Delta OHM HD2817T Series User manual

1

Our instruments’ quality level is the results of the product continuous development. This can bring about

differences between the information written in this manual and the instrument that you have purchased. We

cannot entirely exclude errors in the manual, for which we apologize.

The data, figures and descriptions contained in this manual cannot be legally asserted. We reserve the right

to make changes and corrections without prior notice.

HD2817T...

ENGLISH

REV. 1.2

28th Nov. 2011

2

HD2817T…

Transmitter, indicator, ON/OFF regulator,

temperature and humidity datalogger

The HD2817T... series instruments are transmitters, indicators, ON/OFF regulators with

datalogger function. They measure temperature and humidity.

They are fitted with an LCD backlit graphic display 128x64 pixel.

The main characteristic of these instruments is the interchangeable probe. The user can

virtually change the probe without interrupting the process. Then the probe can be calibrated

or repaired.

We have models with horizontal (S.TO), vertical (S.TV) or separate (S.TC) probes, connected

to the instrument using cables of different lengths. The S.TO and S.TV probes are made of

AISI304 steel, the S.TC probes can be made of AISI304 steel or POCAN plastic material.

To measure the dew point in compressed air systems, the probe S.TC2.480.2 can be

connected to the HD2817T...

The probe, factory calibrated and ready for use, is fitted with a SICRAM2 module storing its

calibration information and allowing its interchangeability.

The devices measure:

Temperature in Celsius or Fahrenheit degrees

Relative humidity

and calculate:

Absolute humidity

Mixing ratio

Dew point

Wet bulb temperature

All models are fitted with current or voltage analogue outputs.

We supply models with two working relays and an alarm relay, user configurable.

All models have a multistandard RS232/RS485 output and an auxiliary RS232C serial output.

You can connect several network devices through the RS485 serial port.

The HD2817T... models use a wide LCD backlit graphic display (128x64 pixel) showing three

physical quantities simultaneously or a real time graph of any of the measured quantities.

The datalogger function allows recording of the measurements detected by the instrument,

according to a frequency set by the user.

The instrument configuration is permanently stored. The internal clock is protected against a

mains power failure by a special Lithium battery.

When making the order, you can select the power supply between 24Vac/dc or universal

90...240Vac.

3

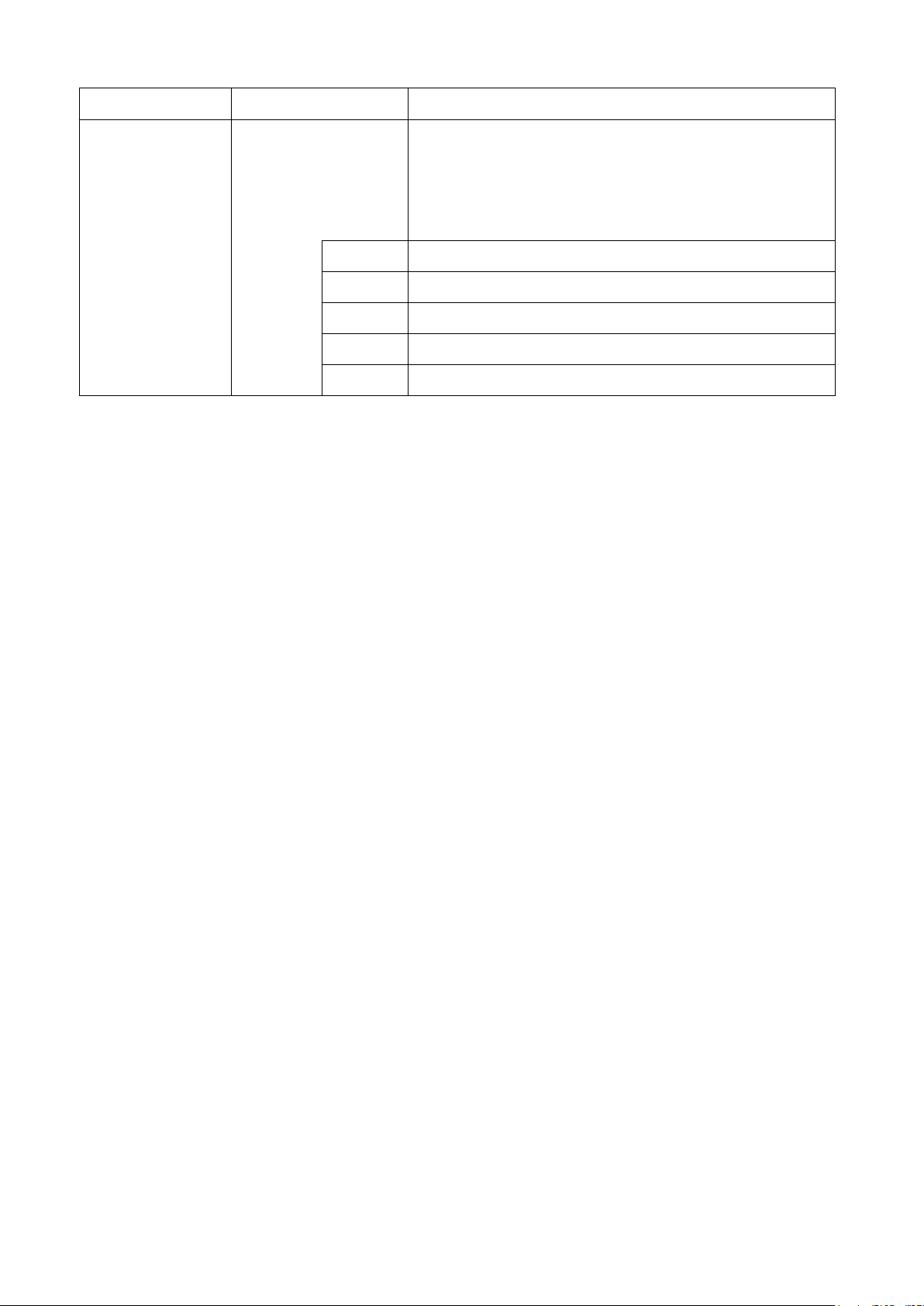

1. Instrument versions and available probes

Relay

HD2817Tx-D0

None

HD2817Tx-DR

2 working relays with exchange contact,

1 alarm relay with normally open contact.

Type of probe

HD2817T.xx

Instrument with vertical probe S.TV or probe with cable S.TC.

HD2817TO.xx

Instrument with horizontal probe S.TO.

Probes complete with SICRAM2 module for HD2817T.xx instruments

S.TV

Vertical probe L = 130 mm

The material of the S.TC... series probe can be chosen between AISI304 steel or POCAN

plastic material.

