DencoHappel MultiMAXX HD User manual

OPERATION MANUAL

Decentral Systems Industry

MultiMAXX®HD

Powerful Heating for Mixed-Air Application

MultiMAXX HD

2PR-2007-0350-GB • Subject to modifications • R2-04/2016

1 DencoHappel product range

MultiMAXX HD Unit Type Code

PR-2007-0350-GB • Subject to modifications • R2-04/2016 3

2 Unit Type Code

Fig.1-1 Unit code Fig.1-2 Controls system Fig.1-3 Accessories

HD1 1.USAR L C.CKE I0.001.GA ZHX.XX X X

Size

1 = Size 1

2 = Size 2

3 = Size 3

4 = Size 4

Capacity stage

1 = Capacity stage 1

2 = Capacity stage 2

3 = Capacity stage 3

4 = Capacity stage 4

Air flow function

Circulating air

U = Position 1

V = Position 2

W = Position 3

X = Position 4

Y = Position 5

Mixed air

M = Position 1

N = Position 2

O = Position 3

P = Position 4

R = Position 5

Medium flow function

S = Only heating (steam)

W = Only heating

(LPWW and LPHW)

Heat exchanger

A=

Cu/Al, max. 130 °C; 1,6 MPa

C=Cu/Cu, max. 130 °C; 1,6 MPa

S=

Galvanized steel, circular finned pipe;

1,6 MPa - fin spacing 3 mm

T=

Galvanized steel, circular finned pipe;

1,6 MPa - fin spacing 6 mm

Coil connection (front view)

O = from top

R = from right

L = from left

Heat exchanger connection

A = External thread

O = Internal thread

Discharge louvres

Z=

Basic discharge ceiling, two sides, only heating

C=

Secondary air louvre, ceiling, manually adjustable

D=

Secondary air louvre, ceiling, actuator (230 V, on/off),

for DencoHappel MATRIX®

V=

Four sides discharge, ceiling

A=

Discharge nozzle, ceiling, only heating

T=

Gate nozzle, only heating

L=

Double deflection louvre, ceiling / wall, only heating

P=

Profile, ceiling / wall, only heating with ceiling installation

U=Secondary air louvre, wall installation, manual adjustment

W=Secondary air louvre, actuator (230 V, on/off) for DencoHappel

MATRIX®

B=

Basic discharge, wall

K=

Terminating flange, pressure side

O=

Without dischage, (design panel not possible)

Intake modules

20 = Mixed air module, type 1, direct

21 = Mixed air module, type 2, lateral

22 = Mixed air module, type 3, corner

23 = Fresh air shut-off damper

25 = Flexible connection/

hygiene connection frame

26 = Rectangular duct 150

27 = Rectangular duct 1000

28 = Duct connecting bend 90°, symmetrical

29 = Duct connecting bend 90°, assymetrical

31 = Air intake hood, wall

32 = Weather protection grille

34 = Roof bushing for slanted roof

35 = Air intake hood, roof

36 = Bag filter module

37 = Mat filter module

49 = Roof bushing with flat roof plinth

51 = Frame for wall connection

Ohne Auslass

Motor, speeds

C=3х400 V, 3-speed, diagonal distributor

S = 3x400 V, 3-speed, diagonal distributor upper speed range, only size 3

Electric equipment

K = Terminal box

S = Fan switch

R = DencoHappel MATRIX®

Casing

A = Heat exchanger - design steel sheet RAL 9002, plastic corners RAL 7000

B = Heat exchanger and discharge in selectable RAL

D = Heat exchanger in industrial design RAL 7000

Size

1 = Size 1

2 = Size 2

3 = Size 3

4 = Size 4

Material

0 = Steel sheet, plastic

8 = In accordance with VDI 6022

Actuators for louvers and mixed air modules

0 = Actuator by others

1 = Manual adjustment

2 = Actuator 230 V, on/off

3 = Actuator 230 V, on/off + potentiometer

4 = Actuator 230 V, on/off

+ final position switch

5 = Actuator 230 V+ spring return

6 = Actuator 24 V, on/off

7 = Actuator 24 V, continuous control

Filter class / electrical equipment

0=without

2 = G2/ without differential pressure switch

3 = G3/ without differential pressure switch

4 = G4/ without differential pressure switch

5 = G2/ with differential pressure switch

6 = G3/ with differential pressure switch

7 = G4/ with differential pressure switch

8 = F7/ without differential pressure switch

9 = F7/ with differential pressure switch

Additional modules and suspensions

55 = Modular (for wall mounting)

56 = Ceiling (for ceiling mounting)

Model 55 Modular suspension with types

R = Type U, M, W, O

S = Type V, N, X, P

Z = Accessory type V, N, X, P

Model ceiling suspension set:

57 for type U, V, W, X, M, N, O, P

58 for type Y, R

0 = Installation without threaded rod

1 = Kit with threaded rod 1 m

2 = Kit with threaded rod 2 m

3 = Kit with threaded rod 3 m

Controller type

0 = Terminal box

2 = MATRIX 2000

3 = MATRIX 3000

4 = MATRIX 4000

Controls package Nr.

1-999 = Package №

001-999

Control panel

IP54;

with sensor 903454

G = MATRIX OP21I

I = MATRIX OP31I

K = MATRIX OP44I

L = MATRIX OP50I

M = MATRIX OP51I

N = MATRIX.IR

Z = without control panel

Unit type

A = Master unit with loose

control panel

C = Master unit without control

panel

D = Slave unit without control

panel

Table of Contents MultiMAXX HD

4PR-2007-0350-GB • Subject to modifications • R2-04/2016

Table of Contents

Product Type Code ...................................................................................... 3

Table of Contents ....................................................................................... 4

Technical Description and Scope of Delivery ........................................... 5

Safety and User Information ....................................................................... 7

Availability of the operation manual ................................................................... 7

Scope of the operation manual .......................................................................... 7

Used symbols ..................................................................................................... 7

Labelling of safety instructions ........................................................................... 8

Safety-conscious working .................................................................................. 9

Proper use .......................................................................................................... 9

Safety regulations and codes ............................................................................. 9

Modifications and changes ................................................................................. 9

Spare parts ....................................................................................................... 10

Disposal ........................................................................................................... 10

Personnel selection and qualification ............................................................... 10

Technical Description ............................................................................... 11

Functional description of the unit ..................................................................... 11

Unit dimensions and location of heat exchanger connecting spogots ............. 12

Range of application ........................................................................................ 18

Transportation and Storage ..................................................................... 19

Delivery ............................................................................................................ 19

Transport .......................................................................................................... 19

Storage ............................................................................................................. 19

Installation .................................................................................................. 20

Load-bearing capacity of the installation site ................................................... 20

Ceiling installation ............................................................................................ 20

Wall installation ................................................................................................ 21

Installing the unit .............................................................................................. 23

Installing unit casing ......................................................................................... 23

Medium Connections ................................................................................ 26

Electrical Connections .............................................................................. 28

Connection diagrams ....................................................................................... 28

Terminal box or electrical switch box ............................................................... 29

Connecting switch unit MC 300 or regulator by others .................................... 30

