Dema Electric D6 Series User manual

Thank you to choose inverter of DEMA Electric Co., Ltd.

D6 series inverter is the product developed by the DEMA Electric Co., Ltd, which is characterized with high

performance, multiple functions and high quality. They apply technology platform with high performance,

modular system structure and programmable units which make them with various application scope and

strong adaptability.

Errors in installation, wiring and operation may cause accidents, shorten the inverter’s life and degrade its

performance. Therefore the operators must carefully read and understand this manual before using the

inverter, master the right operation method.

This operation manual must be properly safekept by operator of the machine.

If you have any unclear problems during operation or excellent performance of the inverter isn’t played role,

please refer to this manual.

This manual is applicable to following members of D6 series:

D6B: General inverter with high functions, with open/close loop control, torque control and multiple-application

control mode (including PID, wobbling frequency etc), applicable to very extensive application field.

D6L: General light load type multi-functional inverter, open loop no PG vector control, applicable to light load

constant torque or fan pumps loading applications whose overload capacity demand isn’t high.

D6P: Flat plate through-wall installation type inverter, open loop no PG vector control, applicable to light load

constant torque or fan pumps loading applications whose overload capacity demand isn’t high.

Version number: 1.4

Date: 2013-10-24

DEMA electric cooperation is not responsible for the mistakes in this manual, and reserve the rights to renew

production without informing.

Attentions:

Please read this operation manual carefully, understand each contents, so that you can carry out right

installation, wiring, operation and maintenance.

Use inverter only after be familiar with knowledge, safe information and all attentions of the inverter..

This manual should be reserved by actual user.

The safety levels are divided into ―Danger‖ and ―Warning‖ in this manual, please use the following mark

respectively:

: It may cause death or serious injure of personnel if it isn’t operated according to

requirements.

: It may cause moderate damage or minor injuries of personnel, or property damage if it

isn’t operated according to requirements..

Please be sure to eep the contents marked with safety sign. Because the situation is different, items

marked by ―Warning‖ may also cause serious results, please follow these two level attentions.

English term and abbreviations

ASR: Automatic Speed Regulator

AVR: Automatic Voltage Regulation

AI: Analog Input

AO: Analog Output

DI: Digital Input

DO: Digital Output

EMI: Electric Magnetic Interference

LED: Light Emitting Diode

MOP: Motor Operated Potentiometer

PULS: Pulse Input

PYO: Pulse Frequency Output

PID: Proportional Integral Derivative

PG: Pulse Generator

PWM: Pulse Width Modulation

SVPWM: Space Vector Pulse Width Modulation

S.T.P: Speed, Torque, Position

Contents

1 SAFETY PRECAUTIONS ..............................................................................................................................................1

1.1 INSTALLATION........................................................................................................................................................1

1.2 WIRING..................................................................................................................................................................1

1.3 OPERATION............................................................................................................................................................1

1.4 MAINTENANCE ......................................................................................................................................................2

1.5 DISPOSAL...............................................................................................................................................................2

1.6 APPLICABLE SCOPE OF PRODUCT...........................................................................................................................2

2 INSTALLATION AND WIRING .....................................................................................................................................3

2.1 CHECK UPON DELIVERY..........................................................................................................................................3

2.2 NAMEPLATE DESCRIPTION.....................................................................................................................................3

2.3 TYPE DESCRIPTION ................................................................................................................................................3

2.4 INSTALLATION OF INVERTER ..................................................................................................................................4

2.4.1 AMBIENT CONDITION................................................................................................................................................. 4

2.4.2 INSTALLATION SITE..................................................................................................................................................... 4

2.4.3 INSTALLATION SPACE AND HEAT DISSIPATION .................................................................................................................... 4

2.4.4 APPEARANCE AND INSTALLATION SIZE............................................................................................................................ 5

2.5 REMOVAL AND INSTALLATION OF OPERATION KEYPAD .........................................................................................9

2.5.1 APPEARANCE AND SIZE OF OPERATION KEYPAD................................................................................................................. 9

2.5.2 APPEARANCE AND SIZE OF STANDARD OPERATION KEYPAD INSTALLATION BOX ......................................................................... 9

2.5.3 DIRECT INSTALLED TYPE OPERATION KEYPAD .................................................................................................................. 10

2.5.4 KEYBOARD INSTALLATION BOX WITH POTENTIOMETER AND RJ45 INTERFACE (OPTIONAL)........................................................ 10

2.5.5 INSTALLATION AND REMOVAL OF OPERATION KEYPAD ...................................................................................................... 11

2.5.6 INSTALLATION OF KEYPAD ON CABINET FRONT COVER....................................................................................................... 12

2.6 WIRING OF INVERTER ..........................................................................................................................................13

2.4.1 BASIC WIRING DIAGRAM OF INVERTER ......................................................................................................................... 13

2.4.2 WIRING SPECIFICATIONS ........................................................................................................................................... 14

2.4.3 MAIN CIRCUIT TERMINALS......................................................................................................................................... 15

2.4.4 CONTROL CIRCUIT TERMINALS.................................................................................................................................... 17

3 OPERATION DESCRIPTION OF INVERTER .................................................................................................................22

3.1 NAME AND DESCRIPTION OF EACH PART OF OPERATION PANEL .........................................................................22

3.1.1 APPEARANCE OF OPERATION PANEL............................................................................................................................. 22

3.1.2 DESCRIPTION OF KEY FUNCTION ................................................................................................................................. 22

3.1.3 DESCRIPTION OF LED DISPLAY FUNCTION......................................................................................................................22

3.1.4 UNITS INDICATION ...................................................................................................................................................23

3.1.5 RUN STATUS INDICATIONS..........................................................................................................................................23

3.2 DISPLAY STATUS OF OPERATION KEYPAD OF INVERTER ........................................................................................23

3.2.1 STOP STATUS ..........................................................................................................................................................23

3.2.2 RUN STATUS ...........................................................................................................................................................23

3.2.3 ABNORMAL STATUS..................................................................................................................................................24

3.2.4 PARAMETER EDITING STATUS ......................................................................................................................................24

3.2.5 PASSWORD CHECK STATUS .........................................................................................................................................24

3.3 OPERATION OF OPERATION PANEL ......................................................................................................................24

3.3.1 INVERTER MONITORING PARAMETERS SWITCH................................................................................................................24

3.3.3 SPEED ADJUST ........................................................................................................................................................25

3.4 OPERATION OF CONTROL TERMINALS .................................................................................................................25

3.4.1 STATUS MONITORING OF DIGITAL CONTROL TERMINALS ....................................................................................................25

3.4.2 RUN OPERATION .....................................................................................................................................................25

3.5 JOG RUN OPERATION MODE OF INVERTER ..........................................................................................................26

3.6 SWITCHING ON THE POWER FOR THE FIRST TIME................................................................................................26

3.7 COMMISSIONING GUIDE......................................................................................................................................26

3.7.1 SETTING COMMON PARAMETERS OF EACH CONTROL MODE...............................................................................................27

3.7.2 QUICK COMMISSIONING FOR V/F CONTROL OF ELECTRIC MOTOR .......................................................................................27

3.7.3 QUICK COMMISSIONING FOR VECTOR CONTROL OF ELECTRIC MOTOR ..................................................................................27

4 DESCRIPTION OF FUNCTION PARAMETERS AND SETTING .......................................................................................28

4.1 ENVIRONMENT AND PARAMETERS MANAGEMENT .............................................................................................28

