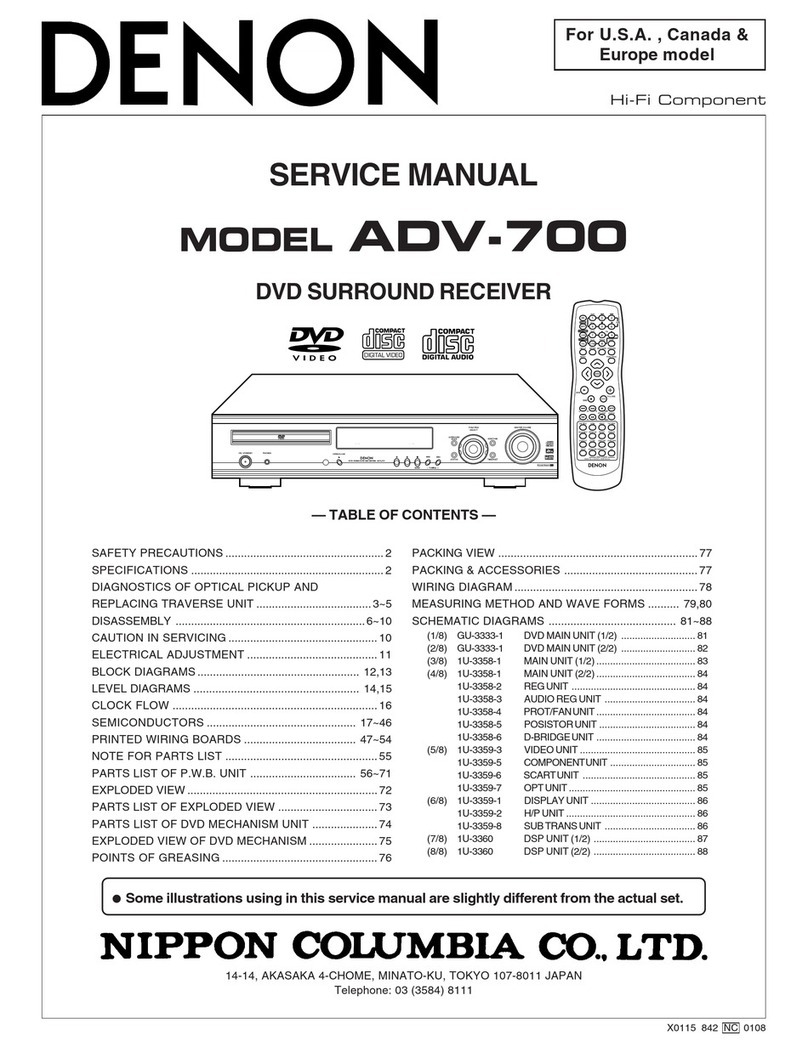

ABOUT THIS MANUAL.............................................................3

What you can do with this manual ............................................3

Using Adobe Reader (Windows version) ..................................4

SAFETY PRECAUTIONS ..........................................................6

NOTE FOR SCHEMATIC DIAGRAM.........................................7

NOTE FOR PARTS LIST ...........................................................7

