Desert Aire GreenAire User manual

Indoor Air Quality

Aura™ (QS)

TotalAire™ (QS)

VerticalAire™ (QV)

• Climate control

systems that provide

cooling, dehumidifi-

cation, and optional

auxiliary heating for

Controlled Environ-

mental Agriculture in a

single, highly efficient

package.

• The GrowAire®GA

Series climate control

system offers a

all-in-one packaged

rooftop configuration.

• The GrowAire®GS

Series climate control

system is available in

a wide range of indoor

and outdoor configura-

tions and sizes to

match the application

requirements.

• The GrowAire®GV

Series climate control

system is a high-quality

cost-effective system

designed for tight

spaces

GreenAireTM

Climate Control Systems

Installation and Operation Manual

• Water system for use

with chilled/hot water

• CEA specic controls

• Unique control over

internal water ow

and temperature

• Internal chilled water

recirculation pump

• Internal chilled water

and hot water valves

Indoor Air Quality

Aura™ (QS)

TotalAire™ (QS)

VerticalAire™ (QV)

Installation and Operation Manual

• Climate control

systems that provide

cooling, dehumidifi-

cation, and optional

auxiliary heating for

Controlled Environ-

mental Agriculture in a

single, highly efficient

package.

• The GrowAire®GA

Series climate control

system offers a

all-in-one packaged

rooftop configuration.

• The GrowAire®GS

Series climate control

system is available in

a wide range of indoor

and outdoor configura-

tions and sizes to

match the application

requirements.

• The GrowAire®GV

Series climate control

system is a high-quality

cost-effective system

designed for tight

spaces

GS Series™

GV Series™

GA Series™

2

3

DANGER

ONLY TRAINED, QUALIFIED PERSONNEL SHOULD INSTALL AND/OR SERVICE

DESERT AIRE EQUIPMENT. SERIOUS INJURY, DEATH AND PROPERTY DAMAGE CAN

RESULT FROM IMPROPER INSTALLATION/SERVICE OF THIS EQUIPMENT. HIGH VOLTAGE

ELECTRICAL COMPONENTS AND REFRIGERANT UNDER PRESSURE ARE PRESENT.

For any unit labeled Class 1, Group D, Division 2, all wiring must be in accordance to

Class 1, Group D, Division 2 requirements. Insure that all local, state, national and any

other applicable codes are adhered to when connecting any device to this equipment.

All electrical connections to units labeled Class 1, Group D, Division 2 must be done

with a conduit seal.

Desert Aire

Climate Control Equipment Standard Limited Warranty

Desert Aire warrants the climate control unit to be free from defects in materials and workmanship subject to the

terms, conditions and limitations stated herein.

TERMS

Desert Aire warrants all components (except as noted) for a period of two (2) years from the date of shipment. This

warranty shall be limited to the supply of new or rebuilt parts for the part which has failed because of

defects in workmanship or material, and does not include the cost for labor, transportation or other costs not herein

provided for. Replaced parts are warranted only for the remaining portion of the original warranty period.

CONDITIONS

The warranty is subject to the following conditions:

1. The unit must be properly installed and maintained in accordance with the Desert Aire

“Installation and Operation Manual” provided with each unit and/or other documentation provided.

2. The Start-Up Report must be completed and returned to Desert Aire Service for evaluation. If no

decienciesareidentiedaWarrantyValidationLetterwillbeissuedthatprovidesallwarrantydates

andcoverage.Ifinstallationorstart-updecienciesarepresent,thesemustbecorrectedand

communicated to Desert Aire in order to activate warranty.

3. This warranty shall not apply to any part that has been tampered with, or has been subject to

misuse, negligence or accident. A warranty can be obtained for altered equipment but only with

written consent from Desert Aire.

4. The following parts and components are excluded from the warranty: belts, lters, driers, fuses.

Desert Aire - GreenAire™ Manual

4

5. Coils or other components that corrode due to corrosive air quality will not be warranted.

6. All replacements or repairs will be FOB Germantown, WI.

7. This warranty shall be null and void if defects or damages result from

tampering with factory set controls,

or operating outside the original design conditions.

8. Desert Aire shall not be liable for labor costs incurred in diagnosing the problem, or the removal

or replacement of the part or parts being repaired.

