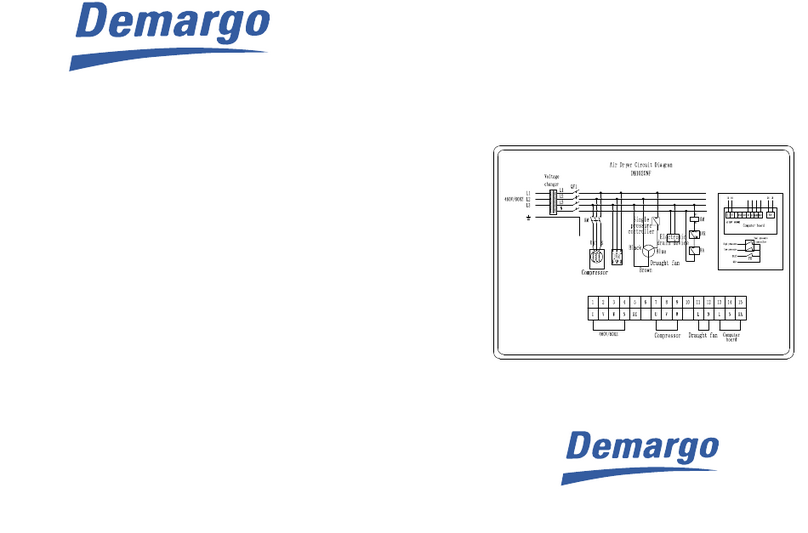

REFRIGERATED COMPRESSED AIR DRYER

Notice

1. Note:

If the evaporating pressure gauge exceeds 7KG during working,

it may be over-loaded, please check the over-loaded conditions

as bellows.

2. Loading conditions:

It will go to over loaded under the following conditions and run

constrainedly. Then it will stop running when the protector “orange”

indicators light.

1). Compressed air temperature is excessive.

2). Compressed air capacity is exceeded.

3). Ambient temperature is higher than 13 .1℉

4). Voltage under 198V (220V rated) or under 340V (380V rated).

5). Badness of thermolysis.

3. Attention:

The auto-drain may not act as there's some impurity contained in the

compressed air, please check if there's condensate water coming out

from the draining hole everyday. According to the characteristic and

structure of drain, it may drain out from the draining hole provide the

2

pressure is under 1.5kg/cm . Therefore, the pressure may not be raised

if gas production of air compressor is too small. Please pay attention to it.

Troubleshooting

Familiar faults caused by the refrigerated air dryer itself and external

factors conditions as well as its trouble-shooting as follows:

Pressure drop is excessive

The differential pressure is too

large of the whole air compression

station

The piping valves don’t be fully opened.

Pipeline is too long, lots of elbow and

tie-in.

Re-configurate the piping system.

Much leakage of the piping

connections.

Check the elbows and connections.

Block of the piping filters.

Clean the filters or change new

one(s).

Shortage of the air using

Actual using capacity exceeds the

compressor rated capacity.

Change larger compressor, or

increase pressure.

Ice over of the evaporator

Fault of temperature switch.

Renew temperature switch.

Invalidation of expansion valve.

Badness of draining

The air by-pass valve doesn’t be fully

closed.

Compressed air doesn’t go through the

dryer.

Open the inlet and outlet valves of

dryer.

The flowrate is too much.

Re-design the compressor system.

The drainpipe is higher than the auto-

drain.

Re-setting the drainpipe.

Compressor is too large, while the dryer

is too small.

Re-setup the compressor and dryer.

Abnormity of the evaporating

gauge.

Evaporating temperature is too high.

Check the air load of compressor.

The ambient air pollution or badness of

ventilation.

Improve the ventilation and ambient

conditions.

Block of the expansion valve.

Change the expansion valve.

Check the leakage, and infuse

some refrigerant.

Out of operation

The fuse blew out or trip of the fuse

disconnecting switch.

Check if the power lack of phase or

short circuit.

Power supply is in normal, but it

can’t start.

Abnormity of voltage or too slim of the

power cord. (voltage drop)

Please choose voltage according to

the rated on the name plate.

Badness of overload relay.

Badness of electric capacity.

Badness of pressure switches.

Badness of temperature switches.

Badness of refrigerated compressor.

All switches in normal, but it can’t

start.

Trips of high-low pressure and desn’t go

to restoration.

Check the reason of trips, press

“RESET”.

Electromagnetic switch doesn’t go to

restoration.

Check and pressure “RESET”.

High pressure switch doesn’t go to

restoration.

Check and pressure “RESET”.

Setting error of the temperature switches.

Badness of refrigerated compressor.

Evaporating temperature

indicator too lower.

Evaporating temperature (badness of low

pressure gauge).

Block of the expansion valve.

Setting lower of the temperature and

pressure switches.

Please adjust the setting.

Check the leakage points, and

infuse some refrigerant.

Evaporating temperature

indicator too higher.

Ambient temperature is too high.

Improve the ambient temperature or

change place for ventilation.

Invalidity of the thermal by-pass valve.

The capacity is too much.

Reposition of the matching.

Abrasion of the valve flap of refrigerant

compressor.

11

10