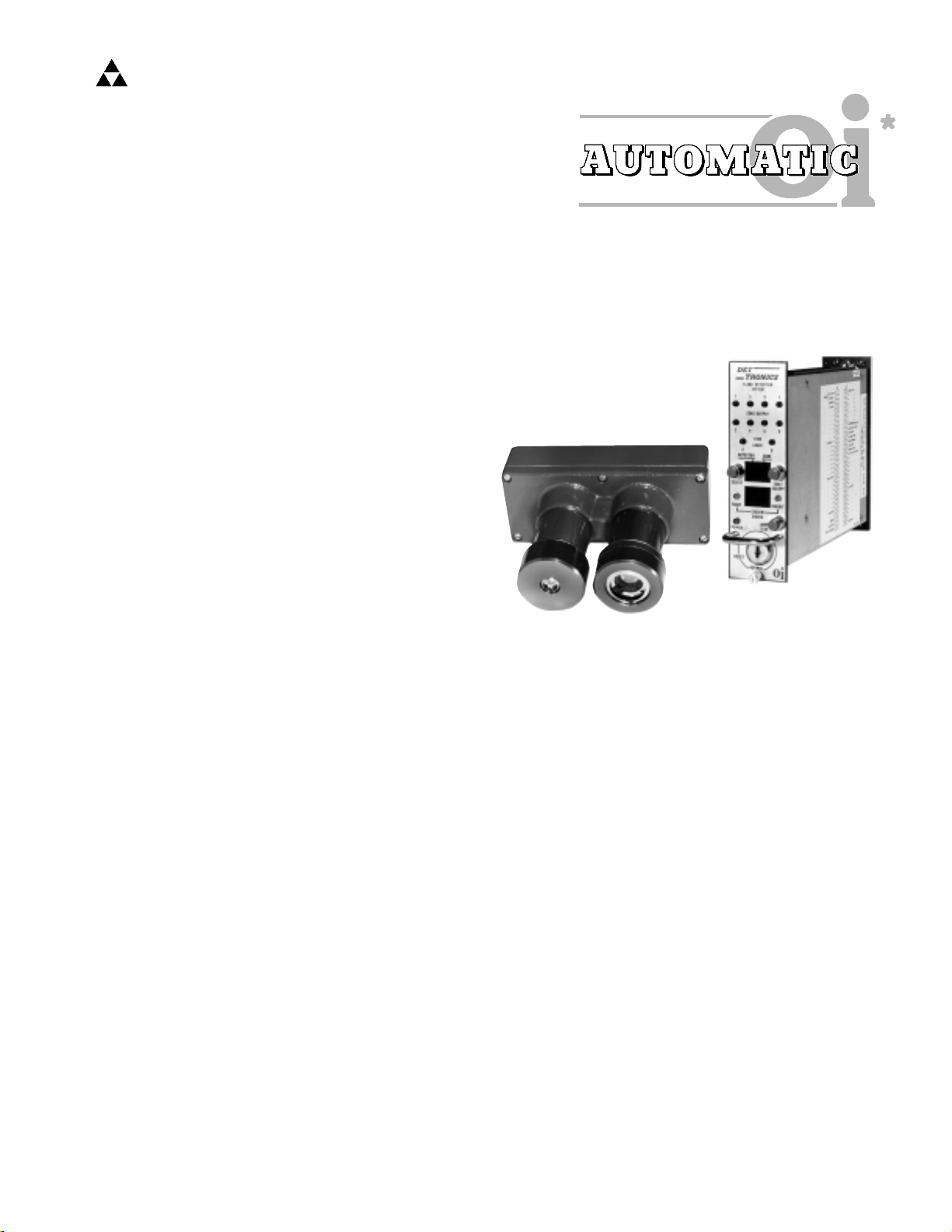

1. A ZONE OUTPUT LED is provided for each

detector to indicate that a fire has been detected.

The LEDs blink while the zone output is active and

latch on when the fire is no longer detected and the

output turns off.

2. The FIRE LOGIC LEDs signal actuation of the cor-

responding Logic outputs.

3. The DETECTOR - ZONE digital display indicates

the detector zone number that first responded to

a fire, detector(s) indicating a fault, detector zone

selected manually in the keylock switch Test

mode, or the counts per second reading from the

detector zone in the Count Test mode.

4. The SYSTEM STATUS display uses a numerical

code to identify system status (see Table 1).

5. Illumination of the FAULT LED indicates a system

malfunction (or that the controller is in the Reset

or Test mode).

6. The INHIBIT LED is energized in the Test or Reset

mode to show that the outputs of the controller

are inhibited.

7. The POWER LED is illuminated when power is

applied to the system.

8. The SELECT button is pressed to choose a detec-

tor for test.

9. In the Test mode the TEST/ACCEPT button initi-

ates a manual oitest for the selected detector.

In the Normal mode, the TEST/ACCEPT button is

used to disable the alarm output when a fire

occurs without affecting the Zone or Fire Logic

outputs.

10. The LAMP TEST button illuminates all LEDs and

all segments of the displays. In the Reset mode,

it initiates a complete microprocessor reset.

11. The keylock switch selects NORMAL, RESET or

TEST mode.

Normal Mode

In the Normal operating mode, the R7494 Controller

monitors the outputs of all detectors connected to it

and compares the detector output signals to field

adjusted settings (refer to the “STAR Logic

Programming” procedure in the “Programming the

Controller” section) to determine whether a fire condi-

tion exists. Diagnostic circuitry continuously checks

the system for wiring continuity as well as faults that

could prevent proper response to a fire through the

Automatic oifeature. The Zone, Fire Logic and Fire

Alarm outputs are de-energized. The Fault output is

energized, as long as no system malfunctions are

detected. None of the LEDs except the POWER LED

are illuminated and the digital displays are blank.

