Desert Aire ExpertAire LC Series User manual

Installation and Operation Manual

• Meets AHRI Standard 910.

• Effective humidity control:

4 to 100 lbs per hour.

• Wide range of ambient

temperatures: 65° to

95° F.

• Air conditioning option.

• Optional outdoor air

intake to help meet

ASHRAE 62 ventilation

requirements.

• Multiple heat sink options

including pool water

heating.

• Scroll compressors for

high efficiency and

longevity.

• Galvanneal cabinet with

high impact, powder coat

textured paint.

• Auxiliary heat including

hot water and electric

coils.

LC System

LV System

2

3

Desert Aire - LC/LV Manual

DANGER

ONLY TRAINED, QUALIFIED PERSONNEL SHOULD INSTALL AND/OR SERVICE

DESERT AIRE EQUIPMENT. SERIOUS INJURY, DEATH AND PROPERTY DAMAGE CAN

RESULT FROM IMPROPER INSTALLATION/SERVICE OF THIS EQUIPMENT. HIGH VOLTAGE

ELECTRICAL COMPONENTS AND REFRIGERANT UNDER PRESSURE ARE PRESENT.

Desert Aire

Dehumidication Equipment Standard Limited Warranty

Desert Aire warrants the dehumidifying unit to be free from defects in materials and workmanship subject to the terms,

conditions and limitations stated herein.

TERMS

Desert Aire warrants all components (except as noted) for a period of two (2) years from the date of shipment. This

warranty shall be limited to the supply of new or rebuilt parts for the part which has failed because of

defects in workmanship or material, and does not include the cost for labor, transportation or other costs not herein

provided for. Replaced parts are warranted only for the remaining portion of the original warranty period.

CONDITIONS

The warranty is subject to the following conditions:

1. The unit must be properly installed and maintained in accordance with the Desert Aire

“Installation and Operation Manual” provided with each unit and/or other documentation provided.

2. The Start-Up Report must be completed and returned to Desert Aire Service for evaluation. If no

deciencies are identied a Warranty Validation Letter will be issued that provides all warranty dates

and coverage. If installation or start-up deciencies are present, these must be corrected and

communicated to Desert Aire in order to activate warranty.

3. This warranty shall not apply to any part that has been tampered with, or has been subject to

misuse, negligence or accident. A warranty can be obtained for altered equipment but only with

written consent from Desert Aire.

4. Thefollowingpartsandcomponentsareexcludedfromthewarranty:belts,lters,driers,fusesand

refrigerant.

5. Refrigerant coils or other components that corrode due to improperly balanced pool chemistry or

corrosive air quality will not be warranted.

6. All replacements or repairs will be FOB Germantown, WI.

7. This warranty shall be null and void if defects or damages result from unauthorized opening of the

refrigerant circuit, tampering with factory set controls, or operating outside the original design

conditions.

8. Desert Aire shall not be liable for labor costs incurred in diagnosing the problem, or the removal

or replacement of the part or parts being repaired.

9. Desert Aire must preauthorize all warranty coverage described herein.

4Desert Aire - LC/LV Manual

Extended Warranty:

Your Desert Aire unit may have extended warrantees beyond this Standard Limited Warranty document.

Extended warrantees are only available at the time of the purchase of the original equipment. These extended

warrantees are covered under a separate document and their terms and conditions are separate from this document.

Itismentionedinthisdocumentforinformationalpurposesonly.AnyExtendedWarrantieswillbeidentiedonthe

Warranty Validation Letter.

Any and all incidental or consequential damages are expressly excluded from this warranty. Some states do not allow

the exclusion of incidental or consequential damages for personal injury, so the above limitations may not apply to you

for certain damages. This warranty gives you specic legal rights, and you may also have other rights, which vary

from state to state. No person or representative is authorized to make any warranty or assume any liability not strictly

in accordance with the aforementioned.

Inquiries regarding warranty matters should be addressed to:

Desert Aire Corp

c/o Service Manager

N120 W18485 Freistadt Road

Germantown, WI 53022

PH: (262) 946-7400

FAX: (262) 946-7401

Additional copies of this manual can be purchased for a nominal fee from Desert Aire. Submit requests to the contact

information listed above.

5

Desert Aire - LC/LV Manual

6

Safety Labels are used throughout this manual. They comply with the ANSI Z535.4 Standard.

Please be familiar with the following labels and their denitions.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible death or injury.

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in minor or moderate injury.

Caution used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, could

result in property damage.

Desert Aire - LC/LV Manual

7

TABLE OF CONTENTS

1. Introduction ...................................................................................................................... 9

1.1. Inspection ............................................................................................................... 9

1.2. Freight Damage Claims ........................................................................................... 9

1.3. Rigging

....................................................................................................................

9

1.3.1.RiggingtheDehumidier

............................................................................

9

1.3.2. Rigging the Remote Condenser ................................................................. 10

2. Installation ........................................................................................................................ 11

2.1. LocationofDehumidier......................................................................................... 11

2.2. Duct Installation ....................................................................................................... 13

2.3. Condensate Drain Piping ........................................................................................ 16

2.4. Water Heating Applications ..................................................................................... 18

2.4.1. Water Piping Connections ......................................................................... 18

2.4.2. Low Water Flow Protection ........................................................................ 21

2.5. Remote Condenser (Optional) ................................................................................ 21

2.6. High Voltage Wiring ................................................................................................ 24

2.6.1. High Voltage Connections

.....................................

...........

.........................

24

2.6.2. Wire and Fuse Sizing ...............................................

..............................

.... 25

2.7. Controls and Sensors ............................................................................................. 25

2.7.1. Wall Mount Sensor .....................................................

...........

..................... 25

2.7.2. Duct Mount Sensor .................................................................................... 25

2.8. Auxiliary Heating Control Wiring ............................................................................. 25

2.8.1. Auxiliary Heating - Dry Contact Closure .................................................... 25

2.8.2. Auxiliary Heating - Proportional Signal .............................

................

