SB-19-085-P PAGE 3

After first 250 hours of operation, remove

gear box and drain gear oil. Refill gear

box with 140-weight SAE Gear Oil or a

high quality worm gear lubricant. Replace

pipe plug and tighten to 20 foot-pounds

(27 N.m) of torque.

6 Months or 2500 Operating Hours -

Replace gear oil according to instructions

above. Replace gear oil more often if

environment causes oil to become con-

taminated during use.

REPLACEMENT OF PARTS

Removal of Air Motor and Gear Box

(Refer to Figure 1 - typical assembly.)

1. Follow pressure relief procedure

(Pg. 1) before removing or loosening

any components.

2. Turn off valve to main air supply and

disconnect air adjusting valve (4) at

nipple (2).

3. Loosen upper cap screw (13) and

remove air motor and gear box

assembly from support (12).

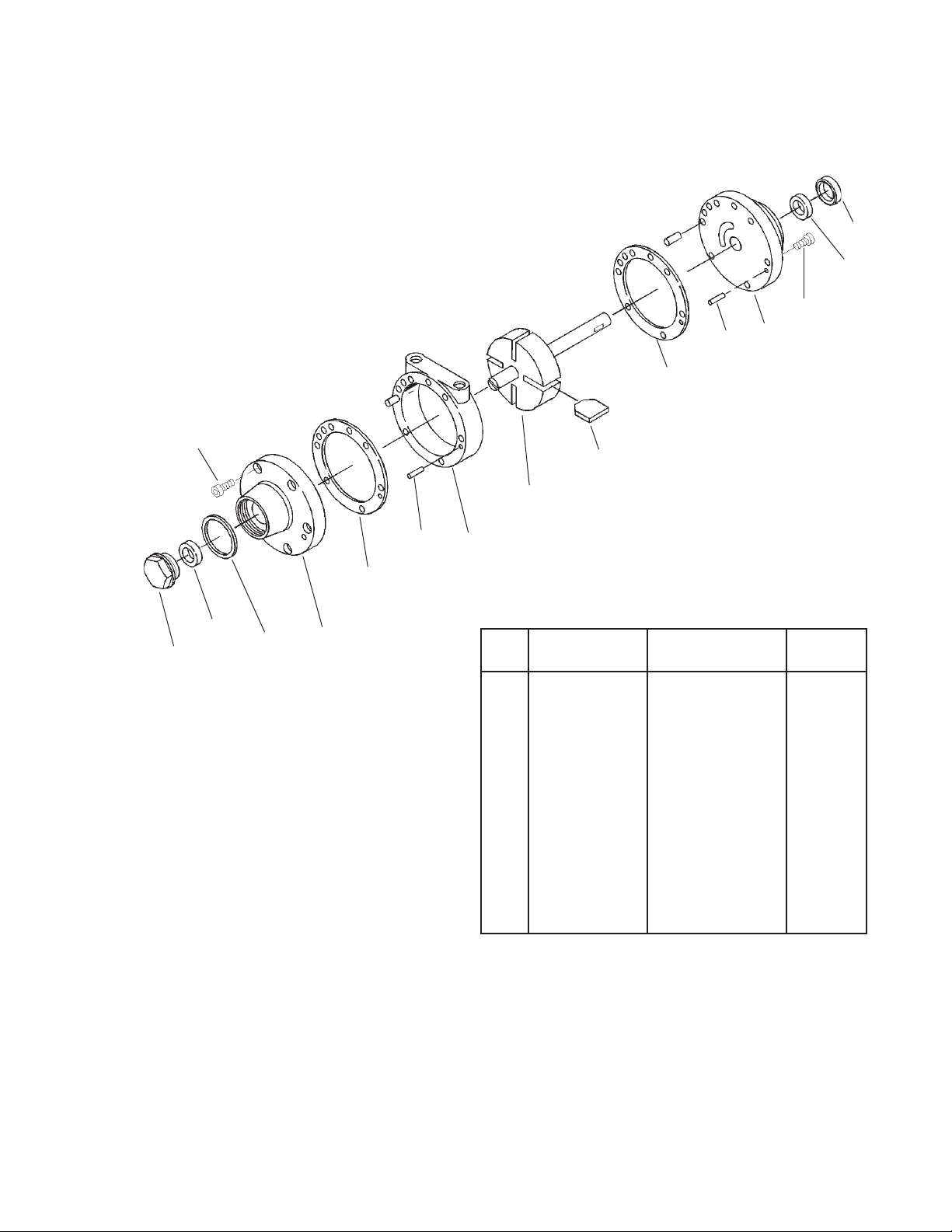

Air Motor (Refer to Figure 2.)

Holes must be drilled for new dowel pins

(21) after assembling front plate (26) on

new body (25) for alignment of parts.

Do not pry front plate (26) or end plate (20)

from air motor body (25) with a screw-

driver; this will dent the surface of the

body and plates, causing leaks. A puller

tool should be used to remove the plate

from the motor body while maintaining

the position of the shaft.

Always install two new gaskets (22)

when reassembling air motor.

Assemble the end plates to the body

using an arbor press with a pusher acting

on both races of the bearing while rigidly

supporting the opposite (drive) end of

the shaft.

Gear Box (Refer to Figure 3.)

1. Remove oil fill plug (37) or cover plate

(33) and drain gear box lubricant.

2. Remove set screws (40) and gear

box (16, Figure 1) from air motor (15,

Figure 1).

3. Disassemble gear box per exploded

view, Figure 3. Discard gaskets (36 and

41). Do not remove oil seal (39) unless

leakage or seal damage is indicated.

4. If oil seal (39) was removed, inspect

seal seating bore in housing (38).

Remove any burrs or contaminants

from seal seating bore. Burrs or con-

taminants could distort new oil seal

during installation.

5. Inspect gear and shaft assembly

(35) for wear grooves, burrs, or con-

tamination of seal seating area. If seal

seating area is damaged, shaft must

be repaired or replaced.

6. Inspect all other parts for wear spots,

chipping, or other damage. Replace

damaged or worn parts.

7. If oil seal (39) is being replaced,

inspect new seal for damage before

installing. Use arbor press to install

seal. Press fixture diameter must be

close fit with gear box bore diameter

to avoid damage to seal. Install with

inner casing and sealing lip toward

bottom of bore. Drive seal squarely

into bore to avoid warping. Check

that seal is fully seated all around at

bottom of bore.

8. Reassemble gear box per exploded

view. Install new gaskets (36 and 41).

Just prior to assembling gear box

with air motor, apply a small dab

of thread locking compound (30) to

threads of set screws (40). Connect

motor and gear box and torque set

screws (40) to 60 inch-pounds (6,8

N.m), minimum. Refill gear box per

gear box lubrication instructions.