Delta UV D-31 Manual

© 2015 Delta Ultraviolet Corporation All Rights Reserved Rev 01/16 P/N 94-35234 Page 1

D/DS –Series

Ultraviolet Sanitizer/Clarifier System

INSTALLATION AND MAINTENANCE MANUAL

DELTA ULTRAVIOLET CORPORATION

CORPORATE HEADQUARTERS

1535 West Rosecrans Ave

Gardena, CA 90249

Phone 310-323-6400

Toll free 866-UV9-8765

Fax 310-323-6403

www.deltauv.com

.#3150259 EPA Est. #075659-CA-001

© 2015 Delta Ultraviolet Corporation All Rights Reserved Rev 01/16 P/N 94-35234 Page 2

Thank you for choosing an Ultraviolet Sanitizer from the Delta UV D/DS series. Our equipment has been

designed to provide long term, reliable service. The sanitizer in the D/DS series has been designed to enable

fast, easy installation. Its design also enables easy maintenance. Please read these instructions carefully in order

to ensure optimal operating conditions for your bactericide unit.

The Delta UV Unit is designed for use in swimming pools, fountains,

water features, waterfalls and fish ponds. It is not designed for use in

potable (drinking) water installations. Use of this product in

applications other than those indicated above will void your warranty and could

be harmful to your health or the health of others.

CONTENTS

A. TECHNICAL CHARACTERISTICS P. 3

B. WARNINGS AND SAFETY P. 4

C. SANITIZER INSTALLATION P. 8

D. ELECTRICAL CHAMBER P. 12

E. START-UP P. 13

F. UV LAMP REPLACEMENT & QUARTZ TUBE MAINTENANCE P. 13

G. FAQ P. 17

H. TROUBLESHOOTING P. 18

I. DELTA UV LIMITED WARRANTY P. 19

IMPORTANT SAFETY INSTRUCTIONS

***PRIOR TO BEGINNING INSTALLATION***

Visually inspect the unit for a broken or cracked quartz tube Contact the dealer/manufacturer

for replacement if quartz tube is broken

© 2015 Delta Ultraviolet Corporation All Rights Reserved Rev 01/16 P/N 94-35234 Page 3

A. TECHNICAL CHARACTERISTICS

D SERIES

REFERENCE

D-31

D-46

D-57

D-80

D-110

SANITIZER

MATERIAL

PVC

PVC

PVC

PVC

PVC

MAX. PRESSURE

40 psi

40 psi

40 psi

40 psi

40 psi

MAX. FLOW

31 gpm

46 gpm

57 gpm

80 gpm

110 gpm

MIN. FLOW

20gpm

31gpm

46gpm

57gpm

80gpm

DIAMETER

9 in.

9 in.

9 in.

9 in.

9 in.

HEIGHT

18 in.

25 in.

28 in.

39 in.

46 in.

INLET/OUTLET

2 in.

2 in.

2 in.

2 in.

2 in.

POWER SUPPLY

120 V/240V

50/60Hz

120 V/240V

50/60Hz

120 V/240V

50/60Hz

120 V/240V

50/60Hz

120 V/240V

50/60Hz

PROTECTION

INDEX

IP 54

NEMA 3

IP 54

NEMA 3

IP 54

NEMA 3

IP 54

NEMA 3

IP 54

NEMA 3

UV LAMP

NUMBER OF

LAMP

1

1

1

1

1

POWER

30W

45W

55W

80W

90W

PERFORMANCE

AT THE

RECOMMENDED

FLOWS

30 mJ/cm²

30 mJ/cm²

30 mJ/cm²

30 mJ/cm²

30 mJ/cm²

DS SERIES

REFERENCE

DS-31

DS-46

DS-57

DS-80

DS-110

SANITIZER

MATERIAL

PVC

PVC

PVC

PVC

PVC

MAX. PRESSURE

40 psi

40 psi

40 psi

40 psi

40 psi

MAX. FLOW

31 gpm

46 gpm

57 gpm

80 gpm

110 gpm

MIN. FLOW

20gpm

31gpm

46gpm

57gpm

80gpm

DIAMETER

9 in.

9 in.

9 in.

9 in.

9 in.

HEIGHT

18 in.

25 in.

28 in.

39 in.

46 in.

INLET/OUTLET

2 in.

2 in.

2 in.

2 in.

2 in.

POWER SUPPLY

120 V/240V

50/60Hz

120 V/240V

50/60Hz

120 V/240V

50/60Hz

120 V/240V

50/60Hz

120 V/240V

50/60Hz

PROTECTION

INDEX

IP 54

NEMA 3

IP 54

NEMA 3

IP 54

NEMA 3

IP 54

NEMA 3

IP 54

NEMA 3

UV LAMP

NUMBER OF

LAMP

1

1

1

1

1

POWER

30W

45W

55W

80W

90W

PERFORMANCE

AT THE

RECOMMENDED

FLOWS

30 mJ/cm²

30 mJ/cm²

30 mJ/cm²

30 mJ/cm²

30 mJ/cm²

B. WARNINGS AND SAFETY

© 2015 Delta Ultraviolet Corporation All Rights Reserved Rev 01/16 P/N 94-35234 Page 4

IMPORTANT SAFETY INSTRUCTIONS

SAVE READ AND FOLLOW ALL INSTRUCTIONS

WARNING

This product should be installed by a professional service technician or similar

person, qualified in electrical equipment installation. Improper installation

and/or operation could cause serious injury, property damage or death.

