9

Palmgren Operating Manual & Parts List 84115

OPERATION (CONTINUED)

•Work should be fed into planer/molder in same direction as the

grain of the wood. Sometimes grain will change directions in

middle of board. In such cases, if possible, cut board in middle

before planing so grain direction is correct.

CAUTION: Do not plane board which is less than 17″long; force

of cut could split board and cause kickback.

PLANING

WARNING: Always turn the planer/molder off and disconnect it

from the power source whenever blade cover is removed. Never

operate planer/molder without the blade cover properly secured.

The planer/molder is supplied with planing blades mounted in the

cutterhead and the infeed and outfeed rollers adjusted to the correct

height.The planer/molder is capable of working at two different feed

rates. Feed rate refers to rate at which lumber travels through plan-

er/molder. Planing can be done at 22 FPM (standard planing) or at 11

FPM for an improved surface finish (see Feed Rate Adjustment).

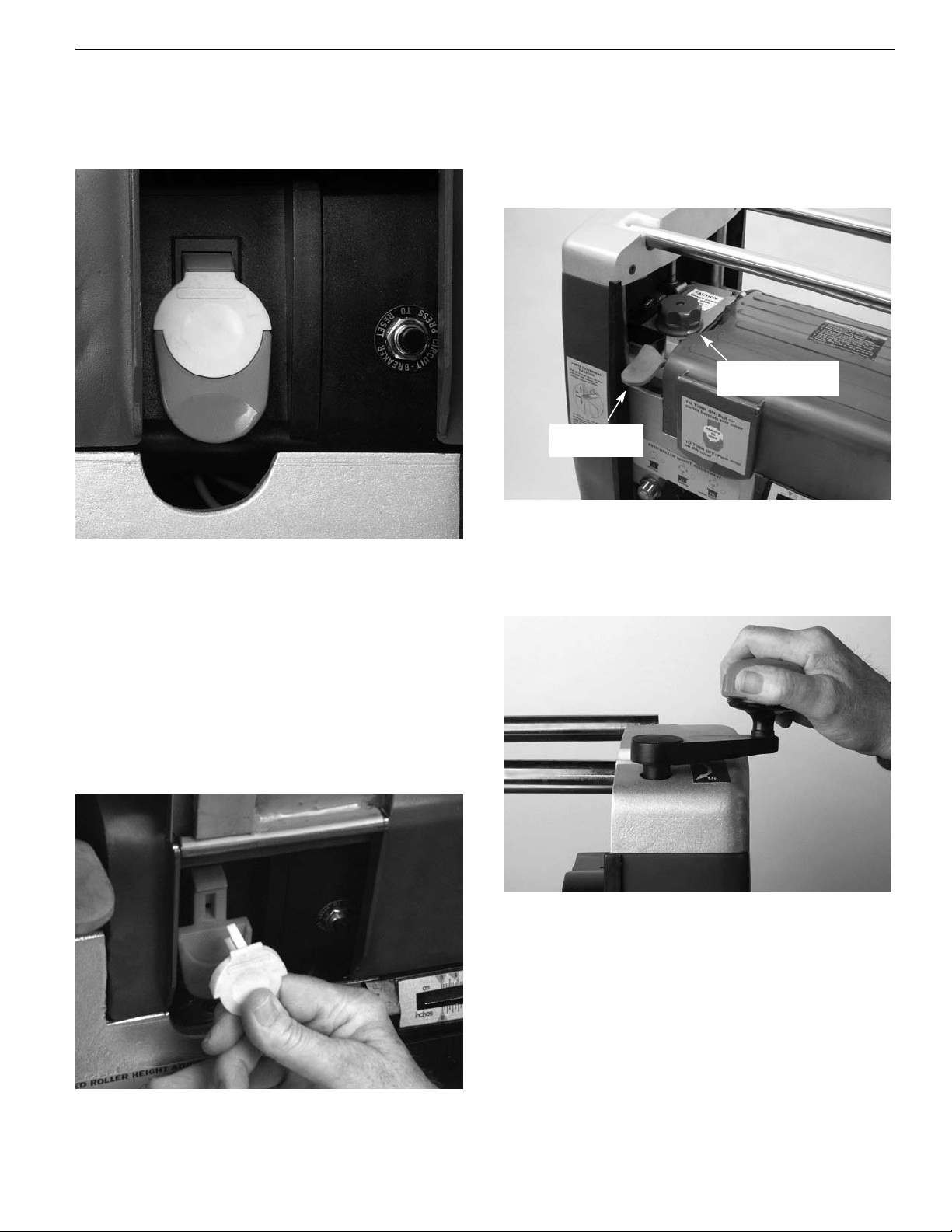

•Position rollercase to produce the depth of cut desired.

•Operator is responsible for aligning work so it will feed properly.

•Lift edge to infeed side of the table by grasping edges of board

at approximately middle of length.

•Boards longer than 24″should have additional support from

free standing material stands.

•Position the workpiece with the face to be planed on top.

•Turn the planer/molder on.

•Rest board end on infeed table and direct board into planer/molder.

•Gently slide the workpiece into the infeed side of the planer/

molder until the infeed roller begins to advance the workpiece.

•Let go of the workpiece and allow automatic feed to advance

the workpiece.

•Do not push/pull on workpiece.

•Move to the rear and receive planed lumber by grasping it in

same manner as it was fed.

CAUTION: Do not stand directly in line with front or rear of planer/

molder.

•Do not grasp any portion of board which has not gone past

out-feed roller.

•Repeat this operation on all boards which need to be same thickness.

