Sofraser 9601 User manual

9

601

Technical Manual

Original version

REF: 382-0

Viscosity and temperature

processor

Technical Manual 9601

REF: 382 2

IMPORTANT

THE OFFSET ADJ STMENT IN THE AIR

M ST BE THE FIRST TASK COMPLETED.

Offset adjustment procedure is detailed in § 9.1.

1. CLEAN AND DRY THE SENSOR ROD.

2. BE S RE THE PROCESS IS EMPTY. THE ROD M ST BE VIBRATING IN THE AIR.

3. INSTALL THE SENSOR ON THE PROCESS AND FIX IT WITH ITS 4 SCREWS.

4. POWER ON THE DEVICE, WAIT 15 MIN TES.

5. REACH THE OFFSET ADJ STMENT F NCTION BY ENTERING INTO MEN /

SETTINGS / OFFSET.

6. FOLLOW THE INSTR CTIONS DISPLAYED ON THE ELECTRONICS SCREEN.

7. PRESS “F3” TO ADJ ST THE OFFSET. IT MEANS THE RAW SIGNAL IN THE AIR IS

SHIFTED TO THE VOLTAGE REFERENCE DEFINED IN THE FACTORY CALIBRATION

STAGE.

Technical Manual 9601

REF: 382 3

Table of contents

1. TRANSMITTER PRINCIPLE ........................................................................................................... 5

2. PROCESSOR TECHNICAL CHARACTERISTICS ....................................................................... 6

2.1 Electronic device si e ............................................................................................................................................ 6

2.2 Mechanical characteristics ................................................................................................................................ 6

2.3 Display ............................................................................................................................................................................. 7

2.4 Keyboard ....................................................................................................................................................................... 7

2.5 Battery ............................................................................................................................................................................ 7

2.6 Consumption .............................................................................................................................................................. 7

2.7 Connection blocks .................................................................................................................................................. 7

2.8 General scheme of the electronic device................................................................................................. 8

2.9 Connections made by Sofraser ....................................................................................................................... 9

2.10 Connections to be done by the user ........................................................................................................... 9

2.11 Digital Inputs TOR ................................................................................................................................................. 10

2.12 Analog Inputs ........................................................................................................................................................... 10

2.13 Density meter (optional) ................................................................................................................................... 10

2.14 Safety considerations ............................................................................................................................................ 11

2.15 Relay outputs ............................................................................................................................................................. 11

2.16 Analog outputs ......................................................................................................................................................... 12

2.17 Outputs wiring ......................................................................................................................................................... 12

2.18 General information .............................................................................................................................................. 12

2.19 Wastes handling ..................................................................................................................................................... 13

3. PROCESSOR MO NTING-INSTALLATION ............................................................................. 14

4. COMM NICATION ........................................................................................................................ 16

4.1 Serial interface .......................................................................................................................................................... 16

4.2 Modbus communication protocol .............................................................................................................. 17

5. GENERAL INFORMATION ON THE SE OF 9601 ................................................................. 18

5.1 Navigation ................................................................................................................................................................... 18

5.2 Diagnosis ...................................................................................................................................................................... 18

5.3 Security codes ........................................................................................................................................................... 18

5.4 Modes ............................................................................................................................................................................. 18

6. TILIZATION MODE ..................................................................................................................... 19

6.1 “Bargraphs” view ..................................................................................................................................................... 19

6.2 “Compensated viscosity” view ........................................................................................................................ 19

6.3 “Acquisition graph” view .................................................................................................................................... 19

6.4 Information – version............................................................................................................................................ 19

6.5 Synoptic ...................................................................................................................................................................... 20

7. ADAPTATION MODE ..................................................................................................................... 21

8. BLOCK “DISPLAYS” ...................................................................................................................... 22

8.1 Menu of the block “Displays” .......................................................................................................................... 22

8.2 Choose the Viscosity Unit ................................................................................................................................. 22

8.3 Choose the Temperature Unit ...................................................................................................................... 22

8.4 Activate viscosity correction ........................................................................................................................... 22

8.5 Status ............................................................................................................................................................................. 23

Technical Manual 9601

REF: 382 4

8.5.1 Current outputs status .................................................................................................................................. 23

8.5.2 Alarms relay outputs status ...................................................................................................................... 23

8.5.3 Data status ........................................................................................................................................................... 23

8.6 Synoptic of Block “Display” ..............................................................................................................................24

