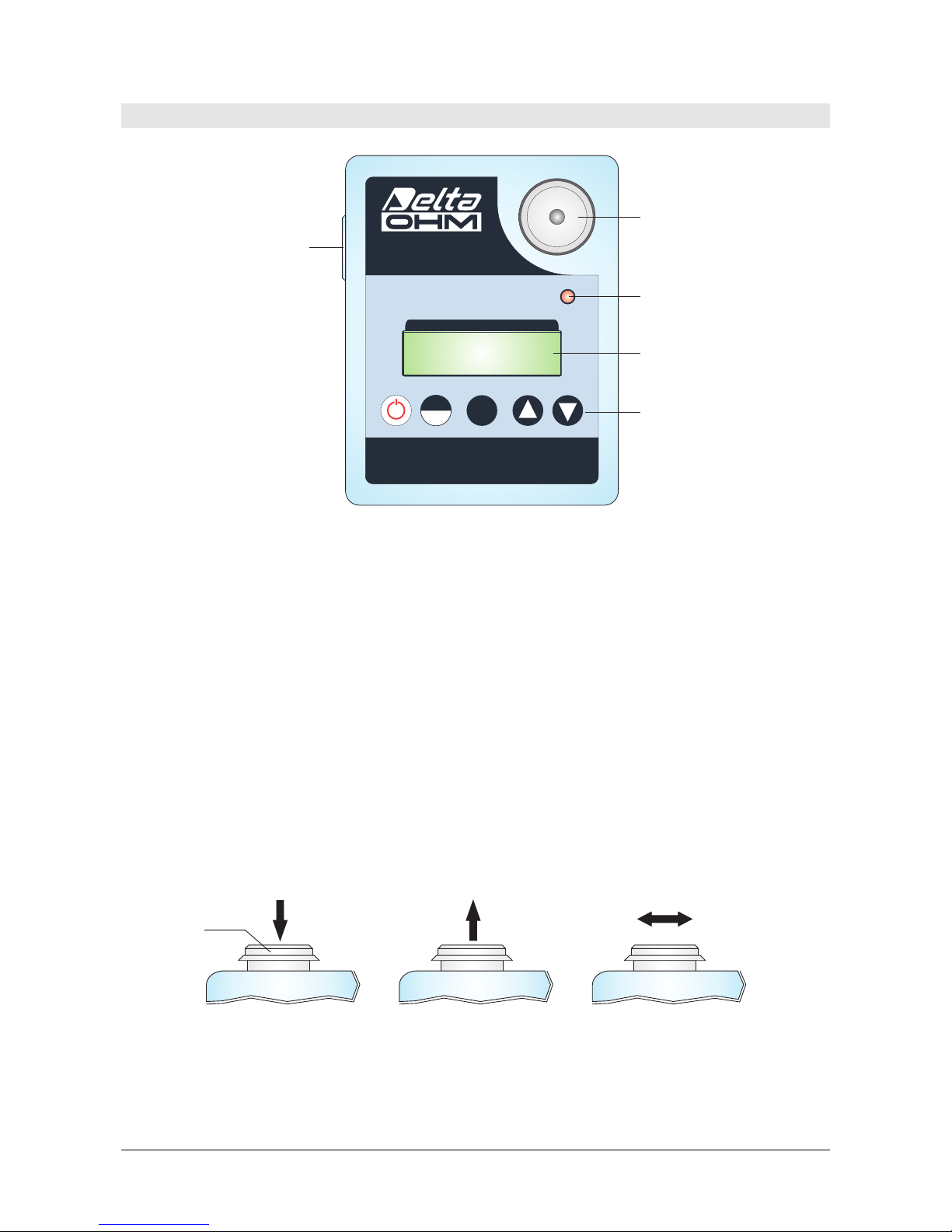

3DESCRIPTION AND MOUNTING OF TRANSDUCER

H D 2 0 6 0

START

STOP

VIBRATION FIELD CALIBRATOR

ISO 8041:2005 - Annex A

Freq.: 15.915 Hz / 159.155 Hz

Acc.: 1m/s (0.1g) / 10m/s (1g)

22

Acc.: 1m/s (0.1g) / 10m/s (1g)

22

CHARGE

SETUP

** DELTA OHM **

** HD2060 **

Fig. 3.1: Description

TRANSDUCER MOUNTING

The calibrator HD2060 presents a flat circular steel fixing base (see Figure 3.1), resis-

tant to abrasions, with a UNF 10-32 threaded hole in the center for the mounting of

the transducers.

The fixing base can freely rotate on its housing so as to avoid damage to the calibra-

tor when mounting the sensors and applying the tightening. To fix the accelerometer

using a screw it’s sufficient a 1-2 Nm tightening force, compatible with a manual op-

eration. For maximum measurements repeatability, the use of a torque wrench is rec-

ommended.

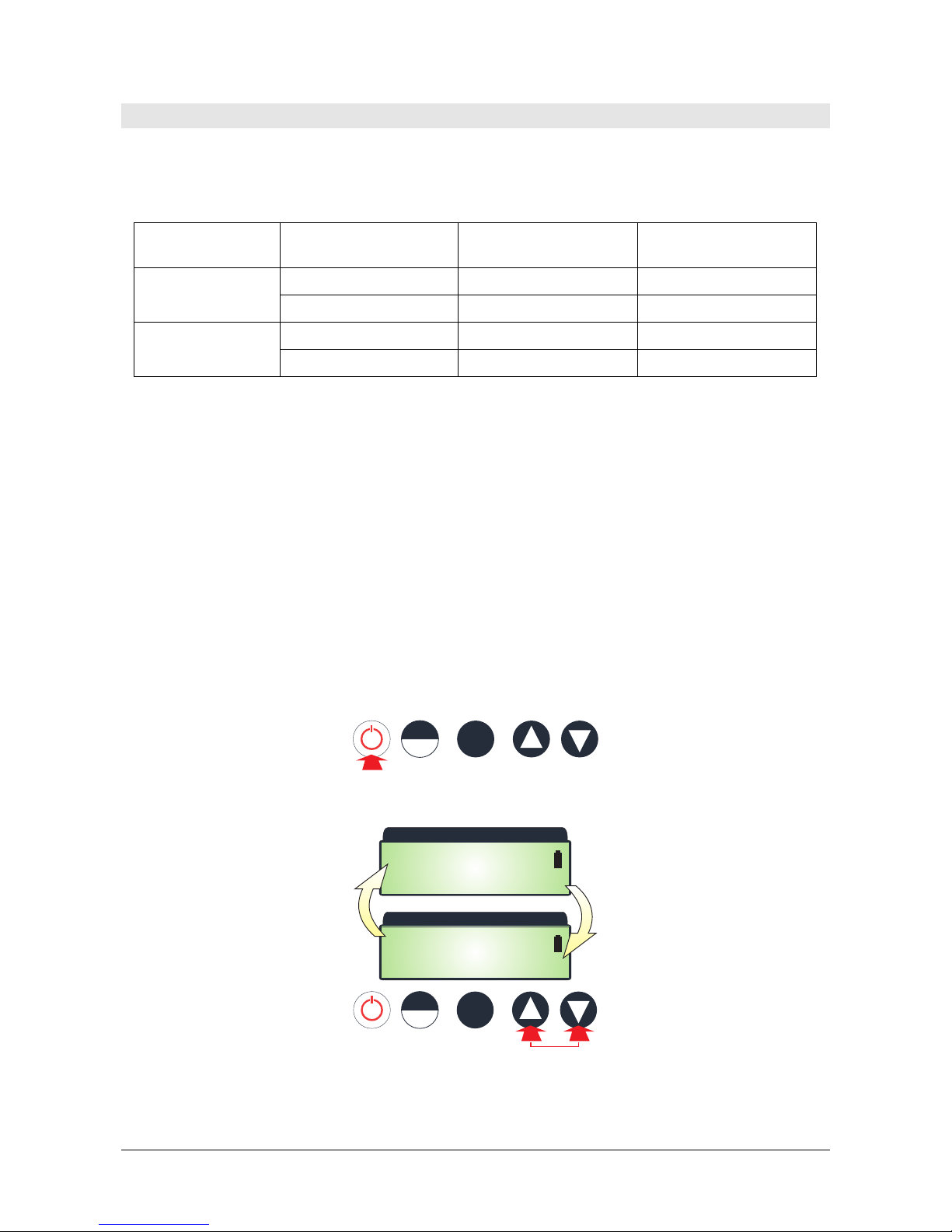

Maximum applicable forces to the fixing base are: 30 N pressure force, 10 N traction

force and 2 N transverse force (see picture 3.2). Applying a load which exceeds

specified limits can permanently damage the HD2060 calibrator.