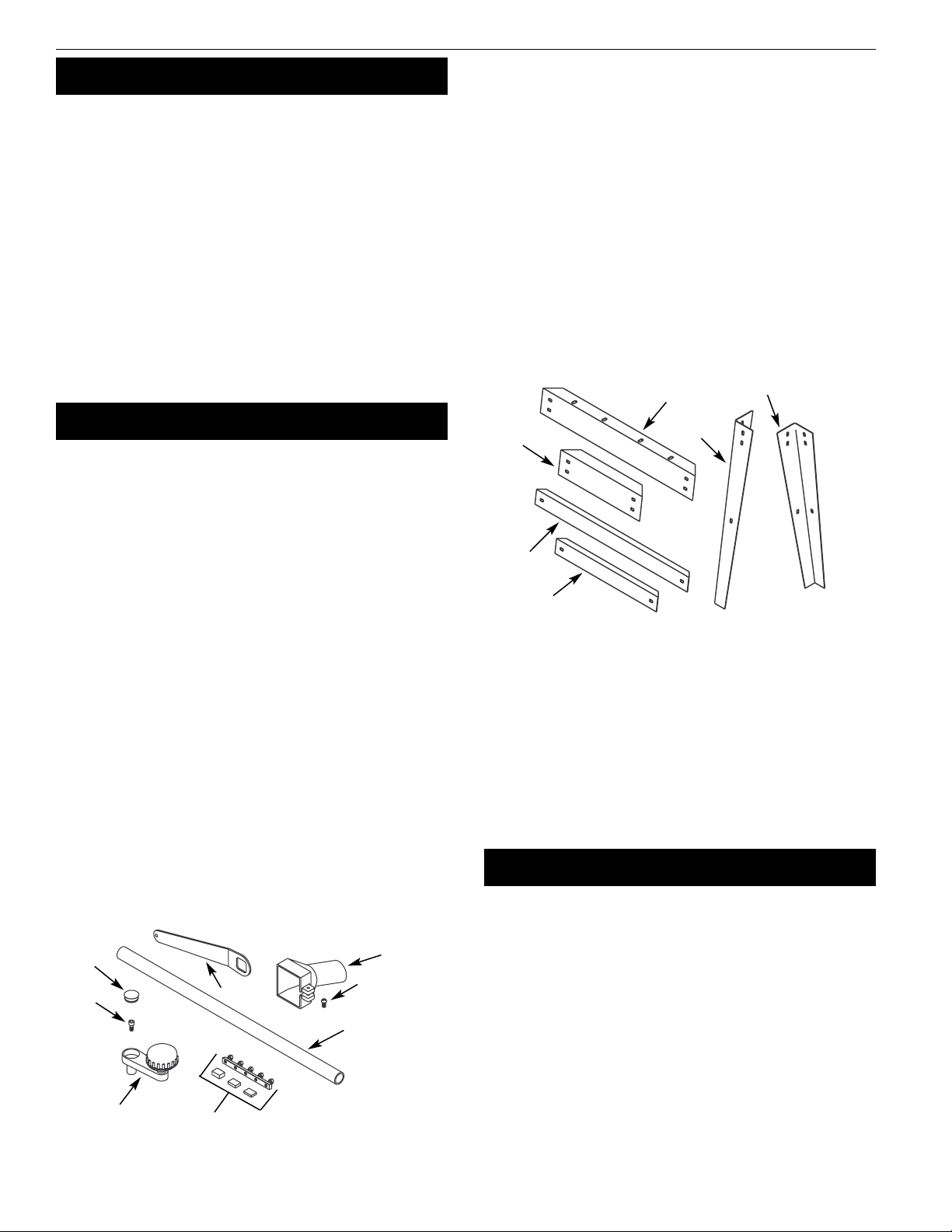

Planer/molder has return rollers on top so assistant can pass work

back to operator (see Figure 20).

NOTE: Assistant must follow same precautions as operator.

•Surface that the planer/molder produces is smoother if shal-

lower depth of cut is used.

