3.1 95-8632

CERTIFICATION—

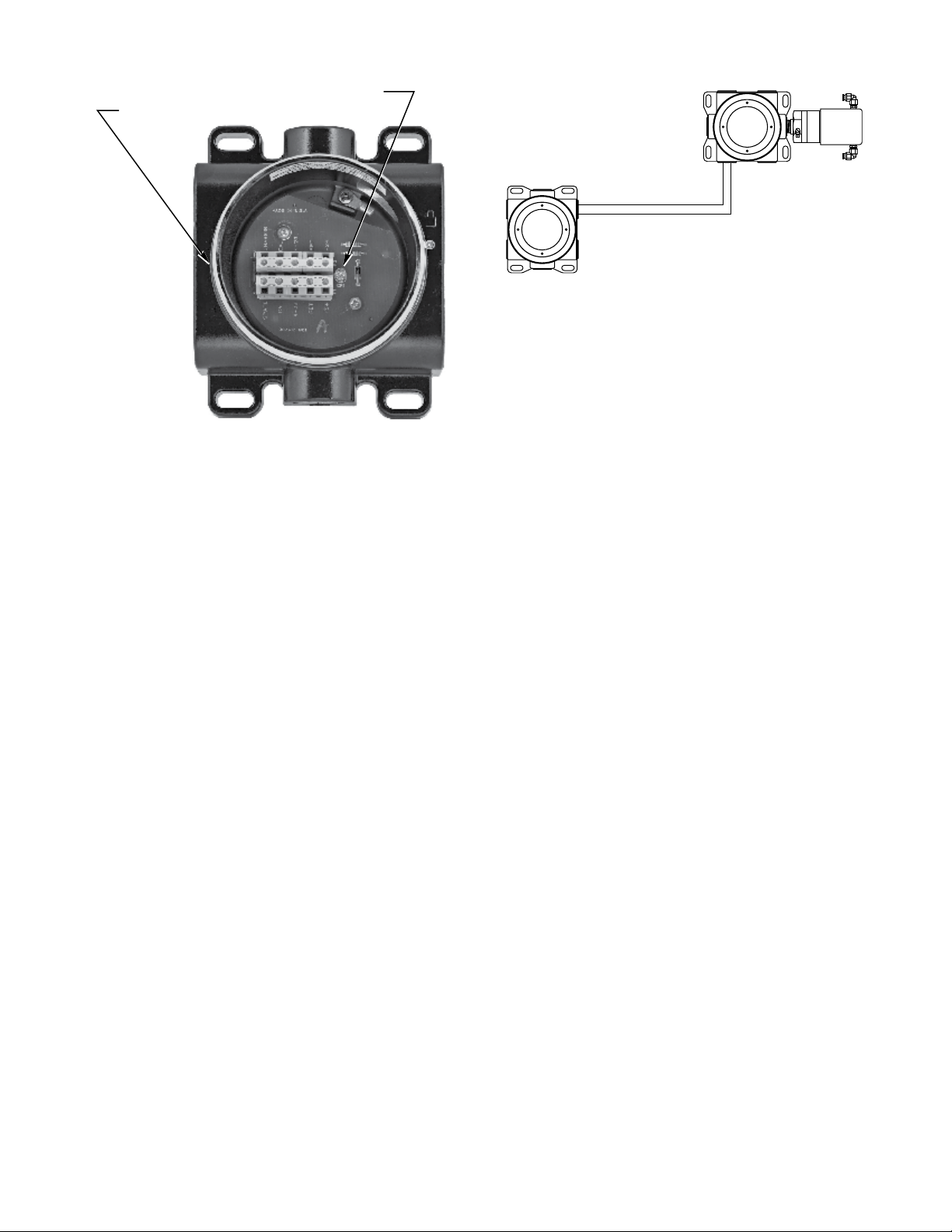

For complete approval details for the PIRVOLHV Process

Gas Monitor and the PointWatch Termination Box Model

PIRTB, refer to the appropriate Appendix:

Appendix A - CSA

Appendix B - ATEX/CE

Appendix C - IECEx

WARNING

Always ensure that the detector/termination

box hazardous (classified) location ratings are

applicable for the intended use.

