NOTICE

• This equipment must be operated by trained cook or professional.

• Do not modify this product as it may cause harm.

• Do not clean the product with a water hose or soak electric box in water while cleaning. Water can conduct

electricity so the product may cause electric-shock by electric leakage.

• High temperature can cause burning. Do not touch when hot.

• Do not use a power supply with dierent voltage.

• Do not use main switch that is unsafe or uncompliant.

• When severe weather occurs the user should shut o the main switch to avoid appliance being damaged by

any lightning strikes.

• Do not use any hard or sharp objects as they may destroy the surface of the fryer.

• The installation and maintenance of electric circuit must be done by an approved site service agent.

• If the power cord is damaged the user should ask manufacturer, maintenance department, or a SHL service

agent to change it.

NOTES FOR INSTALLATION

1. The voltage for this equipment must be coordinated with the supplied voltage.

2. User should install a suitable power switch and breaker switch near the fryer.

3. At the back of the equiment is the earth bolt. Please connect the earth wire in compliance with the safety

regulations reliably with copper cable of no less that 2mm.

4. Before using, check whether every connection is formed, voltage is normal and ground connection is safe.

5. Do not use water to clean the electric box directly.

6. The installation of this fryer must be done by professionals.

7. Limiting temperature can cut o power automatically (reset the device by hand).

8. When lifting the electric box the micro-switch activates at once. It cuts o power safely in case the electric

heating tube gets dry burned.

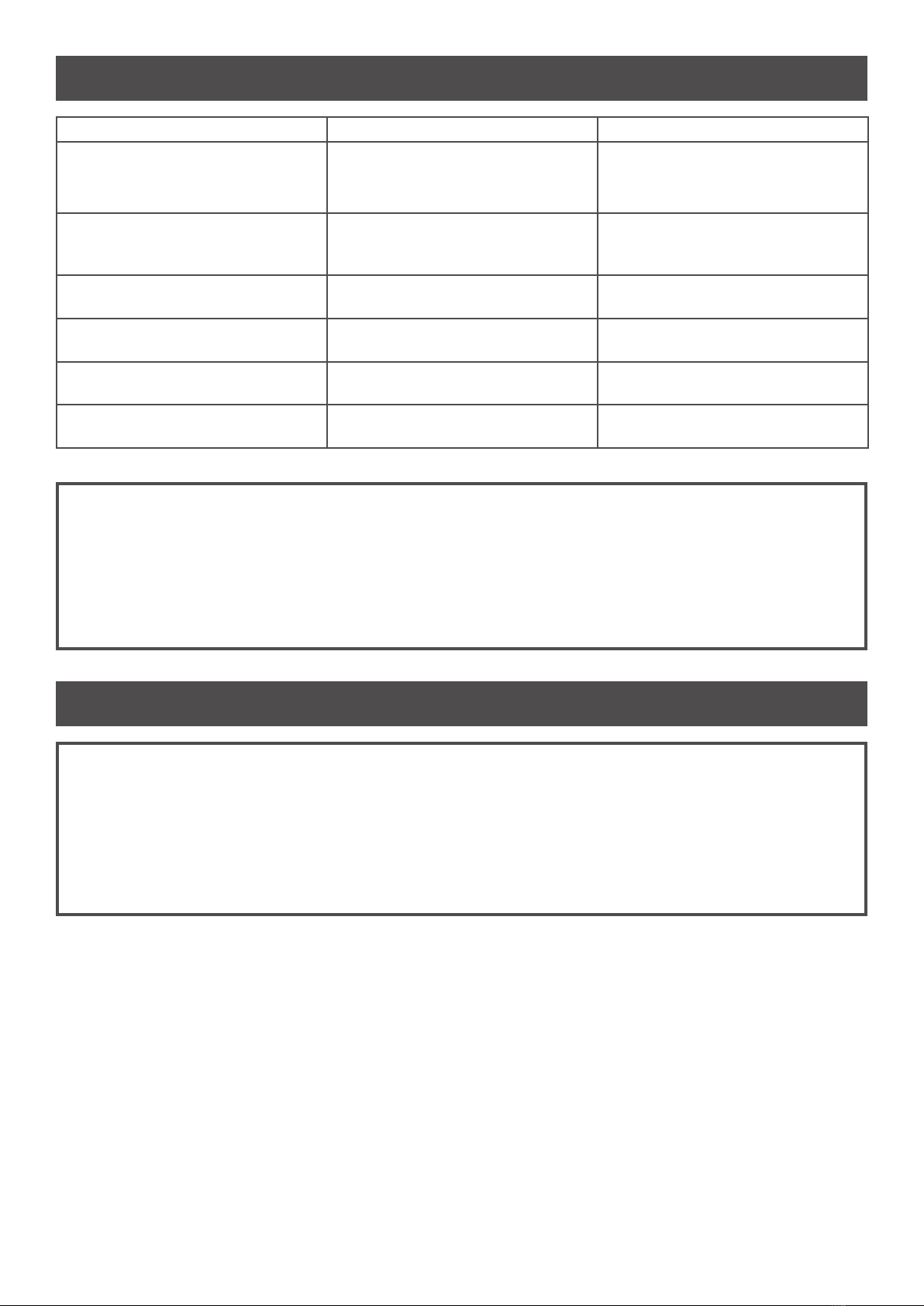

Name Electric Fryer

Model CKEF–1(4L) CKEF–1(6L) CKER–1(8L)

Voltage 220V–230V, 50/60Hz 220V–230V,50/60Hz 220V–230V,50/60Hz

Power 2000W 2500W 3250W

Number of oil tank 1 1 1

Size of oil tank(mm) 295 x 216 x 175 325 x 265 x 150 325 x 268 x 200

Volume 4(L) 6(L) 8(L)

Number of frying basket 1 1 1

Size of frying basket 220 x 150 x 130 240 x 200 x 105 240 x 200 x 145

The setting range of

temperature of oil 60–190°C 60–190°C 60–190°C

Moving temperature of

temperature limiter 230°C 230°C 230°C

Hand resisting temperature <150°C <150°C <150°C

Dimension(mm) 370 x 260 x 320 430 x 275 x 335 270 x 410 x 360

Length of handle(mm) 240 240 240

Weight 6.5kg 7.5kg 9kg

5

Version 1 – 14/12/2018