Page10

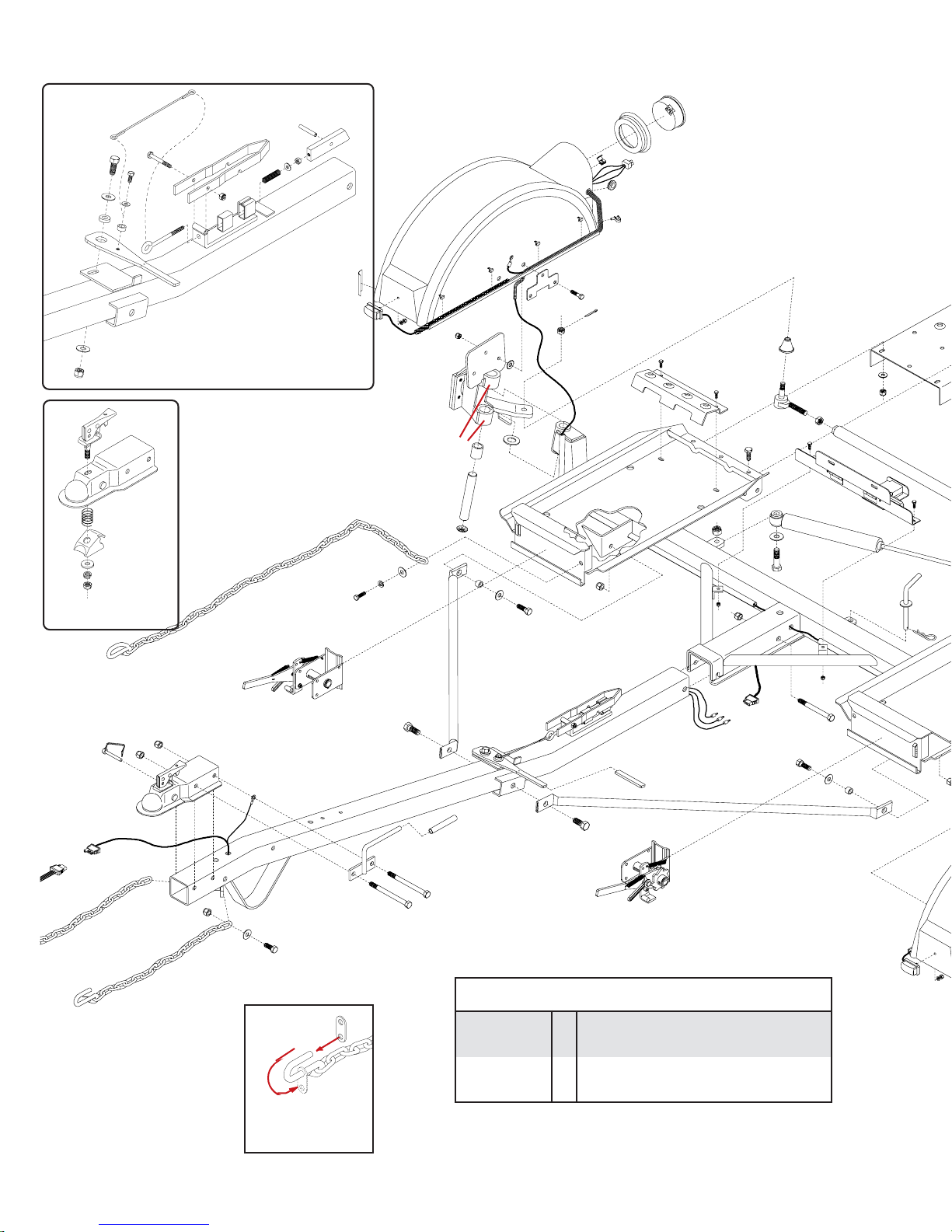

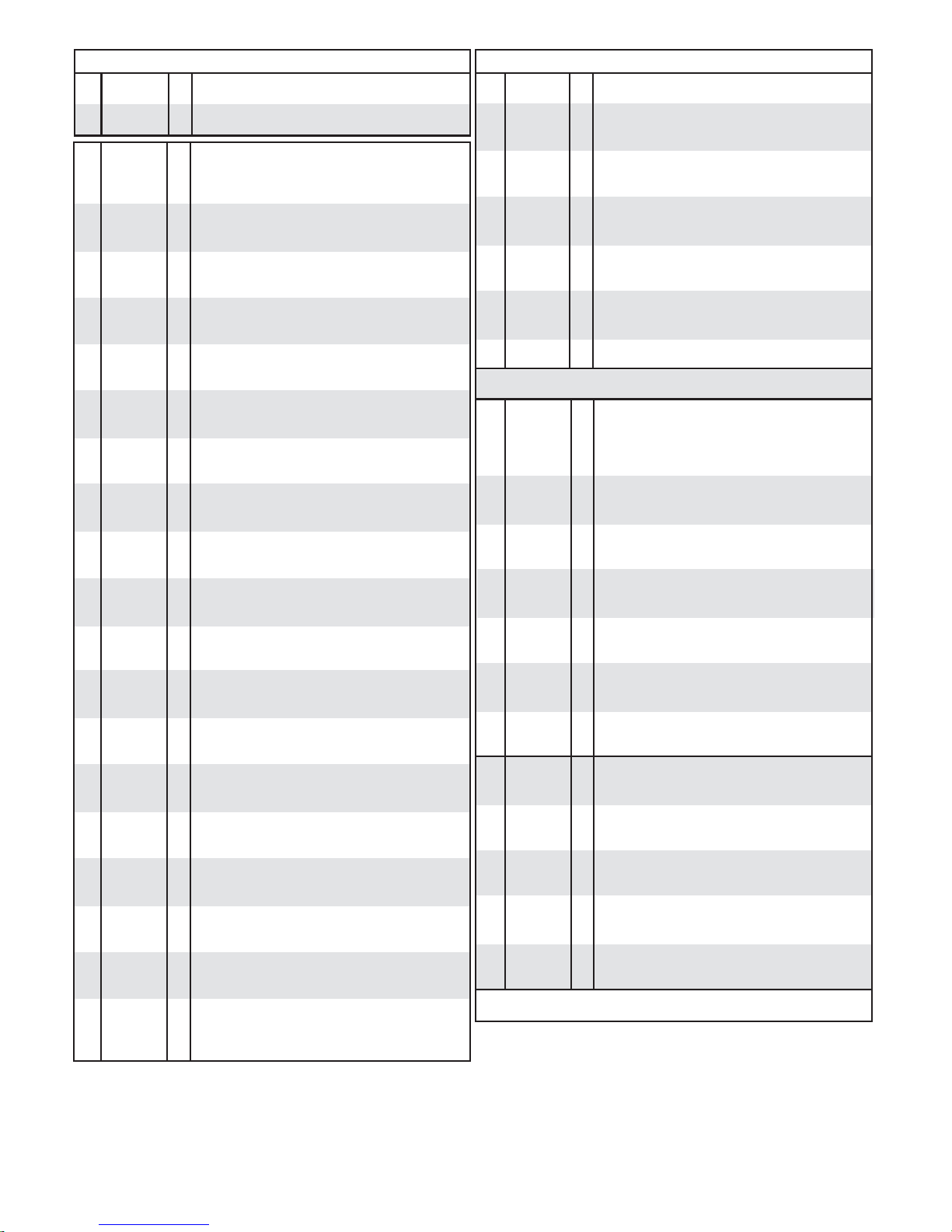

REF. PART

NO. NO. QTY. DESCRIPTION

29. 02580-95 1 License Plate Clip

30. 02770 2 1/4-20UNC Nylon Insert Wing Nut

31. 01077 2 1/4"-20UNC Serrated Locknut

32. 04513 1 Light Cluster

10. 02243 2 Black Vinyl Hand Grip

33. 01883 11 Electrical Wire Splicer

34. 01881 1 Trunk Connector

35. 04785 1 Front Half Trailer Wiring Harness

36. 04786 1 Rear Half Trailer Wiring Harness

37. 01855 1 Safety Lock Pin

38. 04496 1 5000 lb. Ball Coupler (lever lock)