......... 26

2.9. Smoke Alarm Interlock ............................................................................................ 26

3. Start-up Procedure ........................................................................................................ 27

3.1. Preliminary Inspection ..........................................................................

...............

... 27

3.2. Outdoor Air Applications ...................................................................

.................

..... 28

3.2.1. Outdoor Air Option Equipped Units ..................................

...................

....... 28

3.2.2. Standard Systems in Conjunction with Outdoor Air ................................... 30

3.2.3. Outdoor Air Supplemental Information ....................................................... 31

3.2.3.1 LC and LV Operation Modes .................................

.............

.......... 31

3.2.4. Determining if Outdoor Air Pre-Heating is Required .................................. 31

3.2.5. Approximating Outdoor Air Volume ............................................................ 32

3.3. AirowBalancing..................................................

.................

................................. 33

3.3.1. Blower Adjustment Procedure ..................................................

............

...... 33

3.3.2. AirowBalancingforLCDehumidiers...........................

.............

............. 34

3.3.3. AirowBalancingforLVDehumidiers...................................................... 36

3.4. Refrigeration Testing ............................................................................................... 38

3.5. General Testing ........................................................................

......................

........ 40

Desert Aire - LC/LV Manual

8Desert Aire - LC/LV Manual

3.6. Routine Maintenance Schedule ............................................................................. 40

3.6.1. Service Every Month ................................................................................. 40

3.6.2. Service Every Six Months ......................................................................... 41

3.6.3. Pool Water Chemistry ............................................................................... 41

4. Troubleshooting ............................................................................................................. 43

4.1. The Blower Does Not Run ..................................................................................... 43

4.2. The Compressor Does Not Run ......................................................

.................

...... 43

4.3. Evaporator Coil Ices Up ......................................................................................... 44

4.4. Head Pressure is Too High ..........................................................

...................

........ 45

4.5. Unit Runs but Excess Condensation on Walls and Windows ........

....................

.... 46

4.6. Pool Water Heating Problems (Water-Cooled Units Only) ...................................... 46

5. Appendix .......................................................................................................................... 47

5.1. Compressor Failure ............................................................................................... 47

5.1.1. Compressor Replacement .............................................

.....................

...... 47

5.2. Recommended Duct Design .......................................................

..................

........ 51

5.3. System Guidelines ...........................................................................

............

......... 52

5.3.1. Recommended Controller Settings ..............................

..............

.............. 52

5.3.2. Refrigeration System Pressures ........................

..................

..................... 52

5.3.3. Temperature Rise or Drop Across Unit ..................................................... 52

5.4. Sequence of Operation ...........................................................

...................

........... 53

5.4.1. DehumidicationandAirReheat.............................................................. 53

5.4.2. DehumidicationandAirCooling.........................

.......................

............. 53

5.4.3. Cooling and Water Heating (Water-Cooled Unit Only) ............................. 53

5.4.4. DehumidicationandWaterHeating(Water-CooledUnitOnly)...

.......

...... 53

5.4.5. Partial Pool or Spa Water Heating ..................................

............

.............. 54

5.4.6. Operation of Water Condensers and Optional Pump Starts ....

...............

... 54

5.4.7. Blower Operation ............................................................

...................

........ 54

5.4.8. Air Heat (Optional) ..............................................................

............

.......... 54

5.4.9. Outdoor Air (Outdoor Air Equipped Models Only) ..................

..............

..... 55

5.5. Component Replacement, Charge, Evacuation, & Leak Instructions ..

........

.......... 55

5.6. Rating Plate ........................................................................................................... 60

5.7 Start-up Supervision Supplemental Information (Optional) ................................... 60

5.8. System Start-up Report ......................................................................................... 61

LC/LV Factory Start-up Supervision ....................................................................... 62

LC/LV Start-up Report ............................................................................................ 64

LC/LV Series Compressor Replacement Form ...................................................... 68

9

Desert Aire - LC/LV Manual

1. Introduction

DesertAiredehumidiersaredesignedtoprovideyearsofreliableservicewheninstalled

properly.Readtheseinstructionscarefullybeforeyouinstallthedehumidier.

1.1 Inspection

DesertAireinspectsandtestseachdehumidierbeforeitleavesthefactorysothat

you receive a quality piece of equipment. Unfortunately, equipment may become

damagedintransit.Inspectthedehumidiercarefullybeforesigningthereceiving

papers. Check for both visible and concealed damage. Remove crating and inspect

theexteriorcabinetfordamage.Dentedpanels,brokencratingoranyuidsleaking

from the unit should be documented upon delivery.

1.2 Freight Damage Claims

Ifthedehumidierhasbeendamaged,documenttheextentofthedamage.Take

pictures.Next,obtainaclaimformfromthecarrier.Promptlylloutandreturnthe

form.Carriersmaydenyclaimsthatyouhavenotlledoutwithinaweekofdelivery.

Notify Desert Aire of any damage.

1.3 Rigging

1. Failure to observe rigging instructions may lead to equipment damage, personal

injury, or death.

2. Lifting method and procedure must comply with all local and national codes and

regulations.

3. The use of safety slings in addition to lifting lugs is required.

4. Do not lift the dehumidifier in high winds or above people.

DesertAiredehumidiersaresolidlybuiltandcanbeveryheavy.Avoidpersonal

injury and damaging the equipment by planning the installation carefully. Use moving

equipment whenever possible.

1.3.1 Rigging the Dehumidier

Depending upon the unit type, various rigging methods are used to best lift the

equipment. Personnel should avoid stepping on the top of the unit. Desert

Airedehumidiersarenotdesignedtosupporttheweightofapersononall

portions of the roof. Damage incurred through caved or distorted top panels

will not be covered under warranty.

