Desert Aire Aura QS User manual

Installation and Operation Manual

• 100% Outdoor Air

Systems & High

Outdoor Air Systems

• Aura™ (QS), dedicated

outdoor air system,

offers a high quality

dehumidifier with

various options to

cover multiple

applications

• TotalAire™ (QS),

dedicated outdoor air

systems, offers an

optional energy

recovery wheel that

recovers both sensible

and latent heat.

• VerticalAire™ (QV),

dedicated outdoor air

system, is a high-

quality cost-effective

dehumidifier that’s

designed for tight

spaces

Indoor Air Quality

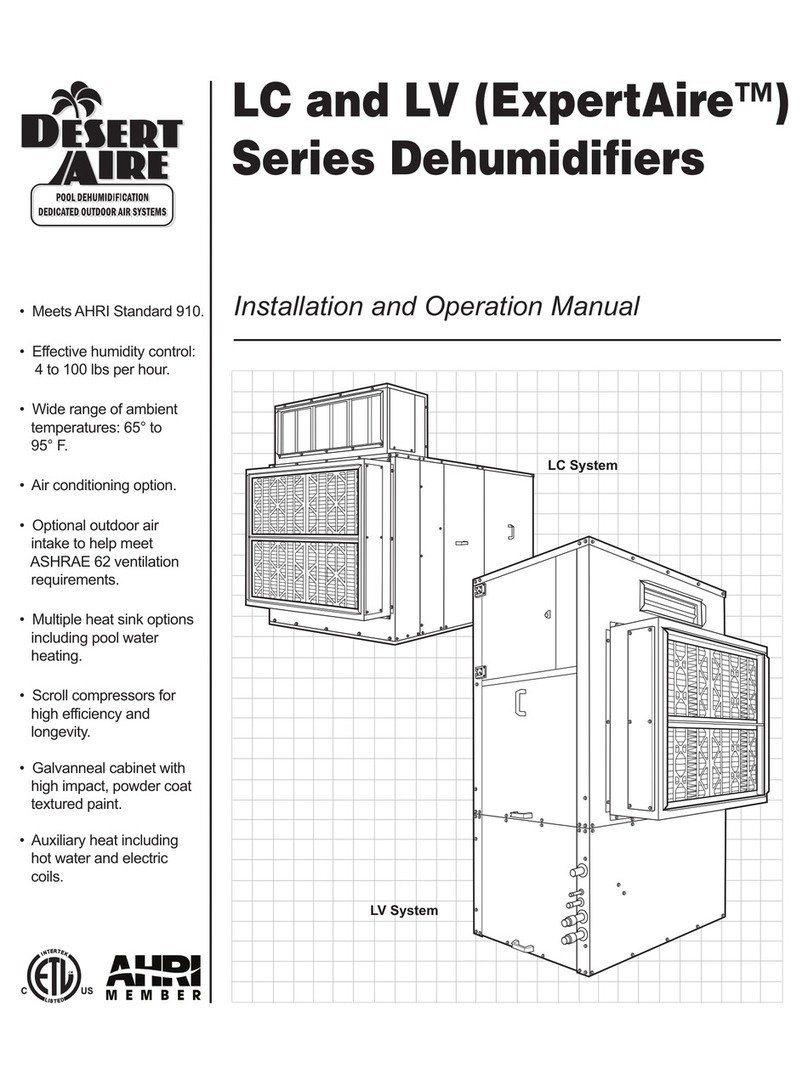

Aura™ (QS)

TotalAire™ (QS)

VerticalAire™ (QV)

TotalAire™ (QS)

Dehumidifier

VerticalAire™ (QV)

Dehumidifiers

Aura™ (QS)

Dehumidifier

2

3

Desert Aire - QS/QV Manual

DANGER

ONLY TRAINED, QUALIFIED PERSONNEL SHOULD INSTALL AND/OR SERVICE

DESERT AIRE EQUIPMENT. SERIOUS INJURY, DEATH AND PROPERTY DAMAGE CAN

RESULT FROM IMPROPER INSTALLATION/SERVICE OF THIS EQUIPMENT. HIGH VOLTAGE

ELECTRICAL COMPONENTS AND REFRIGERANT UNDER PRESSURE ARE PRESENT.

For any unit labeled Class 1, Group D, Division 2, all wiring must be in accordance to

Class 1, Group D, Division 2 requirements. Insure that all local, state, national and any

other applicable codes are adhered to when connecting any device to this equipment.

All electrical connections to units labeled Class 1, Group D, Division 2 must be done

with a conduit seal.

Desert Aire

Dehumidication Equipment Standard Limited Warranty

Desert Aire warrants the dehumidifying unit to be free from defects in materials and workmanship subject to the terms,

conditions and limitations stated herein.

TERMS

Desert Aire warrants all components (except as noted) for a period of two (2) years from the date of shipment. This

warranty shall be limited to the supply of new or rebuilt parts for the part which has failed because of

defects in workmanship or material, and does not include the cost for labor, transportation or other costs not herein

provided for. Replaced parts are warranted only for the remaining portion of the original warranty period.