Overview of the DencoHappel MATRIX®control electronics ........................... 32

Installing control panel ..................................................................................... 38

Electrical connection with DencoHappel MATRIX® ...................................................... 39

Network and shielding connection ................................................................... 49

Commissioning .......................................................................................... 56

Terminating resistors ........................................................................................ 58

Setting address ................................................................................................ 60

Setting limitation functions ............................................................................... 62

Switching the unit ............................................................................................. 64

Checking data connection ................................................................................ 65

Checking control inputs and outputs ................................................................ 66

Functional possibilities ..................................................................................... 68

Cleaning and Maintenance ....................................................................... 73

Cleaning ........................................................................................................... 73

Maintenance ..................................................................................................... 73

Troubleshooting ........................................................................................ 75

Dismantling and Disposal ......................................................................... 76

Dismantling ...................................................................................................... 76

Disposal ........................................................................................................... 76

MultiMAXX HD Technical Description and Scope of Supply

PR-2007-0350-GB • Subject to modifications • R2-04/2016 5

3 Technical Description and Scope of Supply

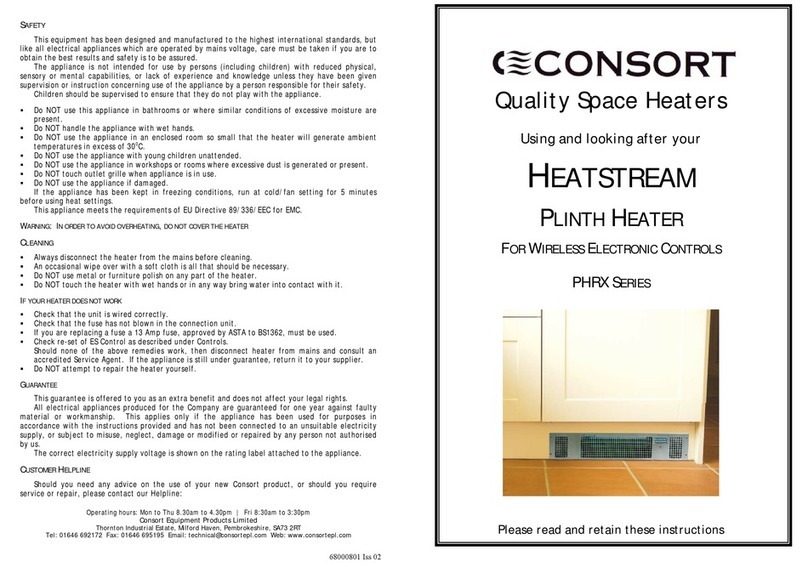

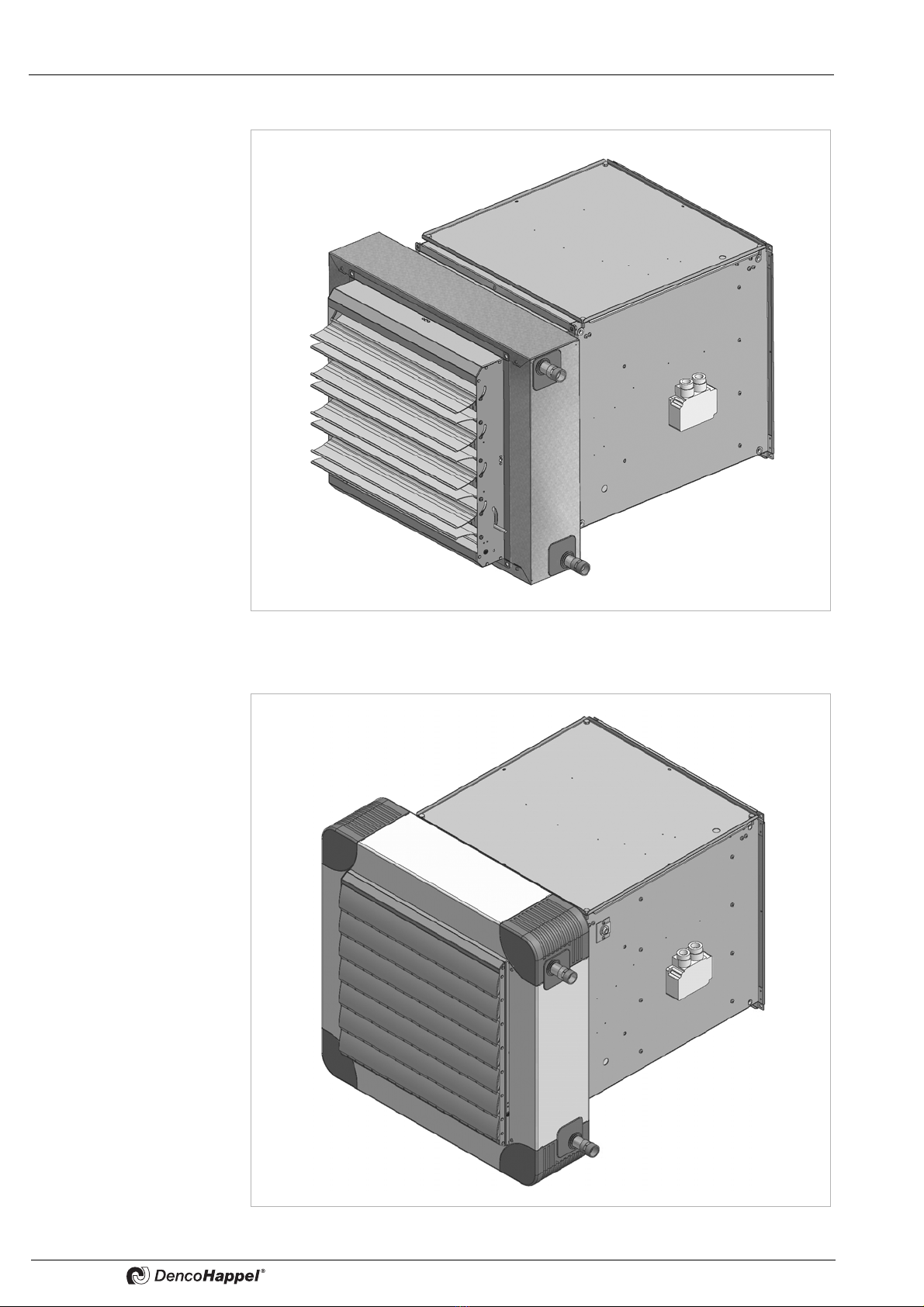

Fig. 3-1: Unit componets

1: Air discharge louvres

2: Heat exchanger

3: Fan module with inlet nozzle and terminal box

4: Fan with contact protection grille

5: Unit casing with plastic corners

1

2

3

4

5

Technical Description and Scope of Supply MultiMAXX HD

6PR-2007-0350-GB • Subject to modifications • R2-04/2016

Unit in industrial casing

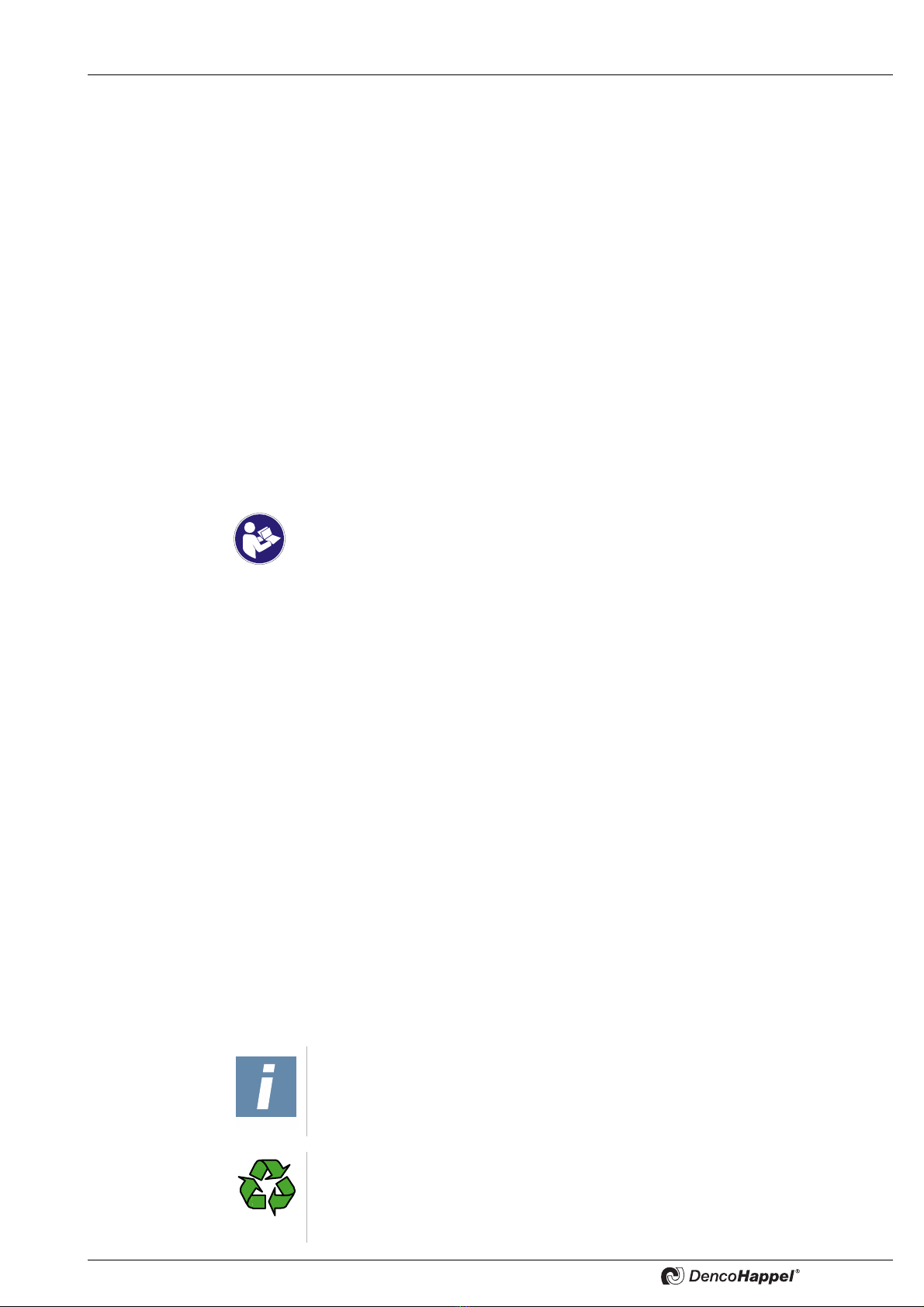

Unit in design / decorative casing

Fig. 3-2

Fig. 3-3

MultiMAXX HD Safety and User Information

PR-2007-0350-GB • Subject to modifications • R2-04/2016 7

4 Safety and User Information

The unit heaters MultiMAXX HD are developed and manufactured in

accordance with the state-of-the-art technological standards and established technical

safety codes and regulations. The unit heaters MultiMAXX HD comply with the EU

Machinery Safety Directive.

The unit heaters MultiMAXX are reliable and satisfy strict quality standards. This

product range combines advanced technology with a high level of user friendliness and

ease of maintenance. However, all unit heaters inevitably pose residual risks of injury

to the user or third parties or material damage to the unit or other objects. For this

