2

TABLE OF CONTENTS

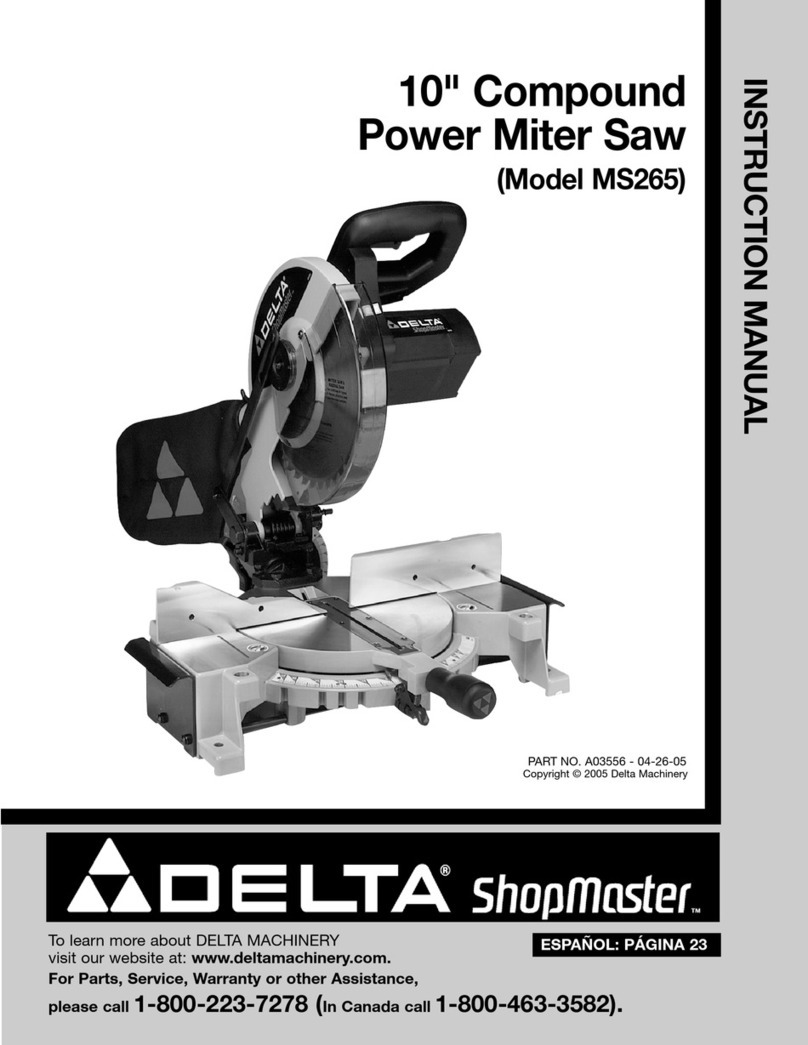

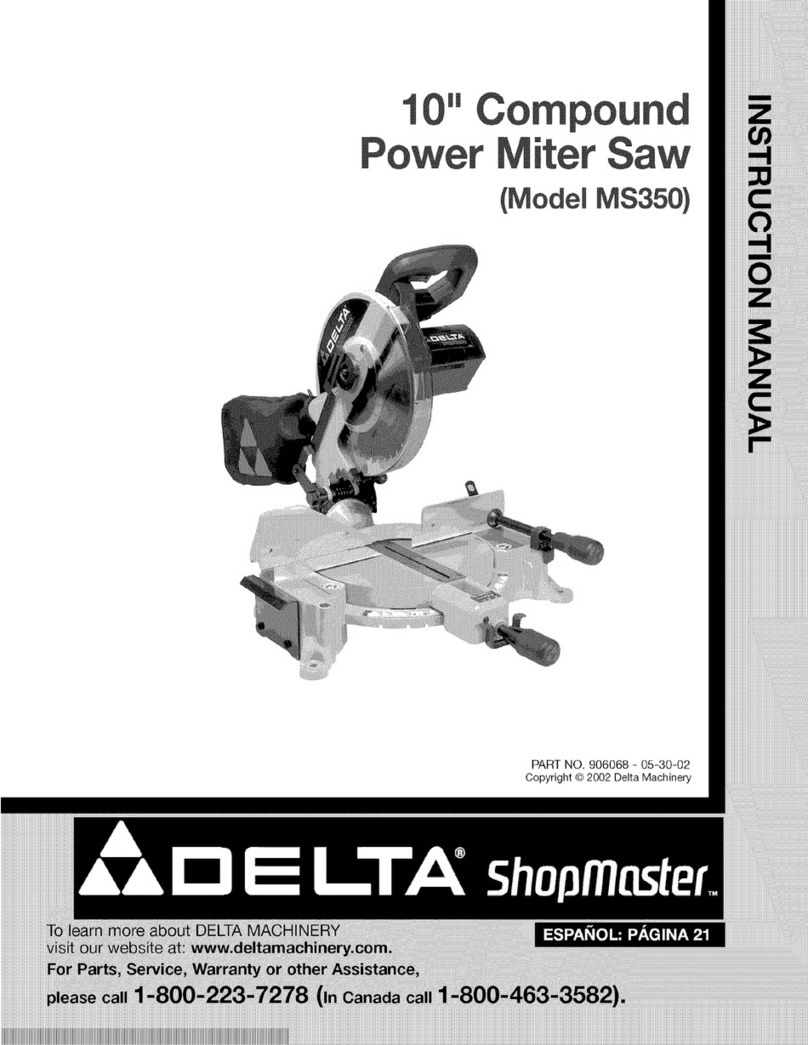

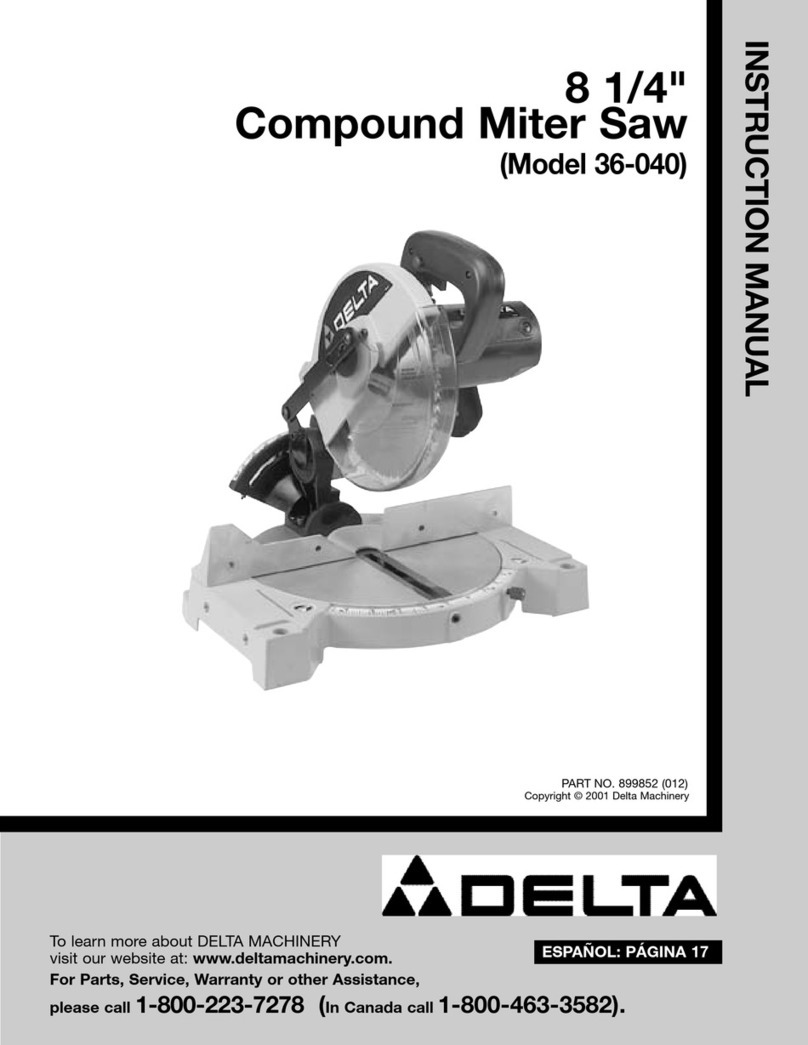

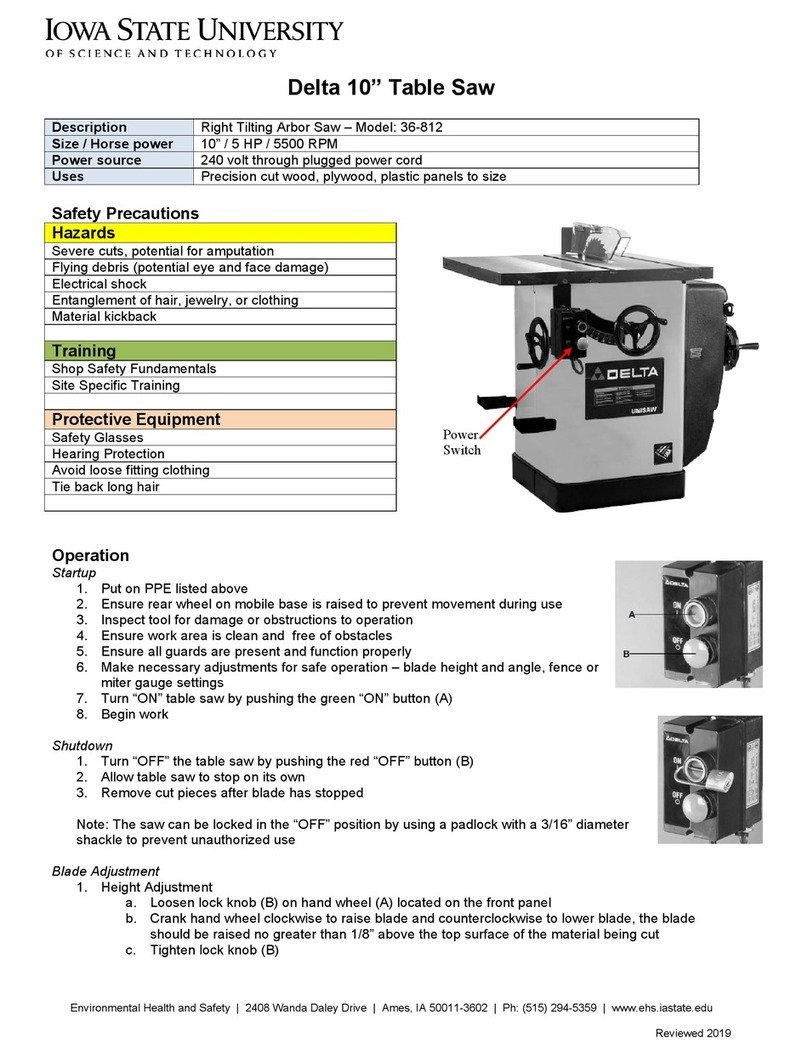

NOTE: The manual cover illustrates the current production model. All other illustrations contained in the manual are representative

only and may not be exact depictions of the actual labeling or accessories included. They are intended for illustrative purposes only.