CONDITIONS

The warranty is subject to the following conditions:

1. The unit must be properly installed and maintained in accordance with the Desert Aire

“Installation and Operation Manual” provided with each unit and/or other documentation provided.

2. The Start-Up Report must be completed and returned to Desert Aire Service for evaluation. If no

deciencies are identied a Warranty Validation Letter will be issued that provides all warranty dates

and coverage. If installation or start-up deciencies are present, these must be corrected and

communicated to Desert Aire in order to activate warranty.

3. This warranty shall not apply to any part that has been tampered with, or has been subject to

misuse, negligence or accident. A warranty can be obtained for altered equipment but only with

written consent from Desert Aire.

4. Thefollowingpartsandcomponentsareexcludedfromthewarranty:belts,lters,driers,fusesand

refrigerant.

4Desert Aire - QS/QV Manual

5. Refrigerant coils or other components that corrode due to improperly balanced pool chemistry or

corrosive air quality will not be warranted.

6. All replacements or repairs will be FOB Germantown, WI.

7. This warranty shall be null and void if defects or damages result from unauthorized opening of the

refrigerant circuit, tampering with factory set controls, or operating outside the original design conditions.

8. Desert Aire shall not be liable for labor costs incurred in diagnosing the problem, or the removal

or replacement of the part or parts being repaired.

9. Desert Aire must preauthorize all warranty coverage described herein.

Extended Warranty:

Your Desert Aire unit may have extended warrantees beyond this Standard Limited Warranty document.

Extended warrantees are only available at the time of the purchase of the original equipment. These extended

warrantees are covered under a separate document and their terms and conditions are separate from this

document. It is mentioned in this document for informational purposes only. Any Extended Warranties will be

identiedontheWarrantyValidationletter.

Any and all incidental or consequential damages are expressly excluded from this warranty. Some states do not allow

the exclusion of incidental or consequential damages for personal injury, so the above limitations may not apply to you

for certain damages. This warranty gives you specic legal rights, and you may also have other rights, which vary

from state to state. No person or representative is authorized to make any warranty or assume any liability not strictly

in accordance with the aforementioned.

Inquiries regarding warranty matters should be addressed to:

Desert Aire Corp c/o Service Manager

N120 W18485 Freistadt Road • Germantown, WI 53022

Additional copies of this manual can be purchased for a nominal fee from Desert Aire. Desert Aire also posts the most

current revision of our I/O Manuals on our website. For a digital copy of the I/O Manual for your unit revision, please

submit request to the contact information listed above.

Gas Heat Exchanger Ten (10)-Year Prorated Warranty Terms (For Aura™ units with gas heat only)

Desert Aire offers an extended prorated eight (8)-year warranty for gas heat exchanger. All other heater components

are covered under the initial 2 year warranty.

2 Years Parts Only from date of shipment. Prorated from years 3-9 as follows:

Year 3: Desert Aire warrants 70% of replacement price

Year 4: Desert Aire warrants 60% of replacement price

Year 5: Desert Aire warrants 50% of replacement price

Year 6: Desert Aire warrants 40% of replacement price

Year 7: Desert Aire warrants 30% of replacement price

Year 8: Desert Aire warrants 20% of replacement price

Year 9: Desert Aire warrants 10% of replacement price

5

For Units w/Gas Heat:

For Your Safety Read Before Operating

WARNING: If you do not follow these instructions exactly a fire or explosion

may result causing property damage, personal injury or loss of life.

A. This appliance does not have a pilot. It is equipped with an ignition device that automatically

lights the burner. Do not try to light the burner by hand.

B. BEFORE OPERATING smell all around the appliance area for gas. Be sure to smell next to the

floor because some gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in your building. Immediately call

your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

C. Use only your hand to push in or turn the gas control knob. Never use tools. If the knob will

not push in or turn by hand, don't try to repair it, call a qualified service technician.

Force or attempted repair may result in a fire or explosion.

D. Do not use this appliance if any part has been under water. Immediately call a qualified service

technician to inspect the appliance and to replace any part of the control system and any gas

control that has been under water.

