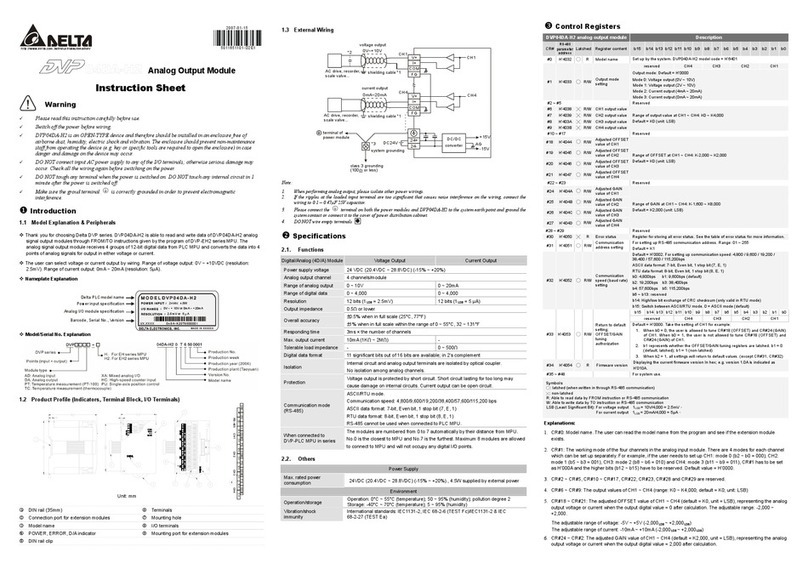

Ethernet Communication Module DVPEN01-SL

DVP-PLC Operation Manual 1

Warning

3

Please read this instruction carefully before use and follow this instruction to operate the device in order to prevent damages

on the device or injuries to staff.

3

Switch off the power before wiring.

3

RTU-DNET is an OPEN TYPE device and therefore should be installed in an enclosure free of airborne dust, humidity, electric

shock and vibration. The enclosure should prevent non-maintenance staff from operating the device (e.g. key or specific tools

are required for operating the enclosure) in case danger and damage on the device may occur.

3

RTU-DNET is to be used for controlling the operating machine and equipment. In order not to damage it, only qualified

professional staff familiar with the structure and operation of RTU-DNET can install, operate, wire and maintain it.

3

DO NOT connect input AC power supply to any of the I/O terminals; otherwise serious damage may occur. Check all the

wirings again before switching on the power and DO NOT touch any terminal when the power is switched on. Make sure the

ground terminal is correctly grounded in order to prevent electromagnetic interference.

Table of Contents

1INTRODUCTION...................................................................................................................................3

1.1 Functions.....................................................................................................................................3

1.2 Specifications ..............................................................................................................................3

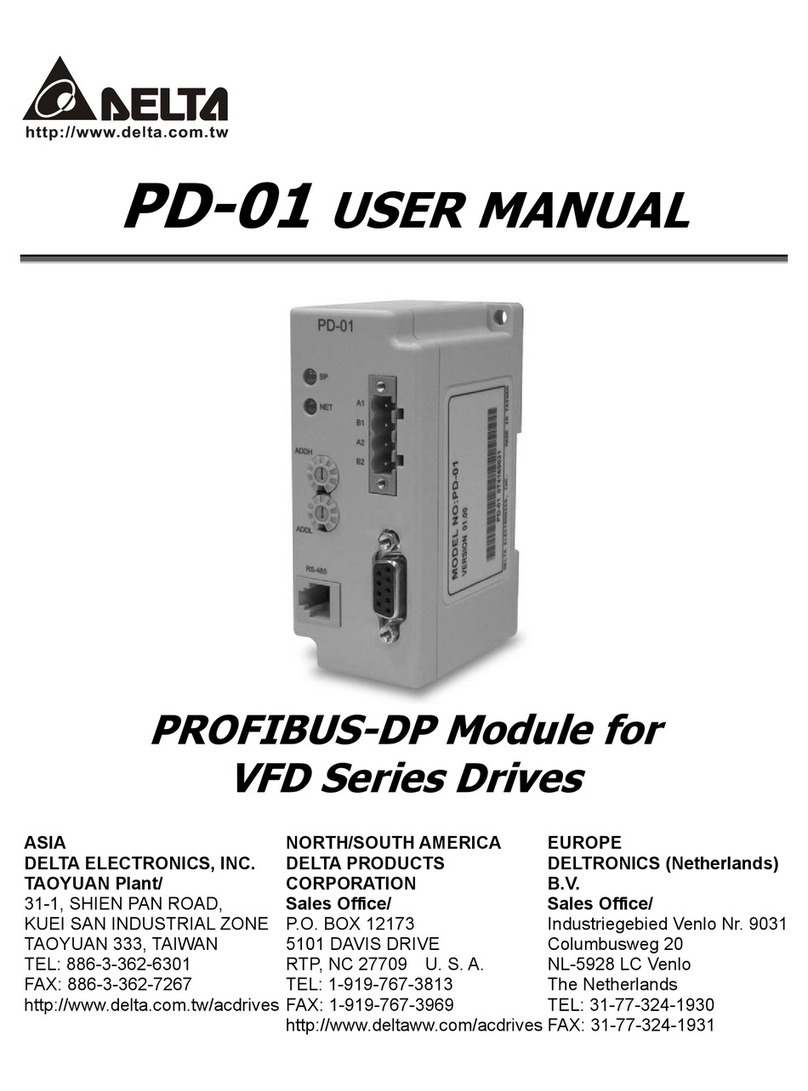

2PRODUCT PROFILE & OUTLINE .......................................................................................................4

2.1 Dimension ...................................................................................................................................4

2.2 Product Profiles...........................................................................................................................4

2.3 LED Indicators.............................................................................................................................5

2.4 RJ-45 PIN Definition....................................................................................................................5

3INSTALLATION & WIRING ..................................................................................................................5

3.1 Installation ...................................................................................................................................5

4CONTROL REGISTER (CR) ................................................................................................................6

4.1 Control Registers in DVPEN01-SL..............................................................................................6

4.2 Explanations on CR ....................................................................................................................8

4.3 Numbering of Left-Side Modules...............................................................................................13

5SETTING UP SOFTWARE.................................................................................................................14

5.1 Setting up Communication & Searching for Modules................................................................14

5.2 Basic Settings ...........................................................................................................................20

5.3 Network Settings .......................................................................................................................21

5.4 Setting up E-Mails .....................................................................................................................24

5.5 Data Exchange..........................................................................................................................25

5.6 RTU ...........................................................................................................................................26

5.7 IP Filter......................................................................................................................................27

5.8 Static ARP Table........................................................................................................................27

5.9 Setting up Password .................................................................................................................28