Deublin 1112-240-001 User manual

DEUBLIN Company

2050 Norman Drive

Waukegan, Illinois 60085-6747 U.S.A.

+1 (847) 689-8600 +1 (847) 689-8690 [email protected]om

http://www.deublin.com

ROTATING UNIONS

Instruction Manual

1112-240-001

Two-Channel Bore-Mounted Rotating Union

for MQL Service and Dry Running

Instruction Manual

for DEUBLIN Bore-Mounted

Two-Channel Rotating Unions

Model/Series: 1112-240-001

Number:

Release: 275 V

Page 2 of 11

DEUBLIN Company • 2050 Norman Drive • Waukegan IL 60085-6747 USA • +1-847-689-8600 • +1-847-689-8690 • customerservice@deublin.com

Please read this instruction manual carefully and thoroughly before installing the DEUBLIN Rotating Union.

This instruction manual contains important information about proper installation, operation and maintenance.

These instructions are copyrighted by DEUBLIN and may not be reproduced by any means. These

instructions are subject to modification. Please consult DEUBLIN directly should you have any questions.

Table of Contents

Features................................................................................................................................................................2

Dimensions ..........................................................................................................................................................3

Operating Parameters...........................................................................................................................................3

Speed vs. Pressure .........................................................................................................................................4

Media Filtration ...................................................................................................................................................5

Interface with Machine ........................................................................................................................................5

Installation Procedure ..........................................................................................................................................6

Installation Diagram ......................................................................................................................................8

Preventing Premature Seal Failure.......................................................................................................................9

Troubleshooting ...................................................................................................................................................9

Maintenance.......................................................................................................................................................11

Warranty ............................................................................................................................................................11

Important Notice ................................................................................................................................................11

Features

Two channels for MQL mixed in the spindle.

Inner channel with patented Pop-Off™ seal technology allows unlimited dry running without lubricating

media such as oil or water-based coolant.

Outer channel with patented AutoSense™ seal technology allows unlimited dry running and contains

pressurized dry air with no seal wear or heat generation.

Accepts up to 15 mm of axial drawbar movement.

Bore-mounted design for easy installation and compatibility with most European-made motor spindles.

Labyrinth system and large drains to protect ball bearings.

Balanced mechanical seals made from silicon carbide for long life even with contaminated or poor quality

media.

Anodized aluminum and stainless steel parts resist corrosion.

Instruction Manual

for DEUBLIN Bore-Mounted

Two-Channel Rotating Unions

Model/Series: 1112-240-001

Number:

Release: 275 V

Page 3 of 11

DEUBLIN Company • 2050 Norman Drive • Waukegan IL 60085-6747 USA • +1-847-689-8600 • +1-847-689-8690 • customerservice@deublin.com

Dimensions

Operating Parameters

The inner channel of 1112-240-001 uses DEUBLIN patented Pop-Off™ seal technology. This kind of seal

closes only when pressure is applied. When pressure is removed, the seal faces separate by a very small

distance. This eliminates friction and seal wear during operation without coolant, and therefore allows

unlimited “dry running” at high speeds. Pop-Off™ designs should be considered when machining will occur

with and without through-spindle coolant (TSC). Because the seals separate during tool changes, when

coolant pressure is off, residual coolant in the supply hose and spindle can drain past the seal faces. Therefore,

a Pop-Off™ union requires a downward-pointing drain line to direct such residual coolant into the sump.

Pop-Off™ seals are not intended for rotation with pressurized dry air.

The outer channel of 1112-240-001 uses DEUBLIN patented AutoSense™ seal technology. Like pop-off

designs, AutoSense seals close when coolant pressure is applied to contain the coolant fluid, and “pop” apart

in the absence of coolant pressure to allow unlimited dry running. In addition, AutoSense seals handle

pressurized dry air by creating a microscopic gap between the seal faces. AutoSense unions handle coolant,

MQL, and dry air, by sensing the kind of media and automatically changing seal operation in response. As

with pop-off seals, a drain line is required.