9. Desert Aire must preauthorize all warranty coverage described herein.

Extended Warranty:

Your Desert Aire unit may have extended warranties beyond this Standard Limited Warranty document.

Extended warranties are only available at the time of the purchase of the original equipment. These extended

warranties are covered under a separate document and their terms and conditions are separate from this

document. It is mentioned in this document for informational purposes only. Any Extended Warranties will be

identied on the Warranty Validation letter.

Any and all incidental or consequential damages are expressly excluded from this warranty. Some states do not allow

the exclusion of incidental or consequential damages for personal injury, so the above limitations may not apply to you

for certain damages. This warranty gives you specic legal rights, and you may also have other rights, which vary

from state to state. No person or representative is authorized to make any warranty or assume any liability not strictly

in accordance with the aforementioned.

Inquiries regarding warranty matters should be addressed to:

Desert Aire Corp c/o Service Manager

N120 W18485 Freistadt Road • Germantown, WI 53022 USA

Additional copies of this manual can be purchased for a nominal fee from Desert Aire. Submit requests to the contact

information listed above.

Desert Aire - GreenAire™ Manual

5

Safety Labels are used throughout this manual. They comply with the ANSI Z535.4 Standard.

Pleasebefamiliarwiththefollowinglabelsandtheirdenitions.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible death or injury.

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in minor or moderate injury.

Caution used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, could

result in property damage.

Product Warning for the State of California

Desert Aire - GreenAire™ Manual

6

TABLE OF CONTENTS

1 Introduction ................................................................................................................................. 9

1.1 Inspection ...................................................................................................................... 9

1.2 Freight Damage Claims ............................................................................................... 9

1.3 Rigging .......................................................................................................................... 9

1.3.1 Rigging the Unit ................................................................................................. 9

2 Installation

..................................................................................................................................

12

2.1 Location and Access ...................................................................................................... 12

2.2 Duct Installation ............................................................................................................ 13

2.3 Condensate Drain Piping .............................................................................................. 14

2.4 Unit Door Access and Lock ........................................................................................... 16

2.5 Water Piping Installation ................................................................................................ 18

2.6 High Voltage Wiring

......................................................................................................

21

2.6.1 High Voltage Connections ................................................................................. 21

2.6.2 Wire and Fuse Sizing ........................................................................................ 22

2.7 Controls and Sensors

...................................................................................................

22

2.7.1 Zone Sensor ...................................................................................................... 23

2.7.2 Photo Sensor ..................................................................................................... 24

2.7.3 Remote Display Terminal (Optional) .................................................................... 25

2.7.4 CO2 Sensors (Optional) ........................................................................................ 26

3. Start-Up Procedure ................................................................................................................... 29

3.1 Preliminary Inspection ................................................................................................... 29

3.2 Principle of Operation .................................................................................................... 29

3.3 Airow Balancing ........................................................................................................... 30

3.3.1 Blower Adjustment Procedure ........................................................................ 31

3.4 System Testing .............................................................................................................. 31

3.4.1 Dehumidication / Cooling Mode .................................................................... 32

3.5 General Testing

............................................................................................................

32

3.6 Routine Maintenance Schedule

...................................................................................

33

3.6.1 Service Every Month ........................................................................................ 33

3.6.2 Service Every Six Months ..................................................................

..............

34

3.6.3 Service Every Year .............................................................

..............................

34

4 Troubleshooting

........................................................................................................

..................

35

4.1 The Fan Does Not Run .................................................................................................. 35

4.2 The Pump Does Not Run ............................................................................................... 35

5 Appendix

......................................................................

................................................................

37

5.1 Recommended Duct Design ...

........................................................................................

37

5.2 Recommended Controller Settings

................................................................................

38

5.3 GreenAire™ Sequence of Operation

.............................................................................

38

5.3.1 Basic Sequence

......................................................................................................

38

5.4 Component Replacement, Drain & Leak Instructions

....................................................

41

5.5 System Rating Plate ...................................................................................................... 42

5.6 Start-Up Suppervision Supplemental Information

.........................................................

43

Desert Aire - GreenAire™ Manual

7

5.7 System Start-Up Report

..................................................................

..............................