10

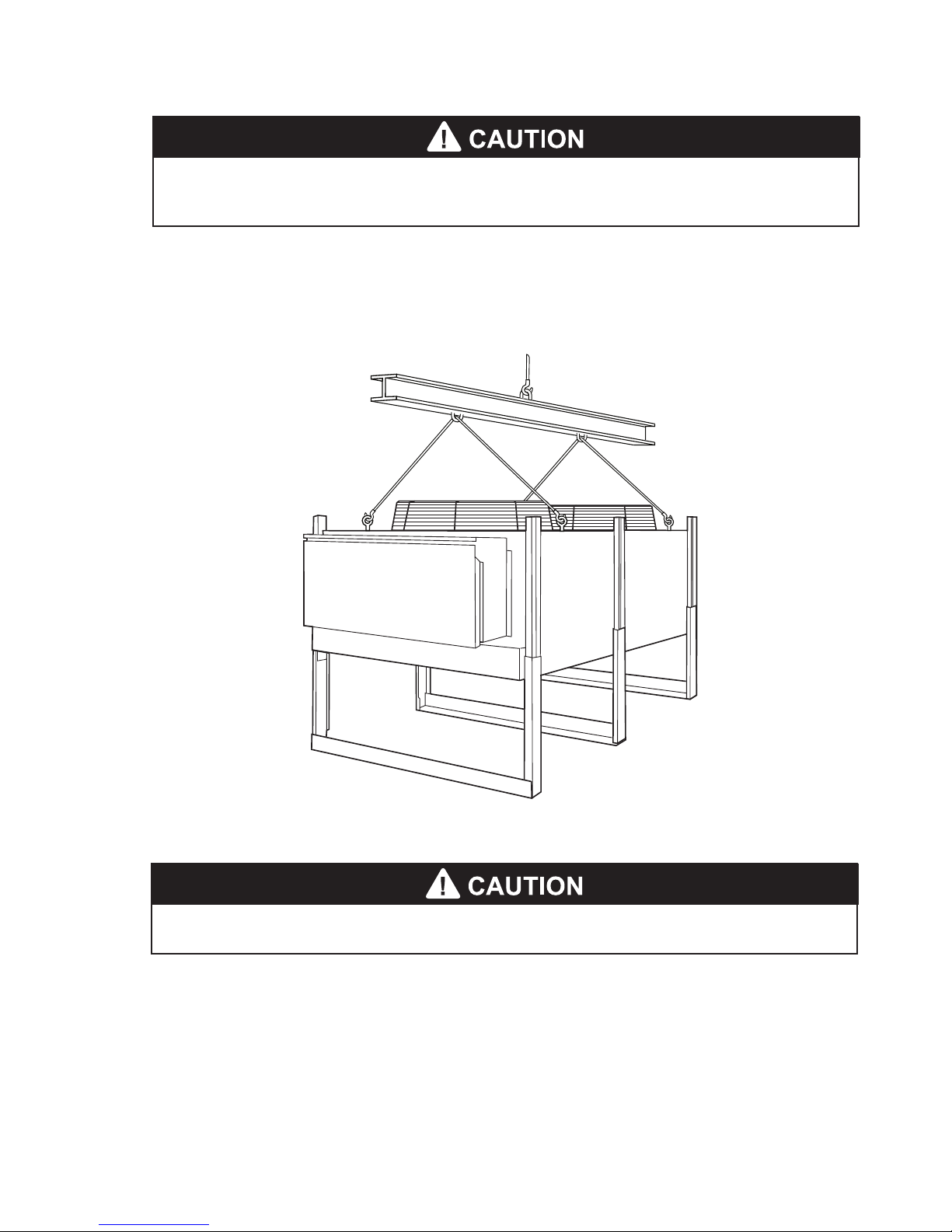

1.3.2 Rigging the Remote Condenser

The optional remote condensers are equipped with four or more lifting eyes.

Test-lift the remote condenser to verify that it is properly balanced.

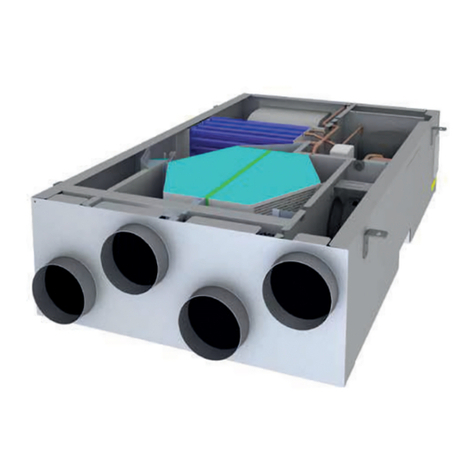

Figure 1 - Typical Rigging for an Optional Remote Condenser

1. Do not lift the remote condenser by its refrigeration headers or return bends.

1. Do not tip the dehumidifier on its side.

2. Avoid dropping the unit down stairways or subjecting it to severe mechanical shock.

Desert Aire - LC/LV Manual

11

Desert Aire - LC/LV Manual

2 Installation

Manual applies to standard unit congurations only.