39. 02288-95 1 Bolt on Handle

-04017-95 1 Bolt on Handle (used with brakes)

40. 01338 2 1/2"-13UNC x 4-1/2" Hex Head Bolt (gr.5)

-01975 2 1/2"-13UNC x 5" Hex Hd. Bolt (gr.5) (used w/ brakes)

41. 02189 1 1/2" I.D. Rubber Handle Grip

42. 02178 13 1/2"-13UNC Nylon Insert Locknut

43. 01863 1 5/8" Grommet for wiring harness

44. 02771 2 7/16"-14UNC Nylon Insert Locknut

45. 01853 2 24" Transport Safety Chain w/ Hook

-02383 2 36î Transport Chain w/ Hook (used w/ brakes)

46. 00059 9 3/8" Flat Washer

47. 01898 4 7/16"-14UNC x 1-1/4" Hex Head Bolt (gr.5)

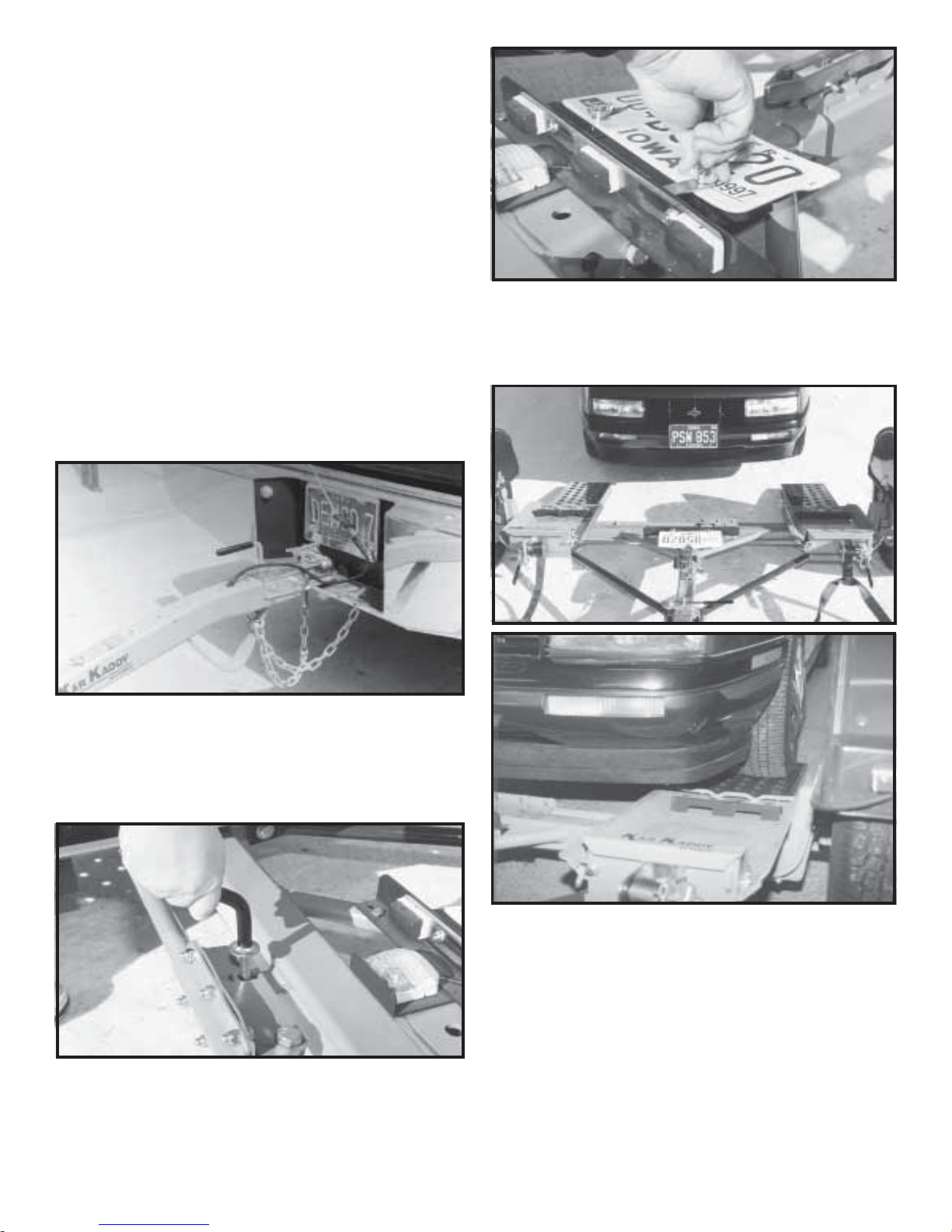

48. 07077-26 1 Kar Kaddy Tongue

49. 03503 2

5/8"-11 UNC x 1-1/4" Epoxied Hex Hd Bolt (gr.5)

50. 02434 1 5/8"-13UNC x 4-1/2" Hex Head Bolt (gr.5)

51. 02587 3 5/8"-13UNC Nylon Insert Locknut

52. 02747-25 2 Bracing Strut

53. 02383 2 36" Safety Chain

54. 02579-95 2 Pivot Bushing

55. 00085 12 1/2" Flatwasher

56. 01254 2 1/2"-13UNC x 1-1/2" Hex Head Bolt (gr.5)