Instruction Manual

for DEUBLIN Bore-Mounted

Two-Channel Rotating Unions

Model/Series: 1112-240-001

Number:

Release: 275 V

Page 4 of 11

DEUBLIN Company • 2050 Norman Drive • Waukegan IL 60085-6747 USA • +1-847-689-8600 • +1-847-689-8690 • customerservice@deublin.com

Inner channel Outer channel

Maximum speed 30,000 min-1

Seal technology Pop-Off™ AutoSense™

Media Coolant or light oil Air

Maximum media pressure

140 bar up to 6,100 min-1

10 bar up to 30,000 min-1

→see Chart A

10 bar (145 psi) up to 30,000 min-1

Maximum recommended flow 6 L/min (1.6 GPM) 18 NL/sec (38.1 SCFM)

Minimum pressure to close seals 1.5 bar 2 bar

Minimum flow to close seals 1.5 L/min (0.4 GPM)

Axial force on drawbar

(as a function of media pressure) 5.02 N/bar

Maximum operating temperature 71° C (160° F)

Minimum operating temperature 5° C (41° F)

Chart A – Speed vs. Pressure

0

20

40

60

80

100

120

140

0 5,000 10,000 15,000 20,000 25,000 30,000

Speed (min

-1

)

Pressure (bar)

Inner (Coolant)

Outer (Air)

When used within the combinations of speed and coolant pressure shown in Chart A, 1112-240-001 is

designed to operate for many thousands of hours. Please consult Deublin if your application requires

simultaneous speed and pressure beyond these limits.

Media Filtration

Deublin unions are designed to handle the various coolant contaminants found in most manufacturing

facilities. To ensure long union life and maximum productivity, however, coolant filtration should conform to

ISO 4406:1999 Code 17/15/12, SAE 749 Class 3, or NAS 1638 Class 8, with a maximum particle size of 60

microns.

Instruction Manual

for DEUBLIN Bore-Mounted

Two-Channel Rotating Unions

Model/Series: 1112-240-001

Number:

Release: 275 V

Page 5 of 11

DEUBLIN Company • 2050 Norman Drive • Waukegan IL 60085-6747 USA • +1-847-689-8600 • +1-847-689-8690 • customerservice@deublin.com

ISO 4406:1999

Code 17/15/12 NAS 1638

Class 9 SAE 749-1963

Class 5

Particle

size (μm)

Particles

per 100ml

Particle

size (μm)

Particles

per 100ml

Particle

size (μm)

Particles

per 100ml

4 – 6 ≤130,000 5 – 15 ≤64,000 5 – 10 ≤87,000

6 – 14 ≤32,000 15 – 25 ≤11,400 10 – 25 ≤21,400

14 – 60 ≤4,000 25 – 50 ≤2,025 25 – 50 ≤3,130

Unacceptable

Acceptable

50 – 60 ≤360 50 – 60 ≤430 (ISO 21/19/17 at 100x) (ISO 16/14/11 at 100x)

Only pure water should be used to make up for coolant evaporation. Calcium and magnesium

salts in most tap water shorten coolant life, by depleting the chemicals in the coolant, by

breaking down the water-oil emulsion, and by encouraging bacterial growth. These salts also

can cause residue to build up inside the rotating union, leading to premature failure. Proper

coolant maintenance also prolongs tool life and improves the surface finish of your parts.

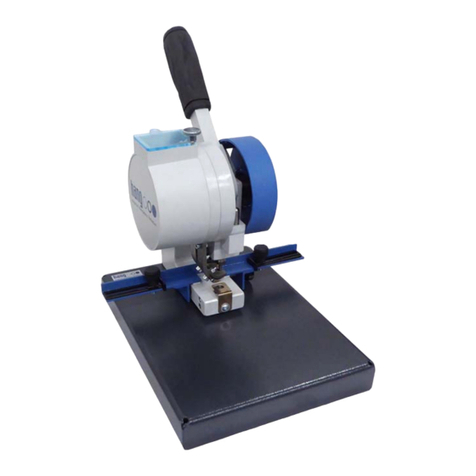

Interface with Machine

1112-240-001 is designed for installation in a 48 mm counterbore with a 7.4 mm octagonal drawbar extension.

This configuration sometimes is found most often on European spindles and machine tools. Detailed

interface dimensions are shown in the drawing below.