S.TC1.2

Probe L = 135 mm with 2 m cable

S.TC1.2P

Probe L = 135 mm with 2 m cable in POCAN

S.TC1.5

Probe L = 135 mm with 5 m cable

S.TC1.5P

Probe L = 135 mm with 5 m cable in POCAN

S.TC1.10

Probe L = 135 mm with 10 m cable

S.TC1.10P

Probe L = 135 mm with 10 m cable in POCAN

S.TC2.2

Probe L = 335 mm with 2 m cable

S.TC2.2P

Probe L = 335 mm with 2 m cable in POCAN

S.TC2.5

Probe L = 335 mm with 5 m cable

S.TC2.5P

Probe L = 335 mm with 5 m cable in POCAN

S.TC2.10

Probe L = 335 mm with 10 m cable

S.TC2.10P

Probe L = 335 mm with 10 m cable in POCAN

Probe with cable for measuring humidity in pipes

S.TC2.480.2

Cable length 2m.

Measuring range: -40…+60°C, -40…+60°C DP.

1/4" Italian standard Quick-fit. Working pressure up to 16bar.

Measuring chamber in AISI 304.

Probes complete with SICRAM2 module for HD2817TO.xx instruments

S.TO1

Horizontal probe L = 135 mm

S.TO2

Horizontal probe L = 335 mm

4

2. Upon first start up

Some notes about first start up are reported below. For the details see the various chapters

in the manual.

Before turning on, the probe should be connected to the instrument.

Apply the correct voltage to the instrument. A wrong voltage can cause permanent damages

to the instrument that are not covered by the warranty.

In order to install and connect the instrument, please see the chapters “Installation and

connection” and “Terminal board description”.

To use the analog outputs and relays, please see the chapters “Current and voltage analog

outputs” and “Instruments fitted with relay outputs”, respectively.

For the connection to a PC or network of instruments, please see the charter “Serial

communication and instrument network”.

Check the instrument date and time as described in the following chapter.

3. Initial setting or date and time update

When you power up the instrument, the date and time check takes about one minute.

The following screen will appear:

2008/01/01 12:00:00

TIME/DATE

year/mm/dd hh:mm

2008/01/01 12:00:00

<UP> <DOWN> change

<ENTER> confirm

<ESC> exit

The date and time are correct: press MENU to go directly to measurement mode.

The date and time are not correct:

1. Use the arrows to modify the year, already selected, and press ENTER.

2. You will get to the month setting. Change it using the and arrows and confirm

with ENTER.

3. Repeat for the other items: day, hour, minutes. After the last confirmation you will

exit the setting page and return to the menu main screen.

4. Press MENU to return to measurement mode.

For the next date and time setting, please see the “TIME/DATE” menu item description in the

chapter “Description of the menu”.

5

4. Description of the display

The display constantly shows three measurements (lines 3, 4 and 5 in the figure)

associated to the A1, A2 and A3 analog outputs, respectively:

the physical quantity associated to the analog output A1 is shown on line (3),

the physical quantity associated to the analog output A2 is shown on line (4),

the physical quantity associated to the analog output A3 is shown on line (5).

Each line can show relative humidity, absolute humidity, mixing ratio, dew point, wet bulb

temperature or temperature.

The temperature can be expressed in Celsius or Fahrenheit degrees.

The first display line (1) shows the current date and time.

The auxiliary indications are shown on line (2): e.g. MAX, MIN or AVG functions when pressing

the FUNC key activating the maximum, minimum and average measurements.

To change the temperature unit of measurement between Centigrade or Fahrenheit, press the

UNIT key.

To show a physical quantity in one of the three lines, you can use the “Conf. OUT” >>

“Output Analog 1-2-3” >> “Analog Output x” menu item, with x = 1, 2 or 3.

Procedure:

1. Press the MENU key. The main menu opens.

2. Use the arrows to select “Conf_OUT” and confirm with ENTER.

3. Use the arrows to select “Output Analog 1-2-3” and confirm with ENTER.

4. Use the arrows to select “Current/Voltage out” and confirm with ENTER.

5. Use the arrows to select the type of analog output: “4...20mA/2...10Vdc” or

“0...20mA/0...10Vdc”. Confirm by pressing ENTER. The asterisk will indicate your new

selection. Press ESC to return to the previous menu;

6. Use the arrows to select one of the three analog outputs and confirm with ENTER.

The analog output 1controls the physical quantity shown on line (3), the analog output 2

on line (4) and the analog output 3 on line (5).

7. A screen with two items will appear: “Mode” and “Range values”.

8. Use the arrows to select “Mode” and confirm with ENTER.

9. Use the arrows to select the physical quantity to be associated to the analog output

and confirm with ENTER:

RH Rel. Humidity corresponds to relative humidity,

AH Abs. Humidity corresponds to absolute humidity,

MR Mixing ratio corresponds to mixing ratio,

Td Dew Point Temp. corresponds to dew point,

T Temperature corresponds to temperature,

TW Wet bulb temp. corresponds to the wet bulb temperature.

The asterisk will indicate your new selection. Press ESC to return to the previous menu.

6

10. Use the arrows to select “Range values” and confirm with ENTER.

11. The “Scale low value” (lower limit of the physical quantity) item will blink: if necessary,

change it using the arrows and confirm with ENTER.

12. You will get to the next item “Scale high value” (upper limit of the physical quantity): if

necessary, change it using the arrows and confirm with ENTER.

13. Press ESC to exit.

14. If necessary, set the other two analog output, repeating the steps from 6 to 13.

15. Press MENU to return to measurement mode.

7

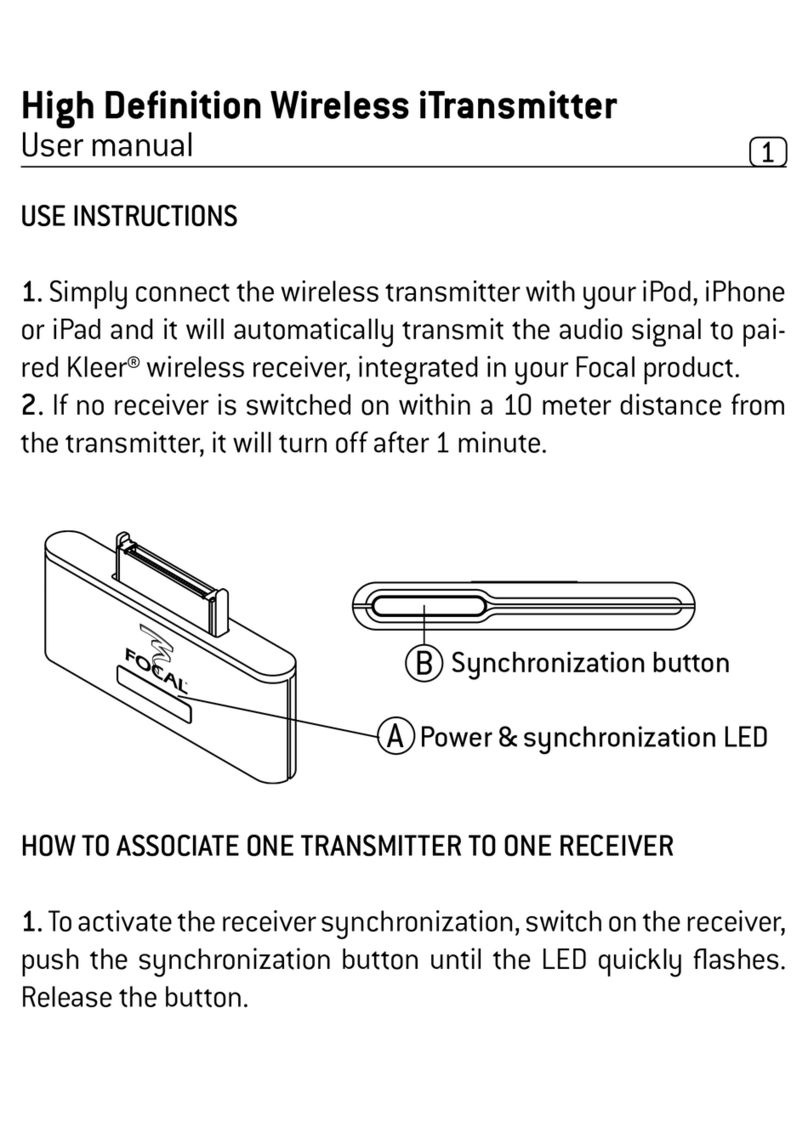

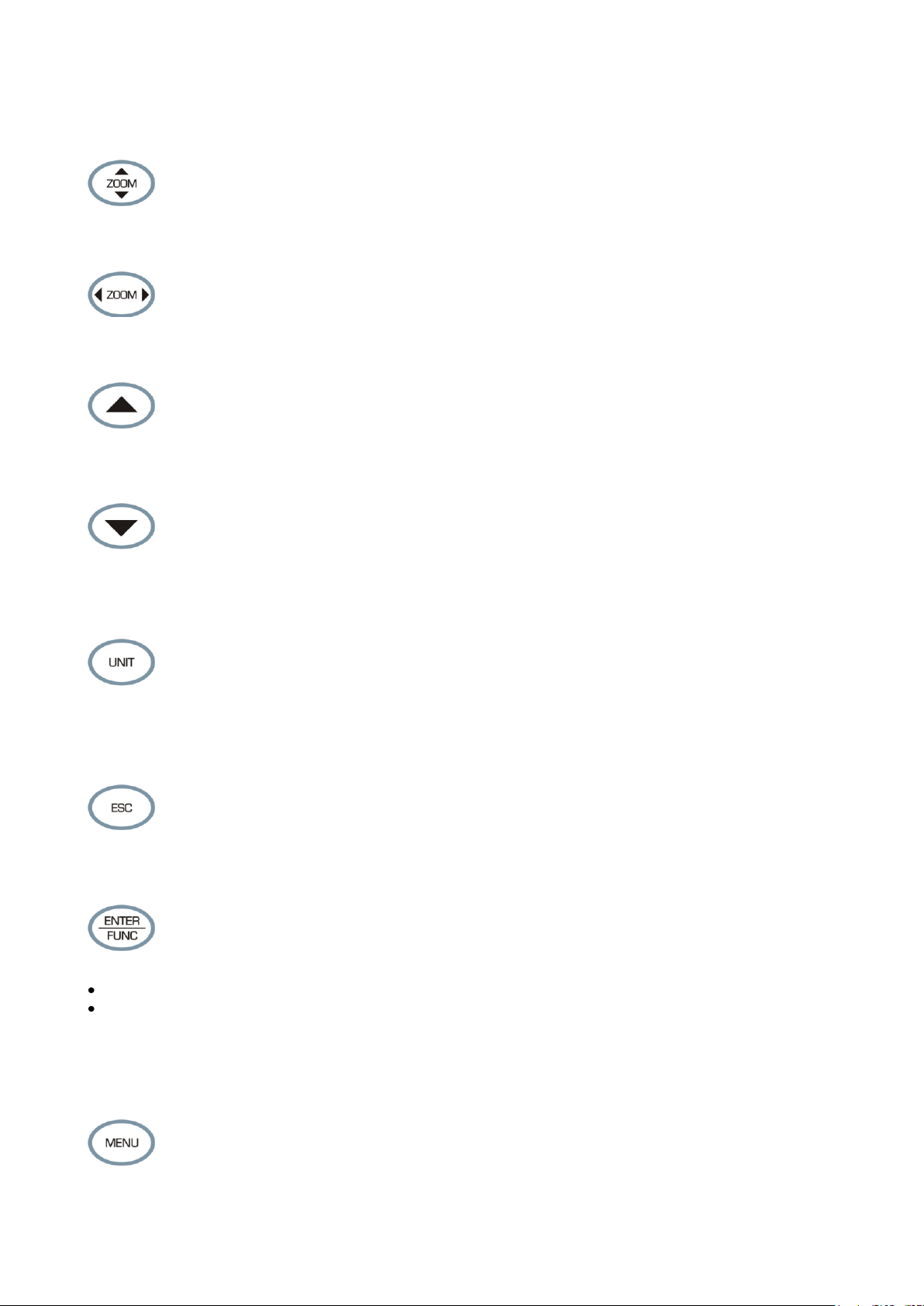

5. Keyboard description

The HD2817T... models are fitted with an LCD display and an eight-key keyboard.

Vertical ZOOM key

In graphic mode, it enlarges or reduces the graph’s vertical scale.

Horizontal ZOOM key

In graphic mode, it enlarges or reduces the graph’s horizontal scale.

Up arrow

When used in the menu, it selects an item from a list or increases the selected parameter

value.

Down arrow

When used in the menu, it selects an item from a list or decreases the selected parameter

value.

UNIT key

It changes the temperature unit of measurement between Centigrade or Fahrenheit. By

repeatedly pressing the UNIT key, the desired unit of measurement can be displayed.

In graphic mode, it allows selection of a new physical quantity.

ESC key

When used in the menu, it goes up one level in the menu hierarchy from a sub-level to an

upper level. To go directly from any level to measurement mode, press MENU.

ENTER/FUNC key

This key has a double function:

As ENTER key, in the menu, it confirms the selected item.

As FUNC key, in standard view, it enables the MAX (maximum), MIN (minimum), AVG

(average) sequence for the displayed measurement.

To reset the previous measurements and restart with a new calculation, press ENTER/FUNC

until the message “CLR Func?” appears, then use the arrows to select YES and confirm

using ENTER.

MENU key

It allows to access the instrument menu main screen. In the menu, it returns to normal

measurement.