Improper installation and/or operation will void the limited warranty

WARNING

When using electrical products, basic precautions should always be followed,

including the following:

1. DANGER: RISK OF ELECTRIC SHOCK.

2. Grounding is required. The unit should be installed and grounded by a

qualified service representative.

3. Install to permit access for servicing. Make sure you choose a position

where the lamp can be taken out –the AVAILABLE HEIGHT should

be DOUBLE the total height of the unit.

IMPORTANT:

Follow the instructions EXACTLY and IN THE ORDER LISTED. Once

installed, your UV unit will provide years of successful operation.

© 2015 Delta Ultraviolet Corporation All Rights Reserved Rev 01/16 P/N 94-35234 Page 5

INSTRUCTIONS PERTAINING TO RISK OF FIRE, ELECTRIC

SHOCK OR INJURY TO PERSON

WARNING: To guard against injury when using this unit, basic safety precautions should always be

taken, including the following:

1. READ AND FOLLOW ALL SAFETY INSTRUCTIONS.

2. DANGER: To avoid possible electrical shock, special care should be taken since water is employed

in the use of this equipment. For each of the following situations, do not attempt repairs yourself;

return the appliance to an authorized service facility for service or discard the appliance.

a. If the appliance falls into the water, DO NOT reach for it! First unplug it and then retrieve it. If

electrical components of the appliance get wet, unplug the appliance immediately.

b. Do not operate any appliance if it has a damaged cord or plug, or if it is malfunctioning or if it is

dropped or damaged inn any manner.

3. Do not use an appliance for anything other than its intended use. The use of attachments not

recommended or sold by the appliance manufacturer may cause an unsafe condition.

4. Always unplug an appliance from an outlet when not in use, before putting on or taking off parts, and

before cleaning. Never yank the cord to pull the plug from the outlet. Grasp the plug and pull it to

disconnect it.

5. Never drop or insert any object into any opening.

6. This unit contains an ultraviolet bulb that can cause discomfort or irritation to the eyes if

viewing while operating. Prolonged exposure to the eyes can cause blindness.

DO NOT VIEW UV BULB WHILE OPERATING OR DURING MAINTENANCE.

7. Read and observe all of the important notices on the appliance.

8. Warning-To reduce the risk of electrocution, keep all connections dry and off the ground. Do not

touch the plug with wet hands.

9. If an extension cord is necessary, a cord with a proper rating should be used. A cord rated for less

amperes or watts than the appliances rating may overheat. Care should be taken to arrange the cord

so that it will not be tripped over or pulled.

10. Always check Local Ordinance and Building Codes for your city before installation of equipment.

11. Protect the unit from direct prolonged sunlight exposure.

© 2015 Delta Ultraviolet Corporation All Rights Reserved Rev 01/16 P/N 94-35234 Page 6

INTRODUCTION

Forward: The Delta UV Unit is designed for use in swimming pools, fountains, water features, waterfalls and

fish ponds. It is not designed for use in potable (drinking) water installations. Use of this product in

applications other than those indicated above will void your warranty and could be harmful to your health or the

health of others.

Introduction - How The Delta UV Unit Works: Within the Delta UV Unit (which we will refer to throughout

this manual as DELTA UV), a high intensity electrically operated Ultraviolet (UV) bulb is located inside the

unit’s wet chamber. This UV bulb gives off Ultraviolet light wave emissions when lit. The bulb’s operating

emission range is within the Ultraviolet light wave spectrum at 253.7 nm of wavelength. This wavelength is

such that when bacteria, protozoa, viruses, algae spores, or other single celled waterborne microorganisms in

the incoming water flow are exposed to the light waves of the UV bulb for a proper period of time, the DNA of

the microorganism is altered or disrupted and this controls and eradicates these unwanted contaminates and

renders them harmless. Your DELTA UV unit has been sized to produce these important UV rays in the same

intensity as is required for Class A potable drinking water, which is 30 microwatts/sec/cm2.

While you may see lesser competitive units of similar vessel size claiming to work on larger ponds or pools,

you will find that these units do not operate at the same high intensity as does the DELTA UV unit and are

unable to obtain the same level of disruption and eradication power as the DELTA UV unit. Rely on the flow

chart shown on page 3 for proper maximum disruption and eradication power unit selection for your

application. See Sect. A

Pond or pool water containing these unwanted contaminates enters the Delta UV wet chamber and is exposed to

the light rays generated by the UV bulb. The DELTA UV unit has been designed to allow for some turbidity in

the water, as turbidity will reduce the UV light wave transmission capability. Therefore, all DELTA UV units

are sized to allow for possible turbidity in the water and the reduction in the disruption and eradication power of

the UV bulb when it nears the end of its useful life. When the incoming water is exposed to the bulb for the

proper duration and intensity, the water exiting the unit is near drinking water biological quality.

CAUTION

THIS UNIT IS FOR POND OR POOL USE ONLY. DO NOT USE THIS UNIT FOR

POTABLE DRINKING WATER SANITIZATION

© 2015 Delta Ultraviolet Corporation All Rights Reserved Rev 01/16 P/N 94-35234 Page 7

PRE-INSTALLATION

Pre-Installation: In order to ensure that your DELTA UV unit functions with the proper exposure time to

achieve the desired water sanitization, it is important to provide the proper water flow rate through the

DELTA UV unit. If water passes through the unit too quickly, the exposure time of the microorganisms to the

UV bulb produced rays will not be sufficient to obtain the desired disruption and eradication rate. The water

flow rate through the UV unit is governed by the piping of your pool or pond and the size and output of your

circulation pump. There also needs to be consideration to the application for the UV unit. Fish ponds have

different requirements than do swimming pools, water features, fountains, or waterfalls.

Swimming Pool Turnover Rates: Swimming pools are somewhat simpler to calculate for flow rates. Most

residential pools are designed to have the capacity of the pool turned over every

12 hours. Semi-commercial pools are normally designed for an 8 hour turnover flow rate. Check with your local

jurisdiction for the required flow rate for your type of pool to be sure. Thus, as an example, using the same

formula as above, a 20,000 gallon residential pool will need to have a pump capable of a 28 GPM flow rate and

a 25,000 gallon Semi-commercial pool will need to have a pump capable of 52 GPM.

Like pools and ponds, the DELTA UV unit needs to be properly sized by flow rate. Moving the water through

the DELTA UV unit’s wet chamber too fast will not allow enough exposure time of the water to be exposed to

the UV bulb rays for the required exposure time. The chart shown on page 3 depicts the desired and

maximum flow rates for your DELTA UV unit. Make sure the flow rate of your circulation system pump does

not exceed the maximum allowable flow rate of the UV rating if you are in doubt). If the pump output

exceeds the maximum flow rate of the DELTA UV unit you have selected. (Consult your supplier or pump

manufacturer for the pump’s GPM rating if you are in doubt). If the pump output exceeds the maximum flow

rate of the DELTA UV unit you have selected, select a DELTA UV model with a higher flow rate capacity

rating or consider a multiple unit installation.

© 2015 Delta Ultraviolet Corporation All Rights Reserved Rev 01/16 P/N 94-35234 Page 8

C. Sanitizer Installation

INSTALLATION

Before starting the installation, PLEASE read this manual from cover to cover. A few moments spent

initially becoming totally familiar with the DELTA UV unit and its installation requirements will save a great

deal of time (and expense) later. If you have questions that are not answered after you have completed the

reading of this manual, contact your supplier or Delta UV. We are ready to assist you at any time and we want

your installation to go smoothly and the equipment to work properly.

LOCATING THE UV UNIT

Once you have confirmed the sizing of your pond or pool and compared that information against the

requirements of your DELTA UV unit by using the charts above, it is now time to install your unit. The

DELTA UV unit comes with all internal components fully assembled and ready for installation. Only the

Inlet/Outlet unions need to be installed to ready your unit for installation. All parts of the DELTA UV units are

UV inhibited PVC plastic. Thus, your unit will function fine in the outdoors. Installing the DELTA UV unit

indoors or inside a covered area is preferred however, to keep your unit looking new. The DELTA UV unit will

need to be directly wired. The DELTA UV unit comes with a twelve foot power cord (D/DS-5, D/DS-10

six foot cord) ready to be directly wired.

Plumbing the UV Unit: Your DELTA UV unit will need to be plumbed into your pond or swimming pool

circulation system. The diagram (Fig. 1) shows how the unit is to be plumbed. Note that the water is to be piped

from the pressure side of the pump and after the filter, in and out of the DELTA UV unit. The inlet for the water

is at the bottom of the DELTA UV unit, and the outlet is at the top of the DELTA UV unit. If your pump exceeds

the maximum flow rate of the DELTA UV unit, installation of a plumbing by-pass will be necessary to bypass

some of the pump’s flow

around the DELTA UV unit so the maximum flow rate of the DELTA UV unit will

not be exceeded. Bypass system is recommended in all installations.

●

CAUTION:

We recommend the presence of a by-pass.

Before accessing the connection terminals, ensure that all supply

circuits are disconnected.

The Sanitizer installation as a whole must be protected with a suitably

adapted circuit breaker.(See A. Technical characteristics)

Check Local ordinances and building codes before installation

of equipment. (See A. Technical characteristics)

© 2015 Delta Ultraviolet Corporation All Rights Reserved Rev 01/16 P/N 94-35234 Page 9

USE & MAINTENANCE

Allow the ultraviolet lamp to cool for at least 30 minutes before

handling

NEVER LOOK AT THE ULTRAVIOLET LAMPS WHEN LIT.

This may cause severe injuries or burns and may even lead to loss of

eyesight.

Do not touch the ultraviolet lamp with bare hand, as these would leave

impurities that shorten the life of the lamp. If you do touch it clean with

alcohol or white vinegar.