44

Start-Up Request Form ................................................................................................ 45

GR Series Start-Up Report

.............................................................................

..............

47

Desert Aire - GreenAire™ Manual

8Desert Aire - GreenAire™ Manual

9

1. Introduction

Desert Aire climate control units are designed to provide years of reliable service when installed

properly. Read these instructions carefully before you install the unit.

1.1. Inspection

Desert Aire inspects and tests each climate control unit before it leaves the factory so that you

receive a quality piece of equipment. Unfortunately, equipment may become damaged in

transit. Inspect the unit carefully before signing the receiving papers. Check for both visible and

concealed damage. Remove crating and inspect the exterior cabinet for damage. Dented

panels, broken crating or any uid leaking from the unit should be documented upon delivery.

1.2. Freight Damage Claims

Freight is shipped FOB, if damage is noted, the BOL must be marked damaged to process a

claim - Failure to do so will void any future claims

If the unit has been damaged, document the extent of the damage. Take pictures if possible.

Next, obtain a claim form from the carrier. Promptly ll out and return the form. Carriers may

deny claims that you have not lled out within a week of delivery. Notify Desert Aire of any

damage. Damaged units must have signed documents at the time of delivery to be eligible

for a freight claim.

1.3. Rigging

1. Failure to observe rigging instructions may lead to equipment damage, personal

injury, or death.

2. Lifting method and procedure must comply with all local and national codes and

regulations.

3. The use of safety slings in addition to lifting lugs is required.

4. Do not lift the dehumidifier in high winds or above people.

Desert Aire equipment is solidly built and can be very heavy. Avoid personal injury and damaging

the equipment by planning the installation carefully. Use moving equipment whenever possible.

1.3.1. Rigging the Unit

Depending upon the unit type, various rigging methods are used to best lift the

equipment. Please reference the applicable sections below:

Desert Aire - GreenAire™ Manual

10

• GreenAire™ Products (GR)

-Vertical Cabinet Models (GRAV,GRBV,GRCV,GRDV)

Personnel should avoid stepping on the top of the unit. Desert Aire

air handlers are not designed to support the weight of a person on all

portions of the roof. Damage incurred through caved or distorted top

panels will not be covered under warranty. If you must walk on the top

panels, carefully walk on the edges where structural integrity is

greatest.