TECHNICAL SPECIFICATIONS................................................9

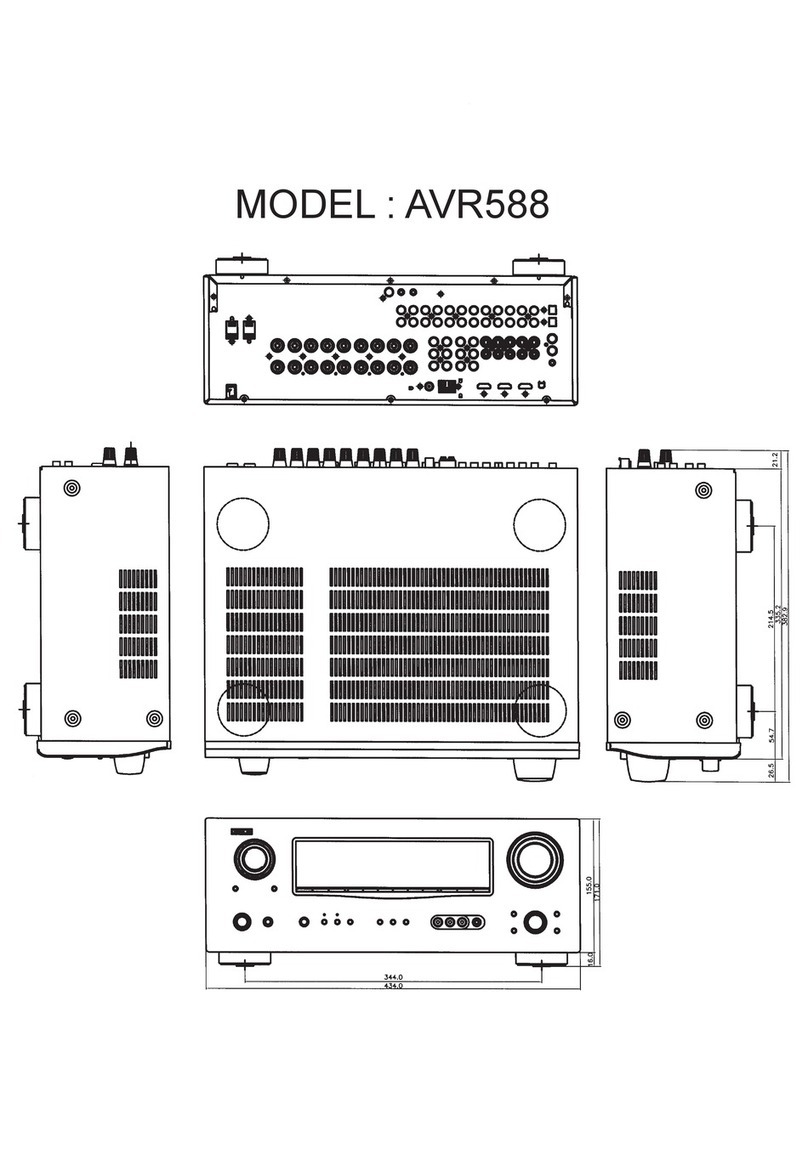

DIMENSION ...............................................................................9

Precautions During Service...................................................10

Initializing This Unit .................................................................10

Service Jigs.............................................................................10