Never unscrew the quartz tube sealing nut when the sanitizer is on load

as the quartz tube could be blown out of the sanitizer with force and will

injure you.

To avoid electric short-circuits; do not place the electric wires or the

sanitizer in the pool water or in any other maintenance or cleaning fluid.

Do not restart the system until the electric unit, the covers exterior

elements of the sanitizer are correctly put back in place. When replacing

the lamp or carrying out annual cleaning of the quartz tube, make sure

that the electrical elements are in place and correctly attached before

switching on the sanitizer.

Do not use the Delta UV sanitizer for any other use than that for which it

was designed. Hg-Lamp CONTAINS MERCURY. For your own safety

manage in accord with disposal laws. Please visit : www.lamprecycle.org

The Delta UV unit comes with all internal components fully assembled and ready for installation. Only the

Inlet/Outlet unions need to be installed to ready your unit for installation.

© 2015 Delta Ultraviolet Corporation All Rights Reserved Rev 01/16 P/N 94-35234 Page 10

INLET / OUTLET UNIONS

Your Delta UV unit will need to be plumbed into your pond or swimming pool circulation system

We recommend the installation of a by-pass valve.

The inlet for the water is at the bottom of the Delta UV unit: The SOLID COLOR union tail piece is

used on the BOTTOM union.

The outlet for the water is at the top: The CLEAR union tail piece is used on the TOP union

Installing Inlet/Outlet Unions - The DELTA UV unit comes with union nuts installed on the housing.

Packed with your DELTA UV unit are the remaining components necessary to complete the

Inlet/Outlet unions. The clear union tail piece is used on the top union, and the solid color union tail

piece is used on the bottom union.

Also packed with your DELTA UV: unit are two white gaskets that are used to complete the

Inlet/Outlet unions. One side of the gasket is flat, the other side has a half round bead on the face.

The two unions each have a groove in the face of the union tail piece and that groove accepts the

half round bead of the gasket to hold the gasket in place correctly. Place the gaskets into the face

of the union tail pieces. Now, install the union tail pieces by screwing them into the union nuts on

the DELTA UV unit.

DO NOT OVERTIGHTEN. Hand tightening is sufficient. OVERTIGHTENING WILL BREAK

THE UNION NUTS. Replacement split nut available from Delta UV only (Part # 86-02338)

© 2015 Delta Ultraviolet Corporation All Rights Reserved Rev 01/16 P/N 94-35234 Page 11

Mounting The UV Unit On A Solid Base - The next step is to secure the DELTA UV unit to a concrete or

wood base. Three mounting holes are located in the mounting base of the DELTA UV unit. These holes

accommodate ¼ inch diameter bolts to mount the DELTA UV unit in place. FAILURE TO PROPERLY

SECURE THE UNIT MAY CAUSE NOISE DUE TO VIBRATION CAUSED BY WATER PASSING

THROUGH THE WET CHAMBER. Secure the DELTA UV unit using bolts and anchors (not supplied) where

necessary and appropriate for your installation. When the DELTA UV unit is secured in position, the piping of

the unit can begin.

Gluing Piping To The UV Unit - The Inlet/Outlet PVC union tail pieces are 2 inch pipe size (63mm for overseas

models). Your PVC supply piping should be glued into the union tail pieces using an appropriate PVC primer

and PVC cement, as recommended by your supplier. Inlet piping should be supported and should not rest solely

upon the unions, to avoid breaking the unions. The installation of valves on the inlet and outlet lines

attached to the UV unit is recommended. If the DELTA UV unit is located with any portion of the unit

below the surface of the pond or pool, then VALVES ARE MANDATORY, so you may winterize or remove

the DELTA UV unit without draining your pool or pond. When you have completed the piping installation

(including bypass if necessary), the final step is to plug in the unit to its power source. It is very important

to mount the ballast a minimum of 16 in. above the ground.

© 2015 Delta Ultraviolet Corporation All Rights Reserved Rev 01/16 P/N 94-35234 Page 12

ELECTRICAL BONDING

Electrical Connection - The electrical power rating for your DELTA UV unit is shown on the label on the

outside of the unit. U.S. and Canadian DELTA UV units operate on 120/240V 50/60Hz –(1.15 Amps

maximum). This low power consumption makes operating your DELTA UVunit very economical. Therefore,

you will need a 15Amp 120V CIRCUIT for your DELTA UV unit to connect into. (Check the label on your

overseas unit for its power requirement). Your DELTA UV unit is meant to be connected to the pump and/or

timer and comes with a standard NEMA plug (This plug can be removed to hardwire the unit). Your DELTA

UV unit is supplied with a twelve foot (six foot D/DS-5, D/DS-10) long weatherproof power cord terminating

in a HOT, COMMON AND GROUND wire ready for connection. (Always use a qualified electrician for proper

installation). Ballast should be mounted to secured object or wall.

Start-Up - Once you have completed all the preceding steps, (IMPORTANT) verify that the unit has no

leaks anywhere, including a possible broken quartz tube damaged during transit, you are ready to start your unit

up.

