Desert Star Acoustic Release Control System User manual

Acoustic Release Control System

The Acoustic Release Control unit (ARC), is designed to make it possible to secure a payload under

a body of water for an extended period of time. The ARC unit is attached to the anchor weight on

one side, and to the payload with a flotation device on the other. Once the ARC station is deployed

underwater in the desired location, it remains there in a sleep mode awaiting commands from the

surface.

Once the payload needs to be retrieved, the command is sent remotely from the surface to release

the ARC unit with the payload from the sea-floor.

The system consists of at least two main components: the submerged ARC unit “holding” the

payload in place under the body of water, and the Surface Transponder Module - or as commonly

referred in this manual - the STM Surface station, functioning as a remote control.

The two-way communication between the ARC unit and the STM Surface station (when deployed to

the sea-floor with the payload), is accomplish via acoustic sonar signals. The submerged ARC

station is designed to respond to the commands sent to it from the surface, and it will report back

various telemetry data such as unique self-ID, batteries status, current state of the operation,

distance.

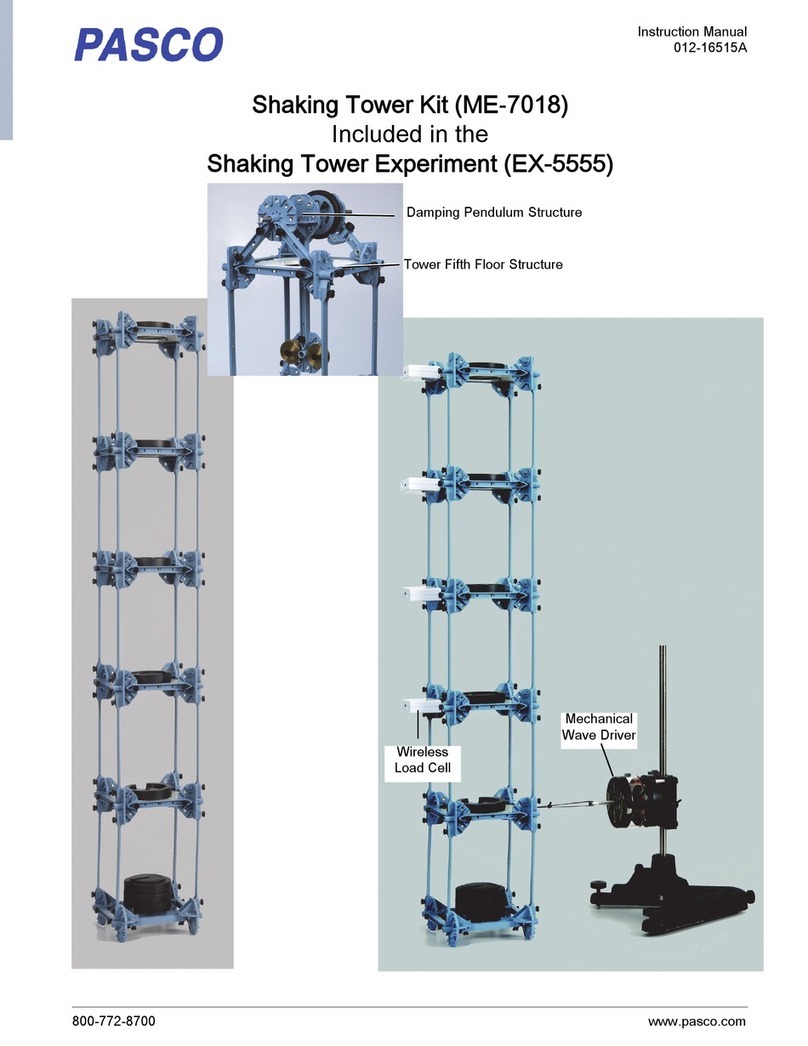

A logical schematic of the submerged components.

A single ARC submerged station is monitored and controlled by one of the STM surface stations.

Desert Star Systems manufactures multiple STM surface stations specific to the application needed.

Customers have a choice of utilizing an STM surface station designed to be installed in a dry

location on board a vessel, or a mobile unit that can be exposed to moisture.

When it is desired to deploy an array of a multiple submerged ARC stations, the single STM surface

unit can be used to manage the entire underwater array. The specifics of these applications will be

described later in this manual.

