Table of Contents

INTRODUCTION............................................... 2

Contact Info.................................................... 2

Manual Accuracy ........................................... 2

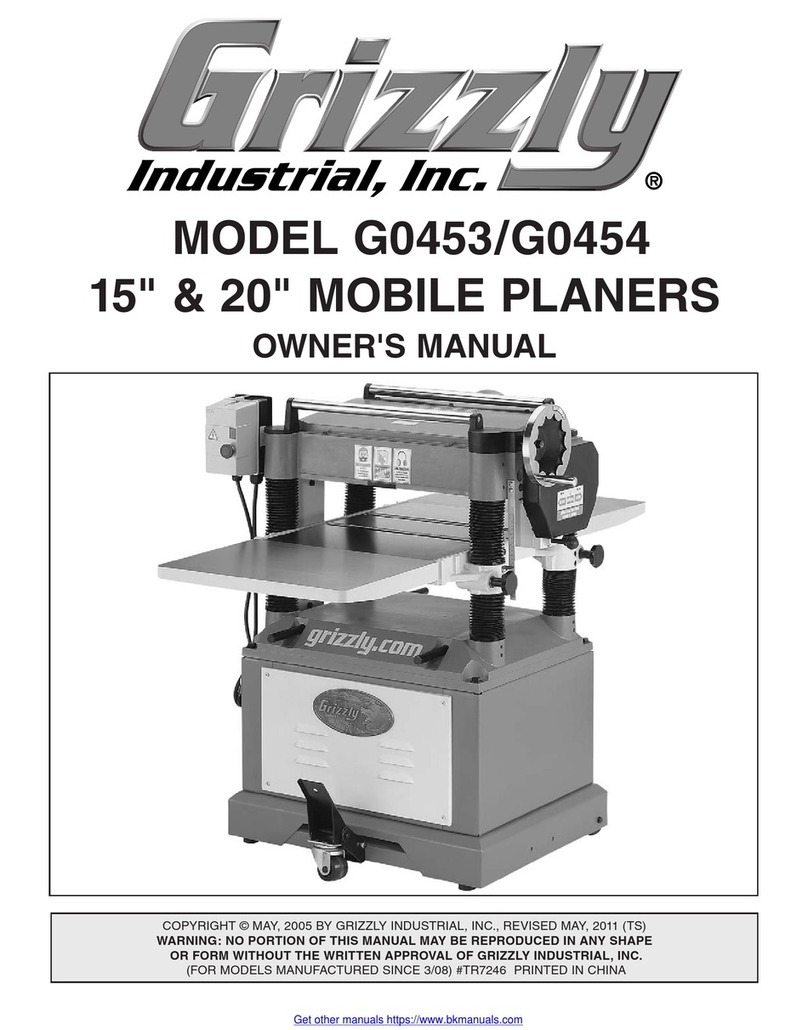

Identification ................................................... 3

Controls & Components ................................. 4

Internal Components...................................... 5

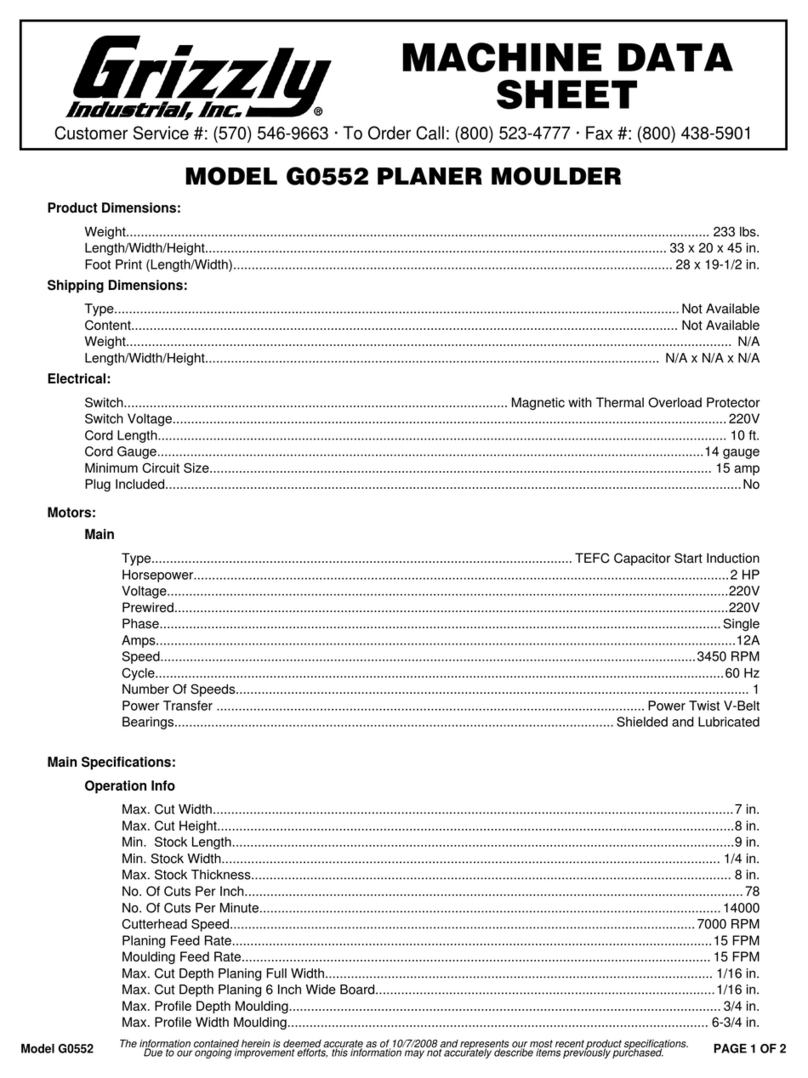

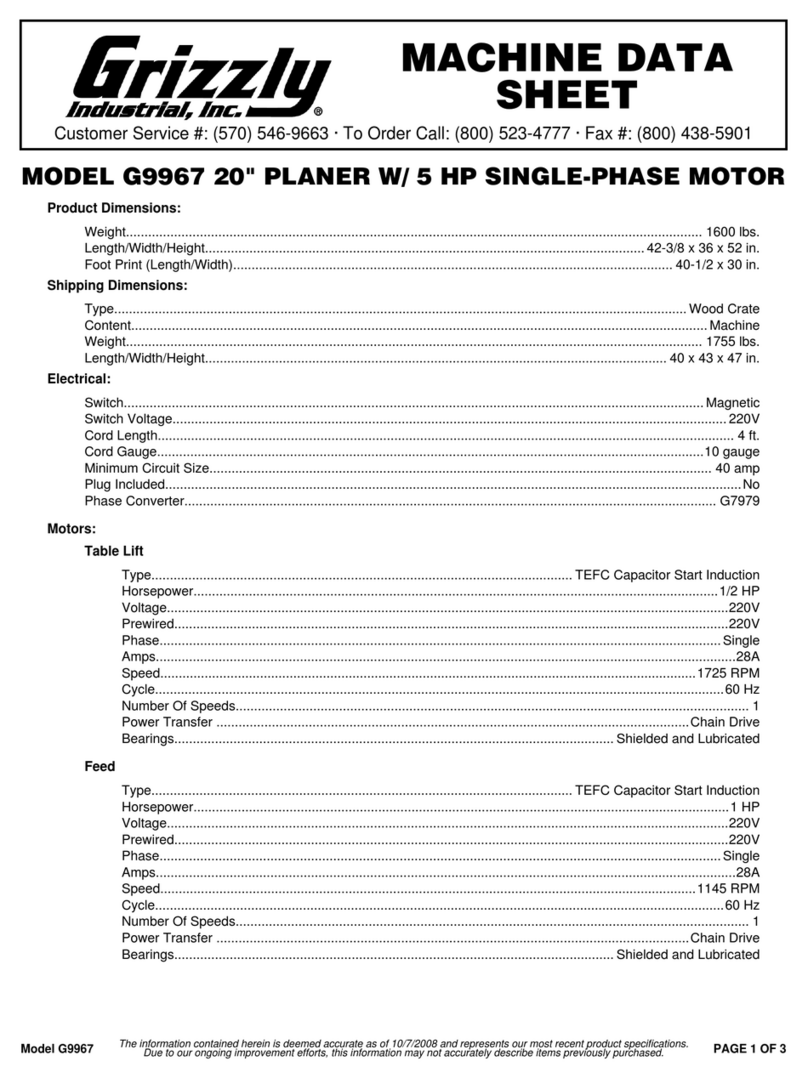

Machine Data Sheet ...................................... 6

SECTION 1: SAFETY....................................... 8

Safety Instructions for Machinery .................. 8

Additional Safety for Planers ....................... 10

SECTION 2: POWER SUPPLY ...................... 11

SECTION 3: SETUP ....................................... 13

Needed for Setup ......................................... 13

Unpacking .................................................... 13

Inventory ...................................................... 14

Hardware Recognition Chart ....................... 15

Cleanup ........................................................ 16

Site Considerations ...................................... 17

Lifting & Placing ........................................... 18

Assembly ..................................................... 18