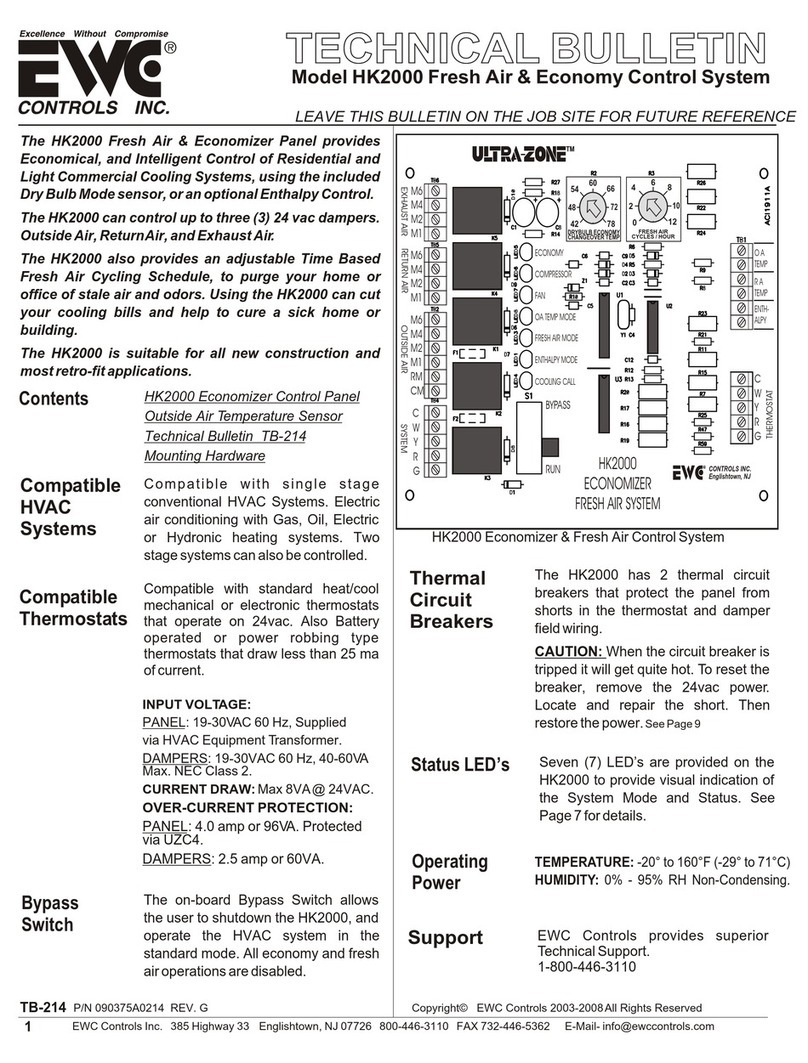

Figure 1 - Fork Pocket Locations

Desert Aire - GreenAire™ Manual

11

Desert Aire - GreenAire™ Manual

Move the unit to the desired installation location with the unit still on

the wood pallet. To remove the unit from pallet, position fork lift parallel

to the fork pockets in the bottom of the unit and found at each end and

in the middle of the unit. Use only the fork pockets to avoid damage.

The unit will have to be carefully removed from the fork lift and placed

into the desired location using hand truck equipment dollies or pipe

rollers. Use caution to not damage the unit with the fork lift or tip the

unit over ensuring it is kept as level as possible. The Vertical Cabinet

GR unit is designed to t through a standard size door (the door itself

may need to be removed temporarily) but will require that the air lter

box be removed or not installed until after the unit is in the nal

location. The unit should be assembled as close to the location of

installation as possible. Use caution when moving the unit through a

doorway to not catch the hinges on the door frame. It may be

necessary to remove the wood pallet to get the unit through the

doorway.

1. Do not tip the unit on its side.

2. Avoid dropping the unit down stairways or subjecting it to severe mechanical shock.

12 Desert Aire - GreenAire™ Manual

2 Installation

Manualappliestostandardunitcongurationsonly.