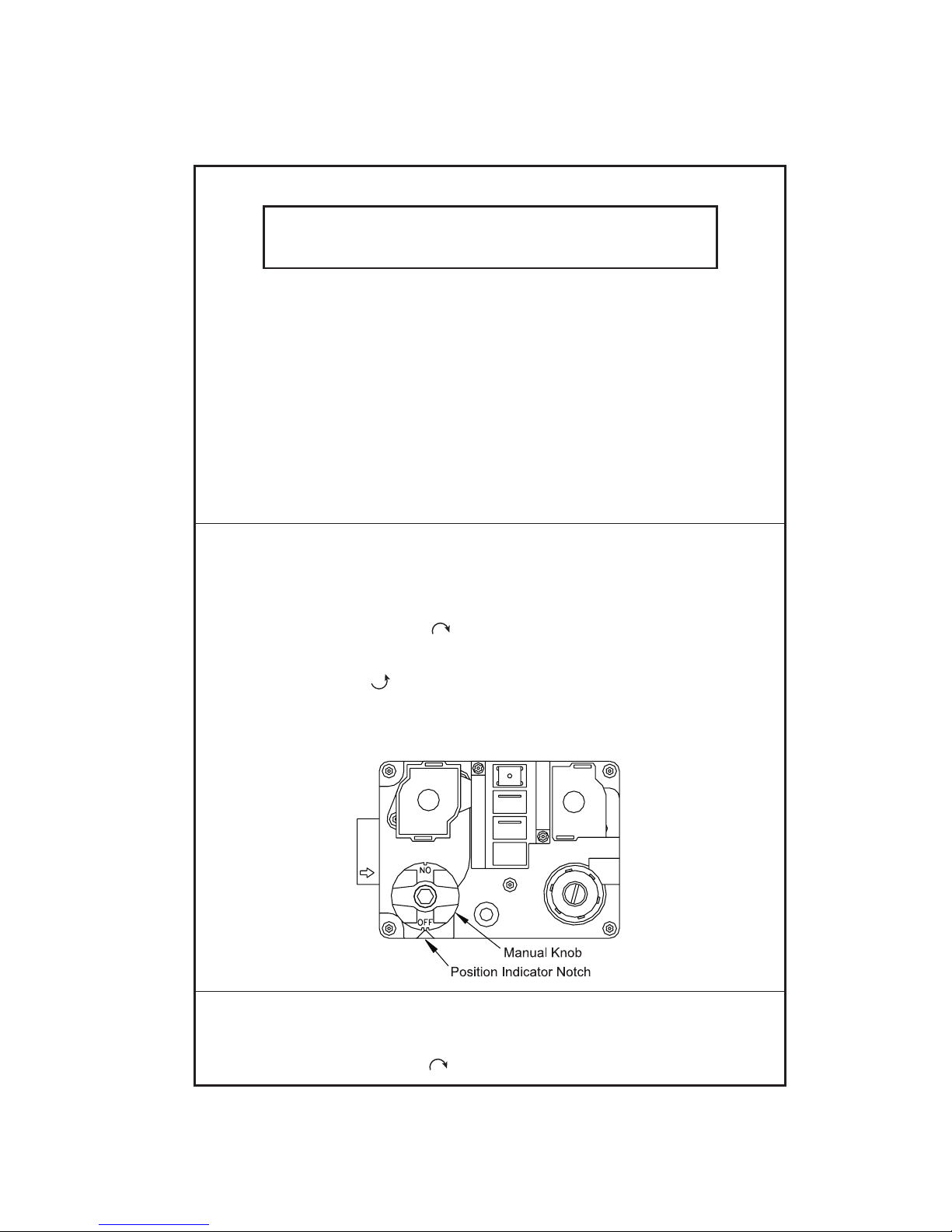

OPERATING INSTRUCTIONS

1. STOP! Read the safety information above on this label.

2. Set the thermostat to lowest setting.

3. Turn off all electric power to the appliance.

4. This appliance is equipped with an ignition device that automatically lights the burner.

Do not try to light the burner by hand.

5. Turn gas control knob clockwise to "OFF" position.

6. Wait five (5) minutes to clear out any gas. Then smell for gas, including near the floor.

If you smell gas, STOP! Follow "B" in the safety information above on this label. If you don't

smell gas, go to next step.

7. Turn gas control knob counterclockwise to "ON" position.

8. Turn on all electric power to unit.

9. Set thermostat to desired setting.

10. If appliance will not operate, follow the instructions “To Turn Off Gas To Appliance” and call

your service technician or gas supplier.

TO TURN OFF GAS TO APPLIANCE

1. Set thermostat to lowest setting.

2. Turn off all electric power to the appliance if service is to be performed.

3. Turn gas control knob clockwise to "OFF" position.

Desert Aire - QS/QV Manual

6

Safety Labels are used throughout this manual. They comply with the ANSI Z535.4 Standard.

Please be familiar with the following labels and their denitions.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible death or injury.

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in minor or moderate injury.

Caution used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, could

result in property damage.

Product Warning for the State of California

Desert Aire - QS/QV Manual

7

TABLE OF CONTENTS

1. Introduction ................................................................................................................................. 9

1.1. Inspection ...................................................................................................................... 9

1.2. Freight Damage Claims ................................................................................................. 9

1.3. Rigging .......................................................................................................................... 9

1.3.1.RiggingtheDehumidier................................................................................... 9

2. Installation

..................................................................................................................................

13

2.1. LocationofDehumidier................................................................................................ 13

2.2. Duct Installation ............................................................................................................ 14

2.3. Condensate Drain Piping .............................................................................................. 14

2.4. Auxiliary Heat Coil Piping .............................................................................................. 16

2.5. Water Piping Installation (for Q-Pump and Water-Cooled Systems Only) .................... 16

2.6. Remote Condenser Installation (Air-Cooled Systems Only) .......................................... 19

2.7. High Voltage Wiring

......................................................................................................

20

2.7.1. High Voltage Connections ................................................................................. 20

2.7.2. Wire and Fuse Sizing ........................................................................................ 21

2.8. Controls and Sensors

...................................................................................................