[PICTURE: A ship with a STM unit on board and a single submerged ARC unit at the sea-floor.]

[PICTURE: A ship at the surface with a single STM unit and a multiple ARC stations submerged

under the vessel.]

1. How the ARC station releases from the anchor

The ARC station placed at the sea-floor uses a unique release mechanism designed exclusively by

Desert Star Systems. Once the command is sent to the ARC station from the surface, the release is

accomplished by “melting” an easily replaceable nickel-chromium wire and subsequently releasing a

hinge lever. The hinge lever frees a wire-loop connected to the anchor, allowing the ARC station to

surface - along with the payload. Please note, the anchor and the wire-loop will remain on the sea

floor and by design are not expected to be retrieved.

Please make sure that you are familiar with a basic principle of the release mechanism, and the

nickel-chromium wire replacement procedure so that ARC station can be redeployed after it has

surfaced.

Once you understand the simplicity and reliability of the release mechanism of ARC station, we

believe you will be confident in your ability to deploy your ARC station successfully many times over

and over again.

Desert Star Systems engineers understand how critical and important your underwater mission is

and this is why we would like to ask you to take special care in understanding the mechanics of the

release mechanism to ensure your success in retrieving of the ARC station with the pay-load.

2. Installing/Replacing Nickel-Chromium Wire in the

Release Mechanism

The following is the Desert Start System approved procedure to install/replace nickel-chromium wire

within the release mechanism of the ARC unit. It is critical to follow this procedure closely in order to

ensure proper function of the release mechanism. Deviation from this procedure may cause a

malfunction of the release mechanism and failure of the ARC station to surface as expected by

design.

In order to replace the nickel-chromium wire you will need the following set of tools and components:

1. Nickel-Chromium wire, also referred in this manual as “release wire”.

1. Type: Nickel Chromium Alloy (60% nickel, 16% chromium, 24% iron)

2. Length: ~2 in. needed for a single deployment.

3. Gauge: 26 AWG

4. Manufacturer: McMaster-Carr Part #8880K24 (1/4 lb spool)

5. Desert Star Systems Part#: WIR00332

2. Torque wrench with 5/64” Allen head. Used to remove/re-install the pair of screws

securing the nickel-chromium wire.

3. 3/16” crescent wrench. Used for insure alignment of two metal posts. The

nickel-chromium wire is secured between these two posts.

4. Wire loop(s). Used to attached the anchor with the body of the ARC unit (NOT included

with purchase)

.

NOTE:If you have any questions regarding the nickel-chromium wire and it’s installation procedure, PLEASE GIVE US A

CALL AT 1(831) 384-8000 and our technical support team will be happy to assist you.

The choice of the wire/cable is critical for the correct operation of the release mechanism! The wire loop(s) must be

plastic coated stainless steel cable. The plastic coating is required so that if there is a tangle, the loop will not short-circuit the

wire posts.

The total diameter (including the plastic coat) of the wire/cable has to be NO MORE than 1/8” (3.175mm) in order for the

wire/cable to pass freely through the release mechanism assembly, once the release lever arm is opened.

Two ends of the cable should be crimped together into a loop. The crimp bracket holding the ends

of the loop together must be made out of stainless steel in order to prevent a dissimilar metal

corrosion and a subsequent disconnect of the loop's ends. During the loop's manufacturing,

please ensure proper crimp placement over the cable ends. Pay close attention to the amount of

force used to secure the crimp. Please make sure to use a proper crimping tools so that the loops

ends are secured and the loop wire is capable of withholding the adequate amount of force.

2.1 Follow this sequence in order to install/replace the

nickel-chromium wire:

STEP 1:

Loosen the setscrews at the top of the two posts using a size 5/64” Allen wrench.

If the ARC unit was previously deployed, make sure to remove any debris or remains of the nickel-chromium cable left from

the previous deployment, in the holes drilled through body the posts on their sides.

Make sure to inspect the holes in the posts. The holes must be clear, so that new nickel-chromium

cable can be threaded through the sides of the posts.

STEP 2:

Move the lever arm in to open position so that the path for the anchor wire/cable loop is clear. Place

the wire/cable anchor loop in the the designated path within the release mechanism assembly.

Anchor weight attaches to this wire/cable loop.