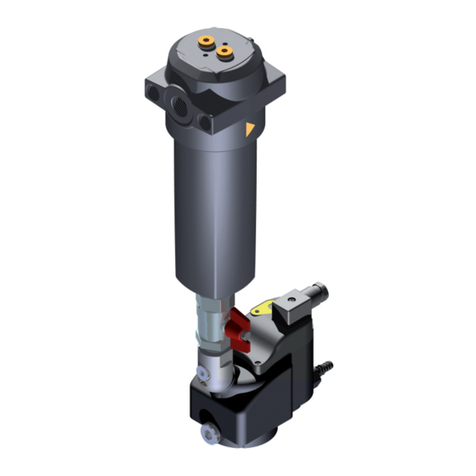

D. Electrical Chamber

The Delta UV D-Series unit should be connected to the pump and or

timer that controls the pump.

Quartz Guide

UV Lamp

Acorn Nut

4-pin connector

of the UV lamp

Delrin Plug

© 2015 Delta Ultraviolet Corporation All Rights Reserved Rev 01/16 P/N 94-35234 Page 13

E. START-UP

1

Start the circulation pump.

2

Drain all air from your system through the air relief valve on the filter (if so equipped).

3

Check DELTA UV Unit For Leaks –Make one final check for leaks in your piping, accessories, and

under the electrical enclosure bonnet. If any water leakage under the DELTA UV unit’s electrical enclose

bonnet is suspected (water dripping from under side of the bonnet), disconnect the DELTA UV unit

immediately, remove the bonnet and verify that there is either no leakage or stop the leakage of the quartz

tube gasket. If quartz tube leakage is encountered follow the instructions in Sections through and through

to remedy the situation before applying electrical power to your DELTA UV unit.

4

Check the chemical balance of your swimming pool (particularly pH, TAC*, and TH*). Adjust the

chemical balance as per your pool chemical supplier's

instructions. - Remember, the DELTA UV unit

dramatically reduces the need for chemical sanitizers, but does not eliminate the need for proper pool

chemical balance.

Reminder: Your Delta UV

does not eliminate the need for

proper pool chemical balance.

F. UV LAMP REPLACEMENT & QUARTZ TUBE MAINTENANCE

The DELTA UV unit requires very little maintenance during the year. The UV bulb in the DELTA UV

unit is placed inside a quartz tube to protect the bulb from the water in the DELTA UV unit’s wet chamber.

This quartz tube can have its ability to transmit the UV rays from the bulb through the quartz tube

diminished if the quartz tube becomes dirty or laden with deposits. The quartz tube should be removed

from the wet chamber every six (6) months and inspected to make sure it is clean and that deposits are not

attached to the quartz tube. To remove the quartz tube, you should follow the steps shown below.

Reminder: Do not touch the UV bulb glass with your bare hands

That can shorten its life. Grasp the bulb on the white ceramic prong end or use a soft clean

cotton cloth or clean cotton gloves to handle the UV bulb. (If you have touched the bulb with

your bare hands, you must wipe the bulb glass off with spirit vinegar using a clean soft cotton

cloth).

© 2015 Delta Ultraviolet Corporation All Rights Reserved Rev 01/16 P/N 94-35234 Page 14

Disconnect

Power:

Unplug the DELTA UV unit from its power receptacle

1. Stop Your Circulation Pump: You must shut off the circulation pump so that

no water is flowing into the DELTA UV unit. Once the pump is shut off if you feel that

there is no pressure present inside the DELTA UV unit, simply unscrew the top union

nut on the DELTA UV unit. This will relieve any pressure. When you are absolutely sure

that there remains no pressure inside the DELTA UV wet chamber, you can proceed to the

next step.

2. Allow the ultraviolet lamp to cool for at least 30 minutes before handling

3. Remove the plastic electrical enclosure bonnet by unscrewing the mounting screw.

4. Unplug the UV lamp by grasping the 4-pin connector (attached to the ballast wires). SLOWLY pull

the UV lamp out of the quartz tube (by grasping the bulb on the white/ gray ceramic prong

end).Check that bulb cushion and O-rings (between the lamp and the quartz tube) are still on bulb.

Carefully place the removed bulb in a safe location while cleaning the quartz TUBE

5. Remove The Acorn Nut: Unscrew acorn nut by hand, if needed use a crescent wrench or 1-11/16"

socket, remove the black plastic acorn nut (Part # 86-02417) holding the quartz tube into the black

plastic mounting gland. Note that there is a rubber sealing gasket (Part # 44-02018) around the quartz

tube (or inside the acorn nut) that seals the quartz tube to the mounting gland. Set the gasket aside to

reseal the quartz tube when you reinstall the quartz tube after cleaning.

6. Grasp the quartz tube and pull straight up. Inspect Quartz Tube: If cracks in the quartz tube are

found, the tube should be replaced. Broken quartz tubes will allow water to enter the dry electrical

chamber and attack the electrical components of the unit, which will cause them to fail and need to be

replaced. BROKEN QUARTZ TUBES, OR WATER DAMAGE CAUSED BY BROKEN QUARTZ

TUBES, ARE NOT COVERED UNDER YOUR LIMITED WARRANTY

7. The quartz tube exterior can normally be cleaned by using acid or spirit vinegar or Muriatic

Acid (liquid) with weak concentration. (ratio of 4 parts water to one part acid)

CAUTION: Follow the directions for use and handling of Muriatic Acid on the acid bottle label,

being careful to protect your eyes, wear rubber gloves, and avoid breathing fumes

Do not use abrasive cleaners. Change the quartz tube if necessary.

