Denchi Oldham DL16 User manual

1

DL16 - Issue 4 November 2023

WARNING

This manual, including the warnings and cautions inside, must be read and followed carefully by all

persons who use or maintain this product, including those who have any responsibility involving its

selection, application, service, or repair.

This cap lamp system will perform as designed only if used and maintained according to the instructions,

otherwise it could fail to perform as designed and persons who rely on this product could sustain serious

personal injury or death.

DL16

CAPLAMP SYSTEM

WITHOUT COMPROMISE

INSTRUCTION

MANUAL

2

DL16 - Issue 4 November 2023

DL16 CAP LAMP SYSTEM

TABLE OF CONTENTS

Important p3

General description p3

Preparation for use p3

Battery charging p3

Cap lamp system p4

Battery Storage p4

Replacing battery p4

Removing cable from battery p4

Replacing battery cover p4

Using DL16 cap lamp systems p4

Repairing headpiece p5

Replacing cable p5

Replacing reflector p5

Replacing circuit board p5

Reassembling bezel ring p6

Replacing the Lock Barrel P6

DL16 diagram –Item list p7

Parts diagram p8

Troubleshooting p10

Use of Equipment p11

Special Conditions for Safe Use p12

Appendix: Commissioning & Charging Instructions p13

3

DL16 - Issue 4 November 2023

IMPORTANT

Pay close attention to Warnings and Cautions in

this manual.

A WARNING describes a condition that may cause

severe personal injury or death if allowed to

happen.

A CAUTION describes a condition that may cause

moderate injury or property damage if allowed to

happen.

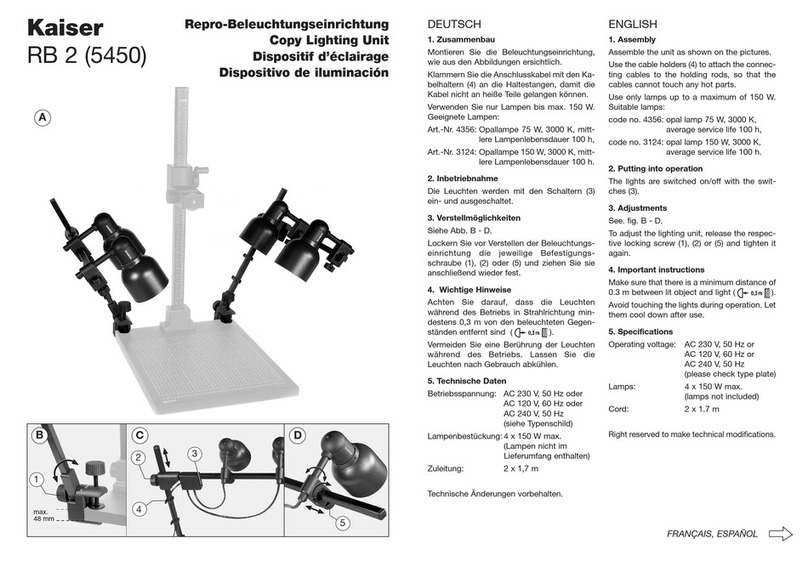

GENERAL DESCRIPTION

The DL cap lamp systems consists of a cap

mounted headpiece powered by a Li Ion battery.

The basis of the headpiece in which some of the

internal connections are integral is as follows:

A selector switch is incorporated, which can switch

on either the main LED light source or the small

emergency LED. The reflector fits over the small

LED and has a rubber gasket around the rim to seal

against the headpiece lens.

PREPARING THE DL6 CAP LAMP FOR FIRST

TIME USE

The battery is packaged separately to the lamptop

and needs to be connected before use.

Tool kit required is 206008

NOTE: THE BATTERY IS TRANSPORTED IN A

PARTIALLY CHARGED CONDITION - EVERY

BATTERY MUST BE FULLY CHARGED

BEFORE FIRST USE.