reason, you should take into account and follow all safety instructions. Ignoring these

safety instructions is connected with risks to your health and safety, can lead to the

environmental damage and/or extensive material damage. Observing the safety

instructions in the operation manual will help you to avoid risks, ensure economical

operation of the unit and enjoy full benefits of the product. The safety aspects covered

by this chapter are valid for the entire operation manual.

4.1 Availability of the operation manual

The accompanying operation manual includes important information about the safe

and correct operation of the unit MultiMAXX HD.

This manual must always be available at the site where unit is in operation. Every per-

son working with or around the unit must read and apply the information contained in

the manual, paying particular attention to the safety instructions.

The operation manual is intended for use by fitting and installation companies, building

services engineers, technical personnel or trained persons as well as electrical and air-

conditioning engineering specialists.

4.2 Scope of the operation manual

This operation manual provides you with the necessary information about the following

subjects:

– Transportation and storage

– Assembly

– Installation

– Electrical connection

– Medium connection

– Commissioning and operation

– Maintenance

– Cleaning and disposal

4.3 Used symbols

The following symbols are used in this manual:

– This symbol is used to indicate normal lists.

•This symbol indicates instructions to follow.

9This symbol denotes the results of an action.

NOTE!

This symbol denotes additional information on use of the MultiMAXX HD.

RECYCLING!

This symbol indicates proper procedure for recycling of package material and disu-

sed unit components. These components need to be separated according to the

material type (e.g. metal, plastic etc.)

Safety and User Information MultiMAXX HD

8PR-2007-0350-GB • Subject to modifications • R2-04/2016

4.4 Labelling of safety instructions

PROTECTIVE SHOES!

This symbol indicated that you must wear protective shoes.

PROTECTIVE GLOVES!

This symbol indicated that you must wear protective gloves.

PERSONAL INJURY!

Here you will find special information as well as rules as restrictions for preventing

personal injury.

ELECTRICAL HAZARD!

This symbol indicates that there is a risk of electrical shock that can result in personal

injury including death and material damage.

HOT SURFACE HAZARD!

Here you can find special information as well as rules and restrictions for the

prevention of personal injuries due to hot surfaces.

DANGER – SHARP CUTTING EDGES!

Here you will find special information as well as rules and restrictions for the

prevention of personal injuries due to cutting on thin metal fins.

HIGH PRESSURE HAZARD.

Here you can find special information as well as rules and restrictions for the

prevention of personal injuries due to high pressure.

DANGER OF OVERHEAD LOADS!

This symbol indicates a hazardous location with a risk of personal injury

including death and material damage.

DANGER OF INFLAMMABLE MATERIALS

Here you can find special information as well as rules and restrictions for the

prevention of personal damage due to risk of fire.

ENVIRONMENTAL DAMAGE.

This symbol warns you against damage to the environment and turns your attention

you to all existing national environmental protection regulations.

DAMAGE TO THE UNIT!