8. Seat the quartz tube DELICATELY into the receptor at the bottom of the wet chamber

(Without dropping it). The quartz tube will not go all the way down into the wet chamber

,

approx.

1”

will be showing after the rounded end of the quartz tube is seated in the receptor at the

bottom of the wet chamber.Take a new sealing gasket (angled seal). (Put a new sealing gasket

every lamp change) Place it on the end of quartz tube (angle downwards).

© 2015 Delta Ultraviolet Corporation All Rights Reserved Rev 01/16 P/N 94-35234 Page 15

WINTERIZING

9. Install and tighten the black plastic mounting gland. Do not over tighten. Be careful not to cross

thread the plastic nut.

10. Reinstalling The UV Bulb: Seat the bulb end cushion on the end of the bulb (the end that goes down

into the quartz tube first).Place the two O-Rings around the top.

11. Without forcing, plug the UV lamp to 4 pin connector (attached to the ballast wires).

12. Reinstall the plastic electrical enclosure bonnet by screwing mounting screw.

13. Plug in Delta UV unit.

14. Turn on the circulation pump.

15. Verify that the bulb is lit by viewing the glow of the bulb through the clear plastic union.

Your DELTA UV unit can be damaged if allowed to freeze. The substantial pressure inside the wet chamber

caused by ice forming inside the wet chamber can break the glass quartz tube as well as the wet chamber itself.

Therefore, you must protect your DELTA UV unit from freezing. Damage due to freezing, including breakage

of glass components, the wet chamber, or water damage to other components caused by freezing IS NOT

COVERED under your Limited Warranty.

Freeze damage - Freeze damage can be avoided by keeping the water flowing at a minimum of .5 PSI

pressure (as noted on the operating pressure gauge) at all times, without interruption during freezing

temperatures. All time clocks must be inoperable and the pump must run continuously. Freeze damage can

also be avoided if the pump and DELTA UV unit are maintained inside a warm enclosure.

Freezing Weather Precautions - If you do not plan to operate your DELTA UV unit during freezing

temperatures, you must take precautions to make sure all water is removed from inside the DELTA UV wet

chamber so it does not freeze inside the wet chamber and damage the quartz tube, acorn nut(86-02417), and

DELTA UV unit. This can be accomplished by first closing any valves on lines in the plumbing system and

then open the inlet union at the bottom of the DELTA UV unit so that the water is drained from inside the

wet chamber tank. Remove Quartz tube (see Section F) and store in safe location. A safe precaution is to place

the DELTA UV unit in a warm location during freezing temperatures (recommended), after draining all the

water from the unit and removing it from the plumbing. Caution: A drain valve and piping to carry water

away from the DELTA UV unit must be installed if drainage of the DELTA UV unit will cause water damage

to the area surrounding the DELTA UV installation.

© 2015 Delta Ultraviolet Corporation All Rights Reserved Rev 01/16 P/N 94-35234 Page 16

D/DS SERIES

MODEL

POWER

LAMP

QUARTZ TUBE

BALLAST

UV HOUSING

ITEM#1

ITEM#2

ITEM#3

ITEM#14

D OR DS-31

30W

70-18405

58-50305

70-10404

N/A

D OR DS-46

45W

70-18410

58-50310

70-10404

N/A

D OR DS-57

55W

70-18510

58-50315

70-10419

N/A

D OR DS-80

80W

70-18420-S

58-50320

70-10419

N/A

D OR DS-80

90W

70-18440-S

58-50340

70-10419

N/A

COMMON PARTS

ITEM

DESIGNATION

PART #

4

DELRIN PLUG 1/8

40-50019

5

QUARTZ TUBE ACORN NUT&HOLDER

86-02417

6

QUARTZ TUBE COMPRESSION GASKET

44-02018

7

O-RING VITON

44-02221

8

BULB CUSHION

44-02019

9

UNION TAIL PIECE 2'' CLEAR

86-02405

10

UNION TAIL PIECE 2'' WHITE

86-02352

11

FLAT O-RING 2'' WHITE

44-02335

12

ELECTRICAL ENCLOSURE BONNET

86-02094

13

SPLIT NUT ASSEMBLY - 2"

86-02338

15

DRAIN PLUG

44-50265

16

BONNET SCREW

44-06013

*86-02421 Acorn Nut Assembly (acorn nut, threaded nipple, lock nut, compression gasket & o rings)

© 2015 Delta Ultraviolet Corporation All Rights Reserved Rev 01/16 P/N 94-35234 Page 17

G. FAQ

Here are a number of FAQ’s that will answer some of the most common questions.

Q-1: Is the Delta UV System Designed For Salt Water Use?