M 30 NAX M 10 NAX M2NAX

Fig. 3.2: Maximum load limits for vibrating base

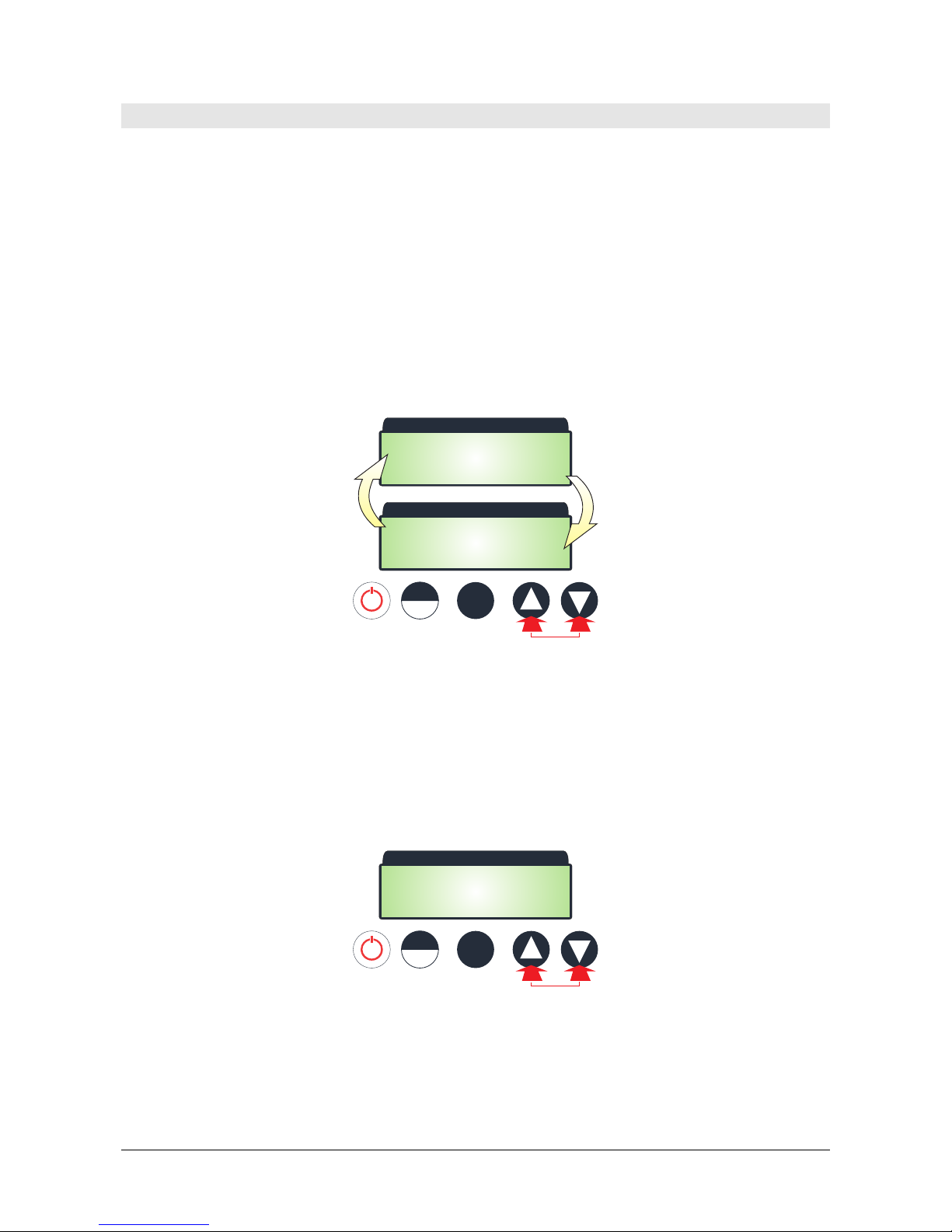

As an alternative to screw mounting, it’s possible to fix the sensor onto vibrating base

using double-sided tape, wax or quick glue; for this can be used the supplied adapter

HD6245.1 (see picture 3.3) to be mounted between vibrating base and transducer. To

Vibratin

g

base

LCD

Keyboard

Batter

y

char

g

e

LED

Power su

pp

l

y

connector

Vibratin

g

Base

HD2060 - 6 - V1.0

avoid an excessive pressure on the vibrating base, we recommend to glue the trans-

ducer on the HD6245.1 adapter before screwing it to the vibrating base.