DISASSEMBLY ........................................................................11

1. FRONT PANEL ASSY ........................................................13

2. RADIATOR ASSY...............................................................14

3. DIGITAL PCB .....................................................................15

4. VIDEO PCB........................................................................16

5. INPUT PCB ........................................................................16

6. SPK PCB............................................................................17

7. SMPS PCB.........................................................................18

8. TRANS POWER ................................................................18

SPECIAL MODE ......................................................................19

Special Mode Conguration Buttons.......................................19

1. Version Display Mode ........................................................20

2. PANEL / REMOTE LOCK Selection Mode.........................24

3. Selection Modes for Service-related Operations................25

DIAGNOSTIC PATH DIAGRAM.........................................30

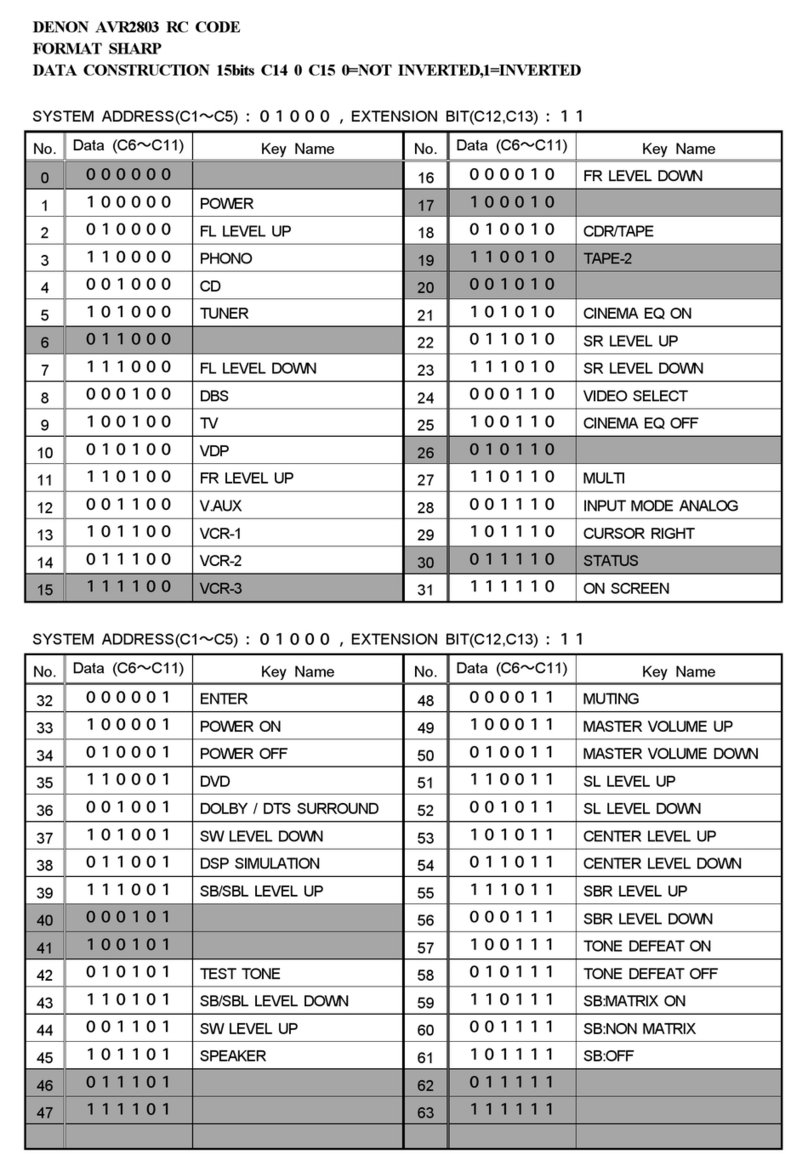

4. Remote ID Setup Mode......................................................64

5. Protection Pass Mode ........................................................65

6. CX870 / CY920 Reboot mode............................................65

7. CX870 / CY920 Initialization mode ....................................66

JIG FOR SERVICING ..............................................................67

Procedure after Replacing the Microprocessor, etc. ..........70

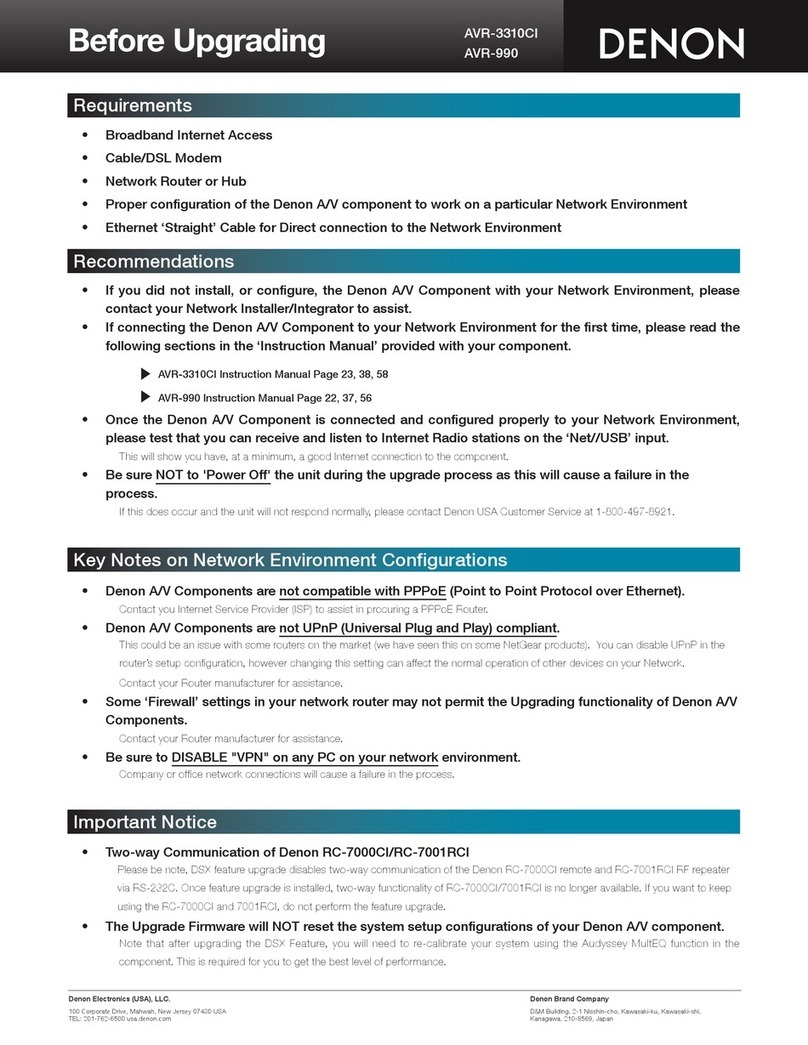

Firmware Update Procedure..................................................70

1. Updating by USB................................................................70

2. Updating by DPMS.............................................................79

ADJUSTMENT.........................................................................86

SURROUND MODES AND PARAMETERS ............................87

TROUBLE SHOOTING............................................................90

1. POWER..............................................................................90

2. Analog video ......................................................................91

3. HDMI/DVI ...........................................................................95

4. AUDIO................................................................................97

5. Network/Bluetooth/USB ...................................................100

6. SMPS ...............................................................................105

Audio Check PASS ..............................................................107

CLOCK FLOW & WAVE FORM IN DIGITAL BLOCK ...........108

LEVEL DIAGRAM..................................................................109

BLOCK DIAGRAM.................................................................115

POWER DIAGRAM................................................................116

WIRING DIAGRAM................................................................117