8

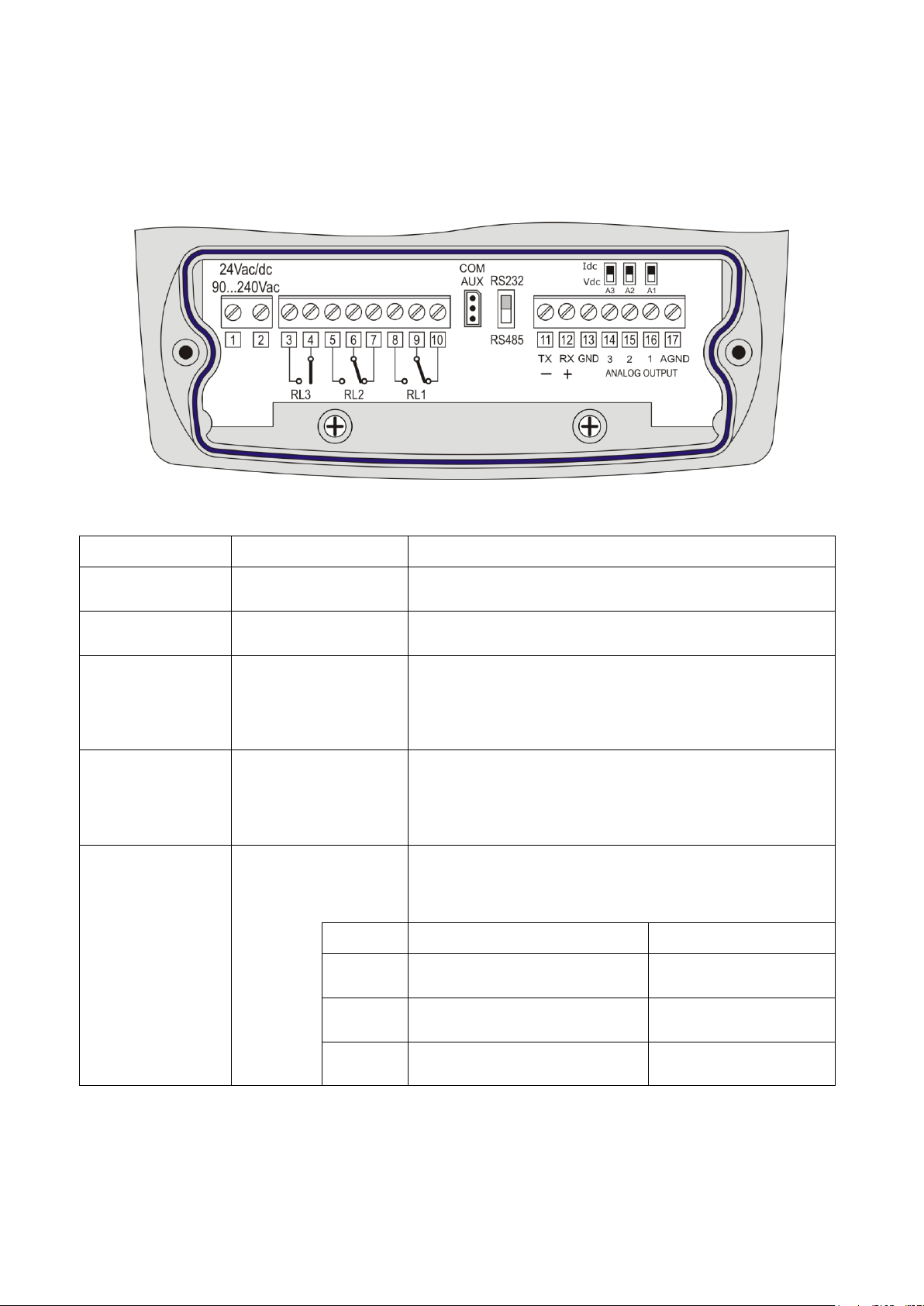

6. Terminal board description

The terminal board is located in the lower part of the instrument, protected against dust and

splashes by two doors: the first external, snap-locked, the second internal, fixed with two

screws.

Number

Function

Notes

1 –2

Power input

When making the order, you can select the power supply

between 90...240Vac or 24Vac/dc

3 –4

Alarm relay RL3

For the settings, please see the chapter “Instruments

fitted with relay outputs”

5 –6 –7

Working relay RL2

The relay can be associated to any quantity measured by

the instrument (relative humidity or correlated

measurements, temperature).

For the settings, please see the chapter “Instruments

fitted with relay outputs”

8 –9 –10

Working relay RL1

The relay can be associated to any quantity measured by

the instrument (relative humidity or correlated

measurements, temperature).

For the settings, please see the chapter “Instruments

fitted with relay outputs”

11 –12 –13

RS232C or RS485

serial connection

The communication protocol selection (RS232C or RS485)

is performed by using the switch on the left of terminal

11. For the settings, please see the chapter “Serial

communication and instrument network”

Terminal

RS232C mode

RS485 mode

11

To be connected to TX line of

PC (pin 3 of connector DB9)

To be connected to line

B (negative of the pair)

12

To be connected to RX line of

PC (pin 2 of connector DB9)

To be connected to line

A (negative of the pair)

13

To be connected to GND line of

PC (pin 5 of connector DB9)

To be connected to

GND line

9

Number

Function

Notes

14 –15 –16 –17

Current and voltage

analog outputs

The analog outputs can be associated, independently, to

any quantity measured by the instrument: relative

humidity, absolute humidity, mixing ratio, dew point, wet

bulb temperature, temperature.

For the settings, please see the chapter “Current and

voltage analog outputs”.

Terminal

Function

14

Positive output 3. The negative pole is terminal 17.

15

Positive output 2. The negative pole is terminal 17.

16

Positive output 1. The negative pole is terminal 17.

17

A GND negative pole common to analog outputs.

AUX-COM connector

The AUX-COM connector (for cable RS27) is an auxiliary RS232C serial port. It is used to

temporarily connect the instrument to a PC with the DeltaLog12 software.

10

7. Measurement probe and calibration of the relative

humidity sensor

The instrument only accepts SICRAM2 type temperature and relative humidity measurement

probes. These probes are fitted with an electronic circuit that converts the signal and stores

their calibration information.

Thanks to their factory calibration, the probes are interchangeable, directly and immediately.

The probes can be sent to our factory for calibration or repair.

Saturated solutions are available for the humidity probe’s checking and calibration.

For the calibration of the humidity sensor, DeltaLog12 software is to be used: see procedure

reported in the software’s instruction manual.

The calibration of the temperature sensor by the user is not required.

The interchangeable probe allows reducing the instrument down time virtually to zero, in case

of faulty probe.

The replacement can be performed without stopping the activity, thanks to the “suspend”

functioning mode.