4.2 SPEED (FREQUENCY) LIMITATION.........................................................................................................................31

4.3 BASIC FREQUENCY ...............................................................................................................................................31

4.4 V/F CURVE ...........................................................................................................................................................32

4.5 TORQUE COMPENSATION ....................................................................................................................................33

4.6 VECTOR CONTROL CURRENT LOOP AND ROTATION DIFFERENTIAL COMPENSATION ............................................34

4.7 START AND STOP..................................................................................................................................................34

4.8 ACCELERATION AND DECELERATION ....................................................................................................................37

4.9 LOCKING THE OPERATION DIRECTION..................................................................................................................39

4.10 SPEED DETECTION..............................................................................................................................................39

4.11 BRAKE UNIT .......................................................................................................................................................40

4.12 DANGEROUS SPEED ...........................................................................................................................................41

4.13 ANALOG INPUT TERMINALS...............................................................................................................................41

4.14 ANALOG OUTPUT TERMINALS ...........................................................................................................................45

4.15 DIGITAL INPUT TERMINALS ................................................................................................................................46

4.16 DIGITAL OUTPUT TERMINALS ............................................................................................................................51

4.17 TWO/THREE-LINE OPERATION CONTROL ...........................................................................................................54

4.18 SPEED CONTROL OPERATION MODE ..................................................................................................................56

4.19 TORQUE CONTROL OPERATION MODE ..............................................................................................................59

4.20 PROCESS PID CONTROL......................................................................................................................................63

4.21 WOBBLE FREQUENCY......................................................................................................................................... 68

4.22 ASR (SPEED REGULATOR AND CURRENT REGULATOR) .......................................................................................71

4.23 AVR FUNCTION ..................................................................................................................................................73

4.24 STALL PREVENTION ............................................................................................................................................ 74

4.25 THE DROOP MECHANICAL CHARACTERISTIC ...................................................................................................... 76

4.26 FAULT AUTO RESET ............................................................................................................................................77

4.27 CARRIER AND MODULATION .............................................................................................................................77

4.28 COOLING FAN CONTROL ....................................................................................................................................79

4.29 RESTART AFTER MOMENTARY POWER STOP......................................................................................................80

4.30 INVERTER AND MOTOR PROTECTION ................................................................................................................81

4.31 POWER LIMIT.....................................................................................................................................................84

4.32 MOTOR PARAMETERS AND AUTO-TUNING........................................................................................................84

4.33 SLIP FREQUENCY COMPENSATION .....................................................................................................................86

4.34 ENCODER ...........................................................................................................................................................86

4.35 PROGRAMMABLE UNIT......................................................................................................................................88

4.36 SERIAL COMMUNICATION .................................................................................................................................93

4.37 MULTI-MODE PLC PARAMETERS ........................................................................................................................94

5 SERIAL COMMUNICATION PROTOCOL.....................................................................................................................98

5.1 GENERAL DESCRIPTION........................................................................................................................................98

5.2 MODBUS FUNCTIONS SUPPORTED BY THE DRIVE................................................................................................98

5.3 TABLE OF COMMUNICATION VARIABLES............................................................................................................ 102

6 INVERTER MAINTENANCE.....................................................................................................................................106

6.1 DAILY MAINTENANCE ........................................................................................................................................ 106

6.2 PERIODICAL MAINTENANCE .............................................................................................................................. 106

6.3 INSULATION TEST .............................................................................................................................................. 107

6.4 REPLACEMENT OF PARTS ................................................................................................................................... 107

7 INVERTER OPERATION FAULTS AND REMEDIES ..................................................................................................... 109

7.1 OPERATION FAULTS AND REMEDIES................................................................................................................... 109

7.2 INVERTER FAULT DISPLAY AND REMEDIES..........................................................................................................109

8 PERIPHERAL DEVICES............................................................................................................................................ 114

8.1 CONNECTING DIAGRAM OF PERIPHERAL DEVICES ............................................................................................. 114

8.2 DESCRIPTION OF ACCESSORIES .......................................................................................................................... 115

8.2.1 NOISE FILTER........................................................................................................................................................115

8.2.2 CURRENT-LEAK PROTECTOR......................................................................................................................................115

8.2.3 BRAKING RESISTOR ................................................................................................................................................115

8.2.4 AC REACTOR ........................................................................................................................................................116

8.2.5 DC REACTOR ........................................................................................................................................................116

8.2.6 EXTENDED CABLE ..................................................................................................................................................117

9 STANDARD SPECIFICATIONS ..................................................................................................................................118

9.1 STANDARD SPECIFICATIONS ...............................................................................................................................118

9.2 COMMON FEATURE ........................................................................................................................................121

10 FUNCTION PARAMETER ......................................................................................................................................123

11 GUARANTEE AND SERVICE ..................................................................................................................................158

PROTECTION TO FIX CARD .......................................................................................................................................159

1 Safety Precautions

1

1 Safety Precautions

You must carefully read the following contents before installation, wiring, operation and maintenance of the

product, and operate strictly according to notes.

1.1 Installation

Install the inverter on a nonflammable object such as metal etc. Otherwise, there may be a risk of fire.

Do not install the inverter in an environment with inflammable gases which may cause explosion.

Install the inverter firmly on an object capable of bearing its weight. Otherwise, the falling of the inverter may cause injury or

damage of human or equipment..

Do not drop any metal foreign matter in the inverter. Otherwise, accident may occur.

Do not install or run the inverter if it is damaged. Otherwise, accident may occur.

1.2 Wiring

Connect a proper circuit-breaker which matches capacity of the inverter on the input power side of the inverter. Otherwise,

human injury, equipment damage or other accident may occur.

The PE terminal of the inverter must be grounded securely. Otherwise, electric shock or fire may occur.

Tighten up power input terminal of power supply and motor input terminal screw. Otherwise, there may be a fire accident.

The wiring must be done by a qualified personnel.

The wiring must be done after the power is cut off and the high-voltage indicator extinguishes.

The input power must conform to the specifications on the nameplate. Otherwise, the inverter may be damaged.

Never connect the output terminals (U, V, W) to the input power. Otherwise it may destroy the inverter.

1.3 Operation

1 Safety Precautions

2

Only when the cover board has been attached, the power can be switched on. Otherwise, there may be a risk

of electric shock.

Do not touch main circuit terminal of the inverter when electrical power is going to the inverter even if the

inverter is in stop state. Otherwise, there may be a risk of electric shock.

Us operation panel ―STOP/RESET‖ key and external controlled terminal to stop the inverter, but not break the main power

supply. otherwise, the inverter may be damaged.

1.4 Maintenance

10 minutes after power is switched off, the inverter can be inspected and repaired. Otherwise, there may be a risk of electric

shock or injury.

Only professional person can maintain the inverter. Otherwise, electric shock or injury may occur.

Do not leave any conductor such as metals in the inverter after repairing it. Otherwise, the inverter may be damaged.

While an inverter which has not been used for a long period is used again, use a voltage regulator to charge the input voltage

gradually until it reaches the rated value, and wait for a while and confirm it is safe. Otherwise, accident may occur.

1.5 Disposal

When the product is discarded, dispose it as an industrial waste. Otherwise, accident may occur.

1.6 Applicable scope of product

Not apply to the machine or system which may cause life danger of human .

If this product is expected to abnormality of this product will occur a major accident or loss, please be sure to add safety device.