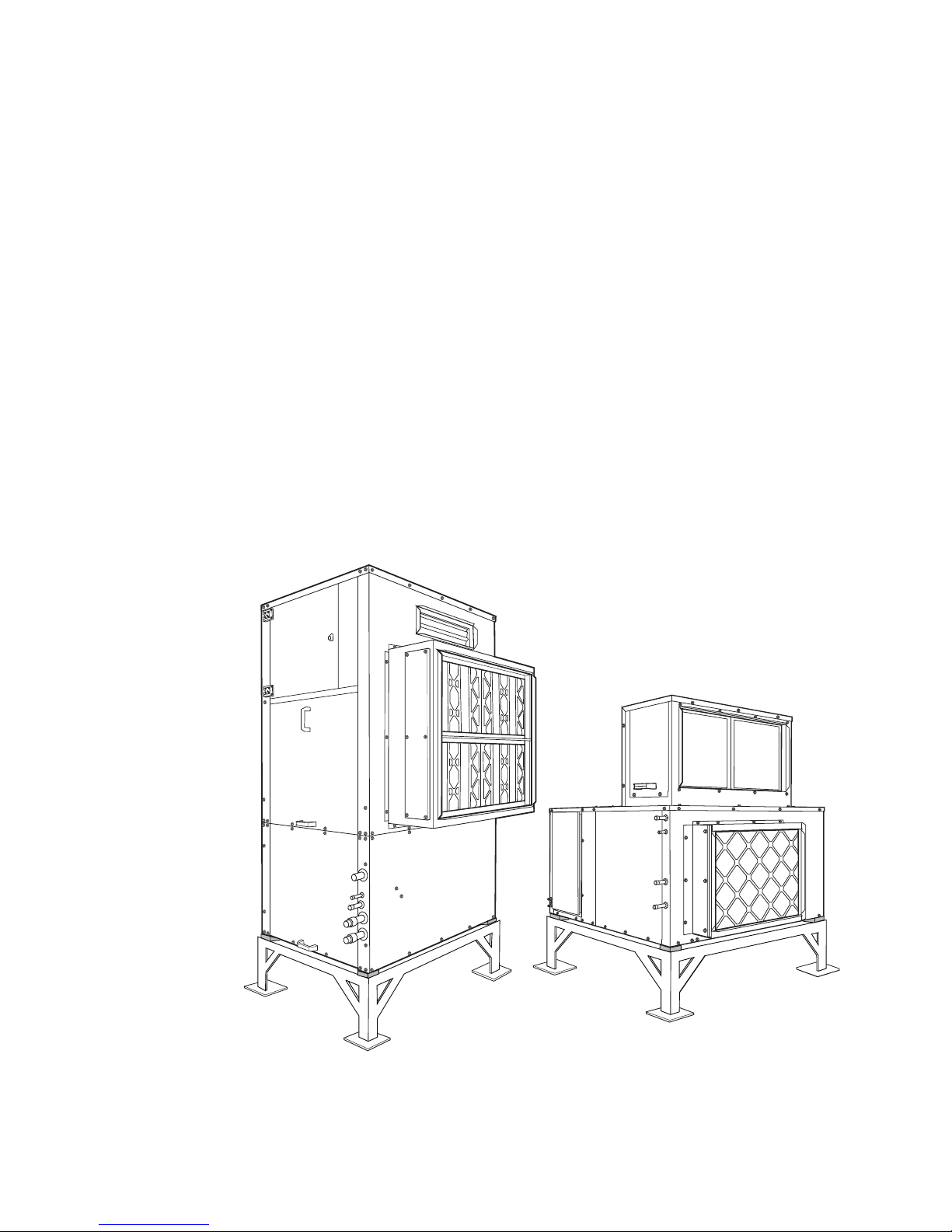

2.1 Location of Dehumidier

DesertAireLCdehumidiersrequirebothleftandrightsideserviceaccesstotheunitfor

service.TheLVdehumidiersrequireserviceaccesstotheleftsideendoppositethereturn

air connection. Allow a minimum of 36 inches of clearance around the service sides of the

dehumidierforpiping,electricalconnections,andserviceaccess.Thenon-accesssidesof

the unit should have a minimum of 12 inches of clearance. Consult local, state, and national

electric codes for other minimum service clearances.

Install the unit on a sturdy, level mounting base or platform that will prevent vibration and

soundtransmission.Neverinstallthedehumidieronawoodenplatformwithoutconsulting

the design engineer for spring isolation requirements and sound control materials. Do not

installtheunitnearoccupiedroomssuchasofcesorguestrooms.Donotattemptto

conserve installation space by fabricating restrictive ductwork with abrupt bends. You may

reducetheoperatingefciencyandthemoistureremovalcapacityofthedehumidier.See

section 5.2 for detailed duct installation instructions.