9. BLOCK “SETTINGS” ...................................................................................................................... 25

9.1 Set the offset ............................................................................................................................................................. 25

9.2 Set the alarms .......................................................................................................................................................... 26

9.3 Set and test the current outputs ................................................................................................................. 27

9.3.1 Set the current outputs ................................................................................................................................ 27

9.3.2 Test the current outputs ............................................................................................................................. 27

9.4 Choose the method of kinematic viscosity calculation ................................................................ 28

9.5 Set the bargraphs .................................................................................................................................................. 28

9.6 Set the graph scales ............................................................................................................................................. 28

9.7 Activate the Pt100 ................................................................................................................................................. 29

9.8 Define the filter ....................................................................................................................................................... 29

9.9 Synoptic of Block “Settings” ...........................................................................................................................30

10. BLOCK “PARAMETERS” ............................................................................................................... 31

10.1 Viscosity corrections ............................................................................................................................................. 31

10.2 Compensation table ............................................................................................................................................ 32

10.2.1 Reading of the compensation table ................................................................................................... 32

10.2.2 Modification of the compensation table ........................................................................................ 32

10.3 Define the density coefficient ....................................................................................................................... 33

10.4 Modify the security codes ................................................................................................................................ 33

10.5 Synoptic of Block “Parameters”....................................................................................................................34

11. BLOCK “CONFIG RATION” ....................................................................................................... 35

11.1 Define the thermal drift table and the calibration data ............................................................... 35

11.2 Define the filter inputs ....................................................................................................................................... 35

11.3 Define the adjustment data ........................................................................................................................... 35

11.4 Synoptic of Block “Configuration” .............................................................................................................. 36

12. SPECIFIC NOTES ........................................................................................................................... 37

Technical Manual 9601

REF: 382 5

1. Transmitter principle

The measuring chain is composed of three inseparable elements: the sensor, its cable and the 9601

processor that controls it. The sensor cannot be used with another transmitter or another cable

type or length because they are all a part of the resonant loop so they are matched together as one

vibrating system.

The active part of the sensor is composed of a vibrating rod held in oscillation at resonance

frequency by driving magnets. When the rod is immersed into a viscous material, the amplitude of

the vibration is dampened. The vibration amplitude varies according to the product viscosity

where the rod is immersed.

The sensor receiving coil detects the response and the signal is converted to a viscosity value

through the electronic device. The factory calibration is performed with standard oils.

The processor acquires the coils’ amplitudes and frequency and generates various signals. These

signals represent the properties being measured. It is also in charge of powering the whole system.

It gives viscosity and temperature information through analog outputs, serial communication and

displays it. The processor also allows settings as the very important “ ero in the air” procedure.

Technical Manual 9601

REF: 382 6

2.

Processor technical characteristics

2.1

Electronic device size

The electronic box has the purpose to be fitted in a panel, close to the process line. The collar

is the only visible part, composed of a face plate and a LCD screen. It is continuously

displaying the viscosity value and, in the case there is a Pt100 probe, the temperature value.

The ID label is stick on the back panel with main information (see §2.6).

2.2

Mechanical characteristics

•Dimensions behind the collar: 138 x 123 x 106.4 mm

•Collar dimensions: 184 x 155 x 6.7 mm

•Case transducer dimensions : 66.2 x 67.1 x 28.2 mm

•Cut-out for assembly on panel: 141 x 126 mm. Thickness ≤ 5mm.

•Weight: about 515 g.

•Tightness: IP 65 with panel mounting and IP20 on rear panel.

•Operational temperature: 0 °C to 45 °C.

Screw for brightness

Technical Manual 9601

REF: 382 7

2.3

Display

•Display type: STN LCD

•Illumination backlight: LED yellow

•Display resolution: 128 x 64 pixels

The brightness can be adjusted using the screw on the top panel

.

2.4

Keyboard

24 keys: alphanumeric keys and function keys.

2.5

Battery

The battery lifespan is about 7 years at 25 °C. When the battery no longer works, the

operating parameters of the sensor are no longer stored in memory. It is then necessary to foresee

the change of the battery after 5 years of use of the sensor.

2.6

Consumption

The processor requires a 24 VDC (± 2.4 V) stabili ed and filtered power supply (not provided

by SOFRASER).

Typical power consumption: 7.2 W maximum

2.7

Connection blocks

On the processor back module, various categories are identified (example: DIGITAL INPUTS,

ANALOG OUTPUTS…).