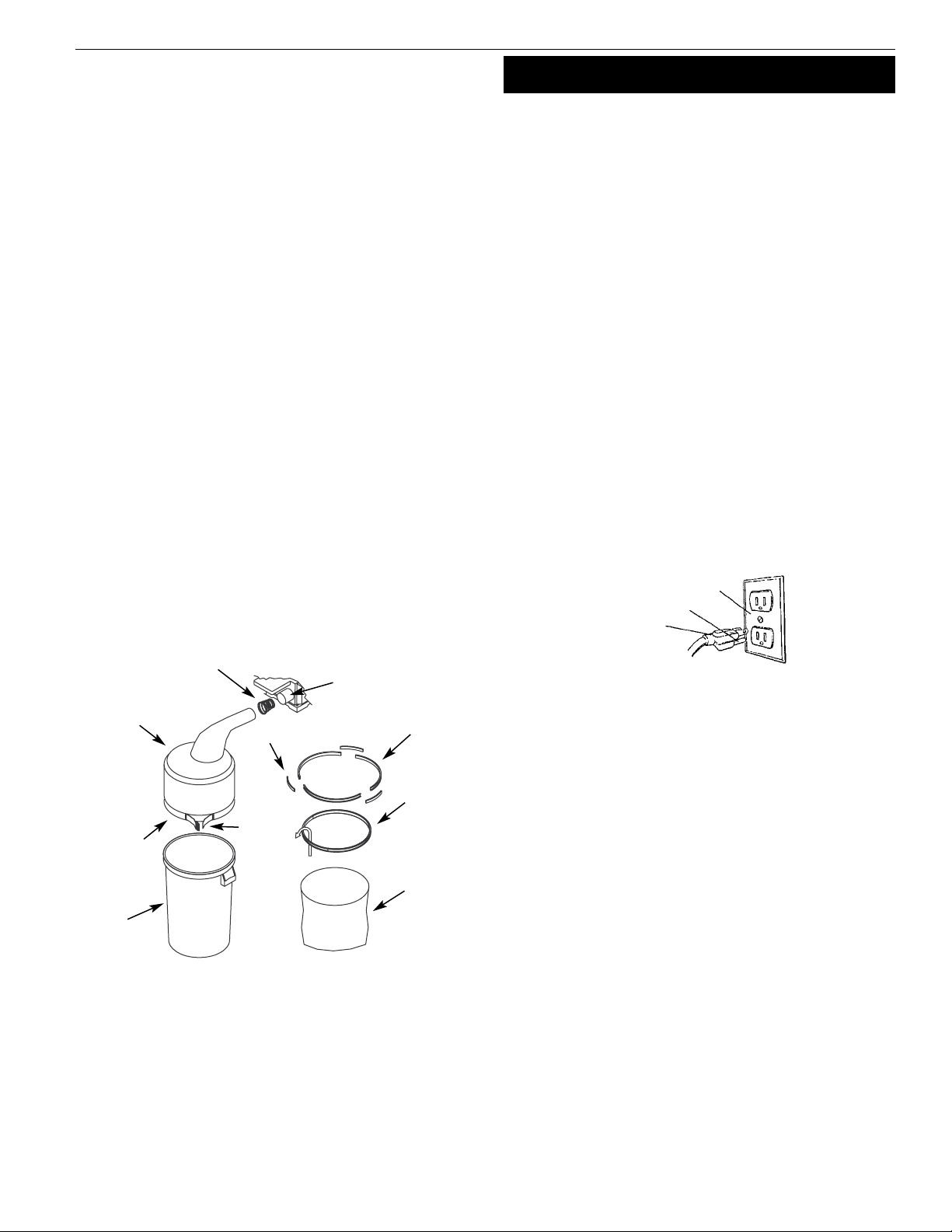

DEPTH OF CUT

Thickness planing refers to the sizing of lumber to a desired thick-

ness while creating a level surface parallel to the opposite side of

the board. Board thickness which the planer/molder will produce is

indicated by the scale, and depth-of-cut-gauge. Preset the plan-

er/molder to the desired thickness of finished workpiece using

knob. See “Workpiece Thickness Pre-set Gauge”, page 8.

Depth-of-cut is adjusted by raising or lowering the rollercase using

handle.

•Quality of thickness planing depends on the operator’s judge-

ment about the depth of cut.

•Depth of cut depends on the width, hardness, dampness, grain

direction and grain structure of the wood.

•Maximum thickness of wood which can be removed in one

pass is 3/32″for planing operations on workpiece up to 8″wide.

Workpiece must be positioned away from the center line of the

table to cut 3/32″.

•Maximum thickness of wood which can be removed in one

pass is 1/16″for planing operations on workpiece from 8″up to

15″wide.

•For optimum planing performance, the depth of cut should be

less than 1/16″.

•Board should be planed with shallow cuts until the work has a

level side. Once a level surface has been created, flip the lumber

and create parallel sides.

•Plane alternate sides until the desired thickness is obtained.

When half of total depth of cut is taken from each side, the

board will have a uniform moisture content and additional

drying will not cause it to warp.

•Depth of cut should be shallower when work is wider.

•When planing hardwood, take light cuts or plane the wood in

thin widths.

•Make a test cut with a test piece and verify the thickness produced.

•Check accuracy of test cut prior to working on finished product.

AVOID DAMAGE TO BLADES

•Thickness planer/molder is a precision woodworking machine

and should be used on quality lumber only.

•Do not plane dirty boards; dirt and small stones are abrasive

and wear out blade.

•Remove nails and staples. Use planer/molder to cut wood only.

•Avoid knots. Heavily cross-grained wood makes knots hard.

Knots can come loose and jam blade.

CAUTION: Any article that encounters planer/molder blades may

be forcibly ejected from planer/molder creating risk of injury.

AVOIDING SNIPE

•Snipe refers to a depression at either end of board caused by

an uneven force on cutterhead when work is entering or leav-

ing planer/molder.

•Snipe occurs when boards are not supported properly or when

only one feed roller is in contact with work at beginning or end

of cut.

•To avoid snipe on the lead edge of the workpiece, adjust the

infeed table up slightly above horizontal.

•To avoid snipe on the trailing edge of the workpiece, adjust the

outfeed table up slightly above horizontal.

•When planing more than one board of the same thickness, butt

boards together to avoid snipe.

•Snipe is more apparent when deeper cuts are taken.

•Feed work in direction of grain.Work fed against grain will have

chipped, splintered edges.

Figure 20 – Workpiece on the Return Rollers