Here you will find special information, rules and restrictions regarding the

prevention of damage to the MultiMAXX HD.

DANGER OF DAMAGE DUE TO STATIC DISCHARGE!

While carrying out connections or adjustments on the MultiMAXX make sure that you

discharge yourself statically before touchning PC boards and electrical

components.

MultiMAXX HD Safety and User Information

PR-2007-0350-GB • Subject to modifications • R2-04/2016 9

4.5 Safety-conscious working

To ensire your own safety consider the following safety instructions:

•Fluctuations and deviations of the supply voltage may not exceed the tolerance

limits specified in the technical data, otherwise functional failures and limit states /

excess pressures can not be excluded.

4.6 Proper use

The MultiMAXX HD unit heaters are exclusively designed for heating, ventilating and

filtering of indoor and outdoor air in industrial buildings, warehouses, sales and exhibi-

tion premises. Such accessories like filters, mixed air and air intake modules, suspen-

sion sets, switch units and control devices can be supplied.

Proper use also stipulates the observance of the operation manual as well as the

inspection and maintenance intervals specified by DencoHappel.

Any use other than that described above is considered improper. The manufacturer/

supplier is not liable for any damages arising from improper use. The user alone bears

the risk.

The following accident prevention regulations apply (VBG1, BGV A2 (previously:

VBG4), VBG7w, VBG9a) and generally recognized codes for machinery and principles

of engineering, particularly DIN VDE 0100, DIN VDE 0105.

4.7 Safety regulations and codes

When carrying out installation work, commissioning, maintenance and repair of the

MultiMAXX HD units all requirements of safety regulations and codes as well as gene-

rally established technical practices shall be considered.

4.8 Modifications and changes

You must not change, add to or modify the MultiMAXX HD in any way. Any changes or

modifications of the MultiMAXX HD will render the CE conformity and all warranty

claims null and void.

ELECTRICAL HAZARD!

All power supply connections must be switched off and checked to see if they

are voltage-free and then secured against unintentional switching on.

Earth and short-circuit them and cover over any neighbouring electrically

conducting parts or block them off. Failure to do so may lead to serious injury

or death.

DANGER OF DAMAGE DUE TO STATIC DISCHARGE!

While carrying out connections or adjustments on the MultiMAXX HD make sure that

you discharge yourself statically before touchning PC boards and electrical

components.

PERSONAL INJURY AND MATERIAL DAMAGE!

It is prohibited to operate the MultiMAXX HD units in following circumstances:

– in explosion risk areas;

– in rooms where conductive dusts are present;

– in rooms where strong electromagnetic fields are present;

– in rooms with aggressive environments that may attack plastics.

Safety and User Information MultiMAXX HD

10 PR-2007-0350-GB • Subject to modifications • R2-04/2016

4.9 Spare parts

You may use only original DencoHappel spare part since DencoHappel is not liable if

any third-party spare parts are used.

4.10 Disposal

Main and operating supply materials must be disposed of according to material type in

a safe and environmentally friendly manner. Also see „Disposal“ on page 47.

4.11 Personnel selection and qualification

Every person authorised to work on or around the MultiMAXX HD must have read this

entire operation manual and understood it completely – particularly the chapter on

safety. It is too late to do this during work.

All work must only be carried out by specialists with sufficient knowledge based on pro-

fessional training and experience in the following:

– Regulations concerning health and safety in the workplace

– Accident prevention regulations

– Directives and recognized codes of practice

All skilled persons must be able to assess what the work entrusted to them entails and

must be able to recognize and avoid any associated dangers.

MultiMAXX HD Technical Description

PR-2007-0350-GB • Subject to modifications • R2-04/2016 11

5 Technical Description

5.1 Functional description of the unit

The MultiMAXX HD unit heater consists of a heat exchanger and a fan with casing. The

casing is made of galvanized steel sheet and can be supplied in RAL colour according

to customer wishes. The air discharge opening can accommodate up to 13 different

types of discharge louvres. The diagonal fan is located in a fan casing on the rear side

of the heating unit. The protection grille prevents possible contact with the fan. The unit

rear side can be supplied with an attachment for mounting air intake accessories. The

fixing possibilities for suspending the unit using the ceiling or wall suspension are loca-

ted laterally on the fan box. The components made of non-ferrous metal and galvani-

zed connection parts are not protected by paint.