A-1: While the ability of the system is not affected by salt water, the harsh environment found in salt water

ponds and aquariums is not recommended for the DS Series units due to the stainless steel inner

wrapper. However, the all plastic D-Series units are compatible with salt water environments.

Q-2: Do I Need To Turn My DELTA UV Unit Off When I Clean My Filter?

A-2: No.

Q-3: Will A Time Clock On My Pool Shorten My Bulb Life?

A-3: Some shortening of the bulb life can be expected when the DELTA UV unit is turned off and back on

frequently. A daily on/off cycle will not create a major bulb life issue however, frequent on/off cycles

should be avoided.

Q-4: Is There Any Residual Effect From UV?

A-4: No, UV light is used as a control and is applied only to the water that passes inside the DELTA UV wet

chamber in visual contact with the UV transmission from the UV bulb.

Q-5: Can The DELTA UV Unit Be Mounted Horizontally?

A-5: No, vertical mounting is required to maintain the weatherproof integrity of the electrical enclosure

bonnet.

Q-6: Can Multiple Units Be Used Together For Larger Systems?

A-6: Yes, you can add any number of DELTA UV units to a plumbing bypass manifold system to allow for

larger outputs and flow rates beyond the capacity of a single D-40 or DS-40 unit. Delta UV also

manufactures a large capacity system, the EM UV system that incorporates factory installed

hydraulically balanced piping and multiple tanks contained within a metal enclosure. The EM system

features the latest technology in high output UV bulbs, dubbed Amalgam bulbs. Contact Delta UV or

your supplier for information on the EM product line, or to obtain a drawing showing the proper method

of plumbing multiple DELTA UV units for larger applications.

Q-7: Can the Delta UV system be installed on a new or re-plastered pool immediately?

A-7: Yes, however the quartz tube may require cleaning more frequently due to conditions of water caused

by the conditioning of the plaster.

© 2015 Delta Ultraviolet Corporation All Rights Reserved Rev 01/16 P/N 94-35234 Page 18

H. TROUBLESHOOTING

1. The UV Bulb Will Not Light:If this occurs upon initial start-up, the problem could be caused by a

number of issues.

a. The bulb has become disconnected from the bulb connector. Disconnect the power cord

from the electrical outlet, open the electrical enclosure bonnet and confirm the bulb connector is

firmly in place. At the same time, check all exposed wires for a possible loose connection. Plug

the electrical cord back into the electrical outlet ONLY after the electrical enclosure bonnet has

been re-installed on the DELTA UV unit

b. Verify that the electrical cord is connected into an energized circuit. Test the electrical circuit.

You should confirm the availability of the same power as indicted on the electrical label on your

DELTA UV unit.

c. Make sure you have not connected your unit into any power source other than that specified on

your unit’s electrical label. If you have done so in error, the ballast has been damaged and

needs to be replaced. Contact your supplier for the correct replacement ballast. (Not warranted)

2. The UV Bulb Is No Longer Lit - This occurs after the unit has been operating successfully for a period

of time.

a. The bulb has burned out. Replace the UV bulb.

b. The ballast has burned out. Contact your supplier or Delta UV for assistance in obtaining a new

ballast.

c. Verify that the electrical outlet where the DELTA UV unit is plugged into has the proper voltage

and the cord is securely plugged into the outlet.

3. The Water Is Green - Green water is an indication that the UV rays generated by the DELTA UV unit

are not effective or are not being generated by the UV bulb.

a. Check pool chemistry for phosphates and chemical balance.

b. Check the bulb to make sure it is on. If it is not on, follow the procedures above regarding the UV

bulb not lighting.

c. Run your unit longer. If your unit is operating on a time clock, run the circulation pump longer

to allow the DELTA UV unit to function fully.

d. Clean the quartz tube.

e. Replace the UV bulb if it is nearing the 13,000 hour useful life. At 13,000 hours of operation,

the UV bulb is 80% as effective as it was when it was new. This is normal for all low-pressure

type UV bulbs, which are the longest life bulbs used in this type of application.

4. The DELTA UV Unit Makes Noise When Operating: This is an indication of the DELTA UV unit

not being properly attached to a firm mounting base of wood or concrete with the bolts placed through

the mounting holes in the DELTA UV unit base. It can also indicate that the UV bulb was installed

without the required bulb cushion and/or bulb O-Rings. Attach the DELTA UV unit correctly to a firm

base as described in Sec. D, or install the bulb cushion and/or bulb O-Rings as described in Sec. G.

5. Water Is Coming Out Of Electrical Enclosure: Water exiting the unit through the electrical enclosure

bonnet can be attributed to either (a) a bad quartz tube seal, or (b) a broken or cracked quartz tube. Check

the quartz tube seal and quartz tube as instructed in Sec. G.

6. Specifications - Due to Delta UV’s commitment to product improvement, all product descriptions or

specifications are subject to change without notice.