Remove the battery from the shipping box and

check for damage. The battery is supplied with the

encapsulated fuse fitted, terminal nuts and

washers.

Remove the nut and washer from the positive end

of the fuse (marked +). Place the ring terminal of

the red wire onto the terminal post, replace the

spring washer and nut, and tighten to 0.5Nm.

Remove the nut and washer from the negative

terminal (not connected to the fuse) and place the

ring terminal of the black wire onto the terminal

post, replace the spring washer and nut, and

tighten down to 0.5Nm.

Hook the cable exit end of the battery cover onto

the battery.

Check that the cables are not trapped under the

edge of the cover then press down into position.

Secure the cover in place with the clip and M4

mushroom head socket screw.

➢Battery charging

WARNING

Li Ion batteries must only be charged on a

specific charger with a Li Ion charge profile.

Use of unapproved chargers may result in

damage to the caplamp’s battery protection

circuit.

For charger information and how to convert

existing charger software please consult the

Caplamp Charger Manual.

Every battery must be charged before it is used for

the first time.

Never discharge completely!

IMPORTANT NOTE:

The battery is supplied with a factory fitted

“OCBL-T” fuse (203500), required for

protection of the internal battery circuitry.

Use of any other fuse type could result in

damage and will invalidate any warranty claim.

4

DL16 - Issue 4 November 2023

Charging before first use:

1. Allow the battery to remain on charge for 24

hours.

2. After a working shift, the battery should be

placed on the charger, following the

instructions included with the charger, and left

to charge. The charger automatically switches

off when the battery is completely charged

3. If cap lamp needs cleaning, use a mild

detergent and wipe. Do not submerge in water.

(see appendix –pg.12 - for full commission &

recharge instructions)

➢Battery Storage

All stored batteries should be given a 24-hour boost

charge 3 months after receipt and thereafter at 6-

monthly intervals until use, where they should

again be fully charged before being placed into

regular service.

Recommended storage temperature: 0oC to 27oC.

➢Replacing battery

1. Remove one M4 button head socket screw

from the end clamp holding the cover as

shown.

2. Un-clip the clamp and slide off the cover to

cable end.

3. Remove the positive cable lead (red)

4. Remove the fuse

5. Remove the negative lead (black)

➢Replacing battery cover

1. Replace the fuse; fit the nuts to hold the fuse in

place

2. Connect the red cable to the positive battery

terminal.

3. Connect the black cable to the negative battery

terminal to ensure correct polarity.

4. Tighten the cable leads down with terminal

nuts to 0.5Nm.

5. Replace the battery cover.

6. When the fuse is removed the safety circuit will

activate. Place battery on charge before use.

Note:

Ensure that the cable leads lie properly on the

battery top without being trapped or pinched.

USING THE DL16 CAP LAMP SYSTEM

The DL headpiece is made up of the lamp-housing

which contains the following parts:

-Bezel (ring)

-Lens (glass)

-Gasket

-Reflector

-Main LED

-Secondary LED

-Circuit board and switch

The on-off-on switch knob is located on the

headpiece. The down position operates the main

LED and up position the secondary LED.

5

DL16 - Issue 4 November 2023

➢Repairing the headpiece

TOOLS:

G & D type spares and tools kit –206008

D type Headpiece fastening & cable lock kit -

201536

The switch should be placed in the off position and

the battery fuse removed (see section “cap lamp

system”) before disassembly of the headpiece.

➢Replacing Cable

1. Remove the cable from the battery terminals.

2. Cut the cable tie around the cable under the

battery cover and pull the cable out from the

battery cover gland.

3. Unscrew the M3 socket head mushroom screw

from the headpiece cable lock.

4. Use a small screw driver to “flick” the cable lock

off the retaining boss. Take care not to lose the

o-ring under the boss as this is required for

reassembly.

5. Replace the mushroom head socket screw.

This is important to ensure the circuit board

support in the headpiece does not become

loose.

6. Hold the lens glass down while unscrewing the

bezel ring.