DESCRIPTION

DETECTION METHOD

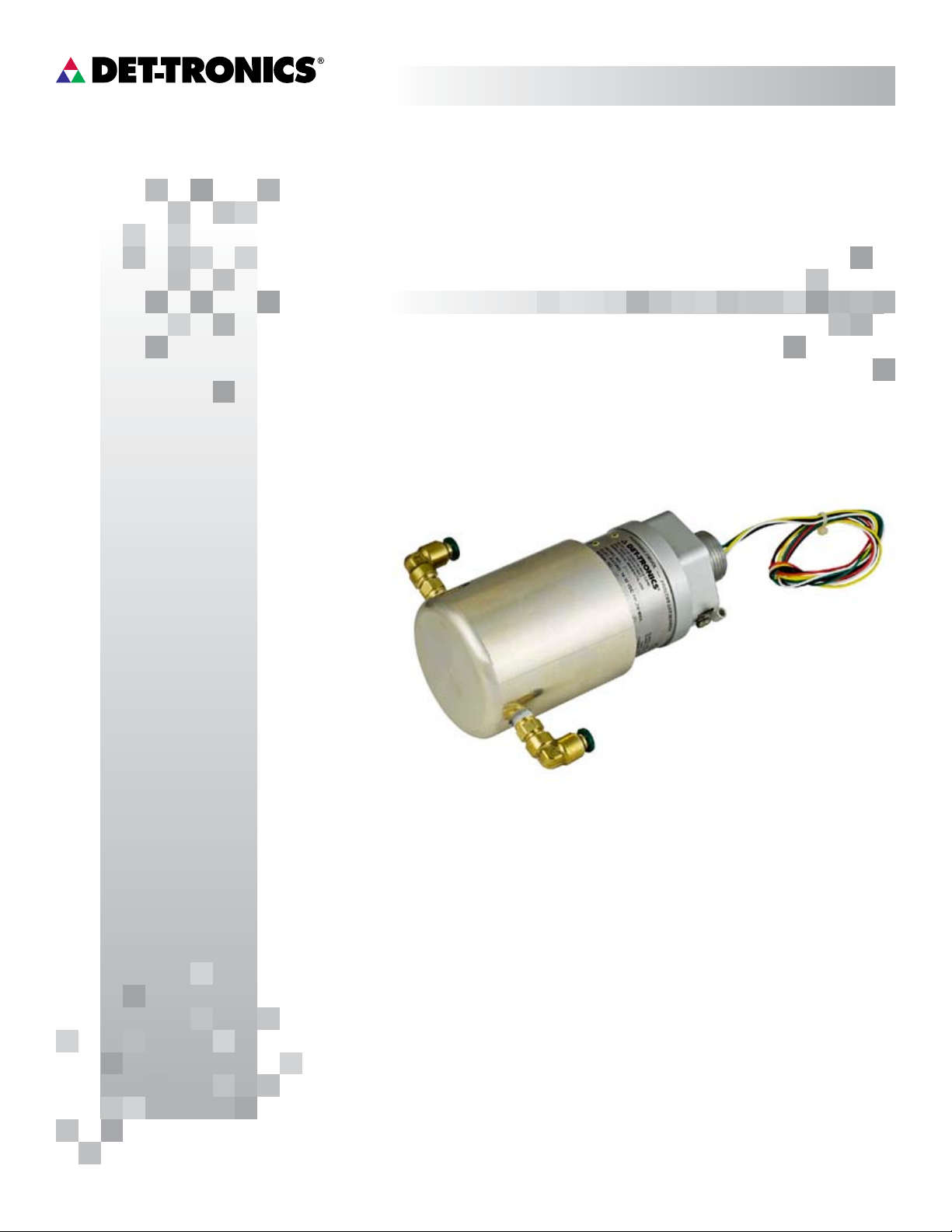

PIRVOLHV operates on the infrared absorption

principle. A beam of modulated light is projected

from an internal infrared source to a reflector, which

sends it back to a pair of infrared sensors. One of the

sensors is designated reference and the other active,

with different optical filters in front of the two sensors to

make them selective to different infrared wavelengths.

The reference wavelength is unaffected by combustible

gases, while the active wavelength is absorbed by

combustible gases. The ratio of the active to the

reference wavelength is computed within the PIRVOLHV

to determine the concentration of gas present. This

value is then converted into a 4 to 20 mA current output

for connection to external display and control systems.

CURRENT LOOP OUTPUT

During normal operation, the PIRVOLHV has a 4 to 20 mA

current output that is proportional to gas concentrations

from 0 to 100% by volume propane. A current output less

than 4 mA indicates a fault condition (see Table 1).

SIGNAL DISPLAY DEVICE

If a local or remote digital display for indication of detected

gas concentration is required, it is recommended to utilize

a scalable display device with a clearly marked unit of

measurement in % by volume. Under no circumstances

should a % LFL unit of measure display module be used

to display the PIRVOLHV signal output.

OPERATING MODES

Warmup

When power is applied to the PIRVOLHV, it enters a

Warmup mode (for approximately one minute) in which

it performs diagnostic checks and allows the sensors

to stabilize before beginning normal operation. The

current output during this period is 0 mA. At the end of

the warmup period with no faults present, the PIRVOLHV

automatically enters the Normal operating mode. If a

fault is present after the warmup, the current output will

indicate a fault.

Normal

In the normal operating mode, the 4 to 20 mA signal

level corresponds to the detected gas concentration.

The PIRVOLHV continuously checks for system faults or

initiation of calibration, and automatically changes to the

appropriate mode.

Fault

Faults detected during warmup, normal operation, or

calibration are indicated by the current loop output as

shown in Table 1.

Calibration

The PIRVOLHV is calibrated at the factory for detection

of propane. No field calibration is required under normal

circumstances.

In the event the PIRVOLHV optics are fouled and complete

optics disassembly for cleaning is required, device re-

zeroing may be required after re-assembly. Refer to the

“Calibration” section for details.

NOTE

A momentary connection of the calibration lead

wire to DC negative (common) of the power

supply initiates the zero and span calibration

sequence. When wiring the PIRVOLHV, use care

to isolate it from accidental contact with the PIRTB

and/or other conductors.