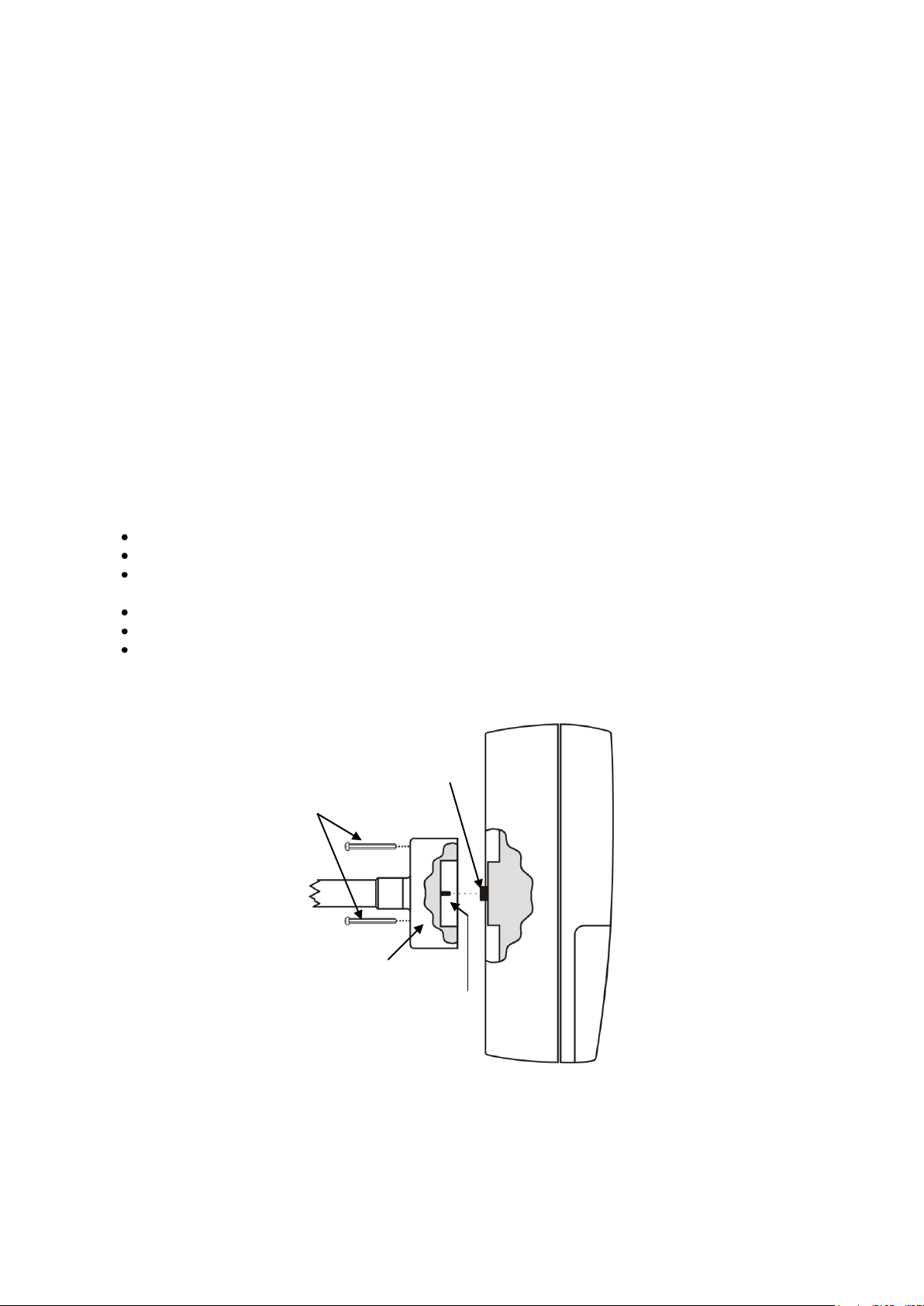

In the HD2817TO.xx models, the probe is fixed on the instrument back using three

screws.

To replace the horizontal probe:

Start the suspend function.

Unscrew the three screws fixing the probe housing module to the instrument.

Extract the probe from the instrument connector: the probe to be replaced can be

removed.

Connect the new probe to the instrument.

Fix the module to the instrument back using the three screws.

The replacement is complete.

Note: if necessary, the suspension time can be reset to 60 seconds by pressing the arrow.

Module mounting screws

Probe housing module

Female connector

Male connector

11

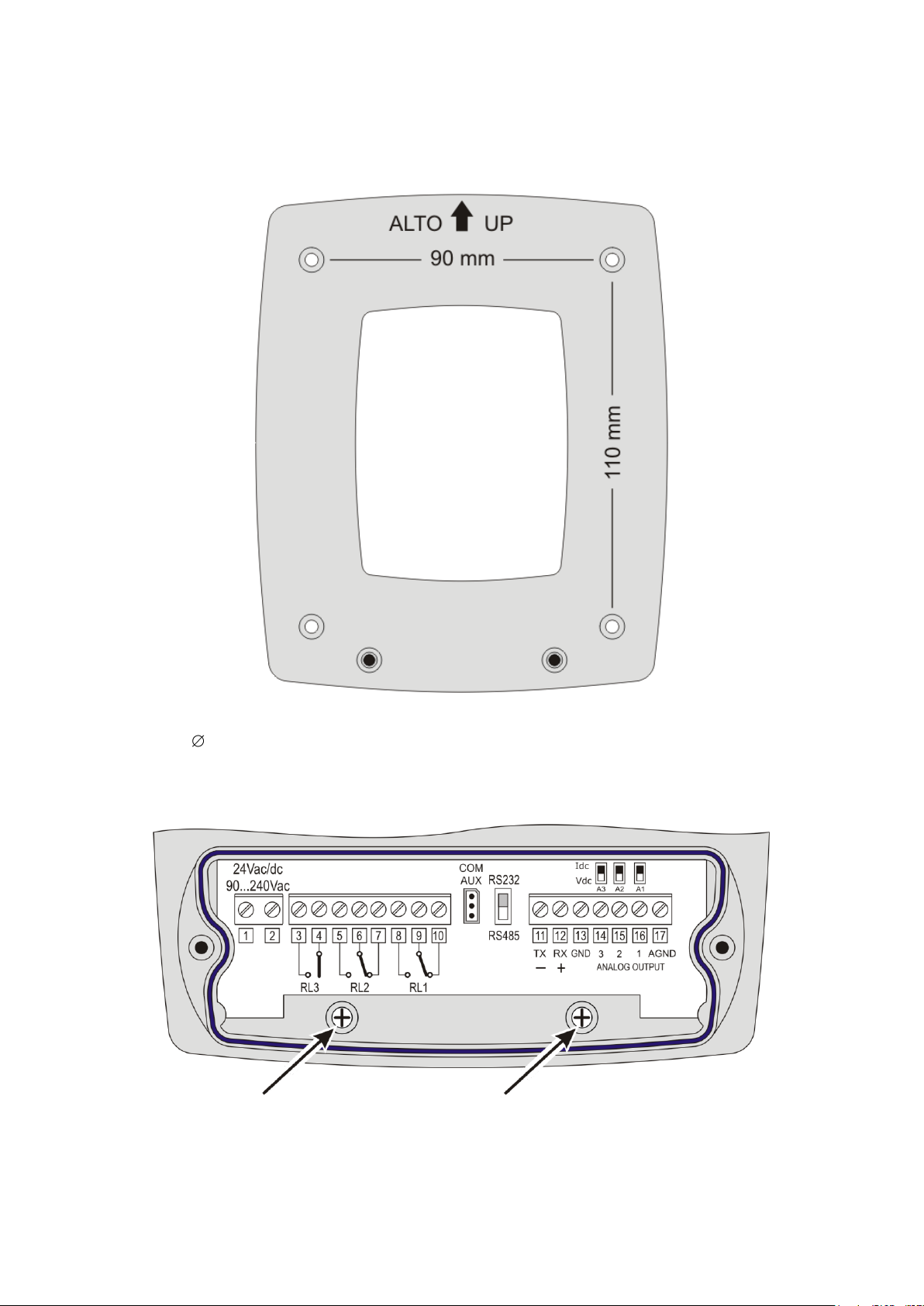

8. Installation and connections

The instrument is set to work indoors.