7. Remove the lens glass and reflector.

8. Unscrew the 2 off M3 slotted screws.

9. Remove the cable

10. To replace the cable reverse the above

procedure.

Note:- Always ensure that one screw is fixed

into the positive cable terminal or the cable

lock. This ensures the circuit board support

does fall out of position.

WARNING

It is essential that all contacts in the headpiece

are tight, so that no electrical resistance is

incurred which might increase the time

necessary to obtain an efficient charge or

possibly reduce the light output of the lamp.

➢Replacing the reflector

1. Remove the bezel ring and lens.

2. Remove the reflector

3. Remove gasket around reflector.

4. Place the gasket around the new reflector.

The reflector is located by two projections

which fit either side of the main LED; the hole

in the reflector goes over the secondary LED

.

The bezel ring should be screwed down firmly

while holding the glass down with your thumb.

5. Reassemble the lens and bezel ring (see

“Reassembling the bezel ring”).

➢Replacing the circuit board

The LE CC driver circuit board can be replaced in

the event of damage to the switch or electronic

failure of the board. This procedure should be

carried out by a person with experience of

soldering on small circuit boards.

1. Remove the cable as described above

2. De-solder the wire connections to the LED at

the circuit board.

3. Carefully bend the cables away from the

circuit board.

4. Use an open ended spanner 206002 to

remove the nut securing the switch. Remove

the washer and rubber backed sealing

washer.

5. Pull the old circuit board out from the front of

the main housing.

6. Put a 10mm spacer in the positive hole

before replacing the board.

6

DL16 - Issue 4 November 2023

7. Replace the circuit board, pull in the threaded

switch boss to ensure it is fully located in the

socket at the back of the headpiece housing.

Ensure the circuit board is correct.

8. Replace the sealing washer and nut, tighten

with the open ended spanner.

9. Re-solder the wires from the main LED.

10. Replace the cable and reassemble the

reflector, lens and bezel ring.

➢Reassembling the bezel ring

1. When the lens is in position over the reflector,

the bezel ring is screwed onto the headpiece

housing, and locked in position by the

stainless steel cable lock.

2. Ensure the cut-outs in the bezel ring line up

with the cable lock.

3. Hook the cable lock into the slot under the cap

hook support. Press down so the cable is in

position, replace the o-ring and then clip over

the boss on the side of the headpiece.

4. Secure with M3x10 mushroom-head screw.

➢Replacing the lock barrel

If the lock barrel is damaged it may become difficult

to connect the lamp to the charger. In this case, the

lock barrel must be replaced (201538 –lock

contact spares kit).

1. Undo the M4 lock nut and remove the dome-

head screw that runs through the charging

contact housing.

2. The metal cap-clip can be lifted off and set to

one side (take care not to lose the spring clip).

3. Remove the lock barrel and ensure that the

charging contact housing is clear of any debris

before inserting the replacement lock barrel.

4. Holding the lock spring in position, refit the cap-

clip cover, insert the dome-head screw and re-

tighten the M4 lock nut.

7

DL16 - Issue 4 November 2023

DL16 Expanded Diagram, Tools and Spare Parts List

200000 (M261551)

DL16 caplamp (complete)

201000

D-type Lamptop complete

(with cable and battery cover)

201000 (M261951)

L16 Type battery

201526 (M259121X)

Bezel ring (D-type)

201504 (M200131X)

Glass lens

201508 (M200411X)

Sealing channel

201527 (M259127X)

Reflector (D-type)

201529 (M259383)

LED CC circuit board

201540 (M260116)

Cable 1.6m (D-type)

203500 (M455323FX)

Fuse (type OCBL-T)

201536 (M259683)

D-Type Headpiece Fastening & Cable Lock kit

201524 (M205083)

D and G Cable Terminal Spares kit

201520 (M204683)

D and G Lock Contact Spares kit

201521 (M204783)

D and G Cap-clip Spares kit

201545 (M455045)