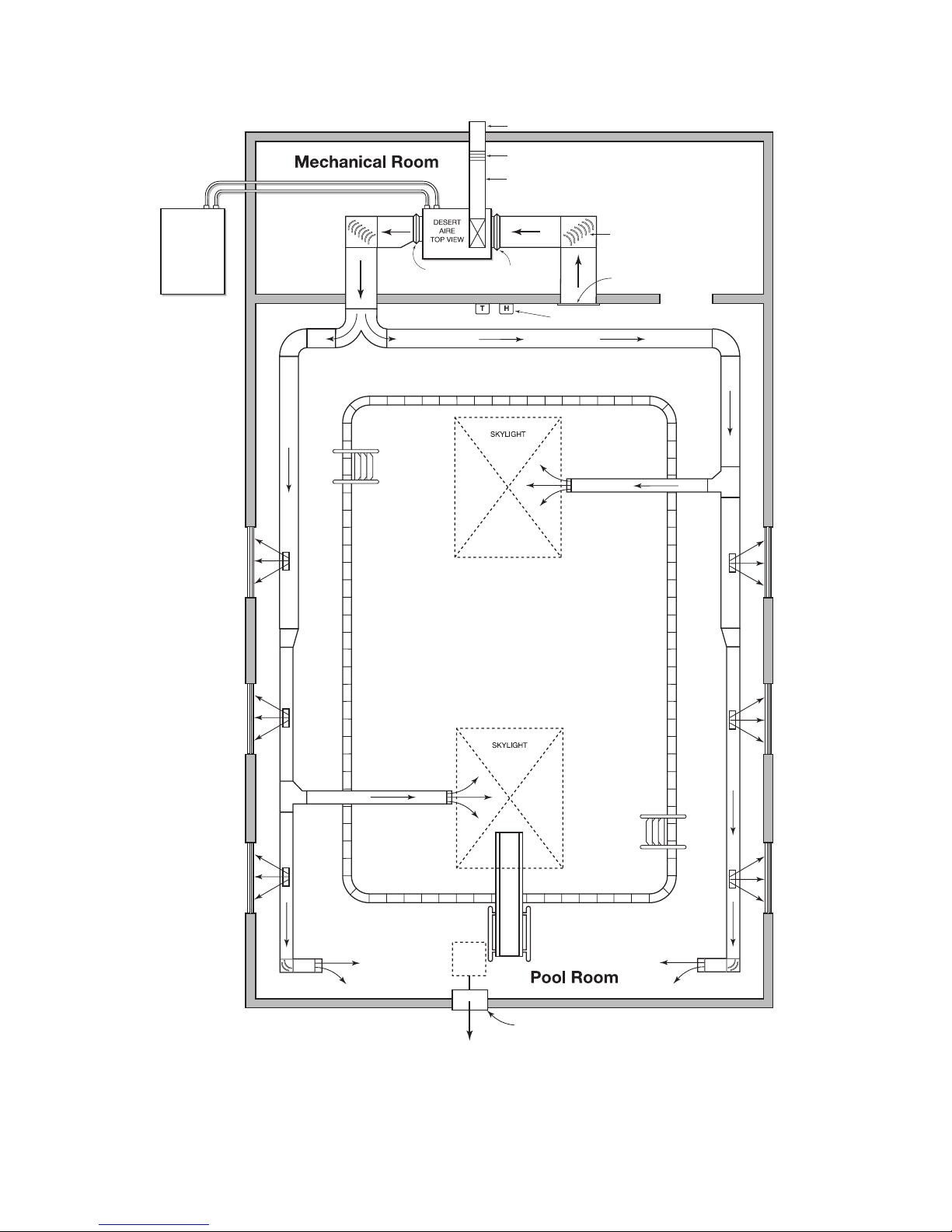

Figure 2 - Typical Floor Installation

12

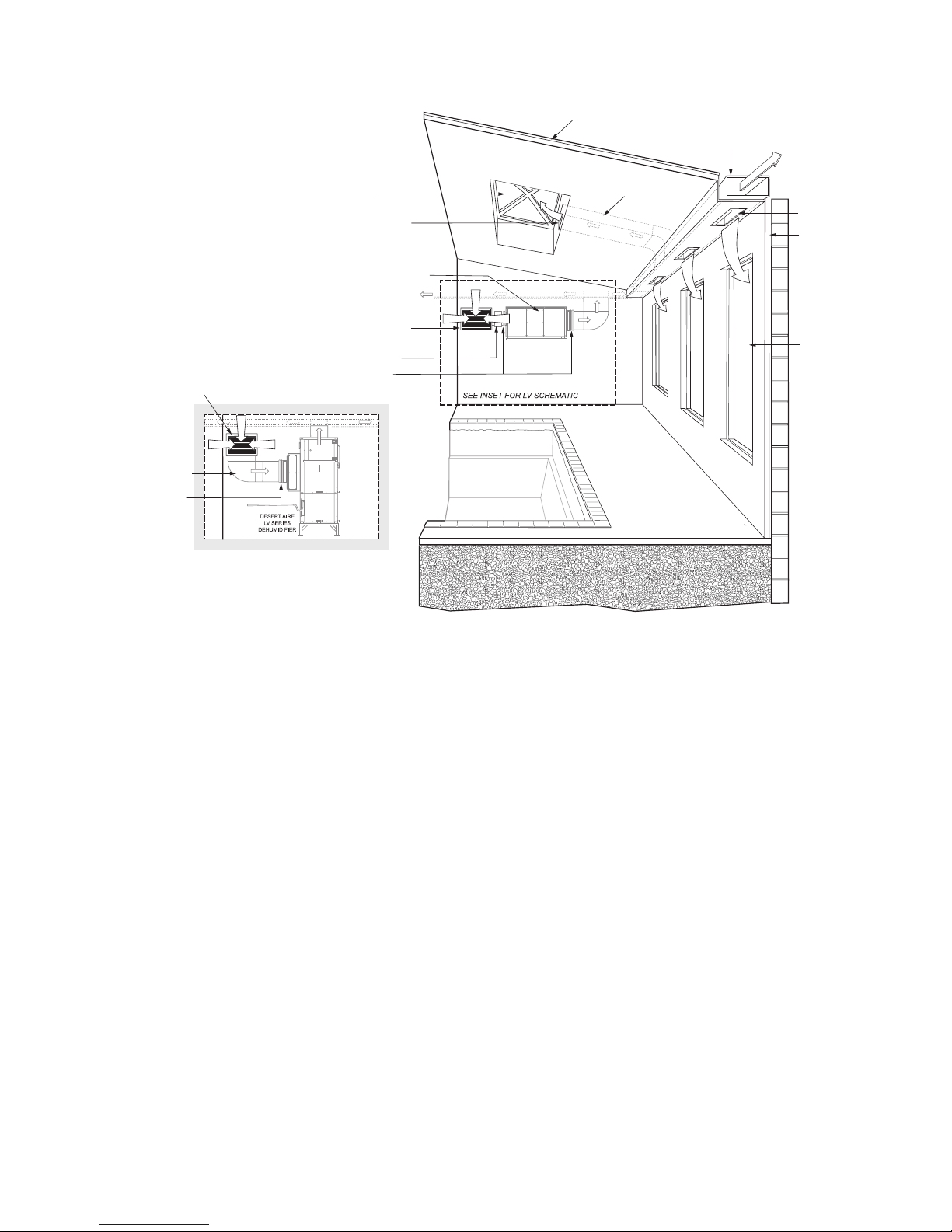

Figure 3 - Typical Suspended Installation - LC Only (LV Units are oor units only)

LV Only - Do not install an indoor-rated dehumidier in an outdoor or a wet

environment.

You must not install a standard dehumidier in an unconditioned space or where ambient

temperatures can fall below 45°F.Ifyoumustinstallthedehumidieroutsideorinan

unconditionedspace,suchasanattic,youmustuseanoutdoor-rateddehumidier.Desert

Aireequipsoutdoor-rateddehumidierswithweatherproongandthickerinsulation.Youcan

determinewhetheryourdehumidierisoutdoorratedbyinspectingtheunitratingplate.See

section 5.6 for details.