Reset Mode

Any existing system status indications and the con-

troller outputs are returned to normal operating condi-

tion (after the radiation source is removed or the fault

is corrected) in one of the following ways:

1. Place the keylock switch in the RESET position,

then return it to NORMAL.

2. Close the optional remote reset switch connected

to controller terminal 44 and circuit ground (termi-

nal 2).

Test Mode

In the Normal mode, the Automatic oifeature continu-

ously checks the detectors for proper operation.

Additional manual oitesting capabilities are provided

by using the controller Test mode. Among the possi-

ble tests are:

1. A Manual oitest, which individually tests the

selected detector and its electronic circuitry.

2. A Count Test mode, which displays the output fre-

quency of an individual detector using the

DETECTOR and ZONE displays.

3. A Bus Test mode, which tests the data bus wiring

and indicates results on the front panel of the

controller when intercontroller voting is used.

These test features enable the user to more easily

pinpoint a system malfunction. Refer to the

“Troubleshooting” section.

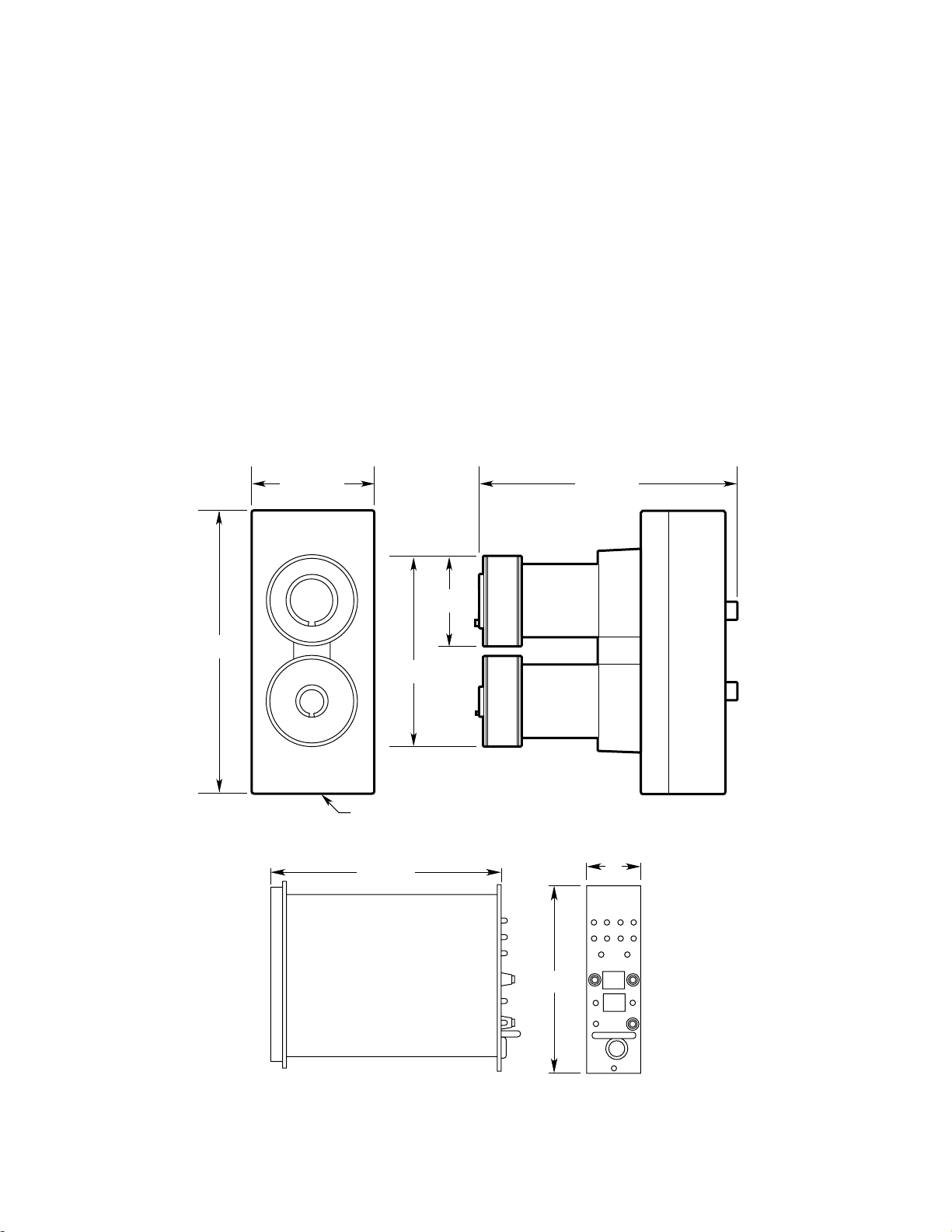

PROGRAMMING SWITCHES

Rocker switches that are located on the side of the

controller are used for selecting various options avail-

able with the R7494. These programming options are

listed below and must be set prior to system opera-

tion. Refer to the “Programming the Controller” sec-

tion for detailed instructions.

1. Number of detectors connected to the controller

(up to eight)

2. Gate Length, Consecutive Gate Selection, Count

Selection (system sensitivity and time delay).

3. Fire Logic (voting arrangement)

4. Latching/non-latching outputs.

5. Intercontroller voting.

4