For wall mounting, the instrument is fitted with a plate to be fixed to the wall. The instrument

is attached through a cavity, near the arrow.

As shown in the figure, 4 holes are needed at 90 mm horizontally and 110 mm vertically. The

holes have a 4,5 mm diameter.

In order to separate the plate from the instrument bottom, open the two front doors to access

the instrument terminal board. Unscrew the two screws shown in the following figure and pull

the instrument toward yourself.

Fix the plate to the wall using four screws. Lock the instrument in the cavity located at the top

and screw again the two screws inside the terminal board housing for final fastening.

12

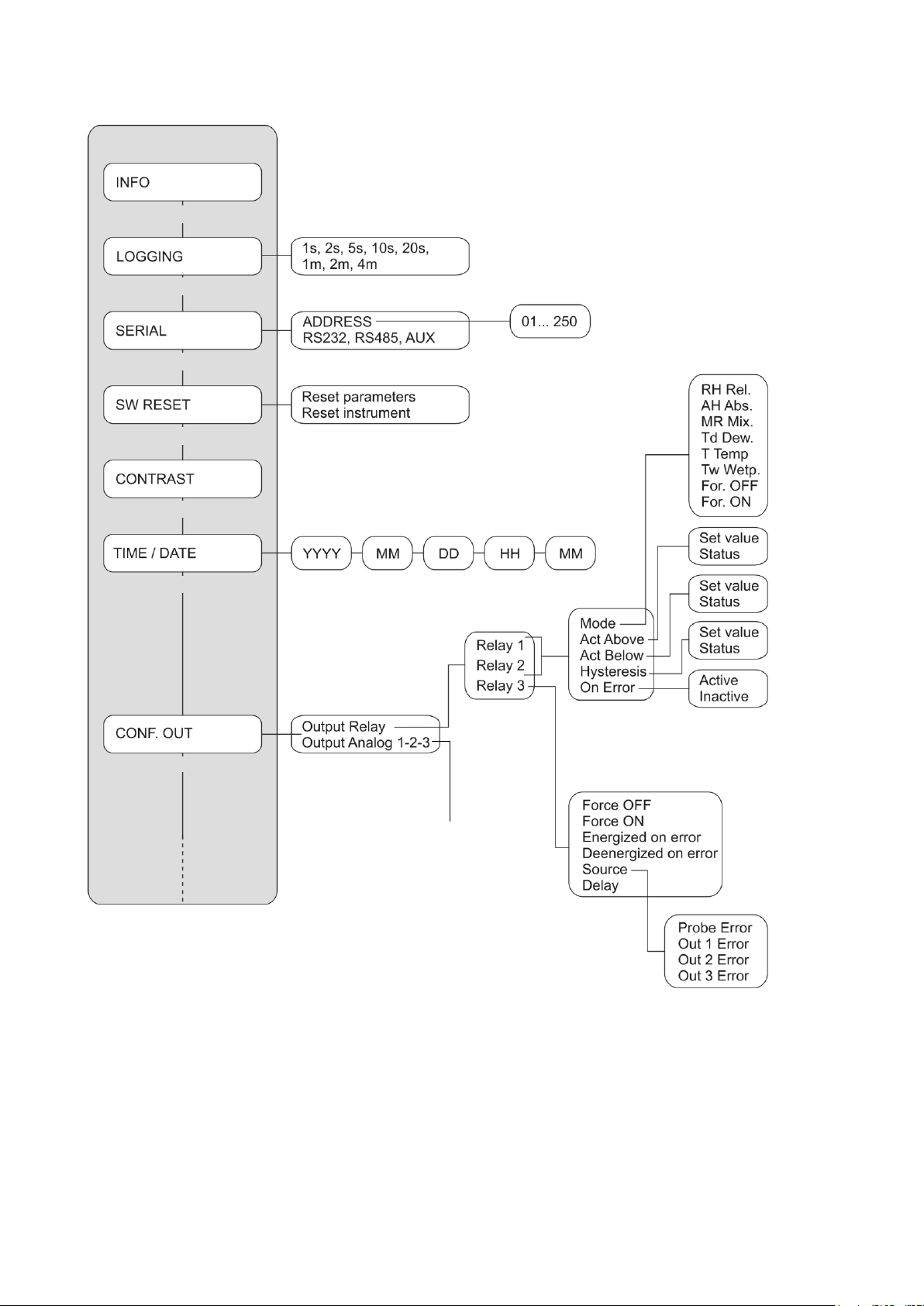

9. Menu description

The MENU key allows accessing the set of items that regulate the instrument functioning.

The menu is nest-structured: with main categories and submenus.

To select a menu item, use the arrows until you select the item to be modified: using

ENTER you can access the selected item.

To move up one level from any point in the menu, you can press ESC.

To exit the menu and return directly to measurement, press MENU.

In measurement mode, the MENU key is used to access the menu main screen.