21

2.8.1. Duct-Mount Sensor ........................................................................................... 22

2.8.2. Remote Room Sensor(s) ................................................................................... 22

2.8.3. CO2Sensors ...................................................................................................... 22

2.9. Auxiliary Heating Control Wiring

...................................................................................

22

2.9.1. Auxiliary Heating - Dry Contact Closure .......................................................... 22

2.9.2. Auxiliary Heating - Proportional Signal ............................................................ 22

2.10. Gas Heater (Optional) ................................................................................................... 23

2.10.1. Gas Heater Installation ................................................................................... 23

2.10.2. Gas Piping ...................................................................................................... 24

2.10.3. Gas Heater Location ........................................................................................ 30

2.11. Electric Heater (Optional) .............................................................................................. 33

2.12. Auxiliary Heat Coil Piping (Optional) ............................................................................. 33

2.13. Smoke Alarm Interlock .................................................................................................. 34

2.14. Cover Plates (if applicable) ........................................................................................... 34

2.15. Roof Curb w/ Wood Nailer (if applicable) ...................................................................... 35

2.16. Wheel Module Installation (Optional for Aura™ Products) ............................................ 36

3. Start-Up Procedures ................................................................................................................... 37

3.1. Preliminary Inspection ................................................................................................... 37

3.2. Gas Heater Start-Up (Optional) ..................................................................................... 38

3.2.1. Burner Adjustment .......................................................................................... 40

3.3. AirowBalancing........................................................................................................... 40

3.3.1. Blower Adjustment Procedure ........................................................................ 41

3.3.1.1 Units with an EC Blower .................................................................. 41

3.3.1.2 Units without a VFD ......................................................................... 41

3.3.1.3 Unit with a VFD ................................................................................ 42

3.3.2. AirowBalancingforDedicatedOutsideAirSystems(DOAS)....................... 42

3.3.2.1 Aura™ and TotalAire™ Units .......................................................... 43

3.3.2.2 AirowBalancingforQVDehumidiers.......................................... 44

3.3.2.2.1 Damper Box Equipped VerticalAire™ Systems .................. 47

3.3.3. AirowBalancingforDedicatedOutdoorAirSystems(DOAS)with

Unoccupied Recirculation ................................................................................ 47

3.3.4. AirowBalancingforHighOutdoorAirSystems(HOAS)............................... 48

3.3.4.1 For Units with External Enthalpy Wheel (Aura™) ........................... 49

3.3.4.2 For Units with CO2Control (Aura™) ............................................... 49

Desert Aire - QS/QV Manual

8Desert Aire - QS/QV Manual

3.3.4.3 Recirculation Mode (TotalAire™) .................................................... 50

3.3.4.4 Mixed Air Mode (TotalAire™) .......................................................... 50

3.3.4.5 For Units with Systems Equipped with Demand Controlled

Ventilation Option (TotalAire™) ....................................................... 50

3.3.4.5.1UnoccupiedModewithRecirculation(whenspecied)

(TotalAire™) .................................................................. 51

3.3.4.5.2 Occupied Mode Minimum Outdoor Air (TotalAire™) ...... 51

3.3.4.5.3 Occupied Mode Maximum Outdoor Air (TotalAire™) ..... 52

3.4. Refrigeration Testing ...................................................................................................... 53

3.4.1. Dehumidication/CoolingMode.................................................................... 54

3.4.2. Heat Pump Mode ............................................................................................ 55

3.5. General Testing

............................................................................................................

57

3.6. Routine Maintenance Schedule

..................................................................................

57

3.6.1. Service Every Month ........................................................................................ 57

3.6.2. Service Every Six Months ..................................................................

..............

58

3.6.3. Service Every Year .............................................................

..............................

58

3.6.3.1 Energy Recovery Wheel (Optional)

........................

........................... 58

3.6.3.2 Gas Heater (Optional) ..................................

.......................................

59

4. Troubleshooting

........................................................................................................

..................

61

4.1. The Blower Does Not Run ............................................................................................. 61

4.2. The Compressor(s) Do Not Run .................................................................................... 62

4.3. High Pressure Alarms / Readings Above High Pressure Trip Set Point ...

......................

62

4.4. Low Pressure Alarms (Below 97 PSIG) Evaporator Coil Icing ................

.......................

63

5. Appendix

......................................................................

................................................................

65

5.1. Compressor Failure ................

........................................................................................

65

5.1.1. Compressor Replacement ............................................................................... 65

5.2. Recommended Duct Design

..........................................................................................

69

5.3. Recommended Controller Settings

................................................................................

70

5.4. IAQ Sequence of Operation

...........................................................................................

70

5.4.1. Basic Sequence

..............................................................................................

70

5.4.2. Blower Operation ............................................................................................. 71

5.4.3. DehumidicationOperation............................................................................... 72

5.4.3.1. Packaged Units .................................................................................. 72

5.4.3.2. Q-Pump Inverter + Units .................................................................... 72

5.4.4. Cooling Operation ................................................................

............................

73

5.4.4.1. Packaged Units .................................................................................. 73

5.4.4.2. Q-Pump Inverter + Units .................................................................... 73

5.4.5. Heating Operation ........................................................................

...................

. 74

5.4.5.1 Water Source Heat Pump .................

.............................................