We will call these categories "connection blocks". The diagram below identifies the various

connection blocks. The colours codes used and the name of these connection blocks are taken

again for each connection diagram.

Technical Manual 9601

REF: 382 8

2.8

General scheme of the electronic device

Technical Manual 9601

REF: 382 9

2.9

Connections made by Sofraser

All the connections in the following table are already wired when the equipment is delivered.

12/24

VDC

24 VDC

DIGITAL

O TP TS

24 VDC

ANALOG

I/O

DIGITAL

INP TS TRANSD CER

0V

0V

0V

8

+V

V1

V2

COM

9

A 1N4007-type diode (1) is cabled between the digital inputs block and the transducer in

order to protect the transducer from the unexpected power supply inversion.

2.10

Connections to be done by the user

All the wires and terminal blocks at stake here are already numbered and pre-cabled.

Equipment 12/24 VDC

Transducer

Analog

Inputs

Digital

Inputs

POWER

S PPLY

0V 0V

24V +V

Shielding bread

T (Earth)

MIVI

A 1

B C 2

D 3

G T- PT

F T+ PT

E CM

If there is no incorporated Pt100 probe, there are no E, F and G wires to connect. In the case

of a non-provided by SOFRASER external probe, be sure this is a 3-wires one.

An external circuit protection device (such as a fuse) is recommended as shown in (2).

See §3 for power supply earthing (3).

(1)

0

(3)

(2)

Technical Manual 9601

REF: 382 10

2.11

Digital Inputs TOR

18 TOR inputs are available including 2 inputs which can be used as high speed counter, shaft

encoder or for frequency measurement.

In our configuration, we only use one input (for the frequency): I0 (see §2.8).

2.12

Analog Inputs

4 analog inputs are available. Their resolution is 14 bits.

Analog inputs type: voltage 0-10 V, current 0/4-20 mA. These inputs can be used with a

thermocouple or a Pt100 probe.

On the 9601 processor, these inputs are used as follows:

Physical value

Input type

Scale

amplitude voltage 0-10V

coil voltage 0-10V

temperature (optional) Pt100 Ω – 3-wires mode -50°C to 200°C

PT100 external probe -200°C to 600°C

density (optional) current 4-20 mA

Transducer Analog

Inputs

Digital

Inputs

5

T- PT

T+ PT

4

T- PT

T+ PT

7 IO

6 ACM

Note: These connections are also made by SOFRASER.

2.13

Density meter (optional)

In the case of SOFRASER provides its density meter, this is the way to connect it to the

device.

Density meter Transducer Analog Inputs

6 ACM

0V

T

-

PT

24V

T+ PT

3

DIMF

1 (-)

2 (+)

2

1

Technical Manual 9601

REF: 382 11

2.14

Safety considerations

•Do not touch wires while the processor is ON.

•A non-isolated power supply can be used provided that the 0V is connected to the frame.

•In the event of mounting on a metal panel, standard safety considerations require that the

power supply should be earthed to avoid electrocution.

•Do not connect either the “Neutral” or “Line” signal of the 110/220VAC to the device’s 0V pin.

•In the event of voltage fluctuations or non-conformity to voltage power supply

specifications, connect the device to a filtered and stabili ed power supply.

•Double-check all wiring before turning on the power supply.

•Do not use tin on the stripped wire that might cause the strand to break.

•Install at maximum distance from high-voltage cables and power equipment.

•To avoid damaging the wire, do not exceed a maximum torque of 0.5 Nm (0.05 kgf.m).

•We recommend using crimp terminals for wiring. Use 26-14 AWG wire for all wiring

purposes.

•To maximi e the system performances, avoid electromagnetic interferences by mounting

the processor on a metal panel and earthing the power supply.

Note: The wire used to earth the power supply must not exceed 8 cm in length. If your

conditions do not permit this, do not earth the power supply (cf. step 2 § 3).

2.15

Relay outputs

15 relay outputs are available.

In our configuration, 9 relay outputs are used as follows:

Physical value Relays

Viscosity 1 NO relay for LOW threshold

1 NO relay for HIGH threshold

Compensated Viscosity

1 NO relay for LOW threshold

1 NO relay for HIGH threshold

Temperature 1 NO relay for LOW threshold

1 NO relay for HIGH threshold

Density 1 NO relay for LOW threshold

1 NO relay for HIGH threshold

Diagnosis - Dysfunction

1 NO relay

-

Normal functioning: The coils of the relay are under tension and the contact is closed.