FEATURES ...................................................................... 2

PRODUCT SPECIFICATIONS........................................... 2

KNOW YOUR COMPOUND MITER SAW ........................... 5

IMPORTANT SAFETY INSTRUCTIONS...................... 6

SAFETY LOGOS.............................................................. 6

GENERAL POWER TOOL SAFETY WARNINGS......... 7

SAFETY INSTRUCTIONS FOR MITER SAWS............ 8

PROPOSITION 65 WARNING..................................... 9

POWER CONNECTIONS............................................. 10

DOUBLE INSULATION.................................................. 10

ELECTRICAL CONNECTION.......................................... 10

POLARIZED PLUGS...................................................... 10

EXTENSION CORDS .................................................... 10

UNPACKING................................................................. 11

REMOVING CONTENTS FROM PACKING........................ 11

PACKAGED CONTENTS LIST ........................................ 11

ASSEMBLY.................................................................... 12

TOOLS NEEDED .......................................................... 12

WORK CLAMP ............................................................. 13

DUST BAG .................................................................. 13

DUST PORT ATTACHMENT ........................................... 13

INSTALL/REMOVE THE BLADE ..................................... 14

INSTALLING WORKPIECE SUPPORT EXTENSIONS ......... 15

ADJUSTMENTS ............................................................ 15

BEVEL ALIGNMENT ..................................................... 15

MITER ALIGNMENT..................................................... 16

DEPTH STOP ADJUSTMENT ......................................... 17

FENCE EXTENSION ..................................................... 17

BEVEL LOCK TENSION ADJUSTMENT ........................... 17

SLIDE RESISTANCE..................................................... 18

MITER LOCK ADJUSTMENT.......................................... 18

THROAT PLATE ........................................................... 19

MOUNTING AND TRANSPORTATION ..................... 20

PREPARATIONS FOR TRANSPORTATION ....................... 20

MOUNTING SAW TO STABLE SURFACE ......................... 21

OPERATION ................................................................. 22

CUTTING WARPED MATERIAL...................................... 22

CLAMPING WIDE WORKPIECES ................................... 23

SUPPORTING LONG WORKPIECES ............................... 23