To avoid damage to shaft seals inside the rotating union,

no sharp edges are permitted on the male octagonal section of the drawbar extension.

Instruction Manual

for DEUBLIN Bore-Mounted

Two-Channel Rotating Unions

Model/Series: 1112-240-001

Number:

Release: 275 V

Page 6 of 11

DEUBLIN Company • 2050 Norman Drive • Waukegan IL 60085-6747 USA • +1-847-689-8600 • +1-847-689-8690 • customerservice@deublin.com

Installation Procedure

1112-240-001 is suitable for horizontal, vertical, or yoked spindle (B-axis) applications. In vertical

applications, the rotating union should be installed with the rotor pointed down. Although the union will

operate with rotor pointed up, in this orientation the union is more easily affected by media contamination and

incorrect drain hose position. Therefore, this orientation is not recommended.

Horizontal spindle Vertical spindle Yoked (B-axis) spindle Vertical spindle pointed up

A DEUBLIN rotating union is a highly engineering piece of equipment, containing precision bearings and

many small parts. Dropping the union, using it as a hammer, or applying excessive external forces can cause

internal damage and shorten the union’s operating life.

To install the DEUBLIN 1112-240-001 rotating union, follow these steps:

1. Measure runout near the end of the drawbar extension, using hand rotation of the spindle and a dial

indicator. If runout exceeds 0.050 mm, then adjust the drawbar extension to minimize runout.

2. Make sure that shaft seals in union are clean. GENTLY remove any visible contaminants, then

lubricate both shaft seals in the union rotor with O-ring grease.

3. Make sure drawbar extension is clean. Lubricate sliding diameter of the drawbar extension with O-

ring grease.

4. Make sure end of lance is free of debris and contaminants. Lubricate the lance O-ring with O-ring

grease.

5a. Remove the 1/8” PTF flush plug that is pre-installed into a flat surface of the union. Rotate the

union rotor until one of the two M3 set screws is visible. Loosen set screw completely, then

engage the threads and turn clockwise NO MORE than two full turns.

If set screw is turned more than 2 full turns after thread engagement, the lance O-ring may

be damaged during lance insertion. A damaged lance O-ring can allow coolant to leak into

the air channel.

5b. Rotate the union rotor 180° until the other M3 set screw is visible. Loosen set screw completely,

then engage the threads and turn clockwise no more than 2 full turns.

6. Insert lance into union rotor approximately 88 mm (3.5”), until it can slide no further. Be sure to

keep the lance centered in the union rotor during insertion.

7. GENTLY tighten one of the M3 set screws approximately one full turn, until it just touches the

lance. Do NOT tighten set screw completely. Rotate the union rotor 180° and repeat this for the

other M3 set screw.

Instruction Manual

for DEUBLIN Bore-Mounted

Two-Channel Rotating Unions

Model/Series: 1112-240-001

Number:

Release: 275 V

Page 7 of 11

DEUBLIN Company • 2050 Norman Drive • Waukegan IL 60085-6747 USA • +1-847-689-8600 • +1-847-689-8690 • customerservice@deublin.com

8. Alternating between the two M3 set screws, tighten each no more than 1/4 turn at a time, until the

lance is held securely. Re-install the 1/8” PTF flush plug into the union housing.

9. Slide lance gently into drawbar extension, then slide union onto drawbar extension and into 48 mm

counterbore on spindle or unclamp unit. Before mounting union, be sure that male octagon on

drawbar extension and female octagon in union rotor are aligned. Union should slide easily until

circumferential mounting slot is nearly even with top of counterbore.

If octagons are not aligned, the union will slide in only about halfway. If the union does not

slide easily, remove it and try again. DO NOT force the union by pushing harder, by hitting

it, or by other methods. Such efforts only will damage the union or drawbar extension.

10. Rotate the union for correct drainage. In a yoked spindle installation, one of the two drain

connections must point to whichever side of the spindle is lowest during tool change. In a

horizontal installation, one of the two drain connections MUST point straight down (to 6 o’clock).

In a vertical installation, orientation of the drain connections is not critical.

Fix union in place with (2) mounting tabs and (2) M6 socket head cap screws. Tighten both screws

to a minimum of 13 Nm (9.6 ft-lbs).