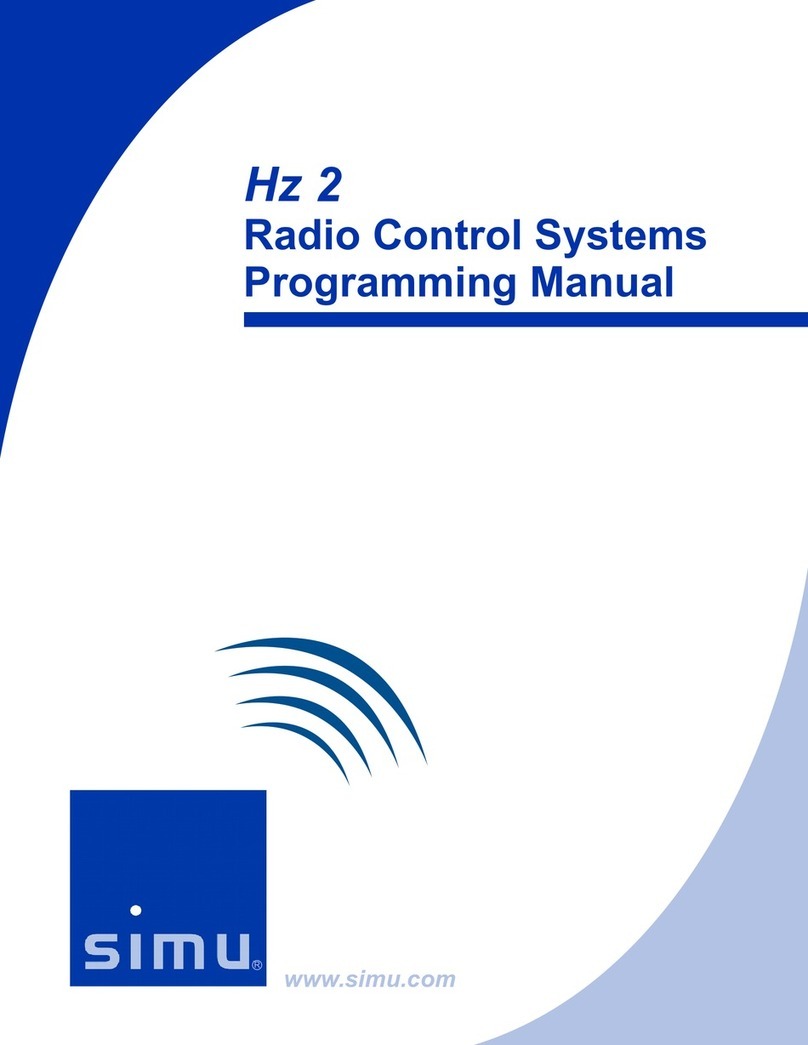

2.1 Location and Access

Desert Aire GreenAire™ air handlers are congured to allow access from the rear and the

sides. This means you can make your service connections and perform routine maintenance

when you must install one side of the air handler close to a wall or other restriction. The

“access side” is the long side with the access doors. The shorter sides also have access

doors. It is recommended that clearance be provided for all of these doors to allow for ease of

service ability in the event large components require replacement. Allow a minimum of 36

inches of clearance around the shorter sides of the air handler for piping, electrical

connections, and service access. Refer to the general arrangement drawing for further details.

Figure 2 - Required Clearance for Working and Safety

13

Desert Aire - GreenAire™ Manual

Install the unit on a sturdy, level mounting base or platform that will prevent vibration and

sound transmission. Never install the air handler on a wooden or metal platform without

consulting the design engineer for isolation requirements and / or sound control materials.

Do not install the unit near occupied rooms such as oces or guest rooms. Do not attempt to

conserve installation space by fabricating restrictive ductwork with abrupt bends. You may

reduce the operating eciency and the moisture removal capacity of the air handler. See

section 2.2 or 5.1 for detailed duct installation instructions.

Units located in unconditioned spaces may form condensation on the exterior of the cabinet as

well as in the interior surfaces. Precautions should be taken for indoor units located within

unconditioned spaces to prevent damage resulting from condensation. When the unit is

exposed to low temperatures, the interior surfaces may become cold enough to drop below the

dewpoint. Condensation may then form on the cold interior surfaces and result in water

collecting; this result could be especially problematic in the electrical box. If the unit is located

in either an outdoor space or in a location that is near a doorway or window which may lead to

humid air entering the air handler unit, condensation is possible. In a unit located outdoors,

some condensation will collect on exterior panels.

Do not install an indoor-rated air handler in an outdoor or a wet environment.

If you must install an air handler outdoors you must use an outdoor-rated air handler. Desert

Aire seals and weatherproofs outdoor air handlers to help prevent water inltration. You can

determine whether your air handler is outdoor-rated by inspecting the unit rating plate. See

section 5.5 for details.

2.2 Duct Installation

Duct design and installation should conform to the latest ASHRAE and SMACNA low velocity

duct standards. See section 5.1 for details. Undersized, restrictive ductwork with abrupt turns

or transitions, can decrease the eciency and the moisture removal capacity of your unit. Size

the ductwork for an acceptable air pressure drop at the airow volume of your unit. Use

neoprene ex connectors when you attach ductwork to the unit to prevent transmission of

excess vibration and noise.

Select the grilles, registers and diusers for low static pressure loss, required throw distance,

and the specied CFM rating. You can nd this information in most grille manufacturer’s

catalogs. If you are installing the grilles in a corrosive environment, choose components made

from anodized aluminum.

If you must install ductwork in an unconditioned area, use berglass duct wrap with vapor

barrier facing. You must install the outdoor air intake away from all sources of airborne

contamination such as exhaust fans or plumbing vents. You can use galvanized sheet metal

ducts for most applications. However, you should use aluminum or stainless steel ducts for

extreme applications such as chemical-laden environments.