Plastic Battery Cover (complete)

Clip for standard cover

Screw for plastic cover

Cable gland

Cable tie

206008 (M614830)

Small tools and spares kit, suitable for all “G” and

“D” type lamps comprising :-

Cable outlet gland key

Allen key for headpiece lock pin

Insulated screwdriver

Spring screwdriver

Spanner for L16 battery terminal nuts

Spanner for D-type switch

Two “OCBL” battery fuses

Note: Only certain replacement items above may

be purchased individually. All others, as noted

above, must be purchased in kit form as this

ensures that other associated parts are also

available for replacement at the same time as part

of an appropriate preventative maintenance

programme.

8

DL16 - Issue 4 November 2023

9

DL16 - Issue 4 November 2023

10

DL16 - Issue 4 November 2023

TROUBLESHOOTING

PROBLEM

CAUSE

LED is dim or fails to light

1) Both LED’s are dim / fail to light

2) Main LED is dim / fails to light

1. Loose connections:

a. Check the connections on the top of the battery to

make sure they are tight.

b. Check the headpiece terminals and the electrical

connections inside the headpiece in the same manner

as those on the battery.

2. Loose connections:

a. Gently wiggle or pry each connection on top of the

battery to make sure it is tight and working properly.

b. Check the cables for broken conductors by twisting or

pulling it at various points along its length.

c. Check the headpiece terminals and the electrical

connections inside the headpiece in the same manner

as those on the battery.

d. Make sure the bulb is secure and making good

contact.

e. If the light flickers or dims when any of the preceding

items are being checked, that item should be repaired

or replaced.

Battery appears “dead” and will not operate

a. Check that the fuse has not blown

b. Check the cross volts of the battery, if no voltage is

recorded the Safety Circuit has activated either

because the fuse has been disconnected or blown or

the battery has been over discharged.

c. After checking continuity across the fuse, place battery

on charge (switched off) and leave for 10 seconds.

Disconnect then reconnect, the charger should then

initialise the charge regime and the battery will

recharge normally.

Battery capacity

a. The 9Ah battery is designed for8-hour operation and

the 16 Ah Li Ion battery is designed for 12 hour

operation. Failure to achieve this is probably due to a

high resistant joint in the circuit.

b. Check Headpiece charging connections

c. Check charger.

d. Check battery connections.

IMPORTANT : ALWAYS RECHARGE THE LAMP AFTER USE.

ENSURE THAT ONLY CHARGERS WITH THE

CORRECT LI-ION CHARGE PROFILE ARE USED.

11

DL16 - Issue 4 November 2023

Certification and equipment marking and instructions:-

Lamp Type Nomenclature Reference:-

The lamp nomenclature indicates the battery, battery cover and headpiece type that are combined

to make the complete caplamp.

The full designation is DPL16, but since battery covers are now only available in plastic, the

designation is commonly abbreviated to DL16.

The assembly combination should not be changed without consultation of Denchi Group Ltd.,

Caithness, Scotland.

The type code sequence is as below:-

1 2 3

Headpiece type Battery Cover type Battery type

DStandard PPlastic Cover L16 Li Ion Battery

AATEX M1 LHand Lamp E16 Li Ion Battery ATEX M1

R Remote Take Off

1 2 3

Sample type code:- D P L16

12

DL16 - Issue 4 November 2023

Use of equipment:-

The user must ensure that the lamp supplied meets the safety standard required for the work

environment, with specific note to Zoned or Hazardous designated areas:-

1. Check that the operating temperature range is in the range 0oC to +40oC for Mining.

2. The lamp must not be disassembled in any hazardous area.

3. The lamp must not be charged in any hazardous area.

4. The battery casings are manufactured from polycarbonate and ABS with nitrile rubber

seals. The performance of these materials, with respect to attack by aggressive

substances that may be present in the operating environment shall be taken into account

before the equipment is used.