Technical Description MultiMAXX HD

12 PR-2007-0350-GB • Subject to modifications • R2-04/2016

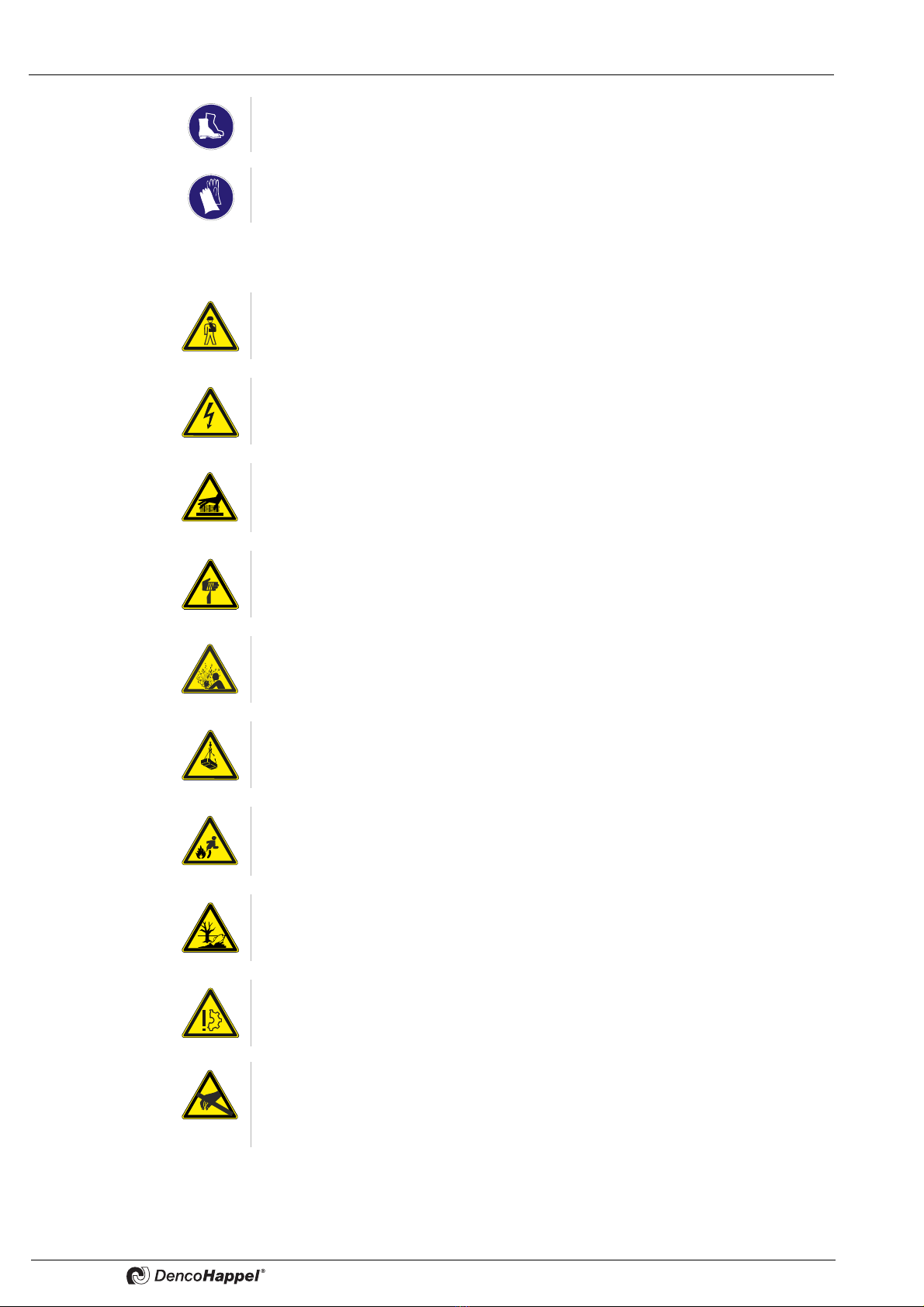

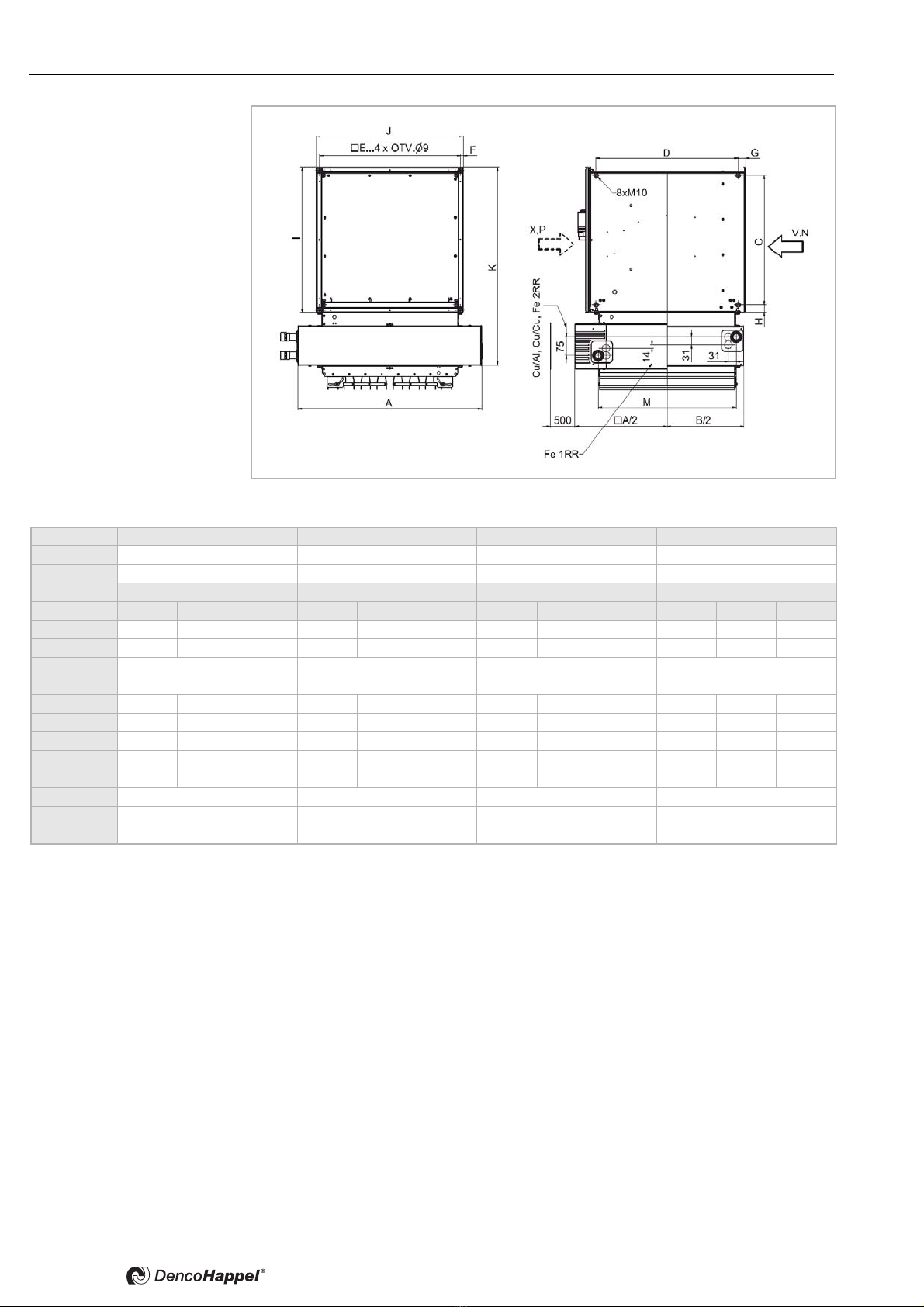

5.2 Unit dimensions and location of heat exchanger connecting spigots

5.2.1 Wall installation

Unit designation

Y, R

Fig. 5-1

Unit designation

U, M, W, O

Fig. 5-2

Space for installation and

maintenance

Space for installation and

maintenance

Size 1 2 3 4

A642 738 866 1026

B532 628 756 916

Model Model Model Model

Y, R U, M, W, O V, N, X, P Y, R U, M, W, O V, N, X, P Y, R U, M, W, O V, N, X, P Y, R U, M, W, O V, N, X, P

C473 427 427 569 523 523 697 651 651 857 811 811

D427 473 473 523 569 569 651 697 697 811 857 857

E470 566 694 854

F12 12 12 12

G3231–3231–3231–3231–

H31 32 34 31 32 34 31 32 34 31 32 34

I535 493 493 631 589 589 759 717 717 919 877 877

J493 547 494 589 643 590 717 771 718 877 931 878

K745 703 703 841 799 799 969 927 927 1129 1087 1087

L (Cu/Al, Cu/Cu) 399 447 511 591

L (Fe) 361 409 473 553

M 457 553 681 841

N300 300 400 400

MultiMAXX HD Technical Description

PR-2007-0350-GB • Subject to modifications • R2-04/2016 13

Unit designation

V, N, X, P

Fig. 5-3

Space for installation and

maintenance

Size 1 2 3 4

A642 738 866 1026

B532 628 756 916

Model Model Model Model

Y, R U, M, W, O V, N, X, P Y, R U, M, W, O V, N, X, P Y, R U, M, W, O V, N, X, P Y, R U, M, W, O V, N, X, P

C473 427 427 569 523 523 697 651 651 857 811 811

D427 473 473 523 569 569 651 697 697 811 857 857

E470 566 694 854

F12 12 12 12

G3231–3231–3231–3231–

H31 32 34 31 32 34 31 32 34 31 32 34

I535 493 493 631 589 589 759 717 717 919 877 877

J493 547 494 589 643 590 717 771 718 877 931 878

K745 703 703 841 799 799 969 927 927 1129 1087 1087

L (Cu/Al, Cu/Cu) 399 447 511 591

L (Fe) 361 409 473 553

M 457 553 681 841

N300 300 400 400

Technical Description MultiMAXX HD

14 PR-2007-0350-GB • Subject to modifications • R2-04/2016

Unit designation

Y, R

Fig. 5-4

Unit designation

V, N, X, P

Fig. 5-5

Space for installation and

maintenance

Space for installation and

maintenance

Size 1 2 3 4

A642 738 866 1026

B532 628 756 916

Model Model Model Model

Y, R V, N, X, P U, M, W, O Y, R V, N, X, P U, M, W, O Y, R V, N, X, P U, M, W, O Y, R V, N, X, P U, M, W, O

C473 427 427 569 523 523 697 651 651 857 811 811

D427 473 473 523 569 569 651 697 697 811 857 857

E470 566 694 854

F12 12 12 12

G32 31 – 32 31 – 32 31 – 32 31 –

H31 32 34 31 32 34 31 32 34 31 32 34

I535 493 493 631 589 589 759 717 717 919 877 877

J493 547 494 589 643 590 717 771 718 877 931 878

K745 703 703 841 799 799 969 927 927 1129 1087 1087

L361 409 473 553

N300 300 400 400

O41 45 49 55

MultiMAXX HD Technical Description

PR-2007-0350-GB • Subject to modifications • R2-04/2016 15

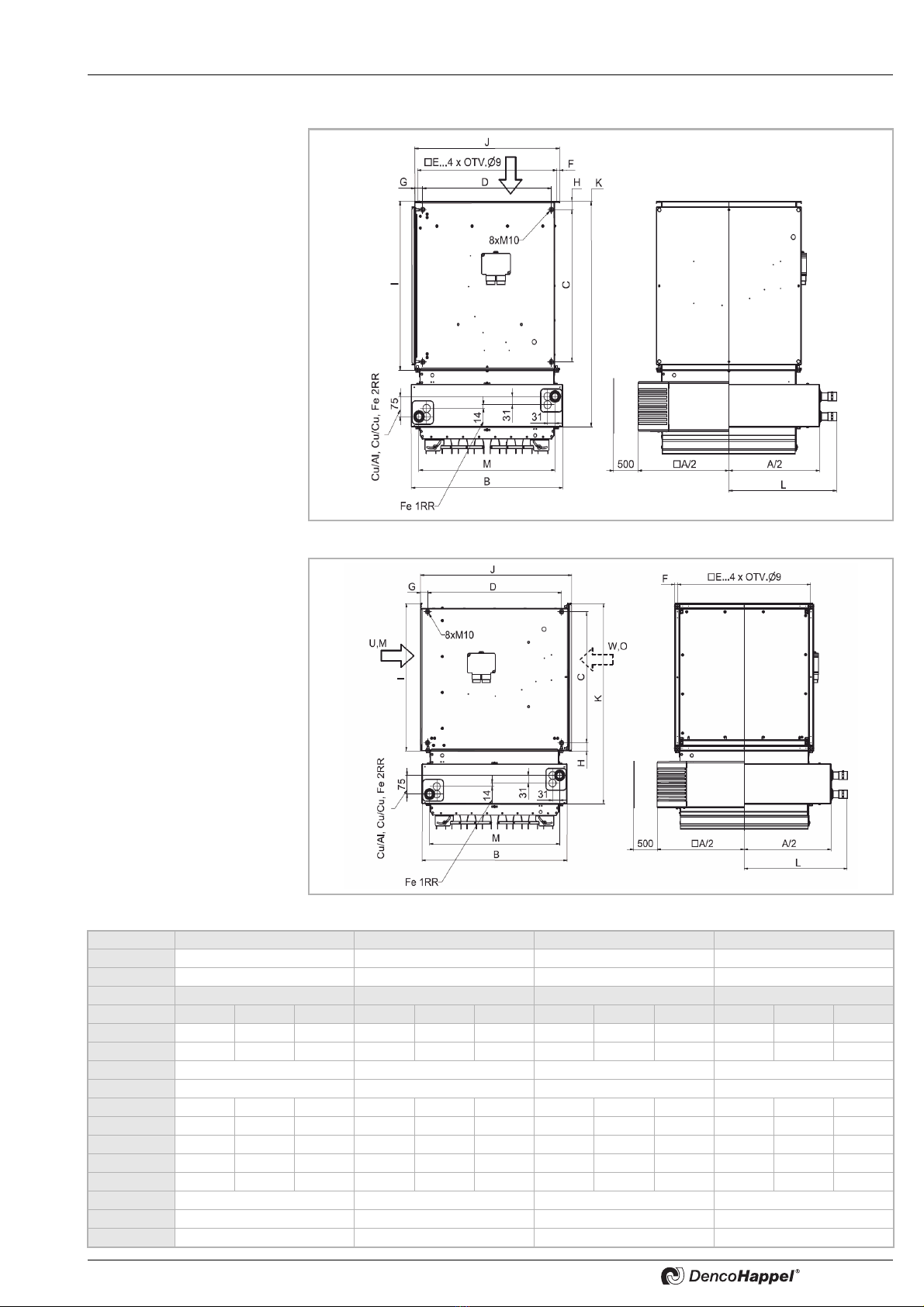

5.2.2 Ceiling installation

Unit designation

Y, R

Fig. 5-6

Unit designation

U, M, W, O

Fig. 5-7

Size 1 2 3 4

A642 738 866 1026

B532 628 756 916

Model Model Model Model