2008/01/31 12:00:00

MAIN MENU

Info

Time/Date

Logging

Conf. OUT

Serial

View mode

SW Reset

Stand-by

Contrast

<ESC> exit

13

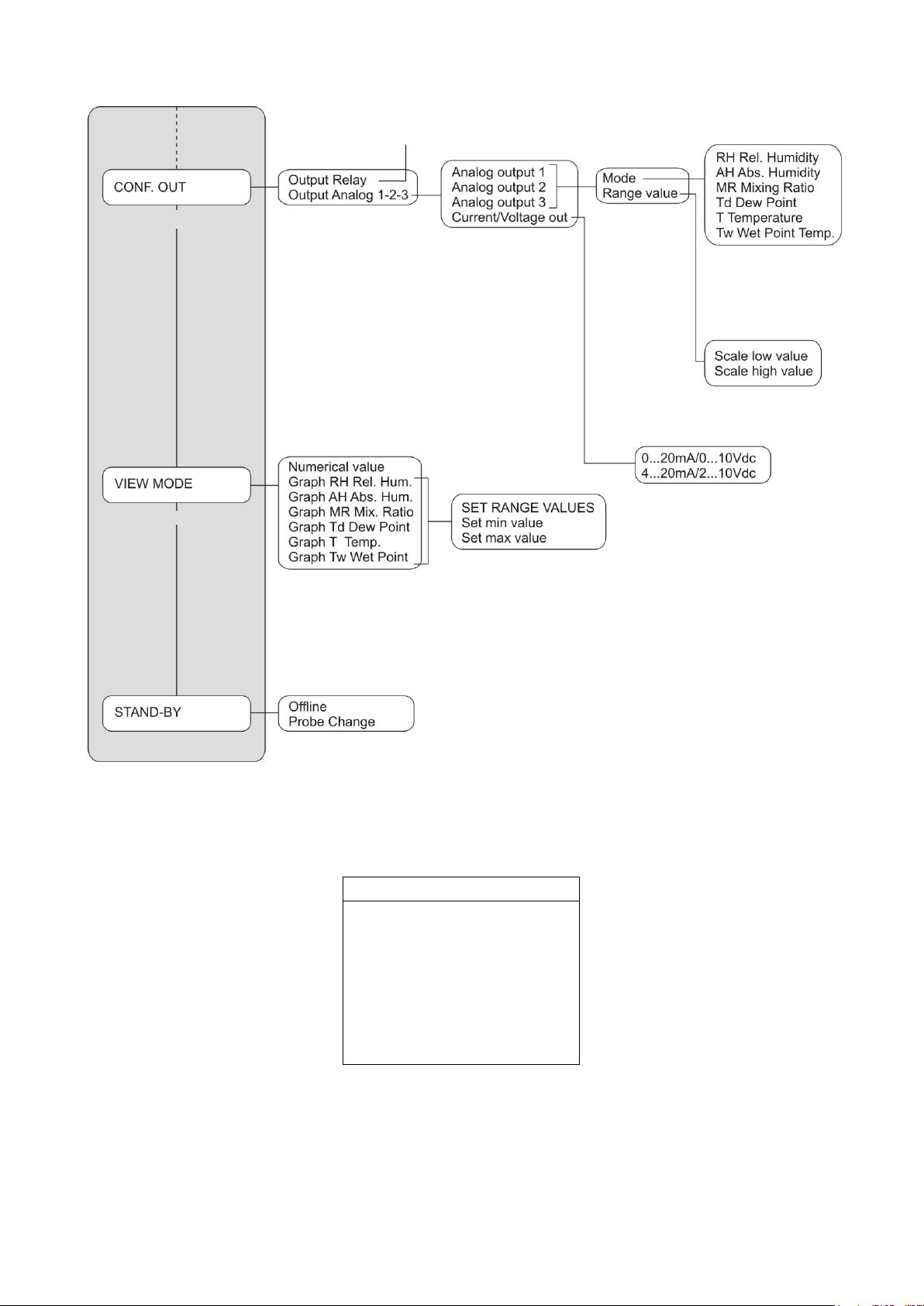

The following diagram describes the instrument menu structure.

MAIN MENU

Information

Logging

Serial communication

Program reset

LCD contrast

Time and date setting

Output configuration

Address

RS232, RS485, AUX COM port

Reset parameters

Reset instrument

Year Month Day Hours Minutes

Relative humidity

Absolute humidity

Mixing ratio

Dew point

Temperature

Wet bulb temperature

Always de-energised

Always energised

Set value

Status

Set value

Status

Set value

Status

Energised

De-energised

Mode

High threshold

Low threshold

Hysteresis

In case of error

Always de-energised

Always energised

Energised on error

De-energised on error

Source

Delay

Probe error

Analog output 1 error

Analog output 2 error

Analog output 3 error

Relay outputs

Analog outputs

Continues in the

next page

Continues in the next page

14

The menu items are listed in this order:

A. INFO

INFO

User ID=00000000000

Model HD28xxxTxxxxxxx

Smart transmitter

Firm.Ver.=xx.xx

Firm.Date=2008/01/31

Ser. Number=12345678

Probe Ser.=12345678

The INFO item provides information on version and firmware date, serial number and

calibration date, probe serial number, instrument alphanumeric ID.

The User ID is a code to identify the instrument and appears in the printouts and in the stored

data. It can be changed using the DeltaLog12 software. Press ESC to return to the menu basic

screen.

Continues from

previous page

Relay outputs

Analog outputs 1-2-3

Output configuration

View mode

Analog output 1

Analog output 2

Analog output 3

Type of output selection

Mode

Range limits

Relative humidity

Absolute humidity

Mixing ratio

Dew point

Temperature

Wet bulb temperature

Lower limit

Upper limit

Numerical value

Relative humidity graph

Absolute humidity graph

Mixing ratio graph

Dew point graph

Temperature graph

Wet bulb temperature graph

Set range

Set minimum level

Set maximum level

Off line mode

Change probe mode

Continues from previous page

15

B. LOGGING

LOGGING

LOG INTERVAL

select LOG interval

mm : ss

now set at: 00 : 01

<UP> <DOWN> change

<ESC> exit

The LOGGING item sets the interval in seconds and minutes between two loggings.

The available interval are: 1, 2, 5, 10, 20, 60 seconds, 2 and 4 minutes.

The set interval influences the graphic mode (please see the description of the “VIEW MODE”

item, later in this chapter).

Use the arrows to change the interval and press ENTER to confirm and return to the

menu main screen.

For the logging function details, please see the chapter “The logging function”.

C. SERIAL (Serial communication)

SERIAL

ADDRESS 001

* RS232

RS485

AUX

<UP> <DOWN> select

<ENTER> confirm

<ESC> exit

C.1. The first item “ADDRESS xxx” sets the instrument address so as to use it within a

network. The numbers from 001 (factory default) to 250 are available. The number 000

and the numbers 251 to 255 are reserved. To change the address, use the arrows

to select the “ADDRESS xxx” item and confirm with ENTER. The “ADDRESS xxx” message

will blink. Use the arrows to change its value and confirm with ENTER.

For the details, please see the paragraph “Serial communication and instrument

network”.

The other items select the serial communication port and the relevant protocol: use the

arrows to select one of the protocols and confirm with ENTER. An asterisk will appear near the

enabled item.

C.2. “RS232” enables the port at terminals 11 – 12 –13 and sets it as an RS232C port.

C.3. “RS485” enables the port at terminals 11 – 12 –13 and sets it as an RS485 port.

C.4. “AUX” enables the COM AUX auxiliary port as an RS232C serial port.

To use the first two ports, you need to shift the dip-switch located between the AUX COM

connector and terminal 11.

16

D. SW RESET (Program reset)

SW RESET

Reset parameters

Reset instrument

<UP> <DOWN> select

<ENTER> confirm

<ESC> exit

It is formed by two sub-functions:

D.1. “Reset parameters”: it performs a complete reset and restores the instrument to the

original factory conditions, restoring all menu parameters. The date and time are not

changed as they are managed by an independent circuit fitted with backup battery. The

memory data are not erased.

D.2. “Reset instrument”: it turns the instrument off and on. The menu parameters are not

changed. It work as disconnecting and reconnecting it to the mains.

Use the arrows to select the desired item and confirm with ENTER. When asked for

confirmation, use the arrows to select “YES” and confirm with ENTER.

E. CONTRAST

CONTRAST

Set contrast with

arrows

<UP> <DOWN> change

<ESC> exit

It adjusts the display contrast to suit different light conditions.

Use the arrows to change the contrast and press ENTER to confirm. The ESC key is used

to return to the menu main screen.

F. TIME / DATE (Time and date setting)

2008/01/31 12:00:00

TIME / DATE

year/mm/dd hh:mm

2008/01/31 12:00:00

<UP> <DOWN> change

<ENTER> confirm

<ESC> exit

17

The “TIME/DATE”item allows access to modify the instrument date and time. An internal

circuit fitted with backup battery ensures the correct functioning of the clock even in case of

mains power failure.

Date and time are expressed as year/month/day, hours/minutes/seconds.