Desert Aire - LC/LV Manual

13

Desert Aire - LC/LV Manual

2.2 Duct Installation

Duct design and installation should conform to the latest ASHRAE and SMACNA low velocity

duct standards. See section 5.2 for details. Undersized restrictive ductwork with abrupt turns

ortransitionscandecreasetheefciencyandthemoistureremovalcapacityofyour

dehumidierandmayleadtounitfailure.Sizetheductworkforanacceptableairpressuredrop

attheairowvolumeofyourdehumidier.Useneopreneexconnectorswhenyouattach

ductworktothedehumidiertopreventtransmissionofexcessvibrationandnoise.

Airflow Rate (CFM)

(LV Only)

-

-

1400

2100

3000

3400

3800

-

-

-

External Static Pressure

(ESP) digit 9 for LC (A, B, C,

K, L, M); digit 10 for LV (A, D)

0.5” WC

Airflow Rate (CFM)

(LC Only)

540

950

1400

1900

2300

3000

3500

4100

5500

8000

Model Size

01 (LC Only)

02 (LC Only)

03

04

05

06

08

10 (LC Only)

12 (LC Only)

15 (LC Only)

External Static Pressure

(ESP) digit 9 for LC (D, E, F,

N, P, R); digit 10 for LV (B, F)

1.0” WC

External Static Pressure

(ESP) digit 9 for LC (G, H, J,

S, T, U); digit 10 for LV (C, G)

1.5” WC

Figure 4 - LC and LV Series Standard Unit Airow Specications

Select the grilles, registers and diffusers for low static pressure loss, required throw distance,

andthespeciedCFMrating.Youcanndthisinformationinmostgrillemanufacturer’s

catalogs. If you are installing the grilles in a corrosive environment, choose components made

from anodized aluminum.

Ifyoumustinstallductworkinanunconditionedarea,useberglassductwrapwithvapor

barrier facing. You must install the outdoor air intake away from all sources of airborne

contamination such as exhaust fans or plumbing vents. You can use galvanized sheet metal

ducts for most applications. However, you should use aluminum or stainless steel ducts for

extreme applications such as chemical-laden environments.

14

FLEXIBLE NEOPRENE

DUCT CONNECTOR

LOCATE ANODIZED ALUMINUM

RETURN AIR GRILLE AS HIGH

AS POSSIBLE IN ROOM.

INSTALL TURNING VANES

IN ALL ELBOWS.

INSULATED OUTSIDE AIR INTAKE DUCT,

(SIZE FOR CODE REQUIREMENTS)

MOTOR OPERATED DAMPER

WEATHER-PROOF INTAKE HOOD

REMOTE

CONDENSER

TEMPERATURE AND HUMIDITY CONTROLS

MECHANICAL EXHAUST WITH BACK-DRAFT DAMPER

(WALL OR ROOF MOUNTED)