Dust Collection ............................................. 20

Checking Gearbox Oil Level ........................ 20

Test Run ...................................................... 21

Recommended Adjustments ........................ 22

SECTION 4: OPERATIONS ........................... 23

Operation Overview ..................................... 23

Workpiece Inspection................................... 24

Wood Types ................................................. 24

Planing Tips ................................................. 25

Cutting Problems ......................................... 25

Depth of Cut ................................................. 26

Setting Feed Rate ........................................ 27

Bed Roller Height ......................................... 27

Rotating/Replacing Cutterhead Inserts ........ 28

SECTION 5: ACCESSORIES ......................... 30

SECTION 6: MAINTENANCE......................... 31

Schedule ...................................................... 31

Cleaning & Protecting .................................. 31

Lubrication ................................................... 31

Checking Anti-Kickback Fingers .................. 34

SECTION 7: SERVICE ................................... 35

Troubleshooting ........................................... 35

Tensioning/Replacing V-Belts ...................... 38

Feed Rollers, Chip Breaker & Pressure Bar

Heights ......................................................... 39

Adjusting Feed Roller Spring Tension .......... 42

Positioning Chip Deflector ........................... 43

Calibrating Table Height Scale ..................... 43

Tensioning Table Height Chain ..................... 44

Aligning Pulleys............................................ 44

Adjusting Table Parallelism ......................... 45

Tensioning Drive Chain ................................. 47

SECTION 8: WIRING...................................... 48

Wiring Safety Instructions ............................ 48

Wiring Diagram ............................................ 49

Electrical Components ................................. 50

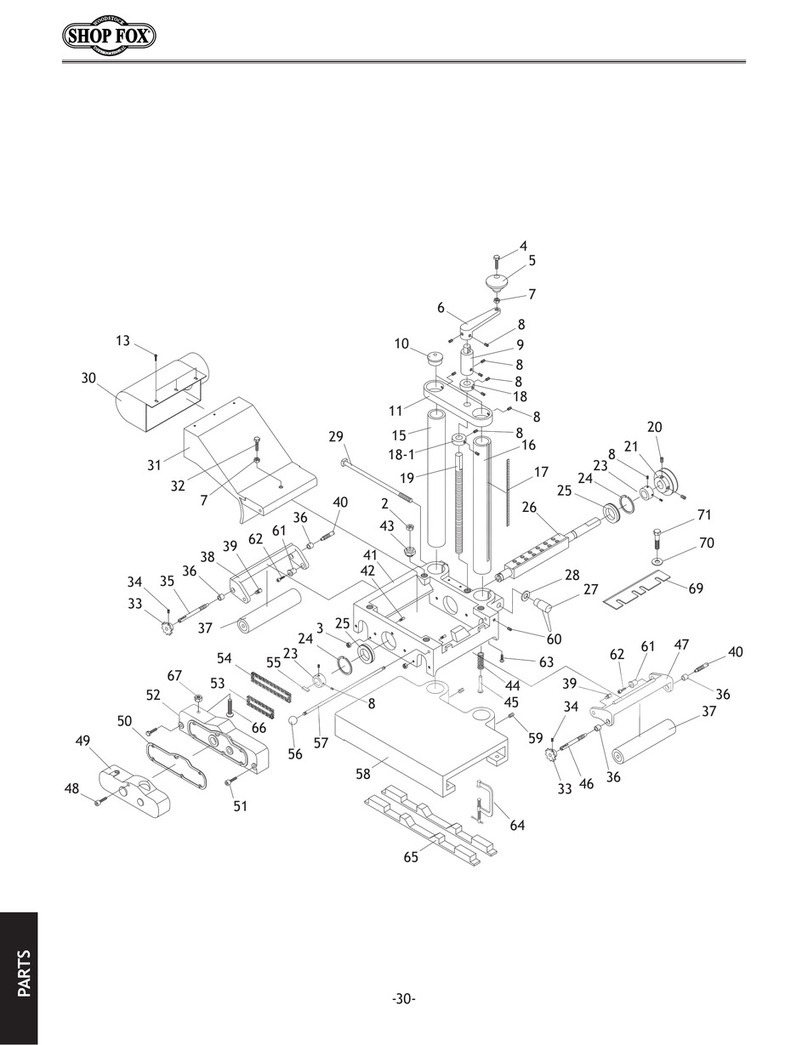

SECTION 9: PARTS....................................... 52

Headstock .................................................... 52

Table ............................................................ 54

Columns ....................................................... 55

Gearbox ....................................................... 56

Stand ............................................................ 57

Labels & Cosmetics (Front, Right) ............... 59

Labels & Cosmetics (Top, Left) ................... 60

WARRANTY & RETURNS ............................. 61