2 Installation and Wiring

3

2 Installation and Wiring

2.1 Check upon delivery

Please check the following items when the inverter is firstly packed:

◆ Whether the product is damaged during shipping.

◆ Read data on the nameplate conform whether type and specification of the product are in accordance with

your order.

◆ Check whether the accessories shipped together with the inverter are complete.

The company strictly develops and manufactures the inverter according to ISO9001, if found to have some

unusual, please contact and agent or agent as soon as possible.

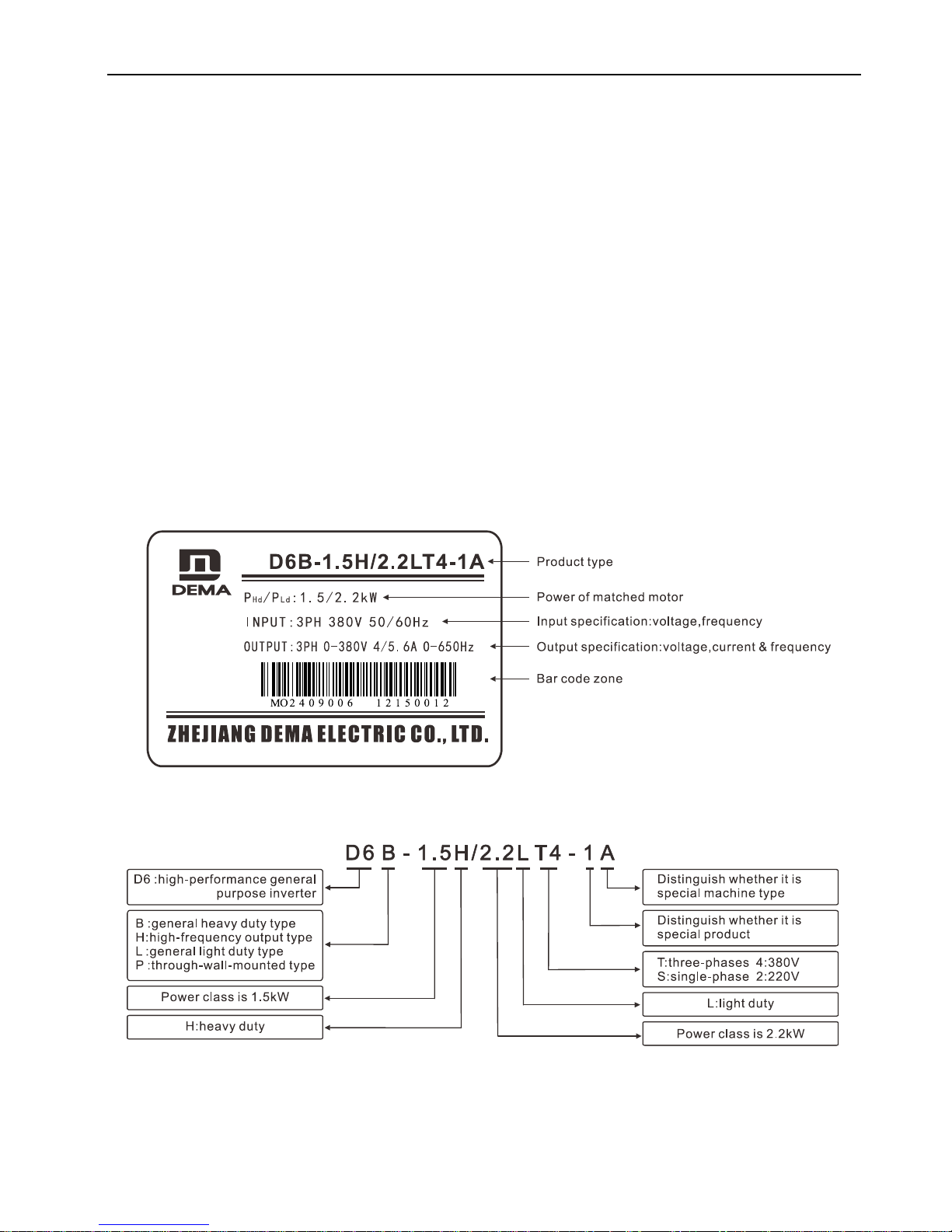

2.2 Nameplate description

2.3 Type description

2 Installation and Wiring

4

2.4 Installation of inverter

2.4.1 Ambient condition

Environment temperature range of inverter: -10℃~50℃. When the ambient temperature is higher than

50℃, please choose well ventilated place and decrease the inverter by 10% for every 5℃ increment.

2.4.2 Installation site

◆No corrosive, flammable or explosive gases or liquids.

◆Humidity: less than 90% RH, no condensation.

◆Vibration: less than 5.9m/s2 (0.6g)

◆Avoid installing it at a place with much dust and metal powder

If users have special installation requirements, please consult and confirm with manufacturer in advance.