[PICTURE shows the assembly with the lever arm in open position with the arrow indicating the

direction the lever should be moved.]

STEP 3:

Once the anchor wire/cable is loaded in to the release assembly, move the lever arm in to a closed

position locking the anchor wire/cable. When lever arm is placed in to closed position correctly, the

end section of the lever arm will be right between two posts.

The assembly with the lever arm in closed position with the arrow indicating the direction the lever should be moved.

Identify two posts and anchor cable been locked in the release assembly.

STEP 4:

Insert the nickel-chromium wire from the outside of the post and through the hole in the post so that

the nickel-chromium wire passes across the lever arm and out through the hole of the second post.

When a nickel-chromium cable is threaded correctly, the end section of the lever arm will be

“trapped” by the nickel-chromium cable between two posts.

Two posts and the N-C wire path, with the end section of lever arm.

STEP 5:

Using the torque wrench set to the 4 inch-pound torque, tighten the screws in the posts securing

nickel-chromium wire in place. While tightening the screws, make sure to hold the posts in

alignment. Prevent the posts from turning out of the alignment, by using the 3/6” crescent wrench

applied at the flat part of the posts. If posts do move only slightly out of the alignment, it is not a

concern because each post sealed within the body of ARC unit by a rubber O-ring. Excessive

turning or twisting the posts may cause a disconnect from the internal electronic components of ARC

unit and should be avoided!

STEP 6:

Cut the excess of nickel-chromium wire, leaving about 1/8” on the side of the each post and bent

towards the unit. This will help to remove the leftovers of the nickel-chromium wire when the ARC

station has resurfaced so that it can be re-deployed.

The final correctly installed nickel-chromium wire

This concludes installation of the nickel-chromium wire in the release mechanism.

3. Installing/Changing the Batteries of an ARC Station

You have two options powering your Acoustic Release Control (ARC) station.

Please note that your ARC units will come pre-loaded with a standard alkaline battery configuration.

STANDARD OPTION

With the maximum total life time of 130 days, consists of eight (8), 1.5 volt ‘AA’ size batteries

installed in two packs of four (4):

●Total number of batteries: eight (8);

●Type: Alkaline;

●Size: AA;

●Brand: Duracell;

●Model: MN-1500;

●Volts: 1.5 volt;

●Amps: 2.5 Ah.

In this battery configuration, the two battery packs are used as follows:

●First pack of four (4) Alkaline batteries is used to power the release mechanism and the

sonar transmitter.

○The life time of this pack is expected to be at least 520 days.

●The second pack of four (4) Alkaline batteries is used to power on-board microcomputer.

○The life time of this pack is expected to be at least 130 days.

LONG DURATION OPTION

With the maximum total life time of 520 days. An extended battery option consist of four (4) 1.5 volt

‘AA’ size batteries installed in one pack, and the second pack of single Lithium D Cell battery.

●Total number of batteries: five (5)

○Four (4) alkaline batteries:

■Type: Alkaline;

■Size: AA;

■Brand: Duracell;

■Model: MN-1500;

■Volts: 1.5 volt;

■Amps: 2.5 Ah.

○One (1) Lithium D Cell battery:

■Type: Lithium;

■Size: ‘D’ cell;

■Brand: Tadiran;

■Model: TL-5930/F

■Volts: 3.6 volt;

■Amps: 18.5 Ah.

In this battery configuration, the two battery packs are used as follows:

●First pack of four (4) Alkaline batteries is used to power the release mechanism and the

sonar transmitter.

○The life time of this pack is expected to be at least 520 days.

●The second pack of a single Lithium D Cell battery is used to power on-board

microcomputer.

○The life time of this pack is expected to be at least 963 days.

Due to hazardous material regulations, the “Lithium D Cell” battery has to be purchased separately by the user. We are

unable to re-sell this type of the battery directly to the consumer. However, you are able to use this type of the battery with our

ARC station. The internal power connector receptacle installed in your ARC station is compliant with the power socket of the

Tadiran TL-5930/F lithium ‘D’ cell battery. No modifications to the power connector is needed and the fully charged battery

can be connected directly to ARC station.