-

In case of anomaly: The coils are not under tension and the contact is opened: measurements

out of set point, processor power supply is turned off…

-

Power cut-out:

Relays O2 to O7 and relays O8 to O15: 3 A maximum per relay, 250VAC or 30VDC

Common: 8 A maximum

Common is not located, refer to the plugging chart

Minimal charge: 1mA for 5VDC

Relays lifespan: 100 000 operations at the maximum charge

Response time: 10 ms

If these relays are used to commute some inductive charge, we advise you to add some RC

networks to the charge terminals (preferably) or to the contacts terminals. They will then lessen

the electro-magnetic phenomena.

Technical Manual 9601

REF: 382 12

2.16

Analog outputs

4 analog outputs are available. Their resolution is 12 bits.

Analog outputs type: current output 4-20 mA or voltage output 0-10 V.

In our configuration, analog outputs are used as follows:

Physical value Output type Scale

viscosity current 4-20 mA

temperature current 4-20 mA

compensated viscosity current 4-20 mA

density current 4-20 mA

2.17

Outputs wiring

Analog outputs

Digital

outputs

COM

Common outputs 4/20mA

O16

NO relay - diagnosis

AOUT0

4/20mA viscosity output

O15

NO relay HIGH - density

AOUT1

4/20mA temperature output

O14

NO relay LOW - density

AOUT2

4/20mA compensated viscosity output

O13

NO relay HIGH - comp. viscosity

AOUT3

4/20mA density output

O12

NO relay LOW - comp. viscosity

O11

NO relay HIGH - temperature

O10

NO relay LOW - temperature

O9 NO relay HIGH - viscosity

O8 NO relay LOW – viscosity

2.18

General information

List of the device generic standards:

Low Voltage Directive EN 61131-2 Power supply 24 VDC-not submitted

CEM Immunity EN 61000-6-2 Electro-static discharges

Radio-frequency

Burst quick transients

CEM Emission EN 61000-6-3

EN 61000-6-4

Radio-frequency

Process variable CEI 751 Pt100

Protection CEI 529 IP 65 on front panel and IP 20 on rear

panel

Size CEI 473 Front panel : 184 * 155 mm

Cut-out : 141 * 126 mm

Climatic conditions Storage -20 to 60°C

5 to 90% HR non-condensing

Work 0 to 45°C

5 to 90% HR non-condensing

Technical Manual 9601

REF: 382 13

2.19

Wastes handling

Within the framework of the directive 2002/96-CE application, commonly named directive

DEEE, relating to the wastes of electric and electronic equipment, SOFRASER considers taking in

charge the equipment arriving at the end of the lifetime.

Do not throw the equipment to the dustbin. If the user does not have the means to take in

charge the wastes of our electronic equipment, he should returned these equipment to our factory

with a signed letter confirming that it is an equipment that has to be destroyed/recycled.

Technical Manual 9601

REF: 382 14

3. Processor mounting-installation

Warning:

The mounting panel should not be more than 5 mm thick.

Step 1

Make a panel cut-out as following:

Step 2

Earth the power supply

-

Bore a hole of Ø4 mm that suits the NC6-32 screw

supplied.

-

Scrape the panel paint away from the contact area to

ensure a conductive connection.

-

Drive the screw into the hole and place the following

hardware in this order: washer, ring cable shoe, second

washer, spring and nut.

Note: The wire used to earth the power supply must not

exceed 8 cm in length. If your conditions do not permit this,

do not earth the power supply.

Step 3 Slide the processor into the cut-out, ensuring that the rubber seal is in place.

Technical Manual 9601

REF: 382 15

Step 4

Push the 4 mounting brackets into their slots on the processor sides as shown as

following:

Step 5

Tighten the bracket screws against the panel. Hold the mounting brackets firmly

against the processor during the screws tightening.

Technical Manual 9601

REF: 382 16

4. Communication

4.1

Serial interface

2 RS ports are available. One is a RS232 (PORT 1), the other one can be either a RS232 or a

RS485 (PORT 2). They are located on one side of the processor.

Serial ports type: RJ-11.

Caution:

-

Turn off power before making communication connections.

-

Do not connect the controller directly to a telephone or a telephone line.

-

Use shielded, twisted pair cables.

-

Minimi e the length of the connection cables. The length should not exceed 1200 m.

-

Do not cross A and B signals: the positive terminals must be wired to +, and the negative

terminals to -.