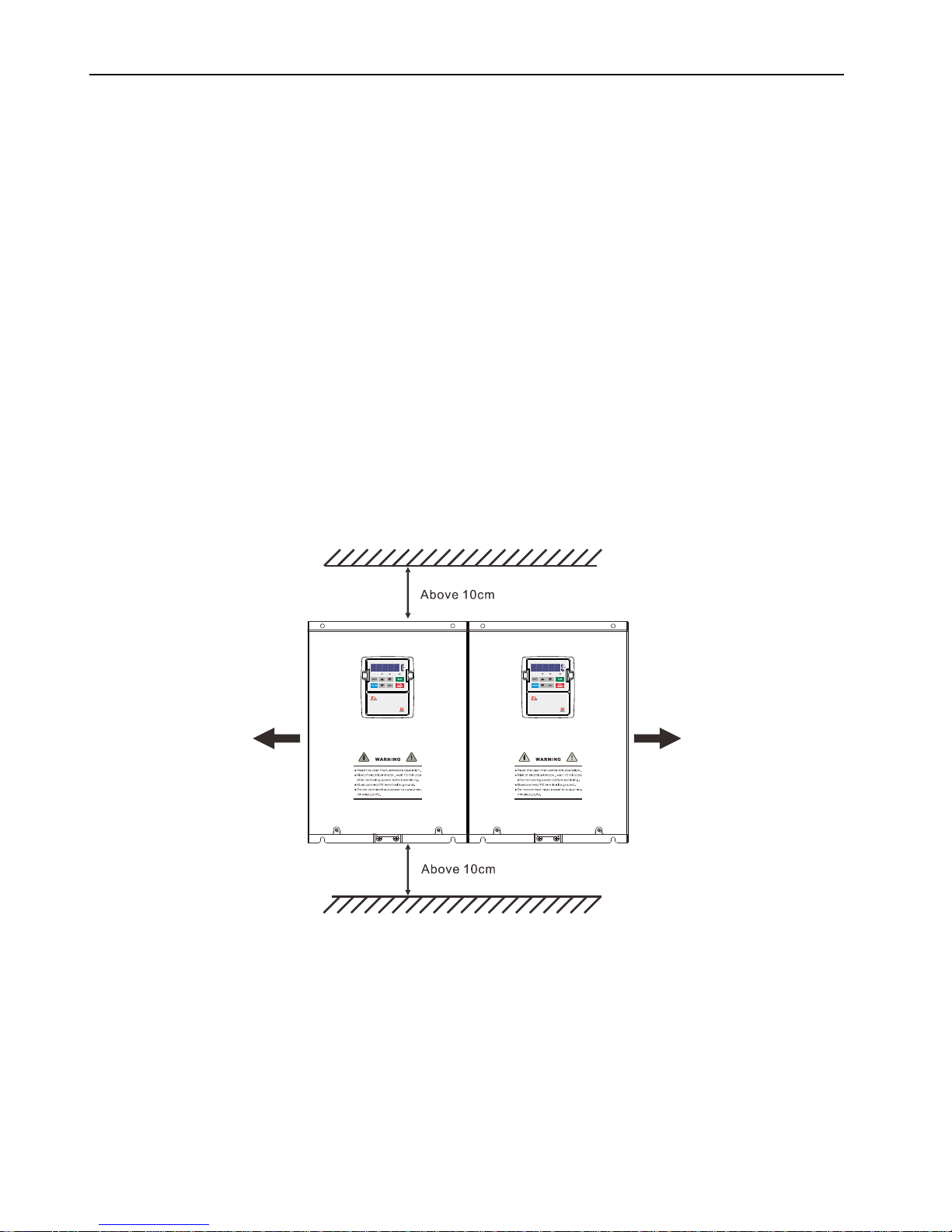

2.4.3 Installation space and heat dissipation

The inverter will create heat during operating. In order to ensure good cooling effect, it must be installed

vertically. The converter cooling duct export is available at the base for cold air entrance, to facilitate the

cooling air circulation flow, top and bottom of converter adjacent to the object must meet the minimum

requirements of the distance, as shown below: D6B/L/P series converter can be installed without clearance

side by side direction .

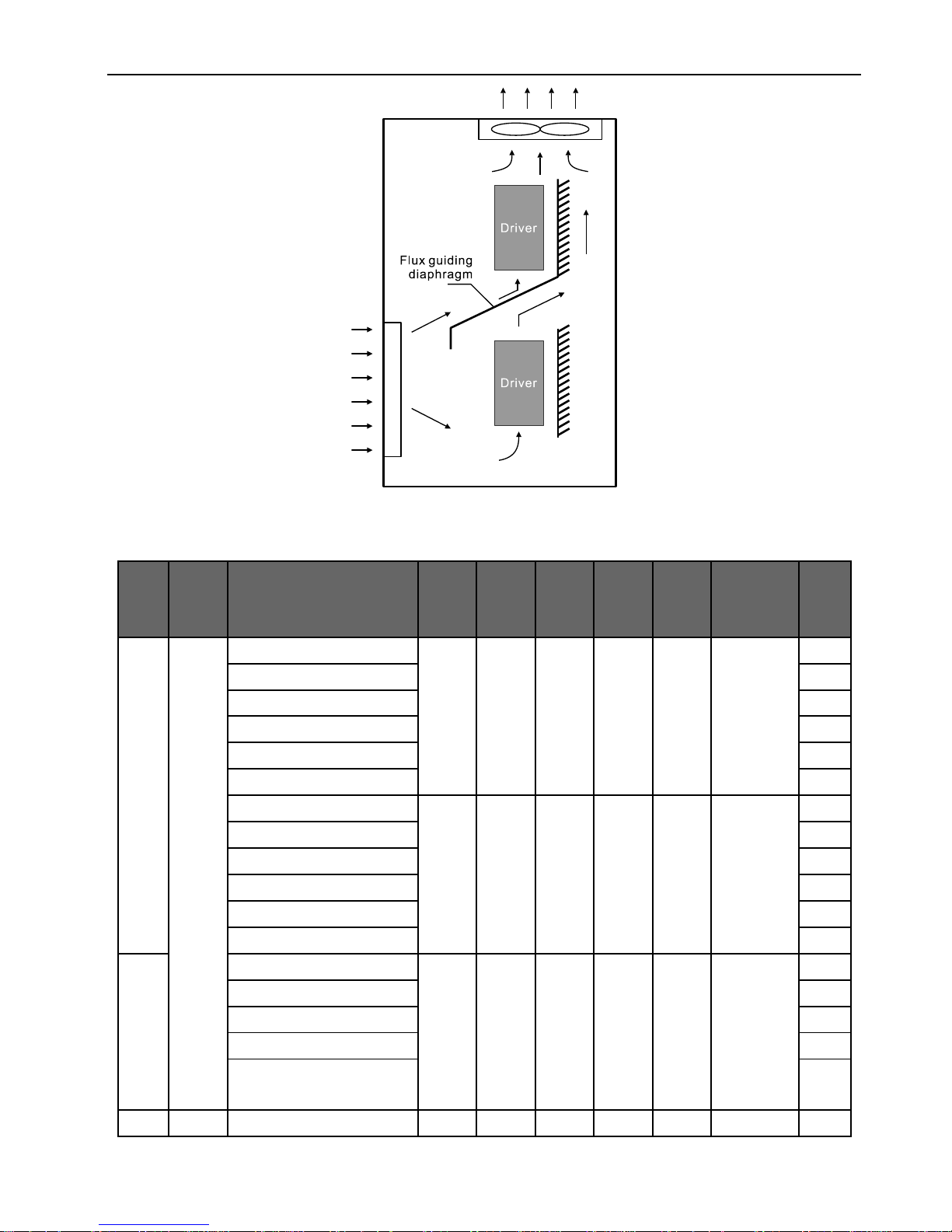

When several inverters are installed in one equipment or control box, horizontal arrangement is

recommended to minimize the mutual thermal influence. If the inverters have to be installed in a vertical row, a

separating board should be provided to prevent the heat from the lower inverter affecting the upper one. If the

cabinet has exhaust fans on its top, the air flow of the fans must be greater than the total out flow of all

inverters. For cabinets without exhaust fans, the top should be left open if possible, if not possible, the area of

the air vents (inlets & outlets) on the top and bottom of the cabinet must be greater than the total area of the

up & down surfaces of individual inverters, and the wind resistance at air vents should be kept as small as

possible.

If the inverter is installed on the wall of a control room, the room should have good ventilation. Installation

methods are shown as following:

2 Installation and Wiring

5

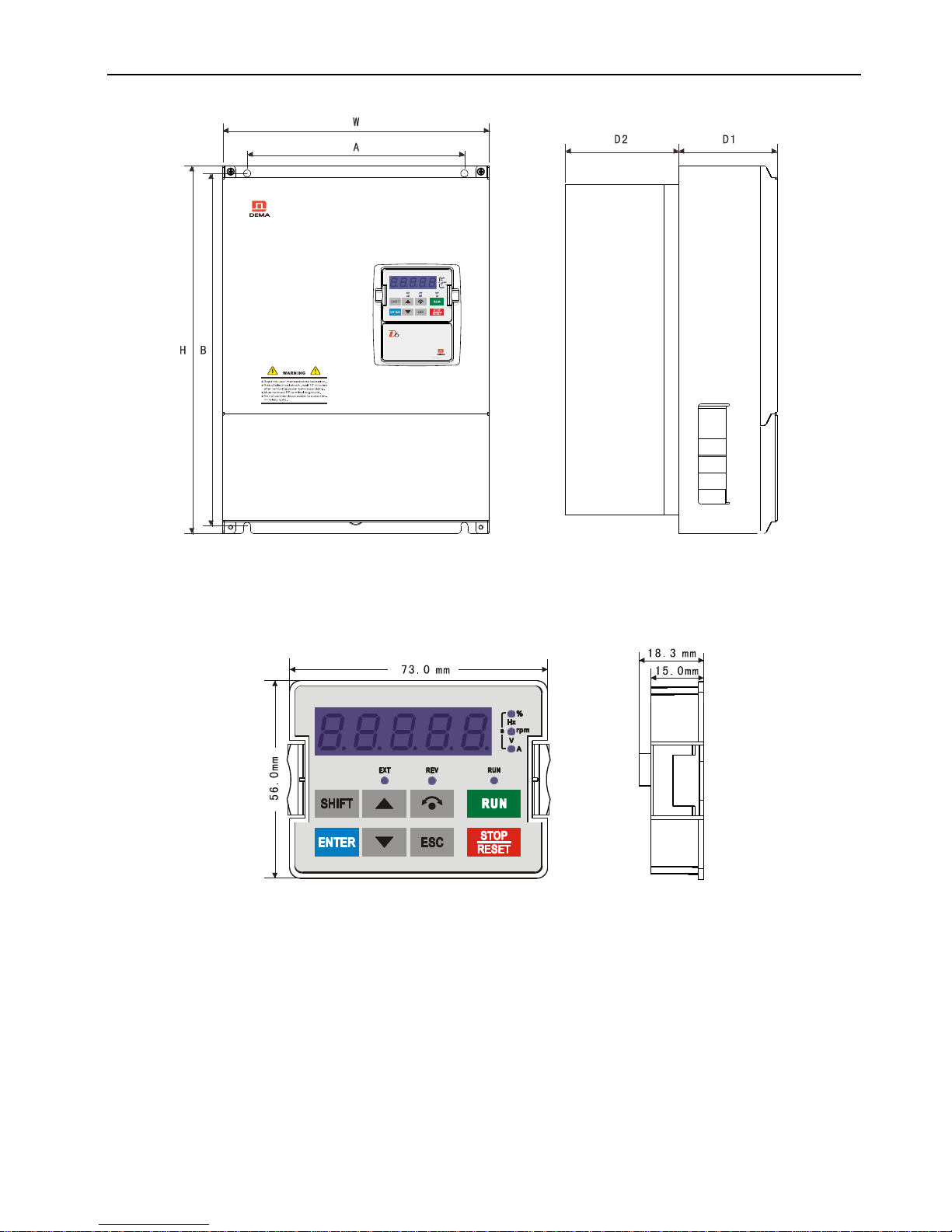

2.4.4 Appearance and installation size

Outline size and approximate weight of inverter:

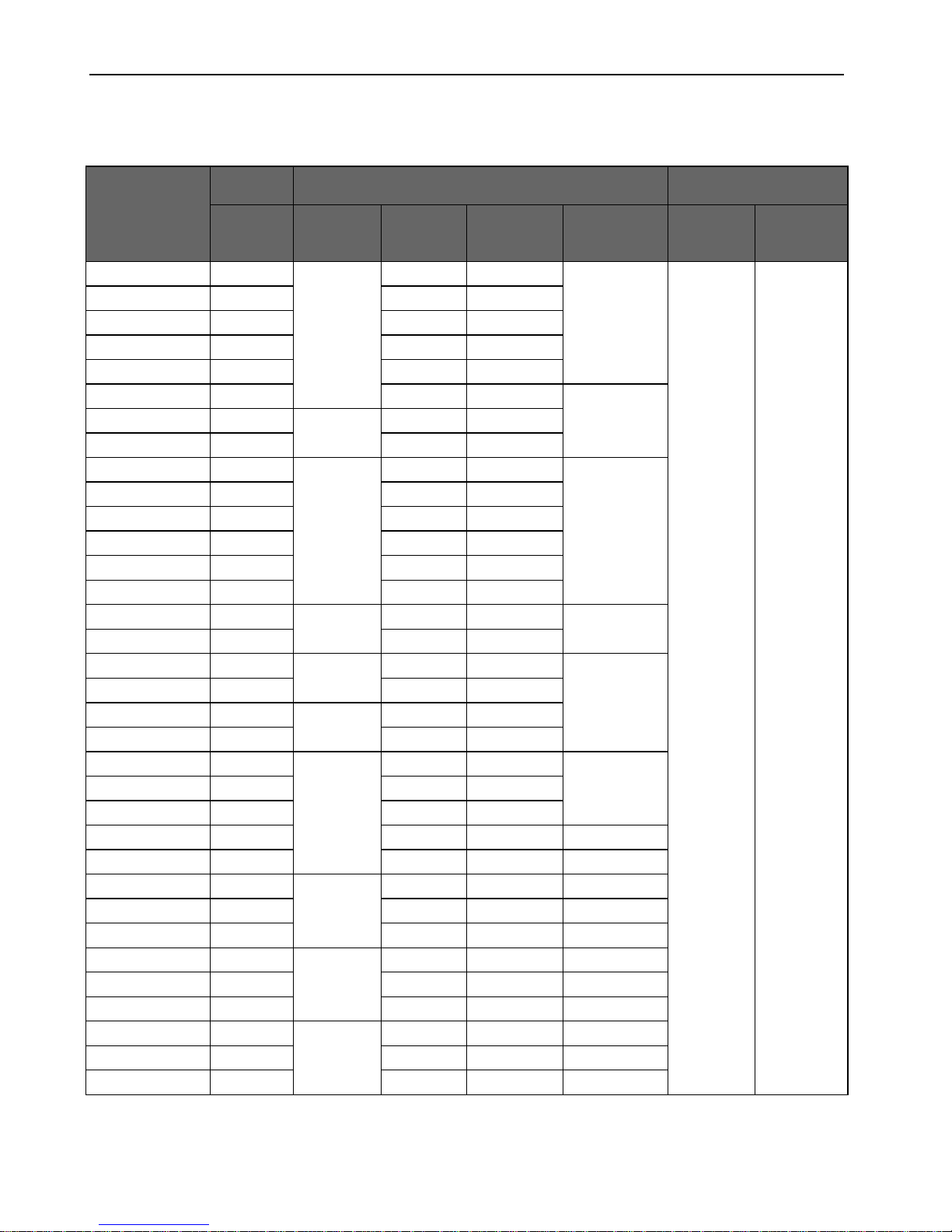

Code

of box

body

Outline

Inverter type

W

(mm)

H

(mm)

D

(mm)

A

(mm)

B

(mm)

Diameter of

installation

hole(mm)

W

(kg)

F0

A

D6B-0.4S2

128

266

168

100

255

6.5

3.8

D6B-0.75S2,D6B-0.75T4

4.2

D6B-1.1S2,D6B-1.1T4

4.4

D6B-1.5T4

4.6

D6B-2.2T4

4.7

D6B-3.0T4

5.0

D6L-0.75T4

128

266

143

100

255

6.5

4.2

D6L-1.1T4

4.4

D6L-1.5T4

4.6

D6L-2.2T4

4.7

D6L-3.0T4

5

D6L-4.0T4

5.2

F1

D6B-1.5S2,D6H-1.5T4

128

276

188

100

265

6.5

4.6

D6B-2.2S2,D6H-2.2T4

4.7

D6B-3.0S2,D6H-3.0T4

5.0

D6B-4.0T4,D6L-5.5T4

5.3

D6B-5.5T4,D6H-4.0T4,

D6L-7.5T4

5.5

F2

B

D6B-4.0S2

176

280

201

140

270

6.5

5.3

2 Installation and Wiring

6

Code

of box

body

Outline

Inverter type

W

(mm)

H

(mm)

D

(mm)