POWER SWITCH LOCK ................................................ 24

SHADOW LINE............................................................ 24

NON-SLIDING CUTS.................................................... 25

FOR MITER CUTS........................................................ 25

FOR BEVEL CUTS........................................................ 26

FOR COMPOUND MITER CUTS..................................... 26

SLIDE CUTS................................................................ 27

TIPS FOR CUTTING CROWN MOLDING......................... 28

AUXILIARY FENCE....................................................... 29

EXPAND WORKTABLE AREA ......................................... 30

MAINTENANCE............................................................ 31

KEEP MACHINE CLEAN ................................................ 31

GENERAL MAINTENANCE............................................. 31

BRUSH REPLACEMENT ................................................ 31

LUBRICATION............................................................. 31

TROUBLE SHOOTING................................................. 31

FAILURE TO START ..................................................... 31

ACCESSORIES ............................................................. 32

PARTS, SERVICES OR WARRANTY ASSISTANCE.. 33

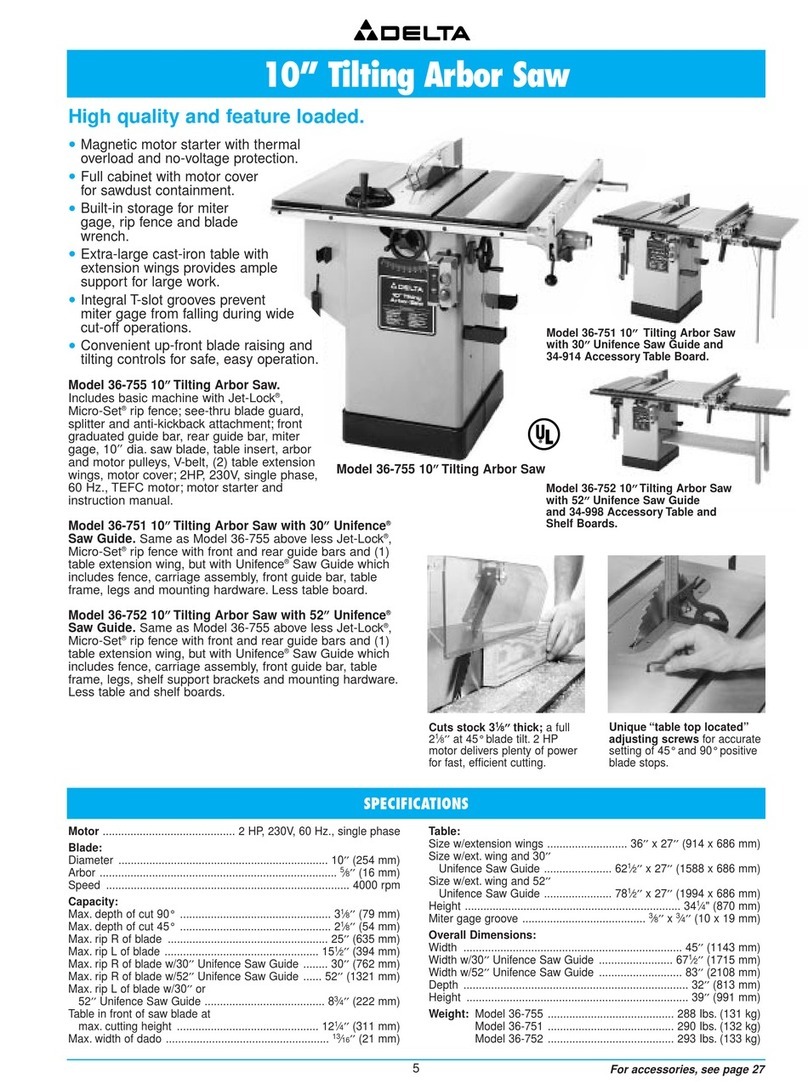

FEATURES

BLADE DESCRIPTIONS

APPLICATION DIAMETER TEETH

Construction Saw Blades

(thin kerf with anti-stick rim)

General Purpose 12 inch (305mm) 40

Fine Crosscuts 12 inch (305mm) 60

Woodworking Saw Blades

(provide smooth, clean cuts)

Fine Crosscuts 12 inch (305mm) 80

PRODUCT SPECIFICATIONS

Cutting Capacity

(Maximum nominal

lumber sizes)

0° Miter/0° L/R Bevel: 2 inch x 14 inch

(Extended Capacity 2 x 18 inch)

45° Miter/0° L/R Bevel: 2 inch x 10 inch

0° Miter/45° L/R Bevel: 2 inch x 14 inch

45° Miter/45° L/R Bevel: 2 inch x 10 inch

Baseboard (Vertical) 6.5 inch

Crown (Vertically

Nested)

7.5 inch

Net Weight 57 lbs

Input 120 V~, 60hz, 15 Amps

Blade Arbor Hole 1 inch (with 5/8 inch reducing spacer)

Blade Diameter 12 inch

No Load Speed 4,000 r/min (RPM)

Blade Max Speed

Rating

5,500 r/min (RPM)

Number of Teeth 60

Blade Thickness 0.07 inch (1.8mm)

Blade Kerf 0.1 inch (2.6mm)

NOTE: ONLY use blades that are marked for speeds

of 4,000 r/min (RPM) or higher. A 12 inch Blade is the

required blade size for the Saw. Larger blades will come

into contact with the Blade Guards and smaller blades will

not be adequately guarded. Use crosscut blades only. DO

NOT use blades designed for ripping, combination blades

or blades with hook angles in excess of 7°.