11. In a yoked spindle installation, attach a drain hose to each of the two drain connections on the

rotating union. In a horizontal installation, attach a drain hose to the drain connection at 6 o’clock

and plug the drain connection at 12 o’clock. In a vertical installation, attach a drain hose to one or

both drain connections, and plug any unused drain connection.

Each drain hose must slope downward continuously from the union. For longest life, it is

recommended to have always at least 15° downward slope.

Each drain hose must have NO orifices, plugs or flow restrictions of any kind.

Each drain hose should have the maximum possible inside diameter (I.D.). A drain hose

I.D. of AT LEAST 6 mm is recommended. Otherwise, over time it is possible that small

chips in the coolant can accumulate and block the drain. Do NOT use a drain hose made

from plastic air tubing, because the 3 – 4 mm I.D. typical of such tubing is too small for

proper drainage.

YES!

At all spindle orientations, at least one

drain hose is at 6 o’clock and slopes

down continuously.

NO!

When the spindle pivots to the other

side, both drain hoses will slope up.

NO!

Drain connection is not at 6 o’clock.

At some spindle orientations, both

drain hoses slope up.

Instruction Manual

for DEUBLIN Bore-Mounted

Two-Channel Rotating Unions

Model/Series: 1112-240-001

Number:

Release: 275 V

Page 8 of 11

DEUBLIN Company • 2050 Norman Drive • Waukegan IL 60085-6747 USA • +1-847-689-8600 • +1-847-689-8690 • customerservice@deublin.com

12. Attach the coolant supply hose to the G1/8” media connection. Attach the air supply hose to the

G1/4" media connection.

The media supply must be flexible hose. Do not connect rigid pipe to the rotating union.

Physical installation now is complete. To confirm correct installation and operation of the DEUBLIN 1112-

240-001 rotating union, follow these steps before replacing any cover panels:

13. Start spindle rotation at 1000 min-1. Listen for any unusual noises coming from the rotating union,

such as buzzing, rattling, or squealing. Increase spindle speed in steps, according to the spindle

manufacturer’s recommendation, until the maximum operating speed is achieved. If unusual

noises are heard, consult the Troubleshooting section below.

14. Start spindle rotation at 1000 min-1 with no tool in the tool holder. While the spindle is rotating,

turn on ONLY the coolant flow (inner channel) for 10-15 seconds, then turn off the coolant flow.

Repeat this three times. If everything is functioning correctly, one will observe:

A strong stream of coolant coming from the spindle nose while coolant flow is on.

At most a few milliliters of coolant dripping from the drains when coolant flow is turned on,

and again when coolant flow is turned off. No coolant should issue from the drains at any

other time.

If drain leakage or the stream of coolant does not meet these guidelines,, consult the

Troubleshooting section below.

Instruction Manual

for DEUBLIN Bore-Mounted

Two-Channel Rotating Unions

Model/Series: 1112-240-001

Number:

Release: 275 V

Page 9 of 11

DEUBLIN Company • 2050 Norman Drive • Waukegan IL 60085-6747 USA • +1-847-689-8600 • +1-847-689-8690 • customerservice@deublin.com

Preventing Premature Seal Failure

During tool change, most machining centers supply air flow to keep the taper of the drawbar mechanism clean.

When this air flow is supplied through the union and the new tool is “dead-ended” (i.e., not designed for

through-spindle coolant), air pressure may become trapped between the new tool and the check valve in the

air line, thereby keeping the Pop-Off™ seal faces closed. Subsequent spindle rotation without coolant will

cause overheating and premature failure of the seals. To avoid this, trapped air must be vented. Consult

Deublin for assistance on how best to do this in your application.

Troubleshooting

Problem Solution

Union temperature seems too high

immediately after installation.

Operating temperature may be higher than normal immediately after

installing the union, especially if the union is used immediately at

high RPMs without media. Generally, it is a good idea to “run in” a

new union in order to evenly distribute grease in the bearings. The

union will operate correctly without being run in, but it will run hot

for a little while.

Union temperature persistently

exceeds 50°C (122°F) after run-in.

Union makes a loud squeaking or

chirping noise at higher RPMs.