14 Desert Aire - GreenAire™ Manual

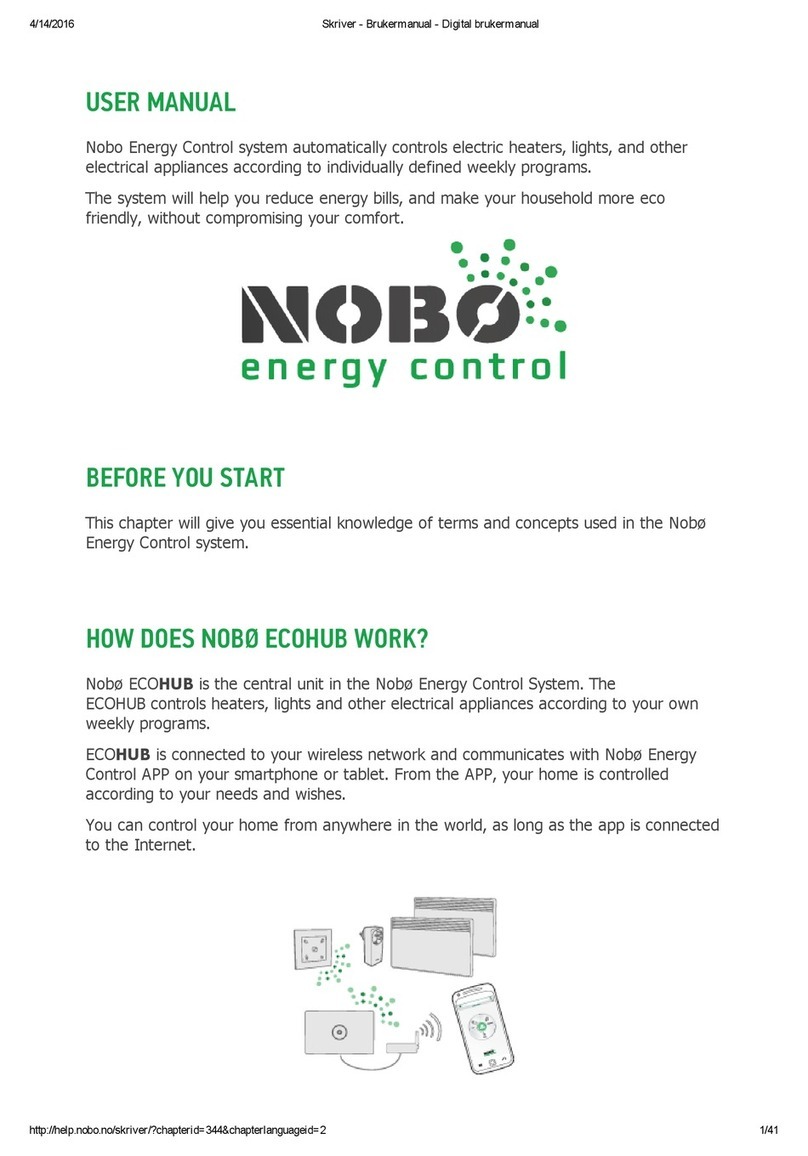

2.3 Condensate Drain Piping

Condensate drain lines installed in an unconditioned space must be heat taped to

prevent freezing. Check the heat tape yearly before winter operation.

The condensate drain connection may be on the side or the bottom of the unit, depending on

the size and style of the cabinet used.

Note: While the supply fan runs, the drain pan area inside the air handler operates at a

negative pressure. Your unit requires a waterless trap or P-trap in the condensate drain pipe to

prevent condensate from being drawn into the cabinet of the air handler.

Figure 3 - Condensate Piping (Side-Mounted Drain Shown)

Waterless Trap Option

A waterless trap may have been included on your GreenAire™ order. This type of trap is highly

recommended in the application. When units are installed outdoors in freezing conditions, the

waterless trap reduces risk of freezing of the trap should there be prolonged periods of shut

down. It also eliminates the need to ensure that the trap is pre-primed on initial start. It can

assist where there is limited height available on higher negative static pressure return ducts or

when indoor units are not placed on a housekeeping pad.

15

Desert Aire - GreenAire™ Manual

When condensation is not present, the negative pressure within the plenum draws the internal

mechanism against the valve seat preventing air from entering the AHU through the drainpipe.

As condensate forms, water builds up in the vertical pipe. When the water pressure equals the

negative air pressure in inches of water column, the force of the water head becomes equal or

greater than the negative pressure and the internal mechanism moves to the right, and water

ows.

When there is no longer a requirement to remove condensation, the negative pressure returns

the ball to the valve seat and prevents airow to the unit plenum. The internal rails aid in

returning the ball to the seat.