.. 74

5.4.5.2 Auxiliary Heat ..........................................................

.......................

... 75

5.4.6. SAT Control Options ........................................................................................ 75

5.4.7. Compressor Rotation ...................................................

.........................

........... 75

5.4.8. CO2Operation ..........................................................

..............................

.......... 76

5.4.9. Suction Pressure Operation ................................................

.............................

76

5.4.10. Enthalpy Wheel Operation ..............................................................

.................

77

5.5. Component Replacement, Charge, Evacuation, & Leak Instructions ..........

..................

77

5.6. System Rating Plate ...................................................................................................... 82

5.7. Start-Up Supervision Supplemental Information

...........................................................

83

5.8. System Start-Up Report

..................................................................

..............................

83

Start-Up Request Form ................................................................................................ 84

Start-Up Report

.............................................................................

................................

86

Compressor Replacement Form

...................................................

................................

91

9

1. Introduction

DesertAiredehumidiersaredesignedtoprovideyearsofreliableservicewheninstalled

properly.Readtheseinstructionscarefullybeforeyouinstallthedehumidier.

1.1. Inspection

DesertAireinspectsandtestseachdehumidierbeforeitleavesthefactorysothat

you receive a quality piece of equipment. Unfortunately, equipment may become

damagedintransit.Inspectthedehumidiercarefullybeforesigningthereceiving

papers. Check for both visible and concealed damage. Remove crating and inspect

theexteriorcabinetfordamage.Dentedpanels,brokencratingoranyuidleakingfrom

the unit should be documented upon delivery.

1.2. Freight Damage Claims

Ifthedehumidierhasbeendamaged,documenttheextentofthedamage.Takepicturesif

possible.Next,obtainaclaimformfromthecarrier.Promptlylloutandreturntheform.

Carriersmaydenyclaimsthatyouhavenotlledoutwithinaweekofdelivery.NotifyDesertAire

of any damage. Damaged units must have signed documents at the time of delivery to be eligible

for a freight claim.

1.3. Rigging

1. Failure to observe rigging instructions may lead to equipment damage, personal

injury, or death.

2. Lifting method and procedure must comply with all local and national codes and

regulations.

3. The use of safety slings in addition to lifting lugs is required.

4. Do not lift the dehumidifier in high winds or above people.

DesertAiredehumidiersaresolidlybuiltandcanbeveryheavy.Avoidpersonalinjuryand

damaging the equipment by planning the installation carefully. Use moving equipment whenever

possible.

1.3.1. Rigging the Dehumidier

Depending upon the unit type, various rigging methods are used to best lift the

equipment. Please reference the applicable sections below:

Desert Aire - QS/QV Manual

10

• All Products (QV and QS)

Personnel should avoid stepping on the top of the unit. Desert Aire

dehumidiersarenotdesignedtosupporttheweightofapersononall

portions of the roof. Damage incurred through caved or distorted top panels

will not be covered under warranty. If you must walk on the top panels,

carefully walk on the edges where structural integrity is greatest.

• VerticalAire™ Products (QV)

- 4-15 Ton

Move the unit to the desired installation location with the unit on the

wood skid. To remove unit from skid, position fork lift parallel to the

boards on the top of the skid. Carefully slide forks between the unit

and cross braces to pick the unit off the skid. The unit will have to be

carefully removed from the fork lift and placed into the desired

location using hand truck equipment dollies or pipe rollers. Use

caution to not damage the unit with the fork lift or tip the unit over

ensuring it is kept as level as possible.

- 20-30 Ton

The base is equipped with a built-in 12 gauge skid. Use a fork lift to

move the unit into place. Use caution to not damage the unit with the

fork lift or tip the unit over ensuring it is kept as level as possible. In all

cases, use appropriate safety practices while lifting the unit. Forklift

tie-down clamps, straps, and other restraints where applicable should

be used to prevent tipping of the load.

• Aura™ and TotalAire™ Products (QS)

Aura™andTotalAire™dehumidiersareequippedwithfourormorelifting

points. Use spreader bars and safety straps when you rig the equipment.

- Utilize all of the lifting lugs provided when hoisting the unit.

- Test-liftthedehumidiertoverifythatitisproperlybalanced.

- Refer to diagram below for additional lifting instructions.

Desert Aire - QS/QV Manual

11

Figure 1 - Typical Rigging for an IAQ Dehumidier

1. Do not tip the dehumidifier on its side.

2. Avoid dropping the unit down stairways or subjecting it to severe mechanical shock.

Desert Aire - QS/QV Manual

12 Desert Aire - QS/QV Manual

13

2 Installation

Manual applies to standard unit congurations only.

2.1 Location of Dehumidier

DesertAireTotalAire™dehumidiersareconguredtoallowsingle-sideaccess.Thismeans

you can make your service connections and perform routine maintenance when you must install

onesideofthedehumidierclosetoawallorotherrestriction.The“serviceside”isdetermined

whentheorderisplacedatthefactoryandcannotbechangedintheeld.Itisrecommended

that clearance be provided on all sides to allow for ease of serviceability in the event large

components require replacement. Aura™ and VerticalAire™ units may require service access

from multiple sides. Refer to the general arrangement drawing for further details.