Fig. 3.3: Adhesive Mounting

To calibrate axes orthogonal to the mounting axis on triaxial accelerometers, it is sup-

plied the adapter HD2060.20, complete with UNF 10-32 dual threading screw to fix

the adapter to the mounting base and screw with UNF 10-32 threading to fix the sen-

sor to the adapter (see picture 3.4).

Fig. 3.4: Use of adapter HD2060.20

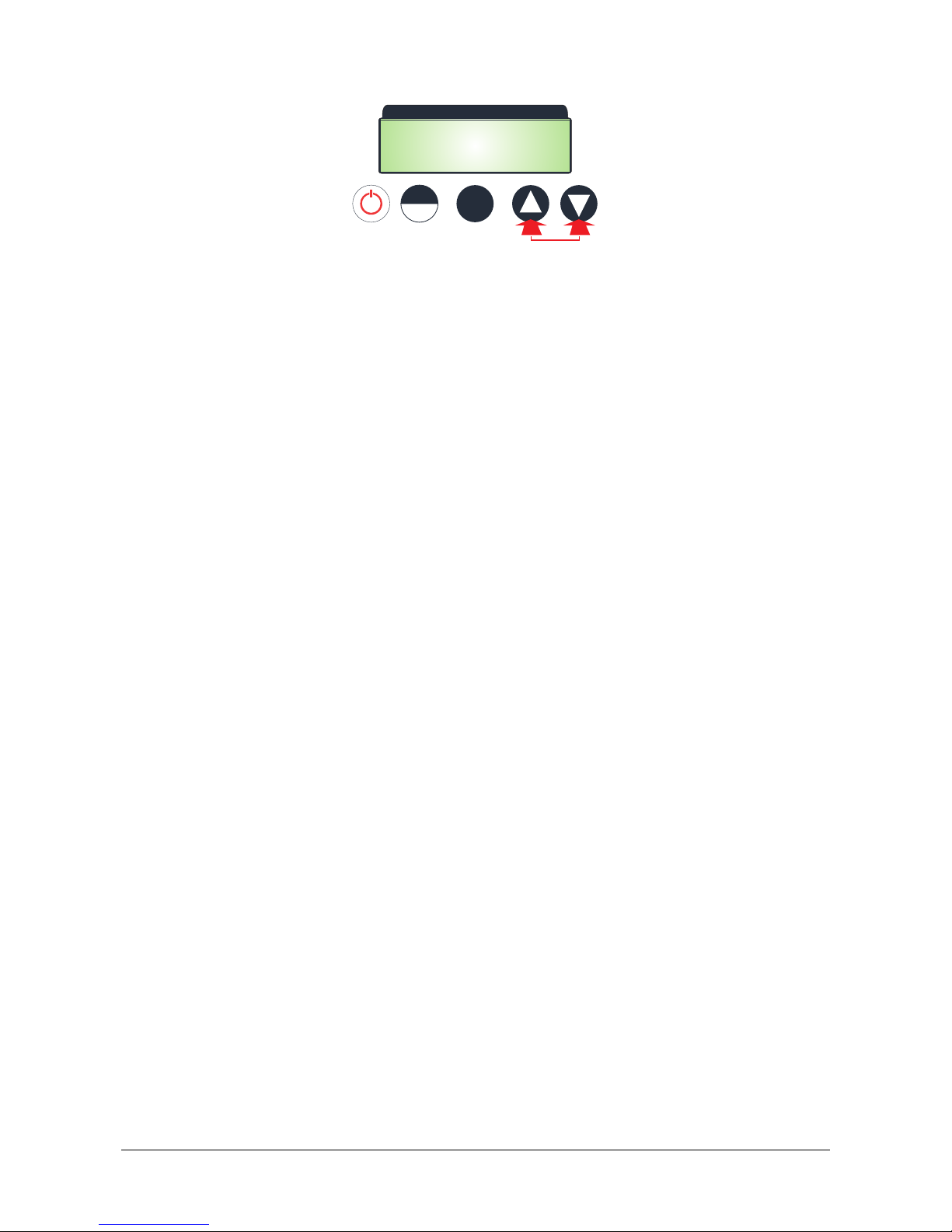

If you use the HD2060.20 adapter to calibrate at 16 Hz perpendicular axis of a triaxial

accelerometer having a mass greater than 30 g, it is necessary to balance the load

using a counterweight equal to that of the transducer to be mounted, as shown in fig-

ure 3.5.