Y, R U, M, W, O V, N, X, P Y, R U, M, W, O V, N, X, P Y, R U, M, W, O V, N, X, P Y, R U, M, W, O V, N, X, P

C473 427 427 569 523 523 697 651 651 857 811 811

D427 473 473 523 569 569 651 697 697 811 857 857

E470 566 694 854

F12 12 12 12

G3231–3231–3231–3231–

H31 32 34 31 32 34 31 32 34 31 32 34

I535 493 493 631 589 589 759 717 717 919 877 877

J493 547 494 589 643 590 717 771 718 877 931 878

K745 703 703 841 799 799 969 927 927 1129 1087 1087

L (Cu/Al, Cu/Cu) 399 447 511 591

L (Fe) 361 409 473 553

M 457 553 681 841

Technical Description MultiMAXX HD

16 PR-2007-0350-GB • Subject to modifications • R2-04/2016

Unit designation

V, N, X, P

Fig. 5-8

Size 1 2 3 4

A642 738 866 1026

B532 628 756 916

Model Model Model Model

Y, R U, M, W, O V, N, X, P Y, R U, M, W, O V, N, X, P Y, R U, M, W, O V, N, X, P Y, R U, M, W, O V, N, X, P

C473 427 427 569 523 523 697 651 651 857 811 811

D427 473 473 523 569 569 651 697 697 811 857 857

E470 566 694 854

F12 12 12 12

G3231–3231–3231–3231–

H31 32 34 31 32 34 31 32 34 31 32 34

I535 493 493 631 589 589 759 717 717 919 877 877

J493 547 494 589 643 590 717 771 718 877 931 878

K745 703 703 841 799 799 969 927 927 1129 1087 1087

L (Cu/Al, Cu/Cu) 399 447 511 591

L (Fe) 361 409 473 553

M 457 553 681 841

MultiMAXX HD Technical Description

PR-2007-0350-GB • Subject to modifications • R2-04/2016 17

Unit designation

Y, R

Fig. 5-9

Unit designation

V, N, X, P

Fig. 5-10

Size 1234

A642 738 866 1026

B532 628 756 916

Model Model Model Model

Y, R V, N, X, P U, M, W, O Y, R V, N, X, P U, M, W, O Y, R V, N, X, P U, M, W, O Y, R V, N, X, P U, M, W, O

C473 427 427 569 523 523 697 651 651 857 811 811

D427 473 473 523 569 569 651 697 697 811 857 857

E470 566 694 854

F12 12 12 12

G32 31 – 32 31 – 32 31 – 32 31 –

H31 32 34 31 32 34 31 32 34 31 32 34

I535 493 493 631 589 589 759 717 717 919 877 877

J493 547 494 589 643 590 717 771 718 877 931 878

K745 703 703 841 799 799 969 927 927 1129 1087 1087

L361 409 473 553

O41 45 49 55

Technical Description MultiMAXX HD

18 PR-2007-0350-GB • Subject to modifications • R2-04/2016

Weight data are indicated for units including basic discharge and 3-speed fan motor.

5.3 Range of application

Unit heater Max. ambient temperature -20 °C to +40 °C

Power supply 3 x 400 V, or 1 x 230 V~ 50 Hz

Protection type IP 54

Power consumption See unit type plate

Heat exchanger

Cu/Al and Cu/Cu

Max. return temperature 70 °C

Max. operating temperature 130 °C

Max. medium pressure 1,6 MPa

Heat exchanger

Fe/FeZn

Max. operating temperature 180 °C

Max. medium pressure 1 row -1,6 MPa, 2 rows - 1,0 MPa

Heat exchanger

Size 1-3

Wall / ceiling units require valve regulation if the inlet temperature reaches +80 °C. The

valve shuts off the medium supply if the fan stops.

Heat exchanger

Size 4

Wall units require valve regulation if the inlet temperature reaches +130 °C (with ceiling

unit from +100 °C). The valve shuts off the medium supply if the fan stops.

Size