-

The RS232 port is not isolated.

-

The RS485 serial port is not isolated. If the controller is used with a non-isolated external

device, avoid potential voltage that exceeds ± 10V.To avoid damaging the system, all non-isolated

device ports should relate to the same ground signal.

-

Signals are linked to the processor’s ground, this is the same ground used by the power

supply.

RS232 characteristics

Baud rates

PORT 1 PORT 2 Voltage limits

300 to 57600 bps

300 to 115 200 bps

-20V to 20V

Pin number Function

1 DTR signal

2 0V reference

3 TxD signal - Transmission

4 RxD signal - Reception

5 0V reference

6 DSR signal

RS485 characteristics

Pin number Function

1 A signal (+)

2 *

3 *

4 *

5

*

6 B signal (-)

* pins 2 to 5 are not used for RS485 communication

.

Baud rates Nodes Voltage limits

300 to 115 200 bps Up to 32 processors -7V to 12V

Technical Manual 9601

REF: 382 17

4.2

Modbus communication protocol

Goal: read amplitude, coil, viscosity and Pt100 values using RS-485 communication

S: send from the console to the board

R: response from the board to the console

Amplitude: signal read before correction, offset and without lineari ation

Coil: signal which is an image of the sensor inner temperature

Viscosity: viscosity calculated in cP

Pt100: value in Celsius degrees of the temperature read by the probe (if there is one)

COM port characteristics

Speed: 9600 bits/s Number of bits: 8 Parity: none Stop bit: 1

Generic frame format

S = SN 3 XX XX YY YY <CRC>

R = SN 3 AA {DATA} <CRC>

SN: slave number (hexadecimal) 3: reading function

XX XX: starting point for the addresses to be read YY YY: number of words to be read

AA: read bytes number DATA: content of all the asked addresses

<CRC>: checksum (automatic)

List of a resses:

Viscosity 0x143C 4 bytes

Temperature 0x0021 2 bytes

Compensated viscosity 0x144C 4 bytes

Density 0x001F 2 bytes

Frequency 0x000D 2 bytes

Amplitude 0x001C 2 bytes

Coil 0x0007 2 bytes

Offset 0x001B 2 bytes

Example:

S = 11 03 14 3C 00 02 <CRC>

R = 11 03 04 00 08 8D F3 <CRC>

11: slave number (hexadecimal) 03: reading function

14 3C: viscosity address 00 02: number of words

04: number of bytes read 00 08 8D F3: viscosity value (0x88DF3 = 560.627 mPa.s)

<CRC>: checksum

Technical Manual 9601

REF: 382 18

5. General information on the use of 9601

Before any use, read carefully the technical manual of the MIVI sensor in order to ensure

the good installation of the unit.

5.1

Navigation

Press on this key:

to return to the previous level

to return to the “Bargraphs” view (see §6.1)

5.2

Diagnosis

When an anomaly is detected by the

processor, the symbol appears on the

main “Bargraphs” view.

Press F6 and the details about the anomaly appear.

Out of range: Viscosity.

We consider that the sensor is out of range

when viscosity exceeds 110 % of full scale

range.

Out of range:

Compensation table

The reference temperature, that can be set

on “Compensated viscosity” view (see § 6.2)

or the instantaneous temperature is out of

the table.

Alarms

Message that appears at the reach of the

low or high threshold for viscosity,

temperature or density.

Rupture

Message that appears when there is a coil

wire breakdown (viscosity or density)

generally related to a connection problem.

5.3

Security

codes

Refer to §12 (Specific notes and manufacturing parameters) and §10.4

(Modify security codes) of this Technical manual.

4 security codes, CODE 0 to CODE 3, are defined.

•Code 3 = 1111 – Modifiable

•Code 2 = 1111 – Modifiable

•

Code 1 =

Not modifiable and reserved to SOFRASER after-sales

service

•Code 0 = Not communicated and not modifiable

5.4

Modes

The utili ation mode enables to visuali e viscosity, temperature and

density values in various forms (§6).

The Adaptation mode enables to adapt parameters, settings and

configuration of the processor according to the using conditions. (§7).

Technical Manual 9601

REF: 382 19

6. tilization Mode

The Utili ation mode enables to visuali e viscosity, temperature and density values in various forms

6.1

“Bargraphs” view

“Bargraphs” view is the principal view. The following data

are displayed:

•Viscosity, temperature and density bargraphs.

