DEUTSCHMANN AUTOMATION V3470E User manual

Short instruction

Starterkit ROTARNOCK

mit PROFIBUS

Artikel-Nr.: V3470E

Deutschmann Automation GmbH & Co. KG

Carl-Zeiss-Str. 8 D-65520 Bad Camberg +49-(0)6434 / 9433-0 +49-(0)6434 / 9433-40

eMail: info@deutschmann.de Internet: http://www.deutschmann.de

3.12.13 Starterkit ROTARNOCK with PROFIBUS V. 1.2 2

Deutschmann Automation GmbH & Co. KG

1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Generating an AWF-file automatically through WINLOC32 . . . . . . . . . . . . . . 5

3 Operation of the „data component generator“ . . . . . . . . . . . . . . . . . . . . 10

4 Operation of the „data component simulator“ . . . . . . . . . . . . . . . . . . . . 12

5 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1 Hardware connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.1 Returning a unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2 Internet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Deutschmann Automation GmbH & Co. KG

3 Starterkit ROTARNOCK with PROFIBUS V. 1.2 3.12.13

3.12.13 Starterkit ROTARNOCK with PROFIBUS V. 1.2 4

Deutschmann Automation GmbH & Co. KG Introduction

1 Introduction

In order to be able to follow this brief instruction step-by-step you have to install a few software

programs on your PC:

Programming software „WINLOC32“ on the Support CD under:

\Software\WINLOC\32Bit\SETUP_WINLOC_29*_D.exe

The menu item can be found under

„Programme\Deutschmann\LOCON_ROTARNOCK\WINLOC32\DEUTSCH“

Data component generator „DBGenerator“ on the Support CD under:

\Software\Tools\NEW DB Generator\SetupS7DBGenerator.exe

The menu item can be found under

„Programme\Deutschmann\LOCON_ROTARNOCK\tools\S7DBGenerator

Data component simulator „DBSimulator“ on the Support CD under:

\Software\Tools\DB Simulator\SetupDBSimulator.exe

The menu item can be found under

„Programme\Deutschmann\LOCON_ROTARNOCK\tools\Datenbausteinsimulator

After the software-installation the hardware is to be set up as described in the „appendix“.

*Version status

Generating an AWF-file automatically through WINLOC32 Deutschmann Automation GmbH & Co. KG

5Starterkit ROTARNOCK with PROFIBUS V. 1.2 3.12.13

2 Generating an AWF-file automatically through WINLOC32

Starting WINLOC32

(For the further operation of WINLOC32 the menue Help is available)

The communication interface between PC and RS232-interface from the ROTARNOCK has to

be defined under „Extras -> Options“.

3.12.13 Starterkit ROTARNOCK with PROFIBUS V. 1.2 6

Deutschmann Automation GmbH & Co. KG Generating an AWF-file automatically through WINLOC32

Supply the device with voltage. A window with the device‘s switch-on message opens.

Read-out the device now (File-> Upload) (configuration + cam data)

Generating an AWF-file automatically through WINLOC32 Deutschmann Automation GmbH & Co. KG

7Starterkit ROTARNOCK with PROFIBUS V. 1.2 3.12.13

The graphic window displays an empty data record after the upload.

Now the cam values can be entered...

(Depending on the device some sectors or functions may be different from the picture below)

3.12.13 Starterkit ROTARNOCK with PROFIBUS V. 1.2 8

Deutschmann Automation GmbH & Co. KG Generating an AWF-file automatically through WINLOC32

After entering the cams the data should be saved by: File -> Save as.

Now the values that have been entered into WINLOC32 have to be transferred to the software

„S7DBGenerator.exe“. This is made by:

(Note: To transfer the data with WINLOC32 the file „s7csv.csv“ is generated by WINLOC32 when

calling the function „S7 Tool“).

Generating an AWF-file automatically through WINLOC32 Deutschmann Automation GmbH & Co. KG

9Starterkit ROTARNOCK with PROFIBUS V. 1.2 3.12.13

The following window opens...

...searching for the drive path of the „S7DBGenerator.exe“ (please use the Browser symbol [...]

for it). The other input fields are not important for further proceeding. Confirm with OK afterwards.

The following window should open now.

3.12.13 Starterkit ROTARNOCK with PROFIBUS V. 1.2 10

Deutschmann Automation GmbH & Co. KG Operation of the „data component generator“

3 Operation of the „data component generator“

Start „S7DBGenerator“ (provided that it has not been started through WINLOC32 yet) and switch

the language to English by left click on the English flag.

(For further operation of the DBGenerator the Help menue is available)

The software „S7DBGenerator.exe“ received all cam values.

The line „angle-angle-cams“ should now contain the value „6“ (=number of angle-angle cams,

that have been set in WINLOC32).

If desired, the value can also either be increased or reduced. If a value is defined > 6, then the

first 6 cams are set in accordance with the WINLOC32-file and the following remain empty. If a

value < 6 is selected it results in a deprecuation of value!

Operation of the „data component generator“ Deutschmann Automation GmbH & Co. KG

11 Starterkit ROTARNOCK with PROFIBUS V. 1.2 3.12.13

In order to generate the data component click on „File“ and „Create DC“.

Allocate a file name...

... and save.

Angle-angle cams = 6

Angle-time cams = 0

Direction cams = 2

Idle times = 1

Logic = 0

3.12.13 Starterkit ROTARNOCK with PROFIBUS V. 1.2 12

Deutschmann Automation GmbH & Co. KG Operation of the „data component simulator“

4 Operation of the „data component simulator“

Start „DatenbausteinSimulator.exe“

Under „Optionen“ -> „Einstellungen“ you will get to the settings...

Operation of the „data component simulator“ Deutschmann Automation GmbH & Co. KG

13 Starterkit ROTARNOCK with PROFIBUS V. 1.2 3.12.13

... for the PROFIBUS-Dongle.

• Adjust the COM-port for the PROFIBUS UART Dongle.

• Enter the PROFIBUS Slave ID. „126“ is default on delivery (current ID is passed out with

„(126)“ with the switch-on message).

• Select the GSD-file „R100.gsd“ under „Option File“ (on the Support DVD: Disc drive: \Sup

port\Profibus)

• Select the module name „S7DB(universal)“ from the GSD-file

• Set Watchdog to „5“

Confirm with OK.

3.12.13 Starterkit ROTARNOCK with PROFIBUS V. 1.2 14

Deutschmann Automation GmbH & Co. KG Operation of the „data component simulator“

There is a second window in the background. After setting the right COM-port it should look as

followed:

Under „Datei“ -> „Oeffnen“

Select the generated AWL-file with a click of the left mouse button on the browser box [...].

The view changes and the data component is displayed in the background.

Operation of the „data component simulator“ Deutschmann Automation GmbH & Co. KG

15 Starterkit ROTARNOCK with PROFIBUS V. 1.2 3.12.13

Select „laden und Übertragung starten“ afterwards.

After a short moment you can see the current position and the „address index“ should be running

continuously.

Output 1 should now be set from „0-100“ (h0 - h64)

Besides, the output status should change when the shaft is turned to a position between 0 and

100.

If you change a value, then the changed data has to be transferred to the PROFIBUS. This is

made by selecting „Aktualwerte übertragen“ with the left mouse button.

3.12.13 Starterkit ROTARNOCK with PROFIBUS V. 1.2 16

Deutschmann Automation GmbH & Co. KG Operation of the „data component simulator“

This method makes the testing of a data component rather simple. It can now be imported into

the S7 as decribed in the instruction manual V3526E „L100, 200, R80, 100 with Fieldbus connec-

tion“.

A sample project for the S7 can be found on the Support or it is available for download at

www.deutschmann.de.

Appendix Deutschmann Automation GmbH & Co. KG

17 Starterkit ROTARNOCK with PROFIBUS V. 1.2 3.12.13

5Appendix

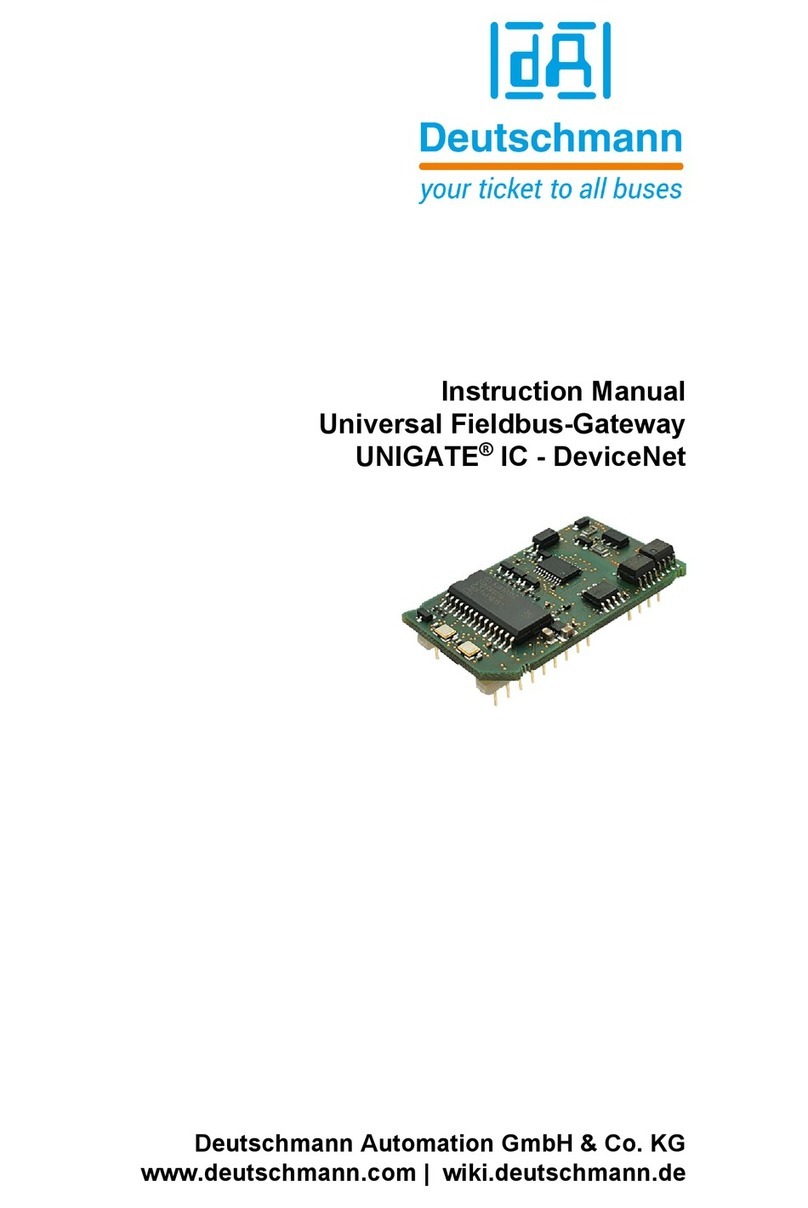

5.1 Hardware connection

A: Cam control V3406

B: PROFIBUS Dongle V2766

C: Power supply V2757

D: RS232 cable V2771

E: Cable cam control - PC V3467

3.12.13 Starterkit ROTARNOCK with PROFIBUS V. 1.2 18

Deutschmann Automation GmbH & Co. KG Servicing

6 Servicing

Should an error message occur, please first take all measures described in chapter Error mes-

sages.

Should questions occur that are not covered by this manual, please contact the responsible

sales partner (see internet: http://www.deutschmann.de) or contact us directly.

Please keep the following information ready at hand when you call:

You can reach us on the following Hotline number. Lines are open from

Monday to Thursday from 8 am to 12 pm and from 1 pm to 4.00 pm, Friday from 8 am to 12 pm.

Central office & sales department: +49-(0)6434-9433-0

Technical Hotline: +49-(0)6434-9433-33

Fax Central office & sales department:+49-(0)6434-9433-40

Fax technical Hotline: +49-(0)6434-9433-49

E-mail technical Hotline: hotline@deutschmann.de

6.1 Returning a unit

If you return a unit to us, we require as comprehensive a description of the error as possible. We

require the following information in particular:

•What error number was displayed?

•How is the unit externally wired (encoders, outputs, ..)? Please state all connections of the unit.

•What is the magnitude of the 24V supply voltage (± 0.5V) with connected LOCON?

•What were you last doing on the unit (programming, error on power-up, ...)?

The more precise your information and error description, the more precisely we can check the

possible causes.

Devices, that are sent in without an error description undergo a standard test. You have to bear

the costs for that test even though no defect was found.

6.2 Internet

The current software WINLOC32 is available for download from our Internet-homepage (URL).

There you can also find topical information on Deutschmann products, instruction manuals and a

list of our distribution partners.

URL: www.deutschmann.de

Device designation

Serial number (S/N)

Item No.

Error number and error description (see also following chapter ‘Returning a unit’)

Table of contents

Other DEUTSCHMANN AUTOMATION Microcontroller manuals

DEUTSCHMANN AUTOMATION

DEUTSCHMANN AUTOMATION UNIGATE IC-DeviceNet User manual

DEUTSCHMANN AUTOMATION

DEUTSCHMANN AUTOMATION UNIGATE FC Operating and installation instructions

DEUTSCHMANN AUTOMATION

DEUTSCHMANN AUTOMATION LOCON 200 User manual

DEUTSCHMANN AUTOMATION

DEUTSCHMANN AUTOMATION UNIGATE IC - AB User manual

Popular Microcontroller manuals by other brands

onsemi

onsemi STR-ECS640A-GEVK quick start

NEC

NEC UPD789026 Series user manual

NGX Technologies

NGX Technologies BlueBoard-LPC1768-H user manual

Silicon Laboratories

Silicon Laboratories Telegesis ETRX357DVK product manual

eInfochips

eInfochips Eragon 624 SOM Hardware reference manual

NXP Semiconductors

NXP Semiconductors KE17Z Series user guide