Fig. 3.5: Use of counterweights

Calibrator must be placed on a flat horizontal surface, possibly free from external vi-

brations. In order to check that transmitted vibration level from supporting surface is

HD2060.20

Vibrating Base

Transduce

r

Counterweigh

t

Vibrating Base

Transduce

r

HD6245.1

Vibrating bas

e

Triaxial transduce

r

Transducer’s mounting

screw

HD2060.20

Double threading screw for mounting

of HD2060.20 on Vibrating base

HD2060 - 7 - V1.0

negligible it is sufficient, after transducer has been fixed to the mounting base, to ve-

rify that acceleration on the measurement chain with calibrator turned OFF is below

1/5 of calibration level. For example, if a calibration has to be made at 15.915 Hz with

1 m/s2amplitude level, acceleration on the measurement chain when calibrator is OFF

should be less than 0.2 m/s2.

During calibration solicitation it’s necessary to avoid unbalances on the base, taking

care of transducer’s connection cable positioning, in order to minimize the transverse

load. Transducer should be mounted so that the load is centered on the base.

HD2060 - 8 - V1.0

4TRANSDUCER CALIBRATION

HD2060 can calibrate acceleration, velocity and displacement sensors. Emission fre-

quencies are chosen to allow an easy conversion among the three measurement units

as shown in the table below.

Frequency [Hz] Acceleration

[m/s2] Velocity [mm/s] Displacement [µm]

15.915 1 10 100

0.98 9.81 98.1

159.155 10 10 10

9.81 9.81 9.81

Selection of the right frequency depends on the type of transducer and measurement

application. For example, according to ISO 8041:2005 requirements, vibration trans-

ducers used in the workplace to evaluate vibration transmitted to hand –arm system ,

must be checked at 159.155 Hz, while those used for vibrations transmitted to the

whole body must be checked at 15.915 Hz.

Some transducers are designed for measurement at very low frequencies, and cannot

be calibrated at 160 Hz. If the application or the type of transducer don’t put con-

straints to the choice, 159.155 Hz frequency is preferable because, in addition to

higher acceleration level, provides a lower distortion and lower sensitivity to vibrations

induced from the support surface.

Procedure:

1. After the transducer has been correctly mounted on the vibrating base, power ON

the calibrator by pressing the ON/OFF key.

START

STOP SETUP

2. Use the arrow keys to select the emission frequency.

HD2060H D 2 0 6 0

F= 16Hz |OUT|

A=0.1g |OFF |

HD2060H D 2 0 6 0

F=160Hz |OUT|

A= 1g |OFF |

START

STOP SETUP

Note: as concerns modification of acceleration amplitude and emission duration

please see configuration paragraph.

HD2060 - 9 - V1.0

3. In order to start emission, press START/STOP key.

START

STOP SETUP

HD2060H D 2 0 6 0

F=160Hz |OUT|

A= 1g |OFF |

4. On the display is shown the indication WT ("Wait") until vibration emission is suffi-

ciently steady. When emission is stable, it appears the indication ON.

HD2060H D 2 0 6 0

F=160Hz |OUT|

A= 1g |WT |

HD2060H D 2 0 6 0

F=160Hz |OUT|

A= 1g |ON |

5. Emission stops automatically after the time period set on the calibrator is elapsed.

In order to manually stop emission, press the START/STOP key.

HD2060 - 10 - V1.0

5CALIBRATOR CONFIGURATION

By sequentially pressing the SETUP key, the following information are displayed:

•Generated Acceleration (AMPL. SETUP)

•Emission Duration (VIBR. TIME)

•Date and time (DATE TIME)

•Calibrator serial number (SERIAL NUM.)