Unit weight with heat exchanger Water content of heat exchanger

Cu/Al Cu/Cu Fe/Zn Fe/Zn, 6mm Fe/Fe steel Cu/Al and Fe/Zn Fe/Zn

circular pipe Cu/Cu

kg kg kg kg kg kg kg kg

(A) (C) (S) (T) (R) (A / C) (S / T) (R)

HD11 51 52 76 66 70 1,0 3,8 2,5

HD12 51 55 96 – 82 1,7 7,2 3,2

HD13 53 58 – – – 2,5 – –

HD14 55 61 – – – 3,2 – –

HD21 72 73 105 90 94 1,3 5,2 3,2

HD22 74 78 132 – 113 2,4 10,1 4,3

HD23 76 82 – – – 3,4 – –

HD24 78 86 – – – 4,3 – –

HD31 97 100 146 126 130 1,8 7,4 4,3

HD32 100 106 185 – 158 3,5 14,4 6,0

HD33 104 113 – – – 5,3 – –

HD34 107 119 – – – 6,3 – –

HD41 150 155 219 189 197 3,0 10,7 5,8

HD42 155 165 273 – 235 5,6 20,9 8,3

HD43 160 174 – – – 8,4 – –

HD44 166 184 – – – 9,9 – –

NOTE!

All other important information about unit capacity, weights, connections and sound

power can be found in the „Data and Facts MultiMAXX HD - New Generation“.

MultiMAXX HD Transportation and Storage

PR-2007-0350-GB • Subject to modifications • R2-04/2016 19

6 Transportation and Storage

6.1 Delivery

When transporting and storing the unit the manuafacturer’s instructions must be

adhered to (see specification on the packaging).

•After the MultiMAXX HD is delivered, check that the delivery is correct according to

the delivery note, and also check for completenes (see “Technical Description and

Scope of Supply” on page 5).

•It is necessary to take photographs of all visible transit damage.

6.2 Transport

•Only use lifting gear with sufficient load carrying capacity.

•Ropes/chains should not be knotted and/or be exposed to sharp edges.

•Never use damaged lifting equipment.

•Pay attention to equal weight distribution.

– For your own safety wear gloves and safety footwear when transporting the unit.

6.3 Storage

Protect the MultiMAXX HD unit from humidity and dirt. Store the unit on premises of

class IE12, in accordance with the requirements EN 60 721-3-1.

Permitted storage conditions / permitted air condition for units which have not yet been installed

Air temperature: -25 °C to +40 °C

Air humidity: up to 85 % (relative humidity with no condensation)

NOTE!

Missing parts or damage in transit can only be claimed with the transport insurance

if the damage has been confirmed by the carrier.

NOTE!

We recommend that you transport or store your MultiMAXX HD in its original pack-

aging. Remove the original packaging only before installation. The packaging must

be disposed of in accordance with the relevant regulations and must be kept out of

reach of children due to potential asscociated risks. Protect the unit from the build-

up of dust and dirt. Be aware of damage during storage until the unit is ready for com-

missioning.

DANGER DUE TO OVERHEAD LOADS.

Never stand beneath suspended loads.

PERSONAL INJURY!

Do not use damaged transport devices.

Use a fork lift truck only if the unit is located on a pallet.

DAMAGE TO THE UNIT!

When transporting / moving the unit never use heat exchanger connections and

spigots as this may result in damage to the MultiMAXX HD.