Use the arrows to modify the year, already selected, and press ENTER to confirm.

You will get to the month setting. Change it using the arrows and confirm with

ENTER.

Repeat for the other items. The seconds start from 00 when pressing ENTER to confirm

the minutes.

After confirmation of the minutes you will exit the setting page and return to the menu

main screen.

G. CONF. OUT (Output configuration)

OUTPUT CONFIGURATION

Output Relay

Output Analog 1-2-3

<UP> <DOWN> select

<ENTER> confirm

<ESC> exit

The “Output configuration”item is composed of two sub-functions concerning the management

of relays (Output Relay) and analog outputs (Output Analog 1-2-3). The two following

paragraphs will outline in detail the relay and analog output settings: for a general description

on how to use of analog outputs and relays, please see the chapters “Instruments fitted with

relay outputs” and “Current and voltage analog outputs”.

G.1 Relay configuration

To set the three relays, select the CONF. OUT >> Output Relay menu item.

You will get to the screen with these three relays:

OUTPUT RELAY

Relay RL1

Relay RL2

Relay RL3

<UP> <DOWN> select

<ENTER> confirm

<ESC> exit/cancel

Use the arrows to select the relay to be configured and confirm with ENTER.

18

Relay RL1 (Working relay RL1)

It is used to set the functioning parameters of the RL1 working relay.

The following screen will appear:

RELAY RL1

Mode: T Temp.

Act Above: 100.0 °C

Act Below: 25.0 °C

Hysteresis: 1.0 °C

On Error: Inactive

<UP> <DOWN> select

<ESC> exit/cancel

Use the arrows to select the line to be modified and press ENTER to access the

corresponding submenu.

Mode It defines the physical quantity associated to the RL1 relay. To change the quantity,

use the arrows to select the line Mode and confirm with ENTER. The RELAY RL1

MODE menu will open.

RELAY RL1

MODE

For. OFF

T Temp.

*RH Rel.

Tw Wet bulb

AH Abs.

MR Mix.

Td Dew

For. ON

<ESC> exit/cancel

The current item is indicated by an asterisk (“RH Rel.” in the example): to change it,

use the arrows to select the new item and press ENTER. The asterisk will indicate

your new selection. Press ESC to return to the previous menu.

You can associate the following quantities to the RL1 relay:

•RH Rel. corresponds to relative humidity,

•AH Abs. corresponds to absolute humidity,

•MR Mix. corresponds to mixing ratio,

•Td Dew. corresponds to dew point,

•T Temp. corresponds to temperature,

•Tw Wetp. corresponds to the wet bulb temperature

•For. OFF (Force OFF) blocks the relay in the OFF state.

•For. ON (Force ON) blocks the relay in the ON state.

The last two items are useful during system maintenance and instrument

configuration.

19

Act above (high threshold) When the measurement increases, it represents the threshold (set

value) that shifts the relay from de-energised to energised when exceeded.

The contact to terminals 9 and 10 goes from closed to open. The contact to terminals

8 and 9 goes from open to closed.

The trigger threshold can be disabled, by setting the “status = inactive”.

RELE RL1

ACTIVE ABOVE

set value: 100.0°C

status: active

<UP> <DOWN> change

<ESC> exit/cancel

To change the threshold value, press ENTER to select the set value line and use the

arrows to set the desired value.

Press ENTER to go to the status line. Use the arrows to select active in order to

enable the trigger threshold, inactive to disable it.

Act below (low threshold) When the measurement decreases, it represents the threshold that

shifts the relay from de-energised to energised when exceeded.

The contact to terminals 9 and 10 goes from closed to open. The contact to terminals

8 and 9 goes from open to closed.

The trigger threshold can be disabled, by setting the “status = inactive”.

RELE RL1

ACTIVE BELOW

set value: 25.0°C

status: active

<UP> <DOWN> change

<ESC> exit/cancel

To change the trigger point value, press ENTER to select the set value line and use the

arrows to set the desired value.

Press ENTER to go to the status line. Use the arrows to select active in order to

enable the trigger threshold, inactive to disable it.

Hysteresis It represents the value of the relay RL1 hysteresis applied to both thresholds

defined above.

RELE RL1

HYSTERESIS

set value: 1.0°C

status: enable

<UP> <DOWN> change

<ESC> exit/cancel

20

To change the hysteresis width, press ENTER to select the set value line and use the

arrows to set the desired value.

Press ENTER to go to the status line. Use the arrows to select active in order to

enable the hysteresis, inactive to disable it.

On Error This parameter controls the relay RL1 behaviour if the physical quantity associated

to the relay goes in error.

The error occurs, e.g. when the measurement exceeds the functioning limits indicated

in the technical information, when the probe becomes faulty or gets disconnected.

This parameter can be set to “Active” or “Inactive”:

•If On_Error=Inactive (factory default), in case of error, the relay de-energises

independently of its current condition. The contact 9 –10 closes, the contact 8 –9

opens.

•If On_Error=Active, in case of error, the relay energises independently of its

current condition. The contact 9 –10 opens, the contact 8 –9 closes.

This parameter does not depend from other settings (upper or lower threshold,

hysteresis, ...) and neither from the relay’s state when the error occurs.

RELE RL1

ON ERROR

*Active

Inactive

<UP> <DOWN> select

<ESC> exit/cancel

The current mode is indicated by an asterisk (“Active” in the example): to change it,

use the arrows to select the new item and press ENTER. The asterisk will indicate

your new selection. Press ESC to return to the previous menu.

Relay RL2 (Working relay RL2)

It is used to set the functioning parameters of the RL2 working relay.

The following screen will appear:

RELAY RL2

Mode: RH Rel.

Act Above: 80.0 %

Act Below: 20.0 %

Hysteresis: 5.0 %

On Error: Inactive

<UP> <DOWN> select

<ESC> exit/cancel

Use the arrows to select the line to be modified and press ENTER to access the

corresponding submenu.

Mode It defines the physical quantity associated to the RL2 relay. To change the quantity,

use the arrows to select the line Mode and confirm with ENTER. The RELAY RL2

MODE menu will open.

This manual suits for next models

2

Table of contents

Other Delta OHM Transmitter manuals

Delta OHM

Delta OHM HD40.2 User manual

Delta OHM

Delta OHM HD45 17V User manual

Delta OHM

Delta OHM HD45 Series User manual

Delta OHM

Delta OHM HD402TR Series User manual

Delta OHM

Delta OHM HD9408.3B User manual

Delta OHM

Delta OHM DO 9861T User manual

Delta OHM

Delta OHM DO 9403T-R1 User manual

Delta OHM

Delta OHM PMsense User manual

Popular Transmitter manuals by other brands

Chiayo

Chiayo SM-2100 IrDA Operation manual

Becker

Becker Centronic SunWindControl SWC241 Assembly and operating instructions

Minebea Intec

Minebea Intec PR 5230 Instrument manual

MobileSpec

MobileSpec MBS13200 owner's guide

Siemens

Siemens sitrans lr 460 operating instructions

Vaisala

Vaisala WXT510 user guide