The seals may be running dry and probably are damaged. This can

happen, for example, if air for cleaning the tool taper blows through

the spindle and trapped pressure is not released after the tool

change. The union should be replaced immediately.

Union makes a loud buzzing or

rattling noise at higher RPMs.

The bearings may be damaged. This can happen when the drain

hose is blocked or does not have a continuous downward slope.

The union should be replaced immediately.

A few milliliters of coolant flow

from the drain hose at the beginning

of each tool change.

This is normal. Pop-Off™ seals close when coolant pressure is

applied and open when pressure is removed. After using through-

spindle coolant, media remaining in the spindle and supply hose

will drain out from the union. This feature eliminates friction and

seal wear during operation without coolant, and allows unlimited

“dry running” at any speed.

Media pressure and flow are insufficient to close the seals. Media

pressure at the union must be at least 1.5 bar to close the seals, with

an initial flow of at least 1.5 L/min. Measure media pressure at the

coolant supply connection and increase system pressure as

necessary.

Coolant flows from the drain hose

for several seconds, or more, after

coolant pressure is turned on, then

stops eventually. Contaminants in the media are jamming the seals and preventing

proper closing. Check the filtration system and replace the filter as

necessary.

The seals have been damaged or have reached the end of their

useful life. The union should be replaced immediately.

Coolant flows continuously from

the drain hose during operation with

through-spindle coolant.

Media pressure and flow are insufficient to close the seals. Media

pressure at the union must be at least 1.5 bar to close the seals, with

a flow of at least 1.5 L/min.

Instruction Manual

for DEUBLIN Bore-Mounted

Two-Channel Rotating Unions

Model/Series: 1112-240-001

Number:

Release: 275 V

Page 10 of 11

DEUBLIN Company • 2050 Norman Drive • Waukegan IL 60085-6747 USA • +1-847-689-8600 • +1-847-689-8690 • customerservice@deublin.com

Problem Solution

The lance is blocked, due to either a malfunctioning internal check

valve, debris trapped in the flow path, or a damaged nozzle.

Replace the lance.

Coolant output at the spindle nose is

very low, even with no tool installed

and the air channel turned off. The lance is not fully installed in the union or the lance O-ring is

damaged, thereby allowing coolant to escape into the air channel.

Remove and reinstall the union and lance.

Instruction Manual

for DEUBLIN Bore-Mounted

Two-Channel Rotating Unions

Model/Series: 1112-240-001

Number:

Release: 275 V

Page 11 of 11

DEUBLIN Company • 2050 Norman Drive • Waukegan IL 60085-6747 USA • +1-847-689-8600 • +1-847-689-8690 • customerservice@deublin.com

Maintenance

The DEUBLIN 1112-240-001 requires no maintenance after installation. Bearings inside the rotating union

are lubricated for life with high-speed, high-temperature spindle grease. Sealing elements are wearing

components

1112-240-001 is not field-repairable. Any attempt to disassemble the rotating union voids the warranty.

Unions that do not provide sufficiently long life should be returned to DEUBLIN for examination and

analysis.

Warranty

For a period of one year from the date of shipment, DEUBLIN warrants that the products sold by it are free

from defects in materials and workmanship. The liability of DEUBLIN is expressly limited to the

replacement or rebuilding of any article, or part thereof, proven defective, when returned to the DEUBLIN

Company, transportation prepaid, within a reasonable time after termination of the 365-day warranty period.

This warranty is void if the product is dismantled, modified, altered, or damaged from improper maintenance,

side loading, excessive temperature, abrasive or chemical action, or other abuse. No representative, agent, or

employee of DEUBLIN has any authority to modify the terms of this warranty. DEUBLIN will not be

responsible for any consequential or resulting damage which may be claimed to have occurred through the

sale or use of such products or parts, thereof, which might be defective.

There are no warranties which extend beyond the description contained under this heading, express or implied,

including warranties of fitness for a particular purpose.

Important Notice

The DEUBLIN rotating union is a precision-made piece of equipment and should be handled accordingly. It

is a rotating sealing device – not just a plumbing union. Improper use or installation can result in premature

leakage or failure. While Deublin unions are of the highest quality and prevision, they are “wear and tear”

items. It is important that they are periodically inspected and, as the seals wear out, replaced or repaired to

avoid the consequences of leakage.