Allowaminimumof36inchesofclearancearoundtheservicesideofthedehumidierforpiping,

electrical connections, and service access. The non-access side of the unit should contain 12

inches of clearance for large component removal. A minimum one unit width clearance shall be

maintained in all directions of outside air intake hood on outdoor units to allow for un-obstructed

airowintotheunit.Forpackagedunits,ensureaminimumofoneunitwidthofclearanceis

maintainedtoallowforproperairowthroughthecondensingsection.Ifthreeormorewalls

surroundtheunitconsultthefactoryforproperunitlocationtoallowforadequateairowthrough

the condenser section.

Install the unit on a sturdy, level mounting base or platform that will prevent vibration and sound

transmission.Neverinstallthedehumidieronawoodenormetalplatformwithoutconsulting

the design engineer for spring isolation requirements and sound control materials. Do not install

theunitnearoccupiedroomssuchasofcesorguestrooms.Donotattempttoconserve

installation space by fabricating restrictive ductwork with abrupt bends. You may reduce the

operatingefciencyandthemoistureremovalcapacityofthedehumidier.Seesection5.2for

detailed duct installation instructions.

Units located in unconditioned spaces may form condensation on the exterior of the cabinet.

Precautions should be taken for indoor units located within unconditioned spaces to prevent

damage resulting from condensation.

Do not install an indoor-rated dehumidier in an outdoor or a wet environment.

Ifyoumustinstalladehumidieroutsideyoumustuseanoutdoor-rateddehumidier.Desert

Airesealsandweatherproofsoutdoordehumidierstohelppreventwaterinltration.Youcan

determinewhetheryourdehumidierisoutdoor-ratedbyinspectingtheunitratingplate.

See section 5.6 for details.

Desert Aire - QS/QV Manual

14

2.2 Duct Installation

Duct design and installation should conform to the latest ASHRAE and SMACNA low velocity

duct standards. See section 5.2 for details. Undersized, restrictive ductwork with abrupt turns

ortransitions,candecreasetheefciencyandthemoistureremovalcapacityofyour

dehumidier.Sizetheductworkforanacceptableairpressuredropattheairowvolumeof

yourdehumidier.Useneopreneexconnectorswhenyouattachductworktothedehumidier

to prevent transmission of excess vibration and noise.

Select the grilles, registers and diffusers for low static pressure loss, required throw distance,

andthespeciedCFMrating.Youcanndthisinformationinmostgrillemanufacturer’s

catalogs. If you are installing the grilles in a corrosive environment, choose components made

from anodized aluminum.

Ifyoumustinstallductworkinanunconditionedarea,useberglassductwrapwithvapor

barrier facing. You must install the outdoor air intake away from all sources of airborne

contamination such as exhaust fans or plumbing vents. You can use galvanized sheet metal

ducts for most applications. However, you should use aluminum or stainless steel ducts for

extreme applications such as chemical-laden environments.