57. 04815 2 Grommet

58. 02772 8 1/4"-20UNC Nylon Insert Locknut

59. 04642 2 Grease Zerk

60. 01731 4 1-1/4" Dust Cap

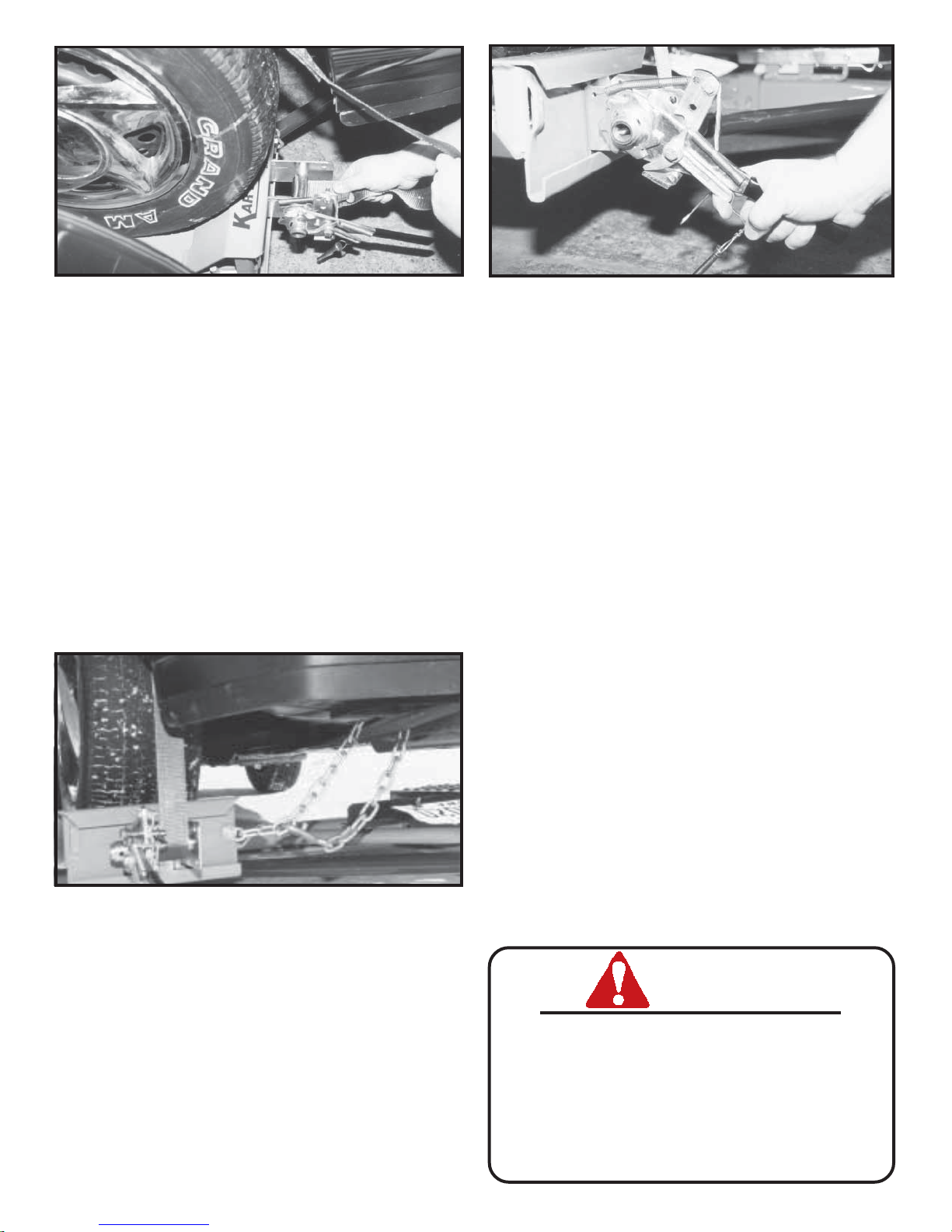

61. 01734 2 1" dia. x 6-1/2" lg. King Pin

62. 01732 4 1"I.D. x 1-1/4"O.D. x 1-1/2"lg. Bushing (brnz)

63. 04165-26 1 Right Wheel Carrier

64. 04166-26 1 Left Wheel Carrier

-04642 4 1/4"-28UNF Grease Zerk

65. 05587 2 1" I.D.x 14 GA Narrow Rim Machine Washer

66. 07075-26 1 KK260 Main Frame (8' wide)

-07076-26 1 KK360 Main Frame (8-1/2' wide)

-09528-26 1 KK260SB Main Frame (8' wide)

-09529-26 1 KK360SB Main Frame (8-1/2' wide)

67. 04369 2 Hub and Spindle (115mm B.C.)

-02917 - Replacement 12mm x 1.5 Stud Bolt

68. 02210 8 7/16"-20UNF x 1-1/4" grade 8 Epoxied Bolt

*69. 5179 1 Right Tie Rod End w\Right Hand Threads