A

(mm)

B

(mm)

Diameter of

installation

hole(mm)

W

(kg)

D6B-7.5T4,D6H-5.5T4

7.0

D6B-11T4,D6H-7.5T4

8.0

D6L-11T4

7.1

F3

D6B-15T4,D6H-11T4,

D6L-18.5T4

220

330

198

150

319

6.5

10

D6B-18.5T4,D6H-15T4,

D6L-22T4

11.2

D6L-15T4

9.7

F4

D6B-22T4,D6H-18.5T4

282

390

200

230

376

7

15.3

D6B-30T4,D6H-22T4,D6L-37T4

16

D6L-30T4

15.2

F5

D6B-37T4,D6H-30T4,D6L-45T4

380

410

248

280

390

11

28

D6B-45T4,D6B-55T4,

D6H-37T4,D6L-55T4,D6L-75T4

30

F6

D6B-75T4,D6L-90T4

390

600

266

300

580

11

43

D6B-90T4,D6L-110T4

46

F7

D6B-110~/160T4

465

806

329

306

780

11

*

D6L-132~/200T4

F8

C

D6B-200~/315T4

633

988

364

309

965

13

*

D6L-220~/355T4

F9

D6B-355T4,D6B-400T4

800

2093

630

*

*

*

*

D6L-400~/500T4

Code

of box

body

Outline

Inverter type

W

(mm)

H

(mm)

D1

(mm)

D2

(mm)

A

(mm)

B

(mm)

Diameter of

installation

hole(mm)

W

(kg)

F1

D

D6P-7.5T4,

176

280

114

103

140

270

6.5

5

D6P-11T4,

6

F2

D6P-15T4,D6P-18.5T4,

220

330

104

103

150

319

7.5

10

F2L

D6P-15T4,D6P-18.5T4,

220

380

104

80

150

369

7.5

10

F3

D6P-22T4,D6P-30T4,

282

390

104

120

230

376

7.5

14.8

F3L

D6P-22T4,D6P-30T4,

282

430

112

90.5

230

415

7.5

14.8

F4

D6P-37T4,D6P-45T4,D6P-55T4

380

410

139

129

280

390

12.0

26

2 Installation and Wiring

7

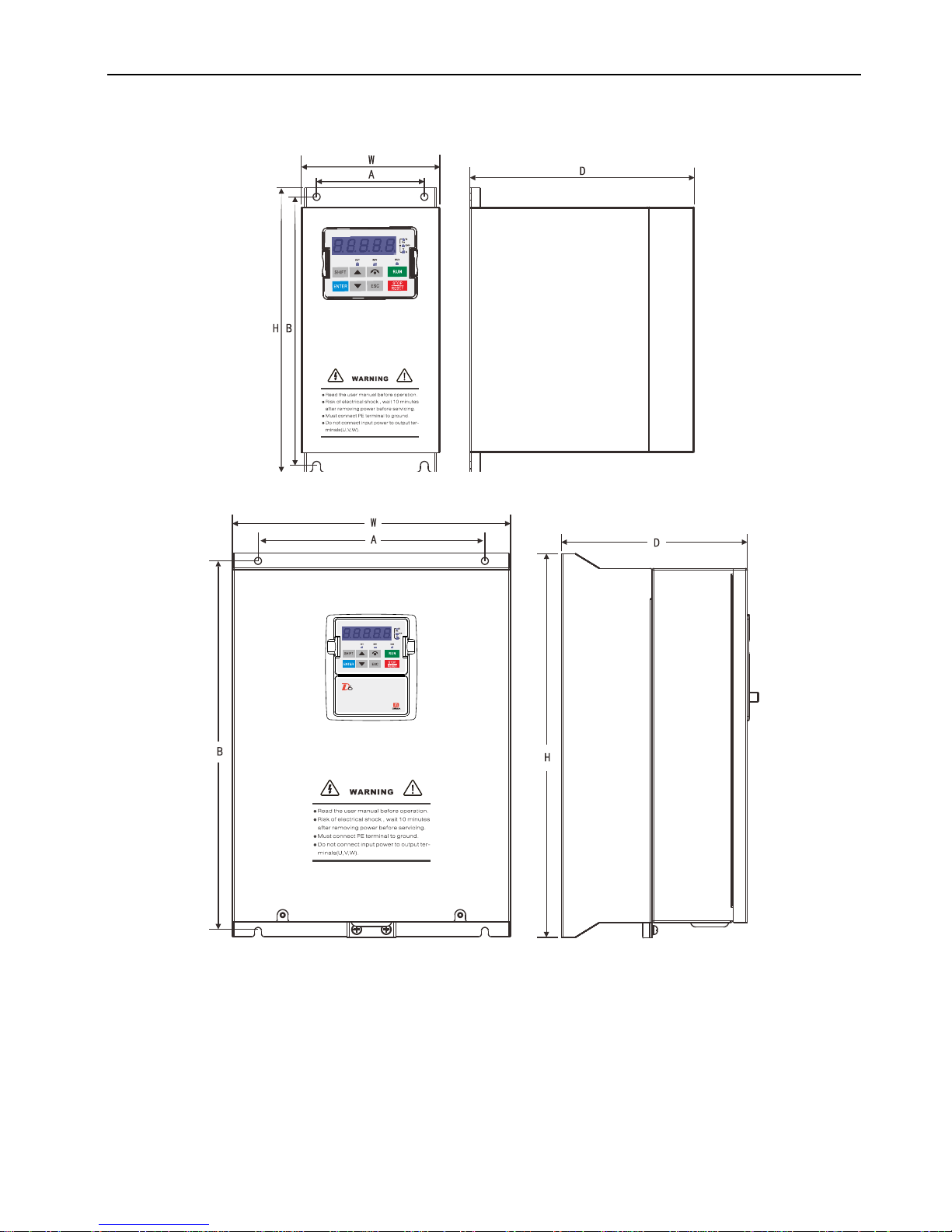

Appearance A:

Appearance B:

2 Installation and Wiring

8

Appearance C:

2 Installation and Wiring

9

Appearance D:

