Deublin 7100 Series User manual

7100

040-551

2021-03

E

Operating Manual Model/Series:

Number: GB

Version:

Rev. Page 1 of 14 ©DEUBLIN

Rotating Unions

Series

7100

OPERATING MANUAL

7100

040-551

2021-03

E

Operating Manual Model/Series:

Number: GB

Version:

Rev. Page 2 of 14 ©DEUBLIN

Content

1 For your Safety _________________________________________________________3

1.1 Intended Use ___________________________________________________________ 3

1.1.1 Example of Application ____________________________________________________ 4

1.2 Misuse ________________________________________________________________ 4

1.3 Safety Instructions _______________________________________________________ 5

1.3.1 Hazards due to hot surfaces________________________________________________ 5

1.3.2 Hazards by improper hoses ________________________________________________ 5

1.3.3 Hazards due to the media__________________________________________________ 5

1.3.4 Hazards by faulty installation _______________________________________________ 5

1.4 Structure of Pictograms ___________________________________________________ 6

2 Information as to this Manual_______________________________________________6

3 Information on the Name Plate _____________________________________________6

4 Information on the Design _________________________________________________7

4.1 Filtering of the Medium ____________________________________________________ 7

4.2 Connecting Options of the Rotating Union at the Machine Shaft ____________________ 7

4.3 Fit, Shape and Positional Tolerances _________________________________________ 7

4.4 Prepare Installation of the Rotating Union _____________________________________ 7

4.5 Options of Hose Installation ________________________________________________ 8

4.5.1 Connection of hose to the rotating union ______________________________________ 8

4.5.2 Connection of a drain line __________________________________________________ 9

5 Installation _____________________________________________________________9

6 Information on the Operation _______________________________________________9

7 Storage ______________________________________________________________10

8 Maintenance __________________________________________________________10

8.1 Maintenance Intervals____________________________________________________ 10

8.2 Daily Inspection ________________________________________________________ 10

9 Trouble Shooting _______________________________________________________ 11

9.1 Potential Causes for Errors and their Elimination ________________________________11

9.2 Pack Rotating Union for Transport __________________________________________ 12

10 Disposal ______________________________________________________________ 12

10.1 Dispose of Packaging ____________________________________________________ 12

10.2 Dispose of Rotating Union ________________________________________________ 12

11 Spare Parts ___________________________________________________________ 13

7100

040-551

2021-03

E

Operating Manual Model/Series:

Number: GB

Version:

Rev. Page 3 of 14 ©DEUBLIN

1 For your Safety

This chapter provides information on the safe handling of Deublin rotating unions.

QFor your own safety and the safety of other people read this operating manual carefully and

completely prior to working on or with Deublin rotating unions.

QThis operating manual exclusively describes the rotating unions of the manufacturer Deublin. In

the further description/explanation the name “Deublin” is left out for a better readability.

QAlways use the latest version of the operating manual, available under www.deublin.eu.

QThis operating manual is a material part of the specified rotating unions. The operator is respon-

sible for the personnel to take note of this manual.

QThe operator of the rotating unions shall not make any modifications or attachments to and ret-

rofitting of the rotating union without the manufacturer’s consent.

QPlease follow the additional instruction “Installation” for a secure and correct installation of the

rotating union. The installation instruction is included with the delivered union.

1.1 Intended Use

The rotating unions of series 7100 supply the feeding of hydraulic oil. The respective medium has to

comply with the following specification: Mineral oils according to DIN 51524-2 (HL; HLP) | ISO 6743-

4 HM, viscosity classes 10, 22, 32, 46, 68 and 100 cSt.

The admissible performance of the rotating unions depends upon the diameter of the pipe through

which the consuming equipment is provided with hydraulic oil.

Max. pressure Min. pressure Max. speed Temperature range

300 bar

(2,900 PSI) 3 bar (40 PSI) 8,000 min-1 statically: -40 up to 90 °C

dynamically: -10 up to 70 °C

Details on the operating range of the rotating unions are provided in the catalogue and/or the model-

specific installation drawing.

The rotating unions referred to are designed for non-potentially explosive environments and non-com-

bustible media.

The rotating unions of the serie 7100 can be used as one-way or multi-passage version depending on

the type of connection.

7100

040-551

2021-03

E

Operating Manual Model/Series:

Number: GB

Version:

Rev. Page 4 of 14 ©DEUBLIN

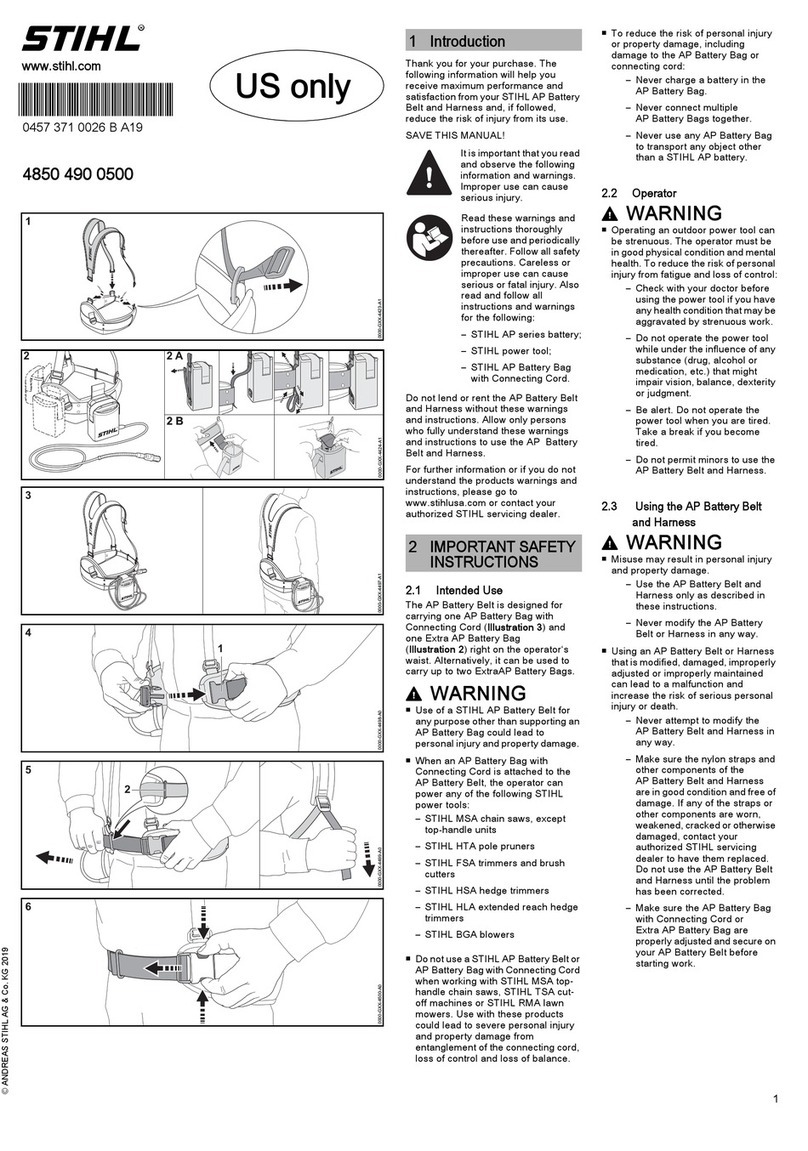

1.1.1 Example of Application

In this example, the principle of the rotating union is described on the basis of a two-way version with

flanged rotor. Other models of series 7100 operate in the same way.

Fig. 1: Schematic diagram two-way version

A rotating union is installed at one end of the shaft, e.g. a two-way version as in this example. The latter

is fitted with two pipes (A) through which the consuming equipment is supplied with hydraulic oil. The

medium leaking from the rotating union is carried off through a leakage line (B) in a controlled way.

1.2 Misuse

This chapter provides information on known misuse of rotating unions of the 7100 series.

The rotating unions are not suitable for the areas and applications described herein. Use in such areas

or for such applications constitutes a misuse endangering people and machines and is therefore pro-

hibited.

Prohibition for the following areas:

QPotentially explosive areas

The rotating unions of the 7100 series shall not be used in potentially explosive areas, as they

are not approved for the requirements in potentially explosive areas. Operation in such areas

may cause explosions.

QFood

Food, cleaning and disinfectant residues cannot be removed from the rotating unions. People

may suffer poisoning.

Prohibition for the following applications:

QConveying of combustible media or hydrocarbons

Combustible media or hydrocarbons may ignite or cause explosions.

QConnection to a piping system with excessive pressure

If excessive pressure is applied to the rotating unions, supply pipes can come off and cause

personal injury or property damage.

QOperation without lubrication

Dry operation (without medium) of the rotating union causes damage to the axial face seals.

QConnection to fixed pipes

If connection is via fixed pipes, the rotating unions may leak and the ball bearings may get dam-

aged.

QConveying of media which are too hot

If the media exceed the maximum admissible temperature for the rotating union, the static seals

(elastomeric seals) can be damaged which may result in leaky rotating unions and personal in-

jury or property damage.

This list is not comprehensive and will be updated with results from product observation.

B

A

7100

040-551

2021-03

E

Operating Manual Model/Series:

Number: GB

Version:

Rev. Page 5 of 14 ©DEUBLIN

1.3 Safety Instructions

This chapter provides information on the hazards through rotating unions.

1.3.1 Hazards due to hot surfaces

The rotating unions are heated by the temperature of the medium. Skin contact with heated rotating

unions can cause injuries.

QUse safety gloves and PPE (Personal Protective Equipment) protecting against heat when han-

dling the rotating union.

QAttach a clearly visible danger sign visibly on/next to the rotating union in order to warn of dan-

ger.

1.3.2 Hazards by improper hoses

For the connection of the rotating union to the machine, you have to choose appropriate hoses for the

respective medium, which meet, the specifications for the application.

If you use incorrect hoses, they may become porous or burst. This can cause personal injury and/or

property damage to components of the machine.

QIn case of the medium hydraulic oil, use hoses which are suitable for the maximum system pres-

sure of the machine and the maximum temperature of the media.

Hoses for leakage lines

If the cross-section of the hose used is smaller than that of the connection of the rotating union, an ex-

cessive pressure may develop in the hoses. Hoses may burst and cause serious injuries.

QUse hoses which fit the cross-section of the connections.

1.3.3 Hazards due to the media

When working on the rotating union, injuries can be caused by skin or eye contact with the media.

QObserve the safety instructions for the flow media. Observe the COSHH Safety Data Sheet for

the flow media.

1.3.4 Hazards by faulty installation

If the rotating unions are installed incorrectly, hoses and connections may become leaky. The medium

can escape. Depending on the medium, personal injury or property damage to the components of the

machine may occur.

QBefore installing the rotating union ensure that no feed pressure and no residual pressure is ap-

plied to the pipeline system of the machine.

QInstall the rotating union on the machine using hoses only, in order to avoid stress on the rotat-

ing union.

QInstall the hoses free from stress.

QInstall the hoses to the rotating union prior to mounting it at the machine shaft.

Table of contents