For your consideration, the ‘D’ size Lithium Battery, suggested as a long duration battery option, is the subject of a Federal

regulations under the U.S. Department Of Transportation. The Lithium type batteries classified as a ‘Class 9 hazardous

material’ and must be transported accordingly. The improper handling and shipping such materials is a subject of significant

fines as mentioned in above regulations. Please take all necessary precautions to comply with your local state and federal

regulations when considering purchase of Lithium batteries.

3.1 Other Battery Configurations:

If your specific application of the ARC station requires a different battery configuration, then please

feel free to call us at Desert Start Systems +1(831) 384-8000. We will gladly assist you and try to

accommodate your specific requirements to power the ARC station.

3.2 Battery Installation

Once you have decided what battery configuration option is best suited for your specific application,

please follow this procedure to install the batteries of your choice.

STEP 1:

Using a 3/32” Allen wrench, loosen and remove six (6) screws located at the top of the ARC station

along the edge of the sonar transducer end-cap.

The side of the ARC station the sonar transducer end-cap is located and where the screws are.

STEP 2:

Once the six (6) screws are removed, carefully pull the sonar transducer end-cap out of the main

ARC body, slightly twisting it back and forth while pulling away at the same time. Take care to

prevent a jerking motionwhen the sonar transducer end-cap separates from the main body of the

ARC station, so that the cable connecting the sonar transducer end-cap to the internal electronics

does not get damaged.

STEP 3:

Locate the BLACK/WHITE cable with the connector used to link the sonar transducer end-cap to the

internal electronic board. Disconnect it carefully. Make sure not to use excessive force when pulling

the cable from the main housing of the ARC station. Put the sonar transducer end-cap aside.

STEP 4:

Pull the battery packs out one by one from the main body of the ARC station. Locate the

BLACK/RED cable(s) connecting each battery pack to the electronic compartment of the ARC

station. Each battery pack power cable has a plastic female/male type of connector. Use this

connector to disconnect the battery pack from the power cable leading to ARC unit internal

electronic components.

STEP 5:

Install batteries in to the battery pack holster making sure to insert each battery according to

corresponding (+) and (-) polarity.

When inserting individual batteries, the negative (-) polarity side of the battery corresponds to the metal spring and the

positive (+) side of the battery corresponds to the opposite side of the metal spring within the body of the battery pack.

The battery pack with one installed AA battery and the empty section next to occupied section so that the metal

spring is visible and marked with the arrow and the (-) sign while the opposite side marked with the arrow and the (+)

positive sign.

STEP 5.1:

If you are using the Lithium battery, follow the instructions in Step 5 for the first battery pack. The

Lithium battery connects directly to the power cable instead of the second battery pack loaded with

AA type of batteries. Remove the second battery pack completely and store in a safe place for future

use.

Battery pack connectors

STEP 6:

Once the battery packs are reconnected to their corresponding power cables, carefully insert each

battery pack back into the body of the ARC station. Make sure to gently “tuck in” the battery

connector cables so that they are not damaged or stressed.

STEP 7:

Locate the sonar transducer end-cap you removed earlier. Reconnect the sonar transducer end-cap

to the corresponding WHITE/BLACK cable. Ensure that the connector on the cable from sonar

transducer end-cap is inserted to the socket on corresponding cable firmly. Once the cable

connection is made, carefully insert the excess cable back in to the body of ARC station using your

fingers.

Before re-inserting the sonar transducer end-cap back in the body of the ARC station, please pay close attention to the

condition of the rubber O-ring stretched around the inner edge of the sonar transducer end-cap. If you notice any debris or

cracks in the structure of the rubber O-ring, pull it from its groove. Remove all the dirt and debris from the groove before

re-installing the rubber O-ring. Please take special care handling the rubber O-ring because it is relatively fragile and can be

damaged by sharp metal objects. Replace O-ring if it is necessary. If you determine that the O-ring needs to be replaced,

contact Desert Star Systems LLC and ask for

Rubber O-ring, Manufacturer: Parker 2-130, Compound E515 (qty 1)

Desert Star Part#: ORI00058.

Before re-installing the rubber O-ring back to its groove on the sonar transducer end-cap, make sure to apply a thin film of

silicone grease.

STEP 8:

With the rubber O-ring properly placed in its groove and stretched around the inner edge of the

sonar transducer end-cap, push/snap the sonar transducer end-cap back into the housing of the

ARC station.