NOTE: EXHAUST LOW

Figure 5 - Basic Pool Room Layout

Desert Aire - LC/LV Manual

15

Desert Aire - LC/LV Manual

VAPOR BARRIER

MAIN SUPPLY

AIR DUCT

WINDOW

POOL

BRANCH SUPPLY AIR DUCT

ANODIZED ALUMINUM

RETURN AIR GRILLE

LOCATE AS HIGH AS POSSIBLE

RETURN AIR DUCT

DESERT AIRE DEHUMIDIFIER

SKYLIGHT

FLEXIBLE DUCT

CONNECTIONS

POOL DECK

ANODIZED ALUMINUM

CEILING DIFFUSER

ANODIZED ALUMINUM

SIDEWALL REGISTER

VAPOR BARRIER

ANODIZED ALUMINUM

RETURN AIR GRILLE

LOCATE AS HIGH AS POSSIBLE

RETURN AIR DUCT

FLEXIBLE DUCT

CONNECTIONS

Figure 6 - Soft Duct Layout

16

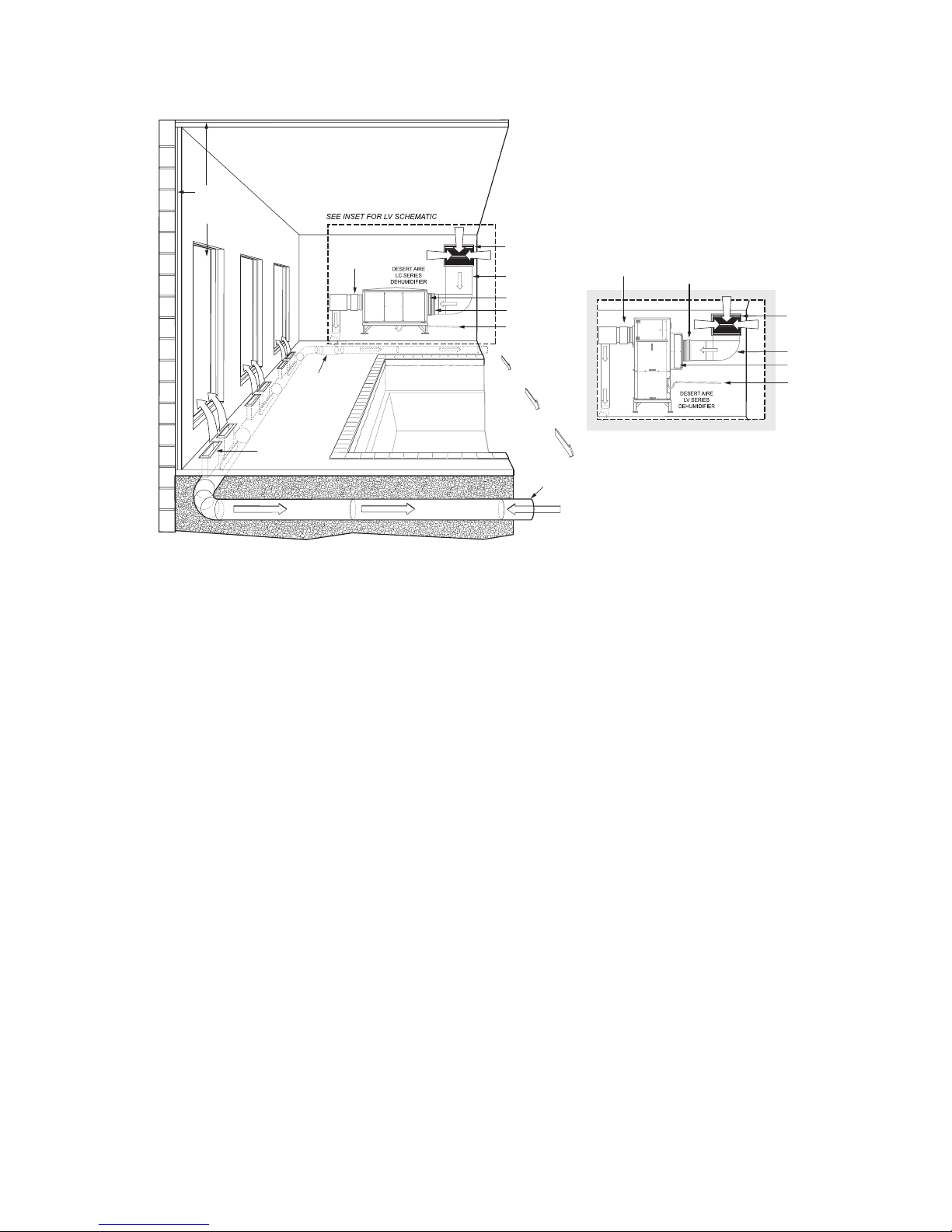

VAPOR BARRIER

AUX. HEATING

WINDOW

ANODIZED ALUMINUM

FLOOR DIFFUSERS

(SIZE FOR PROPER

AIR FLOW)

SUPPLY PIPING

LOOP SYSTEM

POOL

P. C.D. COATED SPIRAL

GALVANIZED PIPE

ANODIZED ALUMINUM

RETURN AIR GRILLE

LOCATE AS HIGH AS

POSSIBLE

RETURN AIR DUCT

FILTER RACK

FLEXIBLE DUCT

CONNECTIONS

POOL DECK

CONDENSATE PIPING

AUX. HEATING

ANODIZED ALUMINUM

RETURN AIR GRILLE

LOCATE AS HIGH AS

POSSIBLE

RETURN AIR DUCT

FILTER RACK

FLEXIBLE DUCT

CONNECTIONS

CONDENSATE PIPING

Figure 7 - Under-Floor Duct Layout

2.3 Condensate Drain Piping

Thecondensatedrainconnectionmaybeonthesideorthebottomofthedehumidier,

depending on the size and style of cabinet used. Use concrete blocks or steel dunnage to

raisethedehumidierhighenoughabovetheoortoprovideclearancefortheeld-supplied

condensate drain trap.

Note:Whilethesupplyblowerruns,thedrainpanareainsidethedehumidieroperatesata

negative pressure. Your unit requires a p-trap in the condensate drain pipe to prevent

condensatefrombeingdrawnintothecabinetofthedehumidier.

Desert Aire - LC/LV Manual

17

Desert Aire - LC/LV Manual

Min. 12”

P-Trap (By Others)

Vibration

Isolator

Base /Support

(By Others)

1/4” Slope

Per Foot

Min. 12” Vibration

Isolator

Base /Support

(By Others)

P-Trap

(By Others) 1/4” Slope

Per Foot

Figure 8 - Condensate Piping

4”

4”

Figure 9 - Sectional View of Condensate Trap Requirements

Trap the condensate as shown in Figure 9. The P-trap dimensions in Figure 9 are sized for a

maximumreturnairstaticof2.0”ofwater.Ifyourreturnairstaticexceedsthisspecication,

consult Desert Aire for help in resizing the P-trap.

You may also need to install a cleanout tee or plug near the trap. Note that the drain

opening in the drain pan is off-center to simplify its cleaning and servicing. Once you have

designed and installed the trap, follow this sequence:

18

1. Connect the trap to a main drain line with 1/4” of downward pitch

per linear foot of run.

2. Supportthedrainpipeeveryvefeettopreventsagging.

3. After you install the drain piping, prime the trap by pouring water

intothedrainpanofthedehumidier.

Condensate drain lines installed in an unconditioned space must be heat taped to

prevent freezing. Check the heat tape yearly before winter operation.

2.4 Water Heating Applications

2.4.1 Water Piping Connections

DesertAireLCandLVSeriesdehumidiersequippedwithpoolwaterheating

condensersmustbeconnectedtopoolwaterltrationlinestooperateasintended.

Thedehumidierwatersupplycircuitmusttapintothemainpoolwaterline

downstreamfromthemainlter.Ifthemainpoolcirculatingpumpislargeenough,

you can use a manual throttling valve to divert a portion of the water to the

dehumidier.Normally,youmustsizeandinstallanauxiliarywaterpumpwhichcan

handletheunit’srequiredwaterowrate,whichislistedinFigure10.Ifyouareusing

a water source other than a pool or a spa (such as a chilled water loop), the required

owratehasbeenprintedonalabelafxednearthewaterlinestubsofthedehumidier.

