and/or instructions for calibration. When a display is not

used or the LED is not visible from the outside, the

enclosure must be opened to observe the LED or to

insert a meter to read the output of the device (intrusive

calibration). With this type of installation, either a permit

must be obtained to open the enclosure or the proce-

dure must be accomplished by two people using walkie

talkies for communication.

Depending on the control devices selected, PointWatch

can be installed for either intrusive or non-intrusive cali-

bration. See Table 3 for a listing of the installation

options.

A user-supplied junction box can also be used, provid-

ed it has the appropriate sized entries. This junction

box must be suitable for use in the application and loca-

tion in which it is being installed. Calibration is initiated

by touching the calibration lead to the negative lead

(common) of the power supply. Although this can be

accomplished manually, installation of a switch is rec-

ommended. It is recommended that this switch be a

momentary contact type to prevent it from inadvertently

being left in the calibrate position.

GENERAL WIRING REQUIREMENTS

NOTE

The wiring procedures in this manual are intended

to ensure proper functioning of the device under

normal conditions. However, because of the many

variations in wiring codes and regulations, total

compliance to these ordinances cannot be guaran-

teed. Be certain that all wiring complies with appli-

cable regulations relating to the installation of elec-

trical equipment in a hazardous area. If in doubt,

consult the authority having jurisdiction before

wiring the system.

The use of shielded cable in conduit or shielded

armored cable is recommended for optimum RFI/EMI

protection. In applications where the wiring cable is

installed in conduit, the conduit must not be used for

wiring to other electrical equipment. To assure proper

operation of the detector, the resistance of the connect-

ing wire must be within the specified limits. The maxi-

mum distance between the detector and power source

is determined by the power supply capability and wire

size. See Figure 2 to determine the proper wire size

and maximum wiring distance allowed.

It is important that moisture not be allowed to come in

contact with the electrical connections of the system.

The use of proper piping techniques, breathers, glands,

and seals are required to prevent water ingress and/or

maintain the explosion-proof rating.

DETECTOR WIRING PROCEDURE

IMPORTANT

Do not apply power until the wiring procedure is

complete and has been verified.

1. Determine the best mounting location for the detec-

tor (refer to the “Detector Location” section above).

If it is determined that sensor separation is required,

see the following section for details.

2. The junction box should be electrically connected

to earth ground.

3. Figures 14 through 18 show typical wiring for vari-

ous system configurations using the PointWatch

detector. Refer to the appropriate figure as a guide

to system connection. Figure 14 shows typical

wiring for standalone operation. Figure 15 shows

typical wiring for PointWatch with Det-Tronics sup-

plied junction box. Figure 16 shows the junction box

terminals and calibration switch. Figure 17 shows

typical wiring for PointWatch/Infiniti transmitter oper-

ation. Figure 18 shows typical wiring for

PointWatch/Eagle communication module configura-

tion. The PointWatch wiring color code is:

Red lead = +24 volts dc

Black lead = – (common)

White lead = 4 to 20 ma signal output

Yellow lead* = Calibration input

Green lead = Chassis ground

*If the calibration wire (yellow lead) is not

being used, do not connect this wire to

ground. Trim excess length and insulate

wire so no shorting can occur.

4. Check the detector wiring to ensure proper connec-

tions, then pour the conduit seals and allow them to

dry (if conduit is being used).

DETECTOR SEPARATION (OPTIONAL)

In applications where the detector must be installed in a

different location from the control device, a junction box

must be installed at the detector location to make the

8

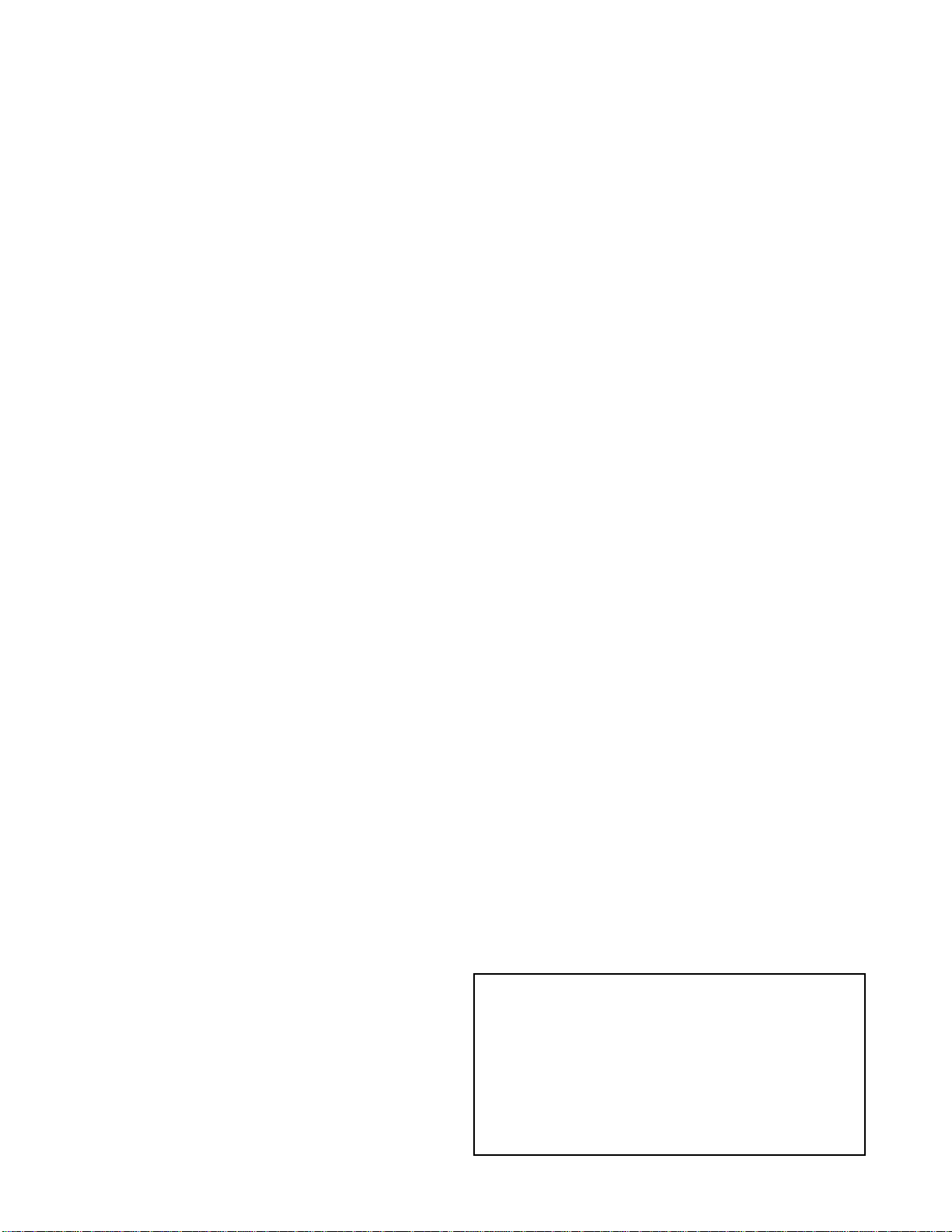

Table 3—

Installation Options for Intrusive and Non-Intrusive Calibration

Control Device Non-Intrusive Intrusive or

& 1 person 2 person

Infiniti Transmitter X

PointWatch Junction Box X

w/ tall cover/window

PointWatch Junction Box X

w/ short cover/no window

Eagle 2000 DCU X

Eagle 2000 Communication Module X