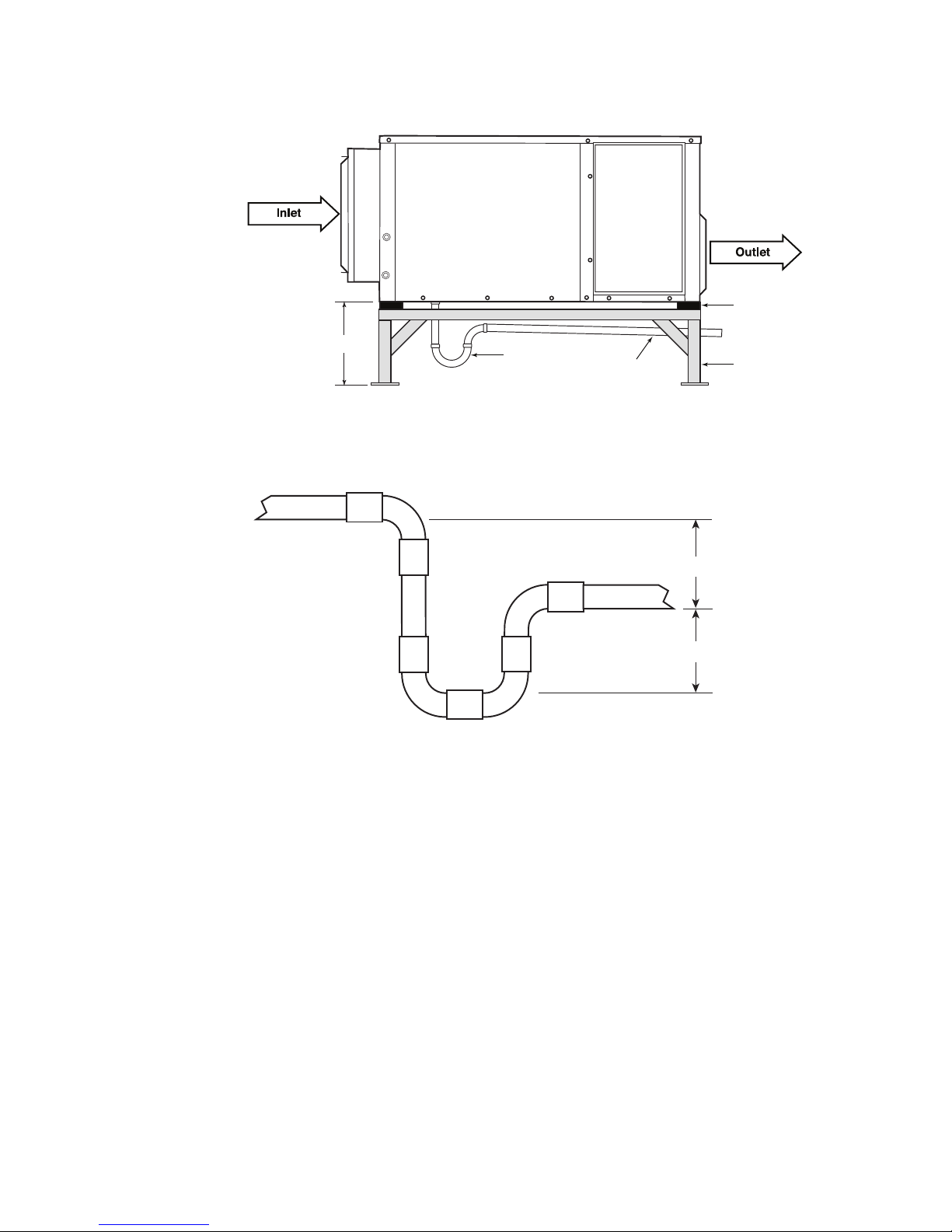

2.3 Condensate Drain Piping

Condensate drain lines installed in an unconditioned space must be heat taped to

prevent freezing. Check the heat tape yearly before winter operation.

Thecondensatedrainconnectionmaybeonthesideorthebottomofthedehumidier,

depending on the size and style of the cabinet used. Use concrete blocks or steel dunnage to

raisethedehumidierhighenoughabovetheoortoprovideclearancefortheeld-supplied

condensate drain trap.

Note:Dehumidierswithgasheatingoptionmayhavecondensateforminsidethefurnaceheat

exchanger since it is located downstream from the cooling coil. On indoor units, you must also

connecttheheater’sdrainline(ifpresent)toyoureld-installedcondensatedrainageplumbing.

Note:Whilethesupplyblowerruns,thedrainpanareainsidethedehumidieroperatesata

negative pressure. Your unit requires a p-trap in the condensate drain pipe to prevent

condensatefrombeingdrawnintothecabinetofthedehumidier.

Desert Aire - QS/QV Manual

15

Min. 12”

P-Trap (By Others)

Vibration

Isolator

Base /Support

(By Others)

1/4” Slope

Per Foot

Figure 2 - Condensate Piping (Bottom-Mounted Drain Shown)

4”

4”

Figure 3 - Sectional View of Condensate Trap Requirements

Trap the condensate as shown in Figure 3. The P-trap dimensions in Figure 3 are sized for a

maximumreturnairstaticof2.0”ofwater.Ifyourreturnairstaticexceedsthisspecication,

consult Desert Aire for help in resizing the P-trap.

You may also need to install a cleanout tee or plug near the trap. Note that the drain opening

in the drain pan is off-center to simplify its cleaning and servicing. Once you have designed

and installed the trap, follow this sequence:

1. Connect the trap to a main drain line with 1/4” of downward pitch per linear foot of run.

2. Supportthedrainpipeeveryvefeettopreventsagging.

3. After you install the drain piping, prime the trap by pouring water into the drain pan of

thedehumidier.

Desert Aire - QS/QV Manual

16

2.4 Auxiliary Heat Coil Piping

TheDesertAiredehumidiermaybeequippedwithanoptionalhotwaterorsteamairheating

coil. This coil, when properly sized, will provide space heating during the winter months.

Use proper practice when designing and installing the coil piping to prevent poor coil

performance, shortened service life, or damage to the coil.

• The supply connections must not be supported by the coil headers.

• Thecontrolvalveshouldbesizedaccordingtothepressureandowrate

requirements, not by the coil connection size.

• On steam systems, use strainers, dirt pockets, and isolation valves to prevent clogging

the control valve and to simplify service.

• Install swing joints in the connection piping to prevent damage to the coil header from

thermal expansion.

• Use a backup wrench on the pipe stubs when attaching connections to prevent

damage to the header.

2.5 Water Piping Installation (for Q-Pump and Water Cooled Systems Only)

Asanoption,thedehumidiermaybeequippedwithatowerwateroraheatpumploop

condenser.Useindustrystandardpipingpracticeswhenconnectingtosuchadehumidier.

Connectionsarecopperstubs.Refertosubmittaldocumentationforspecicsizepermodel.

Water Quality and General System Design

A60meshornerstrainermustbeinstalledinthewaterinletline.Flusheldinstalledpiping

thoroughlybeforeyouputthedehumidierintoservice.Apipingsystemnotproperlyushedor

lteredwillcausethebrazed-plateheatexchangertoloseefciencyorfailprematurelydueto

clogging and/or fouling.