Installation MultiMAXX HD

20 PR-2007-0350-GB • Subject to modifications • R2-04/2016

7 Installation

7.1 Load-bearing capacity of the installation site

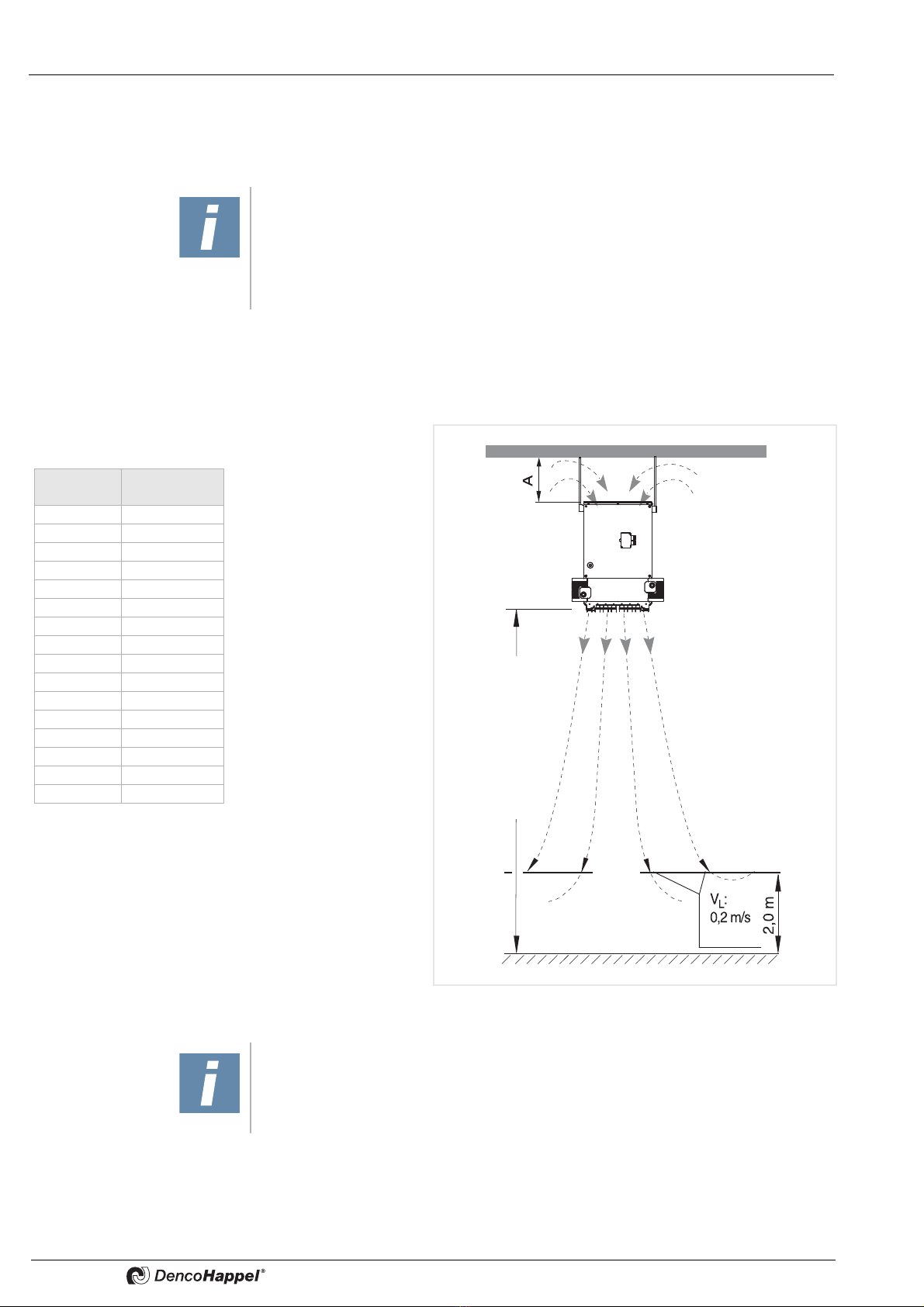

7.2 Ceiling installation

It is necessary to consider the suspension height, the distance between the units and

minimum distance from the ceiling.

Minimum distance from ceiling A (see Fig. 7-1)

It is necessary to keep the minimum distance to allow sufficient air intake and provide

sufficient access for maintenance.

NOTE ON UNIT ASSEMBLY AND INSTALLATION!

The assembly site must be vibration-free and suitable for permanently supporting the

weight of the unit heater. If necessary, the approval of a structural engineer or archi-

tect has to be received.

For fixing the unit there are two sets of 4 M10 nuts on the fan module - see

figure 5-1 and 5-10. The fixing material is enclosed with suspensions.

The suspension height of the unit is given in the table

The data in the chart are approximate and apply to the discharge temperuture if the

latter exceeds room temperature by 15 - 20 K

Fig. 7-1: Unit installation height with ceiling mounting

NOTE!

The maximum height of the unit ceiling installation varies depending on the

discharge temperature, lower speed and smaller air volume flow due to accessories.

Vertical configura-

tion of air louvres

Unit installation

height

Unit model Max. height

of installation (m)

HD11 11,5

HD12 9,8

HD13 9

HD14 7,5

HD21 14

HD22 13

HD23 12

HD24 11

HD31 13

HD32 12

HD33 11

HD34 10

HD41 14,5

HD42 13

HD43 12

HD44 11

Table of contents

Popular Heater manuals by other brands

Jaga

Jaga STRADA HYBRID MM Installation and operation manual

MILL

MILL Invisible & Glass Series Assembly and instruction manual

ELECTROTEK

ELECTROTEK ET-QH01 instruction manual

Clatronic

Clatronic HL 3378 instruction manual

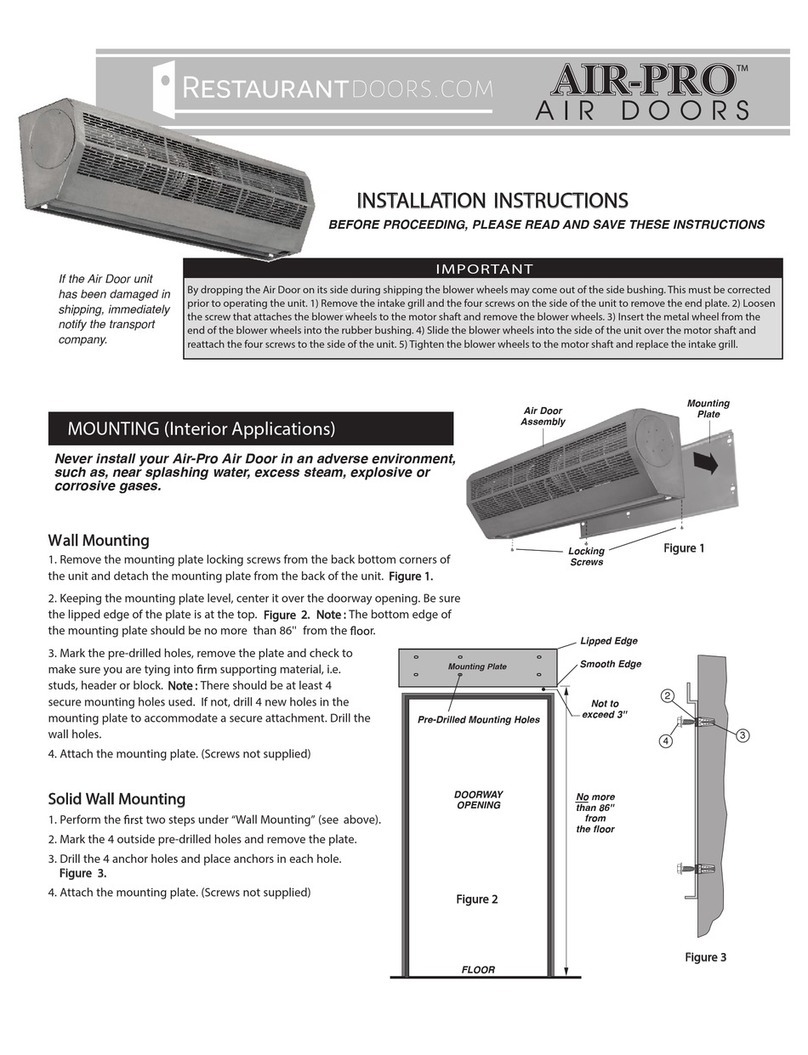

RESTAURANTDOORS.COM

RESTAURANTDOORS.COM AIR-PRO AP-2-36-1-S S installation instructions

Toyoset

Toyoset Radiant 101 Operation and maintenance instructions