2.5 Removal and installation of operation keypad

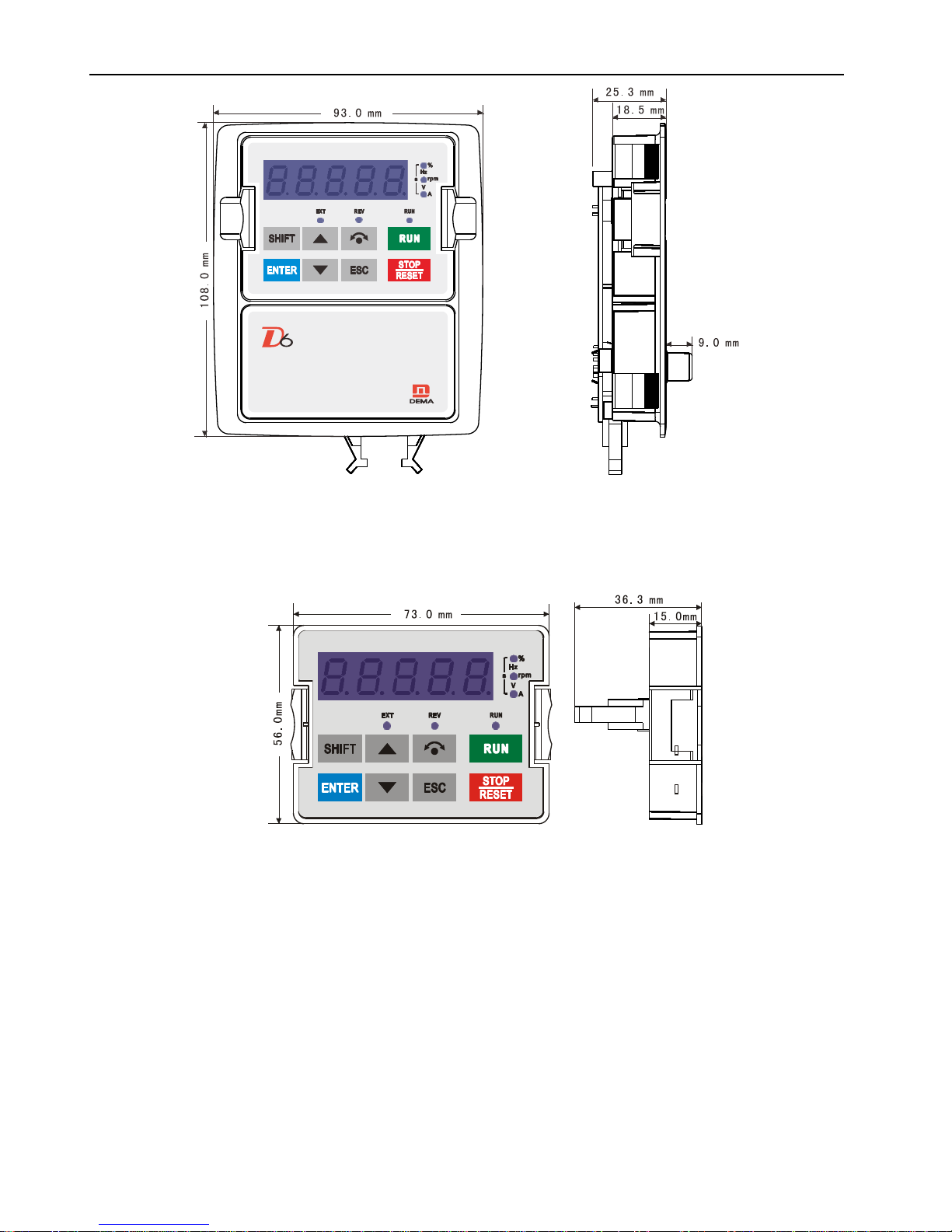

2.5.1 Appearance and size of operation keypad

2.5.2 Appearance and size of standard operation keypad installation box

The keypad box is generally used on motor which power is more than 15kW, it is also used on the installation

operation keypad of the cabinet. The installation box of the operation keypad is connected with the control

board of the inverter through extension line, the operation keypad can be purchased from the company

independently.

2 Installation and Wiring

10

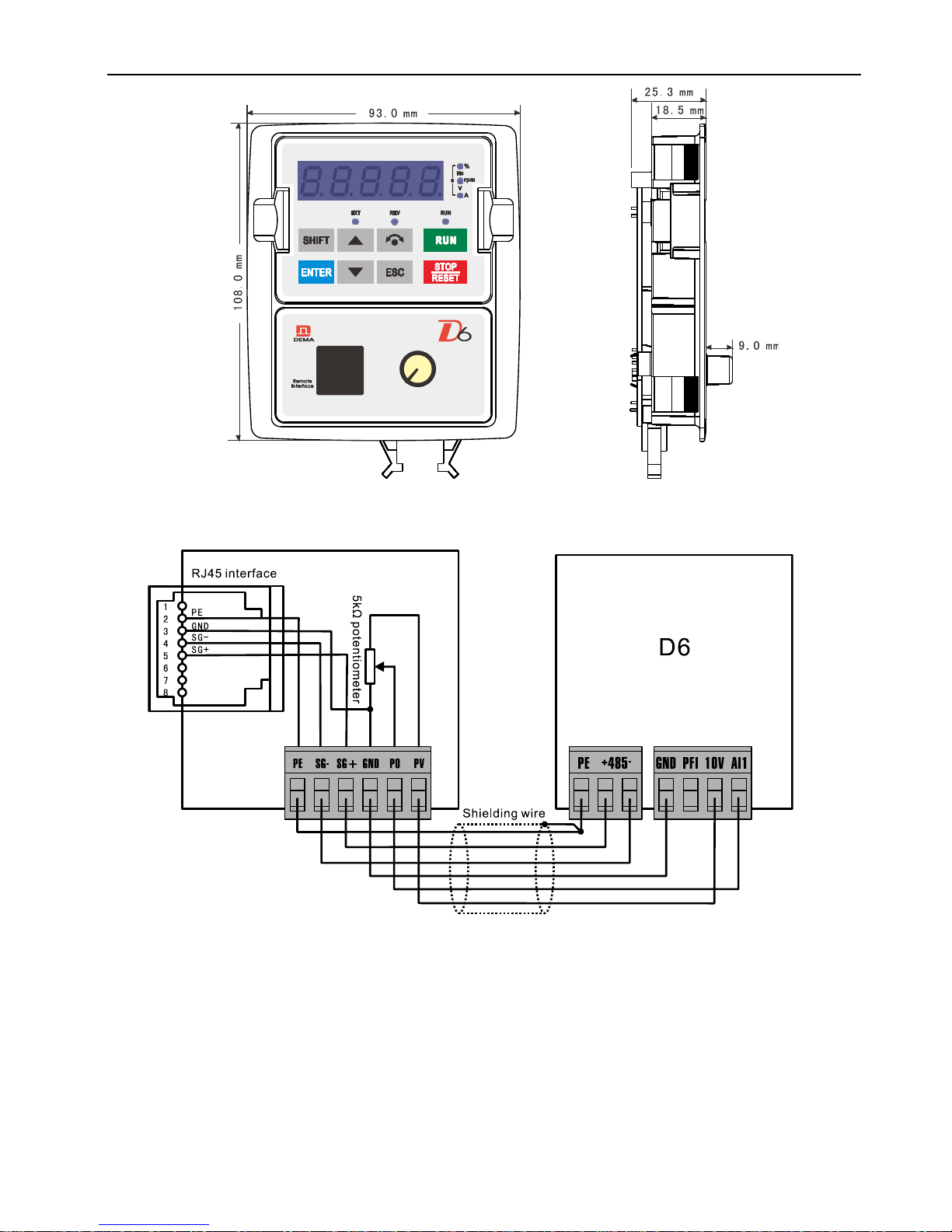

2.5.3 Direct installed type operation keypad

Direct installed type operation keypad is directly installed on the keypad of the machine cabinet and not be

installed through the installation box.

Appearance size figure:

The customer can get special extension line and control panel for connection of direct installed type operation

panel on request.

2.5.4 Keyboard installation box with potentiometer and RJ45 interface (Optional)

The customer may order keyboard installation box with potentiometer and RJ45 interface from the company

as Optional.

Appearance size figure:

2 Installation and Wiring

11

The installation box shall be connected with the control board with 6 cores cables and control board, shown as

following figure:

2.5.5 Installation and removal of operation keypad

◆ Removal

Place finger on clamp parts at left and right of the operation panel, impose force upward from the middle at

same time and pull out the operation keypad.

Installation

Place the operation panel into to groove of the installation box flat, properly press into the operation panel by

force.