To prevent premature failure of the heat exchanger, maintain the water at a pH of 7.4, but

never below 6.0. Do not use water with high concentration of sulfur, chlorine, or sodium

chloride.

A dedicated circulating pump must be used unless the main pump can develop enough head

to overcome the combined resistance of the water condenser and the piping connected to it.

SeespecicFlowRatesectionfortherequiredwaterowrateandheadforyourapplication.

Desert Aire - QS/QV Manual

17

Install an air eliminator at any high point in the water piping. Air trapped in the water circuit

ofthedehumidiercanleadtoelevatedoperatingpressures,unexpectedservicecalls,and

decreased equipment life.

If the water system is connected to a variable frequency drive or to water loops with multiple

units,owregulatingvalvesshouldbeinstalledtoensureowrateismaintained.

Do not exceed these guidelines as excessive flow rates will erode the condenser and piping.

Aura™ Products Flow Rate

Theowrateandantifreezeconcentration(ifused)willdependontheapplication.Pleaserefer

toFigure4and5fortherequiredowrateandtemperaturelimitsforthegivenapplicationand

unit type. If the application deviates from these conditions, please contact Desert Aire Service

at 262-946-7400 for further review.

Unit Size

(Nom. Tons)

8

10

12

15

20

25

30

Fluid Flow Rate

(GPM)

24

30

36

45

60

75

90

Fluid Pressure Drop

(psig)

4.0

5.6

4.1

3.6

3.4

6.4

4.0

Figure 4- Aura™ Q-Pump Water Flow Rates

Desert Aire - QS/QV Manual

18

Glycol Percent

0

5

10

15

20

25

30

35

40

45

50

Min. Fluid Temp. (°F)

40

37

34

31

27

25

25

25

25

25

25

Figure 5 - Aura™ Q-Pump Minimum Water Temperature

TotalAire™ and VerticalAire™ Products Flow Rate

Theowrateandantifreezeconcentration(ifused)willdependontheapplication.PleaserefertoFigure6

and7fortherequiredowrateandtemperaturelimitsforthegivenapplicationandunittypeaswellasthe

glycol concentration requirements. If the application exceeds these conditions, please contact Desert Aire

Service at 262-946-7400 for further review.

Desert Aire - QS/QV Manual

19

Unit Size

(Nom. Tons)

2

3

4

5

8

10

15

20

25

30

36

40

46

50

56

60

Fluid Flow Rate

(GPM)

9

15

15

19

20

28

45

57

70

87

99

123

135

143

156

172

Water Cooled Units

0.9

1.3

1.7

2.6

2.3

2.8

2.7

2.7

2.7

2.8

3.1

2.8

2.8

3.1

3.1

3.1

Q-Pump™ Units

2.3

2.9

4.2

6.3

5.5

6.5

6.3

6.2

6.2

6.4

6.5

6.5

6.4

6.5

6.4

6.5

Fluid Pressure Drop (psig)

Notes: Boiler/Tower loop temperature range must be pure water

between 55°F & 95°F

Ground source loop temperature range must be 30% glycol

between 35°F & 105°F

Figure 6 - Water Flow Rates

Glycol Percent

0

5

10

15

20 and up

Min. Entering Water Temperature (°F)

48

47

45

40

35

Figure 7 - Glycol Concentration Requirements

2.6 Remote Condenser Installation (Air-Cooled Systems Only)

Important: Refer to the separate Air Cooled Condensers Installation and Operation manual for

additional details on line design, traps, clamping, and other condenser installation requirements.

Desert Aire - QS/QV Manual

20

TotalAireandVerticalAiredehumidiersinstalledwithremotecondensersmayrequireadditional

oilandrefrigerantchargeatthetimeofeldinstallation.Refertothesubmittaldocumentationor

labeladjacenttotheremotecondenserconnectionstoconrmthechargeandconnectiontubesizes.

2.7 High Voltage Wiring

1. Disconnect power before servicing. The unit contains high voltage wiring and

moving parts which may cause serious injury or death.

2. Failure to properly wire the dehumidifier may create the possibility of shock and

can lead to premature system failure.

For any unit labeled Class 1, Group D, Division 2, all wiring must be in accordance to

Class 1, Group D, Division 2 requirements. Insure that all local, state, national and any

other applicable codes are adhered to when connecting any device to this equipment.

All electrical connections to units labeled Class 1, Group D, Division 2 must be done

with a conduit seal.

Electrical wiring must comply with all national, state, and local codes. Refer to the wiring

diagram located inside the electrical section for all wiring connections. To connect main power,

attach the supply wires to the three-pole power block mounted on the electrical panel. Test the

phasing by “bumping” the blower contactor. Verify that the blower rotates in the proper

direction. If it rotates the wrong direction, switch any two of the three wires at the power block.

2.7.1 High Voltage Connections

On single phase units the power supply must have 3 connections (2 power and 1

ground). On three phase units the power supply must have 4 connections (3 power

and 1 ground). Connect the power supply wires to the main power block located in the

upper section of the electrical compartment.

Desert Aire - QS/QV Manual

This manual suits for next models

2

Table of contents

Other Desert Aire Dehumidifier manuals