When aligning and preparing to push the sonar transducer end-cap back in it’s place, make sure the

holes around the edges of the sonar transducer end-cap aligned to the the threads for the screws in

the main housing of the ARC station. Pay close attention to the proper alignment in order to avoid

twisting the sonar transducer end-cap once it is inserted in it’s place. Excessive twisting of the sonar

transducer end-cap once it is snapped in to the main housing, may damage the O-ring causing the

subsequent water leak into the ARC station main body.

Make sure that no wires get jammed between the the rubber O-ring and the main housing of the

ARC station.

STEP 9:

Once the sonar transducer end-cap is snapped in its place, re-insert the screws. Make sure to

tighten the screws in the star-shaped pattern to ensure equal pressure applied to all sides of the

sonar transducer end-cap. Tighten the screws to a snug fit.

Do not over tighten the screws.

Acoustic Release System Manual Part 2

4. Battery Life Expectancy

As discussed earlier, there is two options for powering an ARC unit.

●Option #1 Alkaline batteries only, will provide at least 130 days or ~ 4 months.

●Option #2 Alkaline plus Lithium batteries will provide at least 520 days or ~ 17 months.

This is the timeframe between the initial ARC deployment and the first retrieval of ARC unit back to

the surface. After a 130 days or 520 days of uninterrupted presence under the water - depending on

the type of your batteries - a new set of batteries MUST be installed.

If you are planning to execute multiple deployments and retrieval of the same ARC unit with the

same battery (without installing new batteries) it is very important to take the following factors into

consideration…

The battery energy consumed by an ARC unit consist of two parts: It takes energy to communicate

with the surface, listen, process, execute and respond back to the commands send from the STM

surface station, It also takes energy to execute the release from the anchor energizing the release

mechanism.

On a set of an Alkaline only batteries, ARC unit capable to initiate about 700 release cycles. Each

release cycle will require communication with the surface. The more time the ARC unit spends

communicating with the surface, the more energy will be depleted from the batteries.

Use the following statistics in this table to estimate the number of release cycles and associated

maximum communication time available per release cycle.

[TABLE] Show table with an estimated times. TBD

To extend the life of your batteries, be mindful of the number of communication cycles you initiate

from the surface to an ARC unit underwater. Keep the number of those communication sessions and

their duration to an absolute minimum.

With the nickel-chromium wire installed into the release assembly, new batteries connected,

O-ring rubber gasket properly loaded, and sonar transducer end-cap secured, the ARC unit is

now set and ready to communicate with the Surface Transponder Module (STM). The

following section of this manual will guide you through the STM surface station functions and

operations

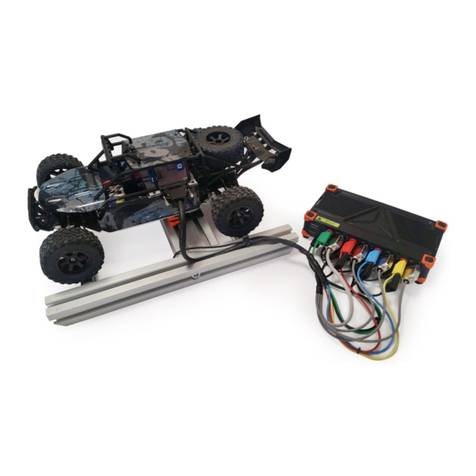

5. Surface Transponder Module (STM)

The Surface Transponder Module (STM) (Model Number STM-3) facilitates a relay-converter

function between a software running on the PC and the submerged ARC unit. The STM surface

station receives the command sent to it from the PC and converts it into sonar acoustic signals. The

sonar acoustic signals are then sent through the water to the ARC unit under the water. The ARC

unit processes the commands it received and sends back a response. The STM surface station

receives the response in the form of an sonar acoustic vibrations, converts them back in to digital

signals and forwards them to the software running on a PC. The software displays the information

received from the ARC unit on a PC's monitor.

The STM surface station is assembled as portable unit, with controls and connections located in its

front panel.

The front panel of the STM surface station.

The STM surface station is equipped with the internal rechargeable battery for mobile operations

when an external power source is not available. The power supplied to the STM surface station via

power cable with a standard IEC 60320 - C13 coupler. External power charges the internal battery

as well as providing a main power for the continues operation.

Table of contents