•

Instantaneous viscosity, temperature according

to the selected unit and density (coefficient or

density meter).

6.2

“Compensated viscosity”

view

The viscosity at reference temperature calculation

requires knowing the viscosity evolution in function of

temperature.

Setting and saving the compensation table is done in the

“Parameters” block.

The reference temperature can be modified starting from

this view as following:

•Using the keyboard, enter the new value of the

reference temperature.

•Press OK: the modification is done and the

viscosity is re-calculated according to this new

value of reference temperature.

6.3

“Acquisition graph” view

The acquisition graph represents viscosity and

temperature.

One graph represents 120 values and the acquisition time

can be set in the “Settings” block.

For example: For an acquisition time setting at 30s, the

graph will represent an acquisition of 1 hour.

A first pressing on F6 enables to display the viscosity

graph, with the same time scale of the graph for viscosity

and temperature.

A second pressing enables to display the temperature

graph.

6.4

Information

–

version

The information view is accessible starting from the main

view by pressing on .

Instantaneous measurements

Compensated viscosity calculated at

reference temperature

Electronic version

Program version

Other manuals for 9601

1

Table of contents

Other Sofraser Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Inficon

Inficon Sniffer line SL3000XL Translation of the original operating instructions

Kofloc

Kofloc RK1812 Series instruction manual

Endress+Hauser

Endress+Hauser Proline Promag 51 operating instructions

TENSITRON

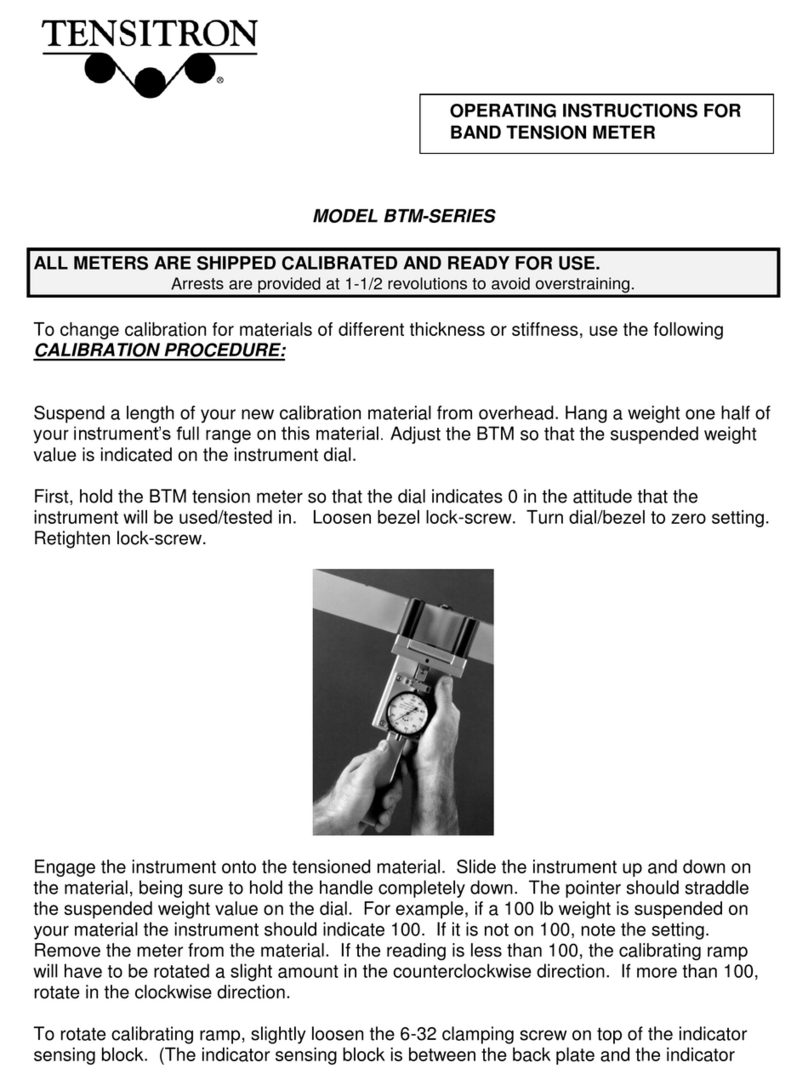

TENSITRON BTM SERIES operating instructions

PCE Instruments

PCE Instruments PCE-2800 manual

Workzone

Workzone 11334 user guide