Figure 4 - Waterless trap ball valve

The column of liquid within the GreenAire™ unit is adequate for moving the ball from the valve

seat. No additional drop of the condensate line is required outside of the unit for external static

pressures up to 2” w.c.

Condensate lines operating in freezing temperatures will still require heat trace and insulation

to prevent freezing in operation.

If waterless traps are needed, these can be purchased by contacting Desert Aire Service

department. If a P-trap is used, it should be of adequate depth to prevent water from drawing

into the cabinet on startup and to hold enough water when the fan is o such that the trap will

not lose the prime on the next start. The depth of each leg and the ratio between these is

important.

4”

4”

Figure 5 - Sectional View of Condensate Trap Requirements

16 Desert Aire - GreenAire™ Manual

Trap the condensate as shown in Figure 5. The P-trap dimensions in Figure 5 are sized for a

maximum return air static of 2.0” of water. If your return air static exceeds this specication,

consult Desert Aire for help in resizing the P-trap.

You may also need to install a cleanout tee or plug near the trap. Note that the drain opening

in the drain pan is o-center to simplify its cleaning and servicing. Once you have designed

and installed the trap, follow this sequence:

1. Connect the trap to a main drain line with 1/4” of downward pitch per linear foot of run.

2. Support the drain pipe every ve feet to prevent sagging.

3. After you install the drain piping, prime the trap by pouring water into the drain pan of

the air handler.

2.4 Unit Door Access and Lock

The doors are removable to allow for access in close spaces. To open the doors, grasp the

latch by the rounded section on the door and pull outward (see photo below). When the latch

handles are rotated 90 degrees, they can be pulled outward and disengage from the door

frame (see photo below). To reattach the handles, push the door closed and rotate the latches

shut.

Figure 6 - Door hinge/latch in closed position

By opening all four latches, the door may be pulled o the unit for better accessibility. Grasp

the latch by the protruding T-shaped section and pull outward to remove the hinged section.

17

Desert Aire - GreenAire™ Manual

Figure 7 - Door hinge/latch in open position

The latch has a hex head shaped key slot that is used to lock the latch and prevent opening

and removal of the door. There is a ridge next to the slot that indicates whether the latch is

locked or unlocked. If the latch is open, the ridge is horizontal. To lock the latch, rotate the hex

head with an Allen wrench 90° until the ridge is vertical. The ridge next to the slot on the

unlocked latch will align with a similar ridge in the middle of the body of the latch handle. There

is a second ridge that aligns with the locked position. There is a raised line that says “OPEN”

which leads from the locked ridge to the unlocked ridge.

Figure 8 - Latch, note positions of the ridges

18 Desert Aire - GreenAire™ Manual

2.5 Water Piping Installation

The air handler may be connected with a water tower or a chilled water unit. Use industry

standard piping practices when connecting to such a unit. Connections are copper stubs. Refer

to submittal documentation for specic size per model.

Water Quality and General System Design

A 60 mesh or ner strainer must be installed in the water inlet line. Flush eld-installed piping

thoroughly before you put the air handler into service. A piping system not properly ushed or

ltered will cause the water ow control valves or heat exchanger to lose eciency or fail

prematurely due to clogging and/or fouling.

To prevent premature failure of the system, maintain the water at a pH of 7.4, but never below

6.0. Do not use water with high concentration of sulfur, chlorine, or sodium chloride.

See specic Flow Rate section for the required water ow rate and head for your application.

Install an air eliminator at any high point in the water piping. Air trapped in the water circuit of

the air handler can lead to poor system performance, unexpected service calls, and

decreased equipment life.

Do not exceed these guidelines as excessive flow rates will erode the condenser and piping.

GreenAire™ Products Flow Rate

The ow rate, pressure, and glycol concentration (if used) will depend on the installation. If

any part of the system is to be installed outdoors, the system must be protected by antifreeze

at an adequate concentration to prevent freezing. For purposes of burst protection during

system idle times and during storage, a minimum of 30% ethylene glycol or 35% propylene

glycol is recommended if any part of the system is installed in locations subject to freezing

conditions. This concentration will prevent system damage. Note that damage to heat ex

changers or piping due to freezing conditions is not covered under warranty.

