Desoutter FAS3000 User manual

Other Desoutter Controllers manuals

Desoutter

Desoutter CVIR II User manual

Desoutter

Desoutter ESP1-A User manual

Desoutter

Desoutter CVIC II L2 User manual

Desoutter

Desoutter CVIL II User manual

Desoutter

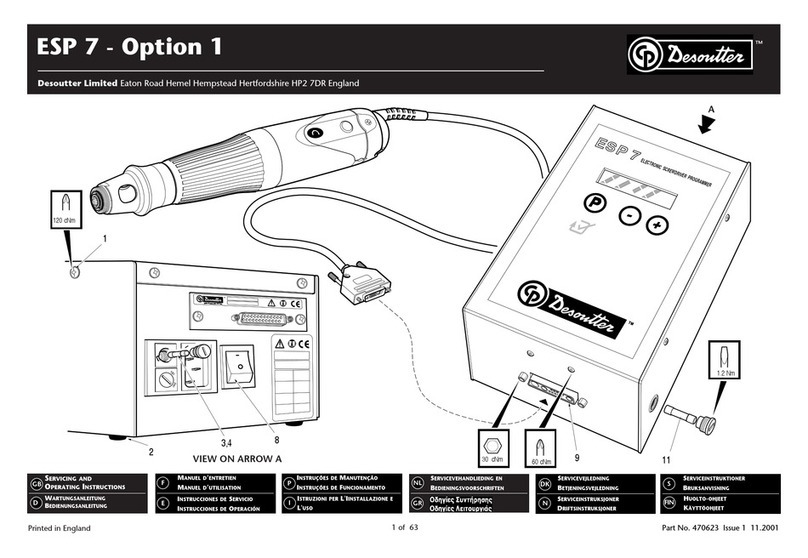

Desoutter ESP 7 Operating instructions

Desoutter

Desoutter CVI3 Essential Instruction sheet

Desoutter

Desoutter ESP1-HT PLUS User manual

Desoutter

Desoutter CVI3 Series Quick start guide

Desoutter

Desoutter CVIC II Series User manual

Desoutter

Desoutter Industrial Tools ESP2-A User manual

Desoutter

Desoutter Industrial Tools CVIC II L2 User manual

Desoutter

Desoutter CVI3 Vision User manual

Desoutter

Desoutter ESP 7 Operating instructions

Desoutter

Desoutter CVI3 Function User manual

Desoutter

Desoutter CVIC II User manual

Desoutter

Desoutter ESP-C 110 V User manual

Desoutter

Desoutter CVI3 Essential Manual

Desoutter

Desoutter ESP-CA 230 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions