Preface

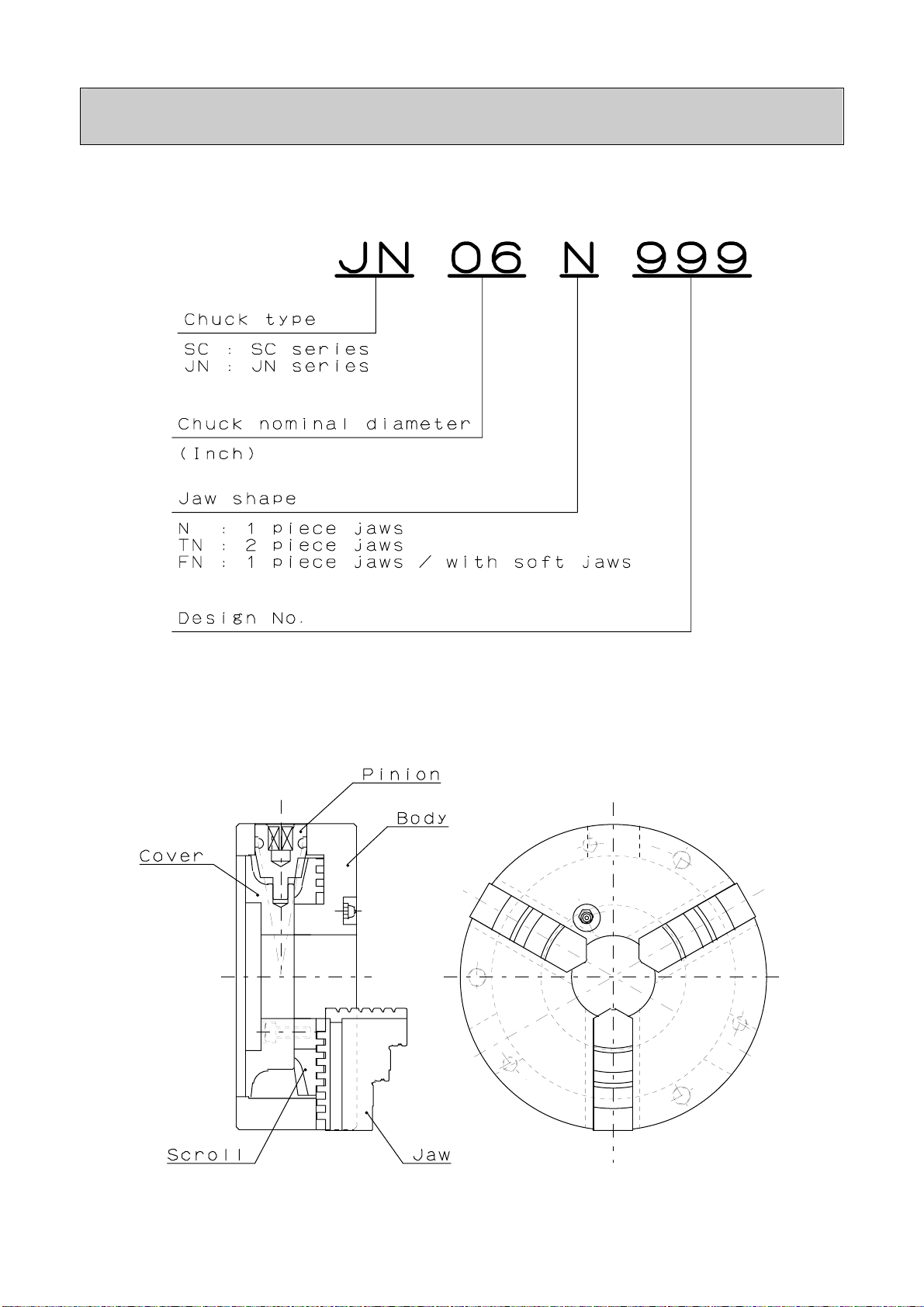

This manual provides detailed information about how to safely and correctly use the scroll

chuck (SC-N, SC-FN, JN-N, JN-TN type) for a rotary table.

Before starting to use this scroll chuck, read this manual carefully and always follow the

instructions and warnings in "Important Safety Precautions" and "Precautions for Use"

at beginning of the manual. Failure to follow these precautions could result in a serious

accident.

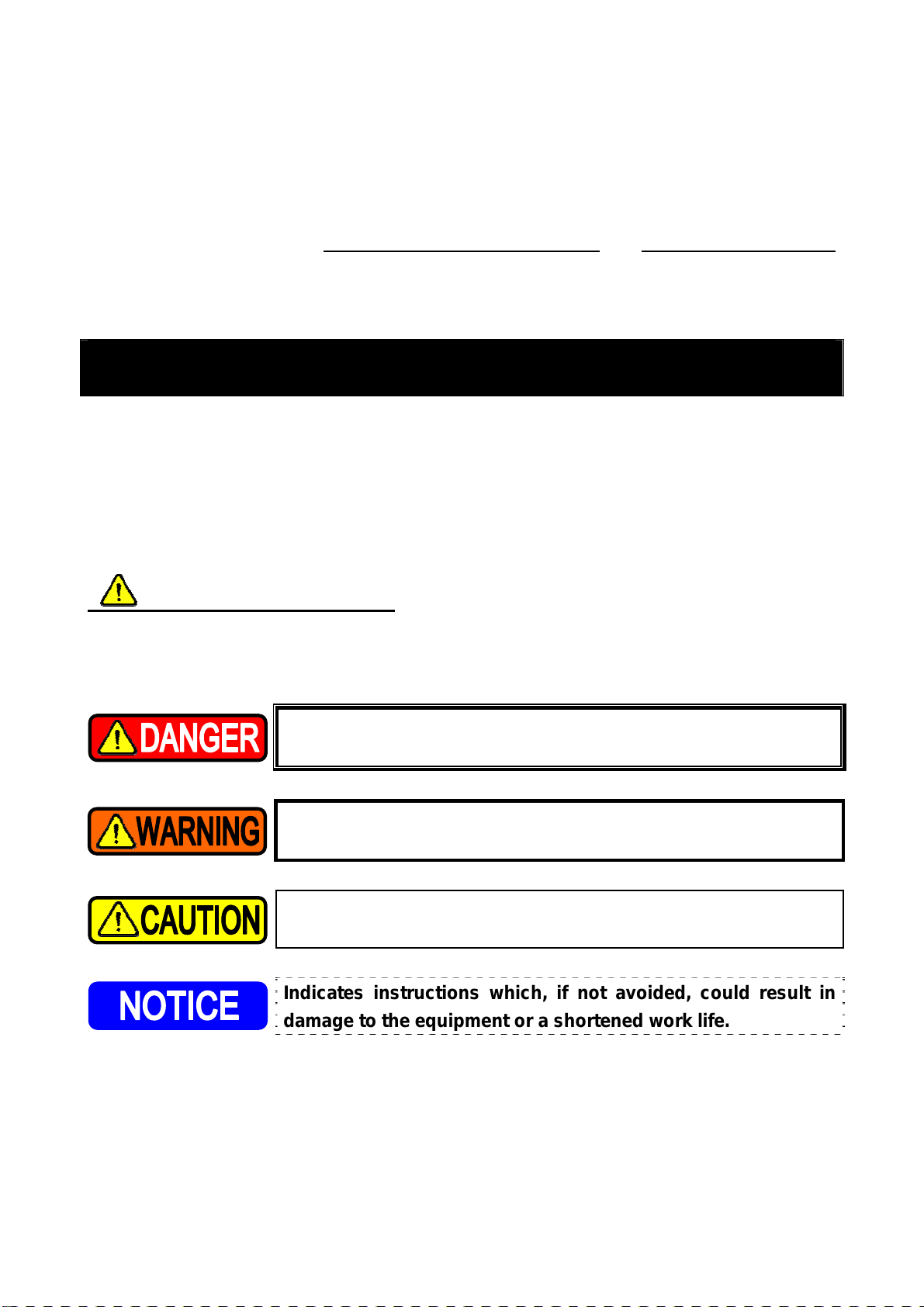

Terms and Symbols Used for Safety Messages

In this manual, precautions for handling that are considered especially important are

classified and displayed as shown below depending on the damage of risk including the

seriousness of the harm that could result. Please sufficiently understand the meanings of

these terms and follow the instructions for safe operation.

Safety Alert Symbol

The triangle is the safety alert symbol used to alert you to potential safety hazards that

could result in injury or death.

1

Indicates a hazardous situation which, if you not avoided, will

result in death or serious injury.

Indicates a hazardous situation which, if you not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if you not avoided,

could result in minor or moderate injury.

Indicates instructions which, if not avoided, could result in

damage to the equipment or a shortened work life.