2 Installation and Wiring

12

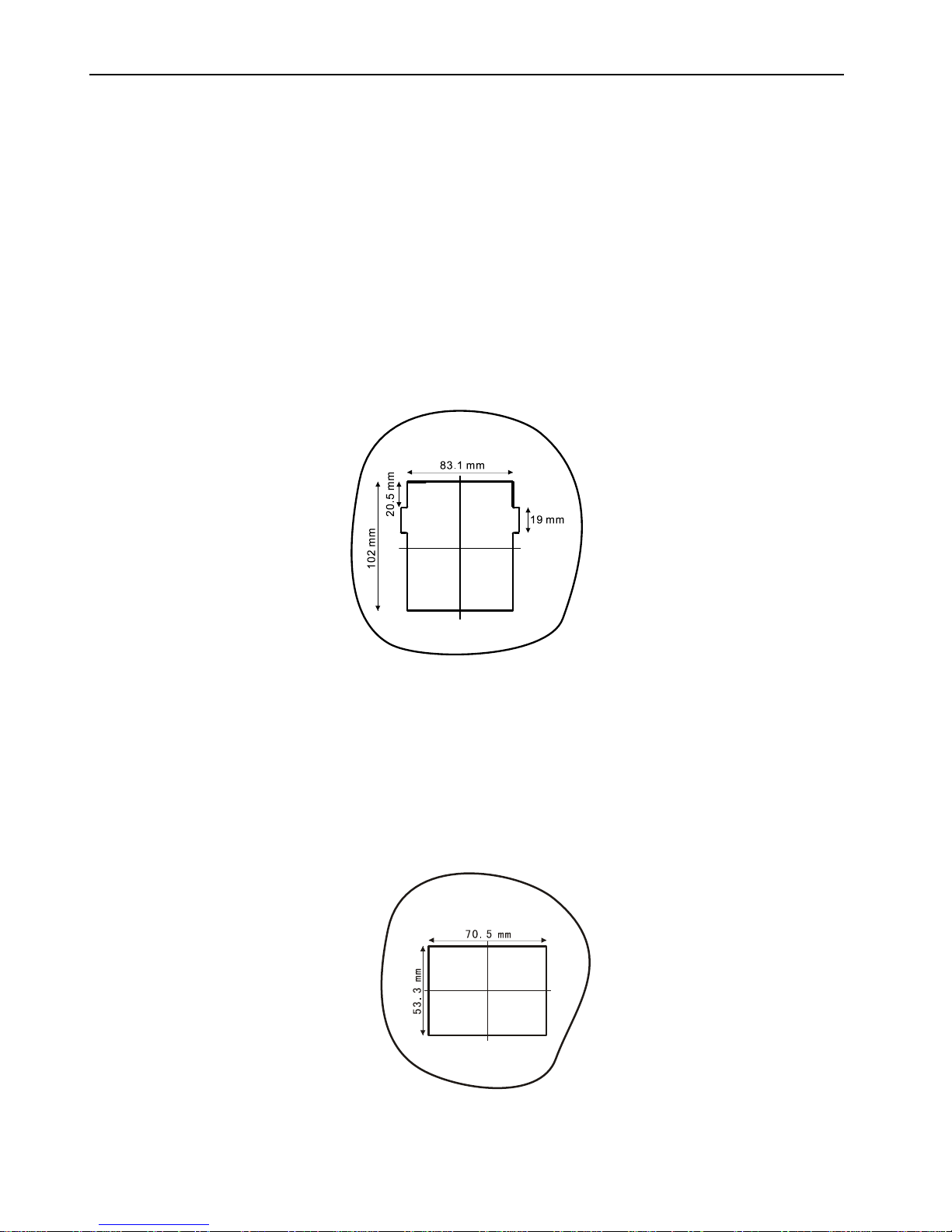

2.5.6 Installation of keypad on cabinet front cover

The keypad of D6B/L inverter can be taken off from the inverter and installed on the front cover of the cabinet,

the keypad and inverter are connected by the extension line (Manufacturer can offer specifications of 1.5

meters ~ 30m). You can choose any one of the following two installing methods.

Method 1: installed through installation box on the operation panel (the installation box can be ordered from

the company independently):

① Drill a hole in the cabinet panel. according to the following drawing;

②Install installation box of the operation panel on the panel of the machine cabinet;

③Take off the operation panel from the inverter and install in on the installation box;

④ Insert one end of the extension line into the keypad, insert the other end of the extension line into the

corresponding slot on the inverter circuit board.

Method 2: direct installation:

This method must use direct installed type operation panel and matched extension wire. The customer may

claim or order from the company, take installation of operation panel of the inverter which power class is 22kW

and below as sample:

Make an opening on the panel of the machine cabinet according to the following drawing.

Directly clamp the direct installed type operation panel on the panel of the machine cabinet.

Insert one end of the extension line into the keypad and the other end into the corresponding slot on the

inverter circuit board.

2 Installation and Wiring

13

2.6 Wiring of inverter

2.4.1 Basic wiring diagram of inverter

The user must properly connect according to following basic wiring diagrams, user can choose the control

terminal according to demand.

2 Installation and Wiring

14

2.4.2 Wiring specifications

Selection of copper-core insulation wires and incoming breaker (parameters in table are recommended

value):

Inverter model

Incoming

switch

Main circuit

Control circuit

circuit

breaker

(A)

Terminals

screws

Input

cable

(mm2)

Output

cable

(mm2)

Grounding

cables(mm2)

Terminals

screws

Control

cable

(mm2)

D6□-002S2

5

M3

2.5

1.5

2.5

M3

1

D6□-004S2

5

2.5

1.5

D6□-008S2

10

2.5

1.5

D6□-1.1S2

10

2.5

2.5

D6□-1.5S2

20

4

2.5

D6□-2.2S2

20

6

6

4

D6□-3.0S2

25

M4

6

6

D6□-4.0S2

32

10

10

D6□-0.8T4

5

M3

2.5

1.5

2.5

D6□-1.1T4

5

2.5

1.5

D6□-1.5T4

10

2.5

1.5

D6□-2.2T4

10

2.5

2.5

D6□-3.0T4

20

2.5

2.5

D6□-4.0T4

20

4

4

D6□-5.5T4

32

M4

4

4

4

D6□-7.5T4

40

6

6

D6□-11T4

63

M5

6

6

6

D6□-15T4

63

6

6

D6□-18.5T4

100

M6

10

10

D6□-22T4

100

16

16

D6□-30T4

125

M8

25

25

16

D6□-37T4

160

25

25

D6□-45T4

200

35

35

D6□-55T4

200

35

35

25

D6□-75T4

250

70

70

35

D6□-90T4

315

M10

70

70

70

D6□-110T4

400

95

95

70

D6□-132T4

400

150

150

95

D6□-160T4

630

M12

185

185

95

D6□-200T4

630

240

240

95

D6□-220T4

630

150×2

150×2

150

D6□-280T4

800

M16

150×2

150×2

150

D6□-315T4

1000

185×2

185×2

150

D6□-400T4

1200

240×2

240×2

150

Table of contents

Popular Inverter manuals by other brands

Xantrex

Xantrex FREEDOM SW 3000 owner's guide

Peak Scientific

Peak Scientific Genius 1022 user manual

Veikong

Veikong VFD700 Series Operation manual

Case IH

Case IH BC12000ER Operation manual

Black & Decker

Black & Decker BDI200 instruction manual

Hobart

Hobart 60CU24 Operation and maintenance manual with illustrated parts list