5. Plastic surfaces may cause propagating brush discharges. Propagating brush discharges

are caused by non-conducting fluid flow over a non-conducting plastic surface. The cap

lights shall not be used in areas where a high fluid flow over the plastic surfaces may occur

(for example in the case of a ruptured process pipe or compressed air pipe).

Special Conditions for Safe Use:

There are no special conditions stipulated.

Denchi Group Ltd.

Denchi House, Thurso Business Park,

Thurso, Caithness, KW147XW

URL: www.oldhamcaplamps.com

Tel.: +44 (0)1847 808000

November 2023

13

DL16 - Issue 4 November 2023

Appendix –LITHIUM-ION BATTERY COMMISSIONING & CHARGING INSTRUCTIONS

The Oldham D-type and A-type (LED) cap lamps are designed to operate at full light intensity for a full 12-hour shift. At the end of

each shift the lamp should be recharged on an approved Oldham micro-processor caplamp charger.

Note: To comply with IATA transport regulations, all li-ion batteries are shipped in a 30% state of charge condition and will

require a full 12-hour charge before being put into service

For 12-hour operation, the charger types 204001 or 204002 for the L16 & E16 batteries are recommended

(2-channel lamp & 10-channel chargers respectively).

PREPARING THE CAP LAMP FOR FIRST TIME USE: DL16 and AE16 lamps

The lamptop and battery are shipped unassembled to comply with international transportation regulations.

Tools required to assemble the lamp are an M4 for nut spinner for the battery terminals, and a 2.5mm

Allen socket key to secure the battery cover. (available in our “Small Tools and Spares Kit” part no.

206008).

Assembly of the DL16 and AE16 lamps.

1. The fuse is pre-fitted to the battery.

2. From the lamptop supplied, fasten the red cable to “+”positive terminal and the black cable to

the negative “-“ terminal with the washer and M4 nut, tightening to 0.5Nm

3. Hook the battery cover onto the battery at the negative end and press down ensuring the cable

is not trapped. (NB./ see picture –battery face/label toward you, cable should exit to the left)

4. Secure with the clamp at the positive end and lock with the M4 Mushroom headed socket screw.

Battery charging

1. Every battery must be charged before it is used for the first time.

2. Insert the headpiece over the charging key (headpiece held upside-down), and rotate the lamp

clockwise (approx. 2/3rd of a turn) until it can not turn any further, making +/- contacts.

3. Allow the battery to remain on charge for 12-24 hours. Note: Batteries which do not perform

satisfactorily, should be removed from service and subjected to a cycle charge process: charge

for 16 hours and discharge for 8 hours. Repeat several times until battery responds.

4. If battery does not respond after three or four cycles, it should be replaced.

Never discharge completely!

5. Lamps should be recharged each time after use, but after weekly shifts have been completed, the battery should be placed

on the charger (following the instructions included with the charger) and left to charge for the remainder of the weekend.

6. Oldham microprocessor chargers provide a maximum 4.20v / 1.0A to the lamp for recharge. USB style chargers delivering

5.0V / 1.0A may be used satisfactorily with the understanding that cycle-life will be diminished and warranty is invalidated

If the cap lamp needs cleaning, use a mild detergent and wipe. Do not submerge in water.

STORAGE OF BATTERIES

Lithium-ion batteries have excellent shelf-life with very slow rates of self-discharge. However, in order to maintain optimum condition,

all stored batteries should be boost charged for 24 hours every 6 months, and again immediately before being placed into regular

service.

Recommended storage temperature range: 32 O F to 80 O F / 0Oto 27 O C.

NOTE: Oldham multi-stage microprocessor controlled chargers have been programmed with a charge profile which is specifically

designed to achieve maximum cycle life in the Oldham range of lithium-ion powered caplamps. Operators may choose to recharge

their lamps on non-approved constant potential (voltage) chargers or other equipment, but daily operation and total cycle-life may be

affected.

Denchi Group Ltd. will not accept any warranty claim against lamps used on non-approved chargers

Table of contents