*70. 5178 1 Left Side Tie Rod End with Left Hand Threads

71. 07426 4 Rubber Hook Retainer

72. 01905 1 9/16"-18UNF Jam Nut w/Right Hand Threads

73. 01904 1 9/16"-18UNF Jam Nut w/Left Hand Threads

74. 01869-26 1 Tie Rod (KK260 - 8' wide)

-04771-26 1 Tie Rod (KK360 - 8-1/2" wide)

75. 02592 16 3/8"-16UNC Nylon Insert Locknut

76. 01871-26 1 Tie Rod Shock and Stop Mount Back-up Plate

77. 01870-26 1 Tie Rod Shock and Stop Mounting Clamp

78. 02696 2 5/8"-11UNC x 2-3/4" lg. Hex Head Bolt (gr.5)

79. 00907 6 3/8"-16UNC x 1" Hex Head Bolt (gr.5)

80. 00477 1 5/8" Flatwasher

81. 01729-26 1 Steering Stabilizer Cylinder

REF. PART

NO. NO. QTY. DESCRIPTION 82. 01718-95 1 Locking Pin

-02189 1 Black Handle Grip

83. 00182 1 Small Hair Pin

84. 03528 2 Tie Down Strap w/J-Hook

85. 04503-25 2 Tilt Bed Ramp (KK260 - 8' wide)

