3

SAFETY RULES

W oodworking can be dangerous if safe and proper operating procedures are not followed. As with all machinery, there are certain

hazards involved with the operation of the product. Using the machine with respect and caution will considerably lessen the possi-

bility of personal injury. However, if normal safety precautions are overlooked or ignored, personal injury to the operator may result.

Safety equipment such as guards, push sticks, hold-downs, featherboards, goggles, dust masks and hearing protection can reduce

your potential for injury.But even the best guard won t make up for poor judgment, carelessness or inattention. Always use common

sense and exercise caution in the workshop. If a procedure feels dangerous, don t try it. Figure out an alternative procedure that feels

safer. REMEMBER: Your personal safety is your responsibility.

This machine was designed for certain applications only. Delta Machinery strongly recommends that this machine not be modified

and/or used for any application other than that for which it was designed. If you have any questions relative to a particular applica -

tion, DO N O T use the machine until you have first contacted Delta to determine if it can or should be performed on the product.

DELTA INTERNATIONAL MACHINERY CORP.

MANAGEROFTECHNICAL SERVICES

246 ALPHADRIVE

PITTSBURGH, PENNSYLVANIA 15238

(IN CANADA: 644 IMPERIAL ROAD, GUELPH, ONTARIO N1H 6M7)

W ARNING: FAILURE TO FOLLOWTHESE RULES

M AY RESULT IN SERIOUS PERSONALINJURY

1. FORYOUROWNSAFETY, READ INSTRUCTION

MANUALBEFORE OPERATING THE TO O L. Learn the

tool s application and limit ations as well as the specific

hazards peculiar to it.

2. KEEPGUARDSINPLACE and in working order.

3. ALWAYSWEAREYEPROTECTION.

4. REMOVEADJUSTING KEYSANDWRENCHES. Form

habit of checking to see that keys and adjusting wrenches are

removed from tool before turning it on.

5. KEEP WORKAREACLEAN. Cluttered areas and

benches invite accidents.

6. DON TUSEINDANGEROUSENVIRONMENT. Don t

use power tools in damp or wet locations, or expose them

to rain. Keep work area well-lighted.

7. KEEPCHILDREN AND VISITO R S A W AY . All children

and visitors should be kept a safe distance from work area.

8. MAKEWORKSHOPCHILDPROOF with p adlocks,

master switches, or by removing starter keys.

9. DON T FORCE TOOL. It will do the job better and be

safer at the rate for which it was designed.

10. USE RIGHT TOOL.Dontforce tool or att achment to do

a job for which it was not designed.

11. WEARPROPERAPPAREL.Noloose clothing, gloves,

neckties, rings, bracelets, or other jewelry to get caught in

moving parts. Nonslip footwear is recommended. Wear

protective hair covering to contain long hair.

12. ALW AYS USE SAFETY GLASSES.W ear safety glasses.

Everyday eyeglasses only have impact resist ant lenses;

they are not safety glasses. Also use face or dust mask if

cutting operation is dusty.

13. SECUREWORK. Use clamps or a vise to hold work

when practical. It s safer than using your hand and frees

both hands to operate tool.

14. DON TOVERREACH.Keep proper footing and balance

at all times.

15. MAINTAIN TOOLSINTOPCONDITION. Keep tools

sharp and clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

16. DISCONNECT TOOLS before servicing and when

changing accessories such as blades, bits, cutters, etc.

17. USERECOMMENDEDACCESSORIES. The use of

accessories and attachments not recommended by Delt a

may cause hazards or risk of injury to persons.

18. REDUCE THE RISK O F UNINTENTIONAL START-

IN G . Make sure switch is in OFF position before plugging

in power cord.

19. NEVER STAND O NTOOL. Serious injury could occur

if the tool is tipped or if the cutting tool is accident ally

contacted.

20. CHECKDAMAGEDPARTS. Before further use of the

tool, a guard or other part that is damaged should be care-

fully checked to ensure that it will operate properly and

perform it s intended function check for alignment of moving

parts, binding of moving parts, breakage of parts, mounting,

and any other conditions that may affect its operation. A

guard or other part that is damaged should be properly

repaired or replaced.

21. DIRECTION OF FEED.Feed work into a blade or cutter

against the direction of rot ation of the blade or cutter only.

22.