DEUBLIN unions never should be used for applications other than as specified in the catalog. DEUBLIN

unions should not be used to seal hydrocarbons or other flammable media as leakage may result in explosions

or fires. The use of our product on hazardous or corrosive media is strictly forbidden. For applications other

than as stated in the catalog, contact the DEUBLIN Engineering Department for recommendations.

These instructions are provided as general guidelines. They do not contain exhaustive information about the

installation, use or maintenance of unions. Purchasers and users of DEUBLIN unions should be certain that

they have reviewed the appropriate DEUBLIN catalog and have sufficient experience and training in the use

of unions before attempting installation or use of DEUBLIN products. The principal responsibility for the

safe and effective use of DEUBLIN unions rests with the user and its employees. Deublin will provide, upon

request, whatever assistance it can to advise users about the use of its products and about any difficulties or

problems which are brought to its attention.

Table of contents

Popular Industrial Equipment manuals by other brands

Siemens

Siemens SIVACON 8PS BD2 Series installation instructions

Opus

Opus MB 300 el-office user guide

Siemens

Siemens BD2-AK 02 M2 Series installation instructions

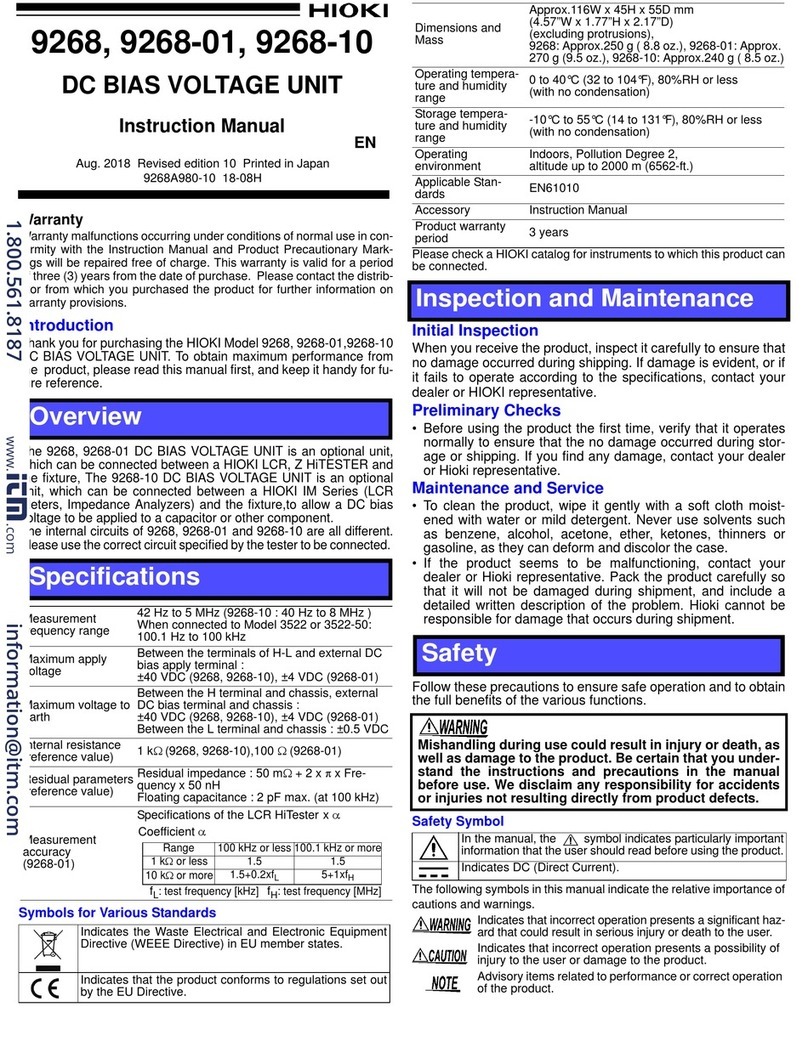

Hioki

Hioki 9268 instruction manual

Freeman

Freeman 540 RPM Driveline Operator and parts manual

Trane

Trane IntelliPak S HL Series installation guide