-04772-25 2 Tilt Bed Ramp (KK360 - 8-1/2' wide)

86. 00078 2 7/16" Lockwasher

87. 00967 8 1/2"-13UNC x 1-1/4" lg. Hex Head Bolt (gr.5)

88. 04167 6 7/16"-20UNF x 1" lg. Hex Head Bolt (gr.8)

89. 04171-25 2 Rear Tire Stop (KK260 - 8' wide)

-04773-25 2 Rear tire Stop (KK360 - 8-1/2' wide)

90. 00523 4 3/8"-16UNC x 1-1/4" lg. Hex Head Bolt (gr.5)

91. 00789 2 3/8"-16UNC x 3/8" lg. Hex Socket Set Screw

92. 01930 2 3/8"-16UNC x 1/4" lg. Hex Socket Set Screw

93. 04941 2

P195/75R14 "B" Range BSW Radial Tire (KK260)

-04826 2 ST205/75R14 "C"Range BSW Radial Tire

(KK360,KK260SB,KK360SB)

94. 04367 2 Rim (6 x 14) (serial # 19001 & later)

95. 02933 10 Chrome Lug Nut

-5333 1 LH Fender Assembly (qtyís below are for 1 fender)

-5334 1 RH Fender Assembly (qtyís below are for 1 fender)

28. 00214 3 1/4" Flatwasher

97. 05356 1 Left Fender

98. 05355 1 Right Fender

- 4 Stainless Steel Ground Strap

99. 04508 1 Amber Fender Reflective Decal

100. 04498 1 Front Fender Light with lead wire

101. 01769 1 Kar Kaddy Mud Flap

102. 05338 2 1/4"-20UNC x 3/4" lg. Brown Sltd Truss Bolt

103. 05446 1 4-1/2" Enclosed Round Tail Light

104. 05447 1 Rubber Grommet for 05446 Light

105. 04424-95 1 Fender Back-up Plate

106. 02316 1 White Ground Wire

107. 00914 3 3/8"-16UNC x 1-1/2" lg. Hex Head Bolt (gr.5)

108. 04499 3 3/8" I.D. External Tooth Lockwasher

109. 02313 1 3-Way Plug Pigtail (tail light)

110. 04944 1 5/8" Grommet (thin wall)

111. 05443 1 Cable Hanger - wire harness

112. 02298 1 22-1/2" Wire Protector Loom

113. 04425 4 Tinnerman Fender Clamp

114. 04515 1 17-1/2" Wire Protector Loom

115. 04804 1 Red Fender Reflective Decal

116. 05449 1 Spacer Bushing - Stainless Steel

117. 05444 1 3/8"-16 UNC x 3/4" Epoxied Hex Bolt (Gr 5)

118. 03382-95 1 Latch Handle Pivot Bushing

119. 03574-95 1 Latch Handle

120. 03434 1 5/16"-18 UNC x 5-1/4" Eye Bolt

121. 04221 1 5/16"-18 UNC x 2-1/2 Hex Head Bolt (Gr 5)

122. 02802 1 5/16-18 UNC Nylon Insert Locknut

123. 03381-95 1 Latch Catch

124. 00007 1 5/16"-18 UNC Hex Nut

125. 03379-95 1 Latch Block

126. 03435 1 Roll Pin (5/16" x 2-1/4")

127. 03499 1 Latch Spring - Stainless Steel

128. 03433 1 Latch Cable

129. 00004 1 5/16" Flatwasher

130. 04168 6 7/16"-20UNF Nylon Insert Locknut

-CMO8021 12 oz. Buckskin Touch-up Paint (Aerosol)

-IC8633 12 oz. Brown Touch-up Paint (Aarosol)

* Indicatesthiskitincludesappropri-

ate tie rod end (left or right hand

threads), grease zerk, rubber cup,

cotter pin and castle nut.