NEVERLEAVE TOOLRUNNING UNATTENDED. TURN

POWEROFF

. Don t leave tool until it comes to a complete

stop.

23. DRUGS, ALCOHOL, MEDICATION. Do not operate

tool while under the influence of drugs, alcohol or any

medication.

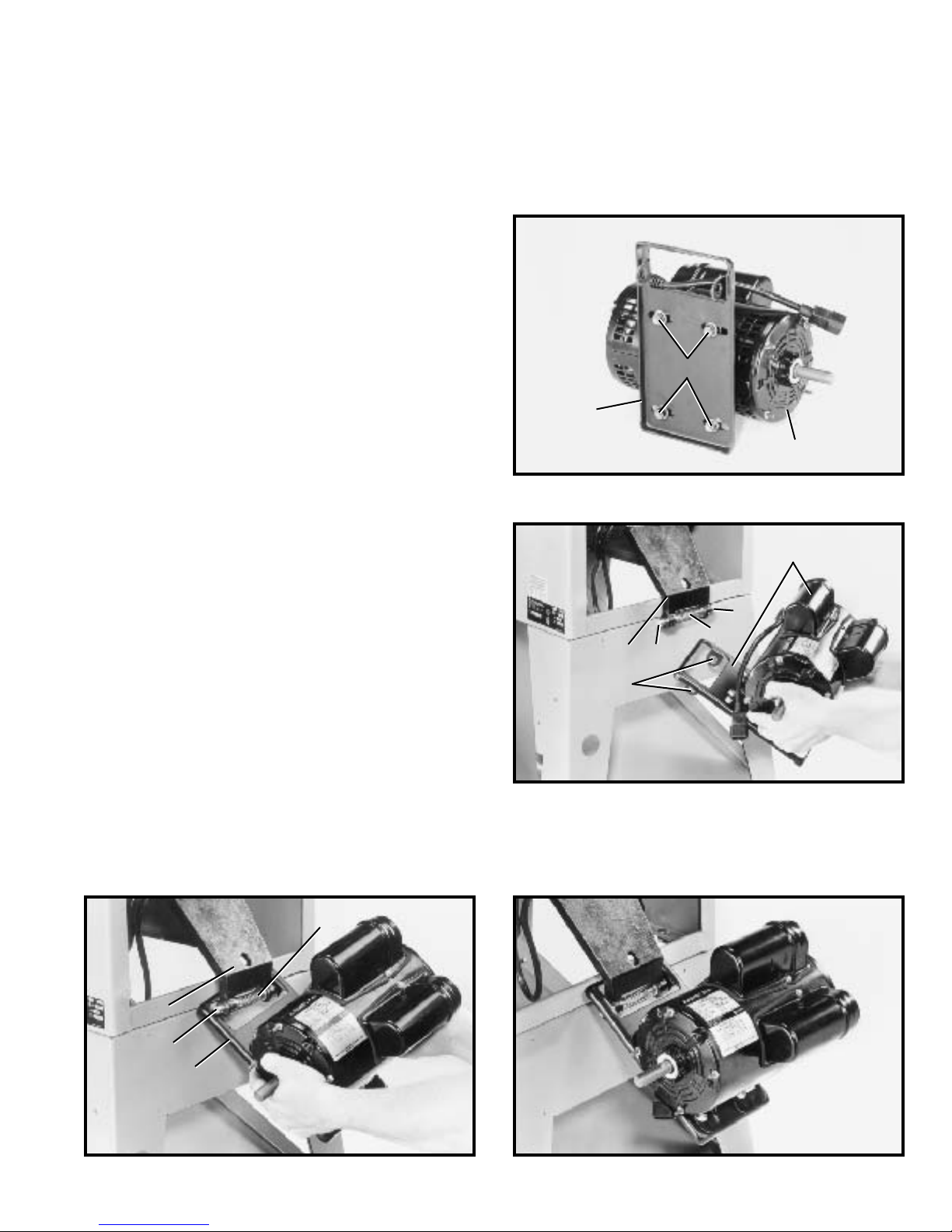

24. MAKESURETOOLIS DISCONNECTED FROM POWER

SUPPLY

while motor is being mounted, connected or re-

connected.

25. W ARNING: The dust generated by certain woods and

wood products can be injurious to your health. Always oper-

ate machinery in well ventilated areas and provide for proper

dust removal. Use wood dust collection systems whenever

possible.