© 2015 Delta Ultraviolet Corporation All Rights Reserved Rev 01/16 P/N 94-35234 Page 19

DELTAUV TWO (2) YEAR LIMITED

WARRANTY

Delta Ultraviolet Corporation warrants to every original Purchaser of Delta UV’s Series Ultraviolet Unit, that the product will be free from defects, as defined herein, for

a period of two (2) years - (D/DS-Series). If at any time during the Limited Warranty period, any defect, as defined herein, prevents the product from performing correctly

in an application for which it was designed, Delta UV will repair or replace the product (at Delta UV’s option) as outlined herein:

COVERED WARRANTY ITEMS:

This Limited Warranty DOES cover the UV unit, its components, and defects thereof against:

Manufacturing Defects

Material Defects –Ballast (1 year)

Housing Corrosion Causing Leakage (D/DS Series)

Plastic Component Degradation

Bulb failure during 1st year (Pro Rated)

ITEMS NOT COVERED BY WARRANTY:

This Limited Warranty DOES NOT cover the following UV unit defects:

Failure Of Any Covered Condition When Caused By Any Of The Following:

oMetal Corrosion Due To Salt Water Use

oMechanical Abuse

oGlass Component Breakage

oImproper Installation

oBulb Failure after One Year

oActs of War or God

oOperation at Pressures Greater Than 40 PSI (3 Bar)

oFreeze Damage

oImproper Operating Voltage

oAny Failure Not Indicated As “Covered Warranty Item”Herein

Note 1: During the duration of this Limited Warranty, should any failure occur, the unit should be inspected at the site to determine the cause of failure, and if that

failure is shown to be a covered item, the Original End User (User) must request a written Return Merchandise Authorization (RMA) from Delta UV, prior to any

product return. Any returned unit is to be accompanied by Delta UV’s RMA and is to be returned freight prepaid to Delta UV for Limited Warranty evaluation. The

User is responsible for any freight damage associated with such return. Unit failures, or components thereof, found to be covered under this Limited Warranty will

be repaired or replaced (at Delta UV’s option) without cost to the User and will be returned to the User via UPS Surface, at the User’s expense. Delta UV shall be the

sole judge in determining the cause of failure of any UV unit. Units arriving in broken condition will not be warranted.

The term “Original End User”(User) shall mean the person or company that was in possession of the physical location where the UV unit was originally installed, at

the time of first installation, as evidenced by an original invoice from the selling company to the User at the location where the unit is to be returned. A photo copy of

said original invoice must accompany the UV unit RMA paperwork. UV units received unaccompanied by the required documentation will not be accepted by Delta

UV for Warranty evaluation and will be returned to the User in the same condition as received, freight collect (COD) if the User fails to provide the required

documentation within ten (10) days from date of notification of missing documentation from Delta UV. Any unit returned to Delta UV COD or freight collect will be

rejected from the freight carrier.

Note 2: This Warranty is Limited in that it does not cover any monetary reimbursement for freight charges, for removal and/or installation labor, or any other

incurred costs by any other person(s) or firm(s), including (but not limited to) any consequential damage or loss of use that might be claimed. The Limited Warranty

period shall commence upon the date of sale to the User, but in all cases no later than one hundred twenty (120) days after the date of manufacture of the UV

unit, as shown on the Delta UV date code located on the product identification label, whichever occurs first. UV units received with factory identification missing,

mutilated or altered, or units received containing components not supplied by Delta UV or modified in any way, will not be warranted under any circumstances.

OTHER RIGHTS - This Limited Warranty supersedes any and all previous Limited Warranties for this product, gives you specific legal rights, and you may have

other rights which vary from state to state.

DELTA ULTRAVIOLET CORPORATION

CORPORATE HEADQUARTERS

1535 West Rosecrans Ave Gardena, CA 90249

Phone 310-323-6400

Fax 310-323-6403

© 2015 Delta Ultraviolet Corporation All Rights Reserved Rev 01/16 P/N 94-35234 Page 20

REFERENCE INFORMATION

DEALER: ______________________________________________________________________

PHONE: ______________________________________________________________________

CONTACT: _____________________________________________________________________

DATE OF INSTALLATION: _____ / _____ / _____

MODEL: _____________________________________________________________________

RE-LAMP DATE _____ / _____ / _____ RE-LAMP DATE _____ / _____ / _____

RE-LAMP DATE _____ / _____ / _____ RE-LAMP DATE _____ / _____ / _____

RE-LAMP DATE _____ / _____ / _____ RE-LAMP DATE _____ / _____ / _____

- NOTES –

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

This manual suits for next models

9

Table of contents

Popular Water Filtration System manuals by other brands

BWT

BWT PERMAQ COMPACT 51 Installation and operating manual

Water Right

Water Right UltroWater Installation, operation & service manual

GE

GE E4-2200 Operation and maintenance manual

Parker

Parker Zander WS Series operating instructions

Oase

Oase Filtoclear 3000 operating instructions

Brita

Brita 1200 Handbook

T.I.P.

T.I.P. PMA 8000 UV 9 operating instructions

Davey

Davey STERIFLO SF1000S mkII Installation and operating instructions

Brita

Brita MAXTRA Aluna Instructions for use

Jandy

Jandy Jandy Pro Series Installation and operation manual

Bermuda

Bermuda BER4001 instruction manual

PREMIER TECH

PREMIER TECH ECOFLO owner's manual