For units that are required to start at very low ambient temperatures, higher antifreeze

concentrations may be required. If units installed outdoors are to be idle and will be required

to start at low temperatures, review low temperature starting concentrations in Figure X. Note

that the uid will warm rapidly after starting, but it is critical that the loop be insulated to protect

from signicant condensation and freezing when the water is cold.

.

19

Desert Aire - GreenAire™ Manual

Minimum Temperature (°F) Minimum Concentration (%)

Ethylene Glycol Propylene Glycol

20 17 19

10 26 31

0 34 38

-10 41 45

-20 46 49

-30 50 53

Figure 9 - Antifreeze Concentrations for Low Ambient Starts

Solutions less than 30% or uids without inhibitor packages may require additional inhibitors

to prevent corrosion and avoid risk of bacterial contamination. Consult the antifreeze uid

supplier for additional information on inhibitors and water quality in loops.

Note that chiller manufacturers, particularly those that utilize a plate heat exchanger, may

require freeze protection uids at low temperatures to prevent freezing of uids in heat ex

changers even if the loop is fully indoors. Consult the chiller manufacturer for

recommendations concerning antifreeze to ensure that minimum requirements are also

maintained for chiller operation.

Chilled Water Flow and Pressure

The chilled water loop in the equipment includes a circulation pump and a valves that

modulates the temperature and ow rate through the system. The system is intended to be

used with a variable speed primary loop.

It may be noted that the ow through the system varies depending on the load. Testing during

startup should be done at maximum cooling capability to ensure that enough ow is available

for specied unit performance. See Figure 10 for the ow rate specication at maximum

cooling.

A minimum pressure is required at the inlet of the unit to protect the internal pump from

cavitation and damage. This minimum pressure is the Net Positive Suction Head Required

(NPSHr). Units that are on the same level as the primary pump or lower typically do not have

issues with this requirement. Should the unit be installed above the primary pump, ensure that

the Net Positive Suction Head available is greater than the requirements shown in the chart. It

should be noted that these values are shown in absolute pressure rather than gauge pressure.

20 Desert Aire - GreenAire™ Manual

Figure 10 - Chilled Water Flow Rate

Hot Water Flow and Pressure

Hot water is provided to the GreenAire™ units to reheat or heat the air. The hot water system

in the GreenAire™ unit includes a valve to vary the ow. There are two options. The unit can

be congured with a two-way valve or a three-way valve. Two-way valves are typically used

on systems with modulating pumps. Three-way valves are typically used with systems with

xed speed primary pumps.

It should be noted that the pressure drop shown is for water only (0% antifreeze). For units

with antifreeze, refer to the submitted specications or the equipment label for the pressure

drop at the specic antifreeze type and concentration.

Model Size Fluid Flow Rate Pressure Drop (Water)

(GPM) (ft w.c.)

GRAV 9.6 8.1

GRBV 14.1 16.6

GRCV 18.0 17.5

GRDV 24.7 25.8

Figure 11 - Hot Water Flow Rate

SpeciedFluidFlowRatesandTemperatures

Performance in the application has been determined based on the ow rates and

temperatures given in specications by the design professional. The expected ow rate and

temperature for both the hot water system and the chilled water system are shown on the unit

labels. At the time of startup, place the unit in a maximum cooling condition and a maximum

heating condition to ensure that temperature and ow rate is as expected. The unit

Model Size Fluid Flow Rate NPSHr

(GPM) (psia)

GRAV 18.9 6.1

GRBV 35.0 6.2

GRCV 5.18 6.6

GRDV 61 7.1

Table of contents

Popular Control System manuals by other brands

Sel

Sel SEL-411L-2 manual

BACHMANN EUROPE Plc

BACHMANN EUROPE Plc E-Z COMMAND DIGITAL COMMAND CONTROL SYSTEM user manual

ADTRAN

ADTRAN Total Access 300 Series Installation and maintenance guide

Skov

Skov FarmOnline+ DataLink 131545 Technical user guide

FLARM

FLARM PowerFLARM Portable installation manual

PACH & COMPANY

PACH & COMPANY AeGIS 8000 Series Quick installation guide