01 (LC Only)

02 (LC Only)

03

04

05

06

08

10 (LC Only)

12 (LC Only)

15 (LC Only)

Water Flow Rate and

Pressure Drop

Pool Application

2 GPM @ 5.5 ft W.C.

4 GPM @ 6.9 ft W.C.

6 GPM @ 5.3 ft W.C.

8 GPM @ 6.1 ft W.C.

10 GPM @ 5.7 ft W.C.

12 GPM @ 9.2 ft W.C.

16 GPM @ 9.0 ft W.C.

20 GPM @ 5.7 ft W.C.

24 GPM @ 7.4 ft W.C.

30 GPM @ 5.7 ft W.C.

Model Size

Water Flow Rate and

Pressure Drop

Spa Application

3 GPM @ 10.6 ft W.C.

5 GPM @ 9.9 ft W.C.

8 GPM @ 8.5 ft W.C.

11 GPM @ 9.1 ft W.C.

13 GPM @ 8.3 ft W.C.

16 GPM @ 14.8 ft W.C.

18 GPM @ 10.8 ft W.C.

26 GPM @ 8.3 ft W.C.

31 GPM @ 9.7 ft W.C.

39 GPM @ 8.3 ft W.C.

Water Flow Rate and

Pressure Drop

Partial Pool/Spa Application

1 GPM @ 1.8 ft W.C.

1 GPM @ 1.8 ft W.C.

2 GPM @ 2.3 ft W.C.

2 GPM @ 2.3 ft W.C.

5 GPM @ 3.9 ft W.C.

5 GPM @ 3.9 ft W.C.

9 GPM @ 4.8 ft W.C.

9 GPM @ 4.8 ft W.C.

10 GPM @ 6.9 ft W.C.

14 GPM @ 7.2 ft W.C.

Figure 10 - Standard Unit Water Flow Rates for LC and LV Units

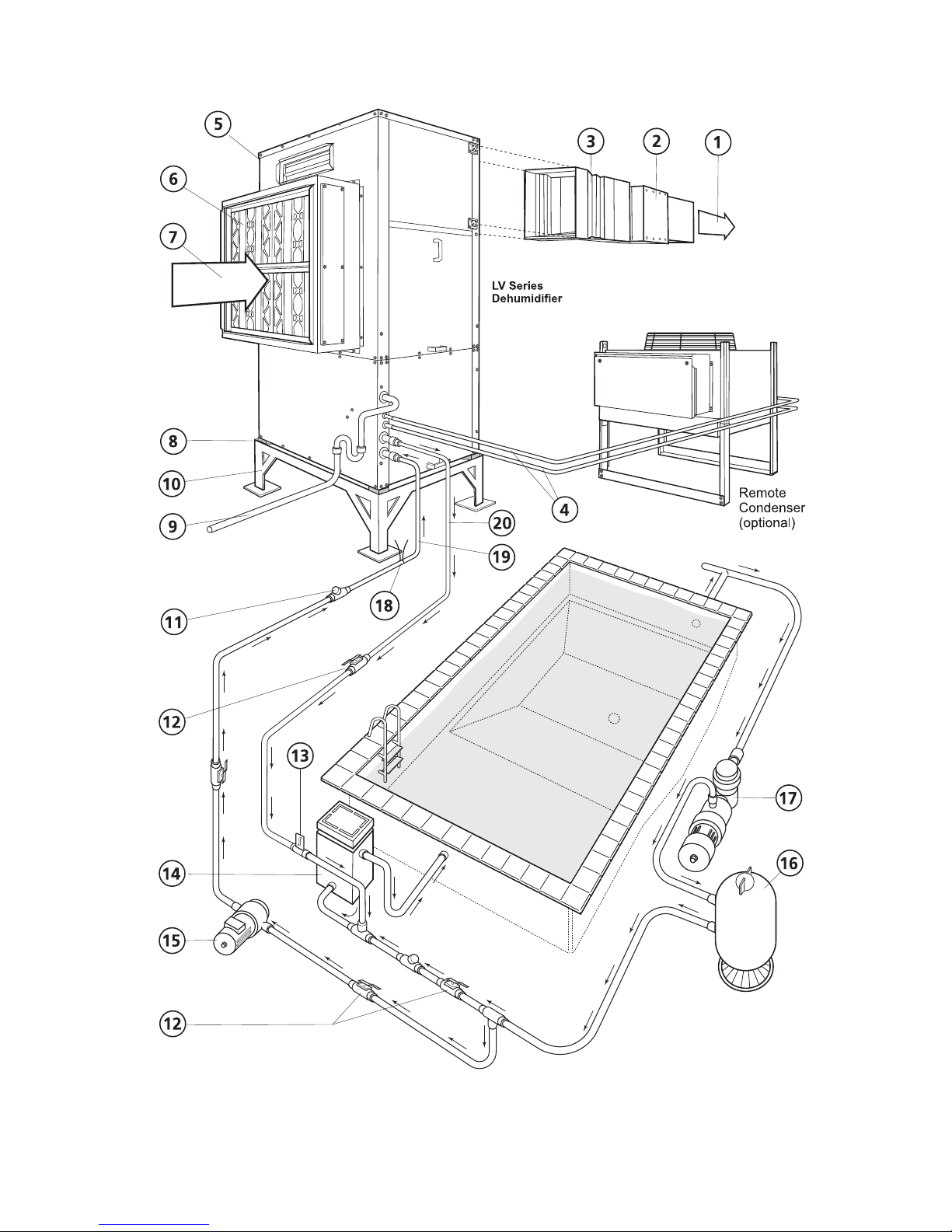

A typical water circuit arrangement is shown in Figure 11. To simplify the

commissioningandservicingofthisjob,youshouldinstallaowmeterandisolation

valvesinthepoolwaterlineswhichfeedthedehumidier.

Desert Aire - LC/LV Manual

19

Desert Aire - LC/LV Manual

1 Supply Air

2 Duct Heater (Gas, Electric, Etc.)

3 Flex Duct Connector

4 Piping to Remote Condenser

5 Desert Aire LC Dehumidifier

6 Filter Rack Assembly with Filters

7 Return Air

8 Vibration Isolators

9 P-Trap

10 Base (If Required)

LEGEND

11 Check Valve

12 Ball Valve

13 Flow Meter

14 Main Pool Heater

15 Auxiliary Pump

16 Filter Assembly

17 Main Pool Pump

18 Water Temp Sensor (Dry Well)

19 Water Inlet

20 Water Outlet

Figure 11 - Proper Pool Water Heating Installation for Desert Aire LC and LV dehumidiers

20

Figure 12 - Proper Pool Water Heating Installation for Desert Aire LV dehumidiers

Desert Aire - LC/LV Manual

This manual suits for next models

1

Table of contents

Other Desert Aire Dehumidifier manuals