•Calibration Date (CALIB. DATE)

•Firmware Version (FIRM. VER.)

Setting Acceleration Amplitude:

Press SETUP key until the AMPL. SETUP screen is shown, then select required accele-

ration value using the arrow keys.

HD2060H D 2 0 6 0

--AMPL. SETUP--

AMPL= 10m/s

2

HD2060H D 2 0 6 0

--AMPL. SETUP--

AMPL= 1g

START

STOP SETUP

Acceleration values that can be set, depend on the emission frequency selected. For

emission frequency of 15.915 Hz can be set acceleration amplitudes of 1 m/s2and

0.1g (0.98 m/s2). For emission frequency of 159.155 Hz can be set acceleration am-

plitudes of 10 m/s2and 1g (9.81 m/s2).

Setting Emission Duration:

Press the SETUP key until the VIBR. TIME screen appears, then select required emis-

sion duration using the arrow keys.

HD2060H D 2 0 6 0

-- VIBR. TIME --

240 sec

START

STOP SETUP

Duration can be set from 120 seconds up to 10 minutes in steps of 10 seconds.

Setting date and time:

Press SETUP key until the DATE TIME screen appears, then modify the year field using

the arrow keys.

HD2060 - 11 - V1.0

HD2060H D 2 0 6 0

-- DATE TIME --

2012/07/04 09:45

START

STOP SETUP

In order to set the next fields (month, day, hour, minute), just press SETUP key until

the desired field starts blinking, then modify it using the arrow keys.

Exit from configuration mode:

In order to exit from the configuration mode, hold down the SETUP key for at least 2

seconds.

Settings are stored in the calibrator’s internal memory and remain stored even if the

device is turned OFF. When the calibrator is powered ON, it always starts with the lat-

est configuration set.

HD2060 - 12 - V1.0

6BATTERY

The battery symbol on the display continuously provides the charge battery status. As

the battery discharges, the symbol "empties". When the charge is insufficient for cor-

rect device operation, the symbol starts blinking and it will be not possible to activate

the emission of the vibrating base.

In order to charge the batteries, connect the SWD10 power supply to the input plug

positioned on the calibrator’s side. During battery charge, the “CHARGE” red LED is

ON. The LED will turn OFF when the charge is completed. The time necessary for a full

charge is about 4 hours.

Power supply has a dual function: supplies the device and charges the NiMH battery.

When power supply is plugged in, the battery symbol on the display, is substituted by

the symbol of a plug.

In order to preserve over time the battery capacity, it is recommended to

make a complete charge cycle at least one time every six months.

The battery can be charged and discharged hundreds times, but it loses its capacity

with the use during time. If, when the battery is fully charged, the operation autono-

my is not sufficient, it’s necessary to replace the battery pack.

As spare part use only original Delta OHM battery pack BAT-40 and proceed as fol-

lows:

•If plugged in, disconnect external power supply.

•Loosen the two screws to remove the cover of battery housing placed on the

bottom of calibrator.

•Disconnect the battery taking care not to tear the wires.

•Connect the new battery: the connector has a reference that avoids uncorrect

operation.

•Place the new battery in the housing.

•Close the battery housing tightening the two screws.

Note: dispose used batteries according to safety normatives. Don’t throw used batte-

ries in the municipal waste; do not put the batteries into contact with flames or high

temperature surfaces.

HD2060 - 13 - V1.0

7STORAGE OF INSTRUMENTS

Storage conditions of the instrument:

•Temperature: 0...+40 °C.

•Humidity: less than 90 %RH no condensation.

•For storage, avoid places where:

•There is a high level of humidity;

•Instruments are exposed to direct sun radiation;

•Instruments are exposed to a high temperature source;

•There are strong vibrations;

•There is vapor, salt and/or corrosive gases.

8SAFETY INSTRUCTIONS

General instructions for safety

The instrument has been manufactured and tested in compliance with the safety stan-

dard EN61010-1:2010 “Safety requirements for electrical equipment for measurement,

control and laboratory use” and left the factory in a safe and secure technical condition.

The regular functioning and operational safety of the instrument can be ensured only

if all normal safety measures, as well as the specific measures described in this ma-

nual, are followed.

The regular functioning and operational safety of the instrument can only be guaran-

teed under the climatic conditions specified in the manual.