PRINTED WIRING BOARDS.................................................118

SCHEMATIC DIAGRAMS (1/33 ) ..........................................124

SCH01_DIGITAL CONNECT ................................................124

SCH02_DIGITAL POWER ....................................................125

SCH03_MAIN CPU ...............................................................126

SCH04_SUB CPU.................................................................127

SCH05_CPU LEVEL CHG ....................................................128

SCH06_DIR ..........................................................................129

SCH07_AUDIO PLD .............................................................130

SCH08_DSP .........................................................................131

SCH09_MAIN DAC ...............................................................132

SCH10_CY920......................................................................133

SCH11_VIDEO DECODER...................................................134

SCH12_HDMI SW2...............................................................135

SCH13_HDMI SW1...............................................................136

SCH14_VSP & IP & OSD......................................................137

SCH15_VIDEO PLD .............................................................138

SCH16_HDMI TX & SCALER ...............................................139

SCH17_ADAPTER................................................................140

SCH18_BLUETOOTH...........................................................141

SCH19_INPUT1....................................................................142

SCH20_INPUT2....................................................................143

SCH21_PREOUT..................................................................144

SCH22_F-HDMI ....................................................................145

SCH23_VIDEO .....................................................................146

SCH24_RC-5 & MX-PORT ...................................................147

SCH25_RS232C & TRIGGER ..............................................148

SCH26_CONNECT_A...........................................................149

SCH27_CONNECT_B ..........................................................150

SCH28_SPK .........................................................................151

SCH29_REGULATOR & TUNER..........................................152

SCH30_7CH AMP 1..............................................................153

SCH31_7CH AMP 2..............................................................154

SCH32_FRONT ....................................................................155

SCH33_SMPS ......................................................................156

EXPLODED VIEW .................................................................157

PACKING VIEW .....................................................................158

SEMICONDUCTORS .............................................................159

1. IC's ...................................................................................159

2. FL DISPLAY .....................................................................181

CONTENTS

2