Do not use the instruments in places where there are:

•Rapid ambient temperature variations that may cause condensation.

•Corrosive or flammable gases.

•Direct vibrations or bumps to the instrument.

•High-intensity electromagnetic fields, static electricity.

If the instrument is transported from a cold environment to a warm one, or vice ver-

sa, the formation of condensation may cause disturbances to its functioning. In this

case, wait until the temperature of the instrument reaches room temperature before

putting into operation.

Obligations of the User

The user of the instrument must ensure compliance with the following standards and

guidelines for the treatment of hazardous materials:

EEC directives on workplace safety

National low regulations on workplace safety

Accident prevention regulations

HD2060 - 14 - V1.0

9ORDERING CODES

HD2060 Portable calibrator for acceleration, velocity and displacement trans-

ducers. Double emission frequency (15.915 Hz and 159.155 Hz).

Backlit LCD display. Power supply with internal rechargeable battery

or external 12Vdc power supply. Includes: support (HD2060.20)

with UNF 10-32 screw for triaxial accelerometers mounting, insulated

base (HD6245.1) with integrated UNF 10-32 screw for accelerome-

ters adhesive mounting, rechargeable internal battery (BAT-40),

mains power supply (SWD10), carrying case and calibration report.

Accessories

SWD10 100-240 Vac / 12 Vdc 1 A stabilized power supply.

BAT-40 Rechargeable NiMH battery pack 1.2 V x 4.

HD6245.1 Insulated base with integrated UNF 10-32 screw for accelerometers

adhesive mounting

HD2060.20 Support for the lateral mounting of tri-axial accelerometers with 10-

32 UNF mounting screw

Delta OHM LAT N° 124 metrology laboratories are ISO/IEC 17025 accredited by AC-

CREDIA in Temperature, Humidity, Pressure, Photometry/Radiometry, Acoustics and

Air Speed. They can provide certificates for the accredited quantities.

GUARANTEE

TERMS OF GUARANTEE

All DELTA OHM instruments are subject to accurate testing, and are guaranteed for 24 months from the

date of purchase. DELTA OHM will repair or replace free of charge the parts that, within the warranty

period, shall be deemed non efficient according to its own judgement. Complete replacement is excluded

and no damage claims are accepted. The DELTA OHM guarantee only covers instrument repair. The

guarantee is void in case of incidental breakage during transport, negligence, misuse, connection to a

different voltage than that required for the appliance by the operator. Finally, a product repaired or

tampered by unauthorized third parties is excluded from the guarantee. The instrument shall be returned

FREE OF SHIPMENT CHARGES to your dealer. The jurisdiction of Padua applies in any dispute.

The electrical and electronic equipment marked with this symbol cannot be disposed of in public

landfills. According to the Directive 2011/65/EU, the european users of electrical and electronic

equipment can return it to the dealer or manufacturer upon purchase of a new one. The illegal

disposal of electrical and electronic equipment is punished with an administrative fine.

This guarantee must be sent together with the instrument to our service centre.

IMPORTANT: Guarantee is valid only if coupon has been correctly filled in all details.

Instrument Code: HD2060

Serial Number

RENEWALS

Date Date

Inspector Inspector

Date Date

Inspector Inspector

Date Date

Inspector Inspector

GHM GROUP – Delta OHM | Delta Ohm S.r.l. a socio unico

Via Marconi 5 | 35030 Caselle di Selvazzano | Padova | ITALY

Phone +39 049 8977150 | Fax +39 049 635596

www.deltaohm.com | info@deltaohm.com

The quality level of our instruments is the result of the constant development of the product. This may

produce some differences between the information written in this manual and the instrument you have

purchased. We cannot completely exclude the possibility of errors in the manual, for which we apologize.

The data, images and descriptions included in this manual cannot be legally asserted. We reserve the

right to make changes and corrections with no prior notice.

GHM GROUP – Delta OHM | Delta Ohm S.r.l. a socio unico

Via Marconi 5 | 35030 Caselle di Selvazzano | Padova | ITALY

Phone +39 049 8977150 | Fax +39 049 635596

www.deltaohm.com | info@deltaohm.com

V1.0

02/03/2018

Other manuals for HD2060

1

Table of contents

Other Delta OHM Test Equipment manuals