DeVillbiss Air Power Company 525DS User manual

DANGER – NO SMOKING

DeVilbiss®5-liter Oxygen COnCentratOr

serViCe Manual

MODEL 525DS

MODEL 525DS-Q

MODEL 525KS

MODEL 525KS-LT

MODEL 525PS

CAUTION

Federal (U.S.A.) law restricts this device to sale by or on the order of a physician.

LT-2023

2

TABLE OF CONTENTS

GENERAL INFORMATION

Introduction.............................................................................................3

Symbol Definitions..................................................................................3

Important Safeguards............................................................................. 4

UNPACKING AND SETUP

Initial Inspection......................................................................................6

Patient Setup.......................................................................................... 6

Operating Instructions ............................................................................6

MAINTENANCE

Patient Alert System...............................................................................8

Alarm Function Testing...........................................................................8

Service Life............................................................................................. 9

Routine Patient Maintenance .................................................................9

Periodic Homecare Provider Preventative Maintenance...................... 10

Provider's Notes ...................................................................................10

Return and Disposal............................................................................. 11

Preventative Maintenance Summary ................................................... 11

TROUBLESHOOTING

System Operation................................................................................. 11

Normal Operating Sequence................................................................12

Low Pressure System ..........................................................................12

Simplified Troubleshooting ...................................................................13

Troubleshooting Chart A....................................................................... 14

Troubleshooting Chart B ......................................................................15

Troubleshooting Chart C ......................................................................15

Troubleshooting Chart D ......................................................................15

Troubleshooting Chart E ......................................................................16

Troubleshooting Chart F.......................................................................16

COMPONENT TESTING, REPAIR, AND REPLACEMENT

Proper Repair Procedures....................................................................17

Cabinet Removal.................................................................................. 17

Accumulator Pressure Test ..................................................................18

Auxiliary Oxygen Port...........................................................................19

Capacitor ..............................................................................................19

Check Valves/Manifold ......................................................................... 19

Compressor..........................................................................................20

Cooling Fan..........................................................................................21

Flow Meter............................................................................................22

Hour Meter ...........................................................................................23

Manifold................................................................................................23

Molecular Sieve Beds...........................................................................23

Power Cord ..........................................................................................24

Power Switch........................................................................................24

Pressure Regulator ..............................................................................24

Printed Circuit Board (PC Board).........................................................25

Rotary Valve ......................................................................................... 25

FIGURES, DIAGRAMS AND PARTS LIST

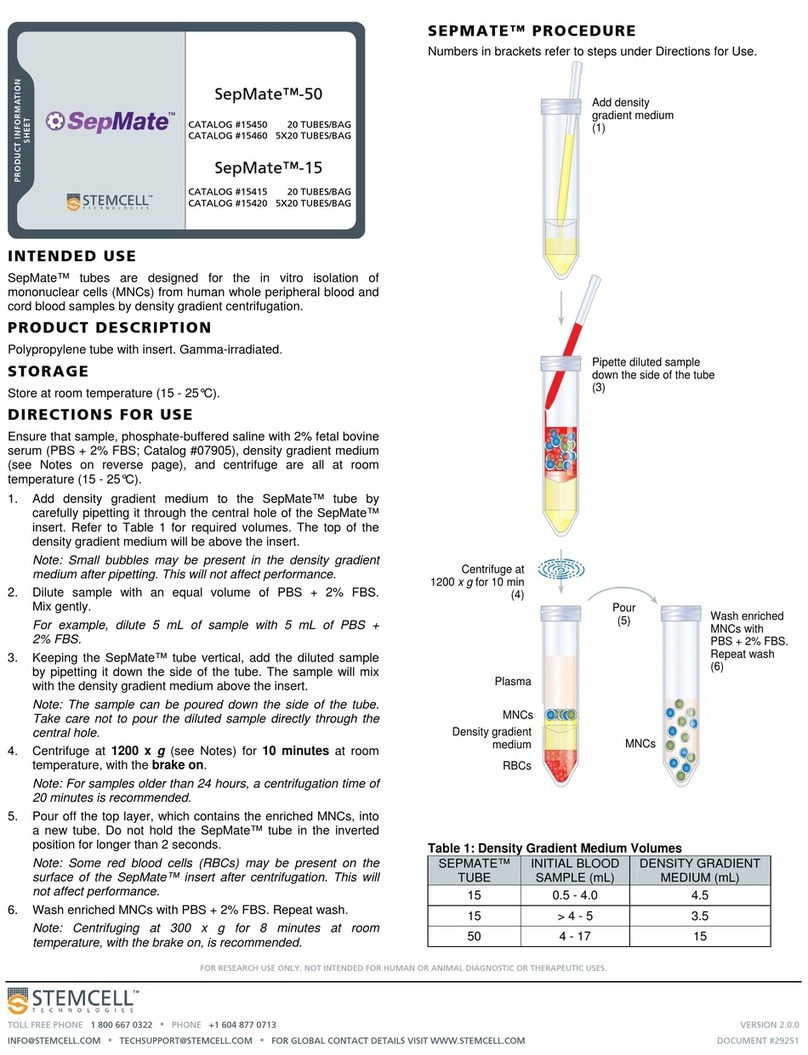

525DS Unit - Serial #F & 525DS / 525DS-Q Units - Serial #J

(115V Units)..........................................................................................27

525DS Unit - Serial #N & 525DS-Q Unit - Serial #R

(115V Units with Auxiliary Oxygen Port)............................................... 29

525DS Unit - Serial #B & 525DS-Q Unit - Serial #B

(115V Units with Auxiliary Oxygen Port)............................................... 32

525KS Unit - Serial #F & 525KS / 525KS-LT Units - Serial #J

(220/230/240V Units) ...........................................................................35

525KS-LT Unit - Serial #N & 525KS Unit - Serial #R

(220/230/240V Units with Auxiliary Oxygen Port) ................................37

525KS-LT Unit - Serial #B & 525KS Unit - Serial #B

(220/230/240V Units with Auxiliary Oxygen Port) ................................40

525PS Unit - Serial #F & 525PS Unit - Serial #J

(220/230/240V Units) ...........................................................................43

525PS Unit - Serial #B

(220/230/240V Units with Auxiliary Oxygen Port) ................................45

Accessories and Tools..........................................................................47

Pneumatic and Wiring Diagrams..........................................................48

ORDERING INFORMATION AND PARTS RETURN

Ordering Information ............................................................................50

Parts Return .........................................................................................50

WARRANTY......................................................................................... 51

SPECIFICATIONS................................................................................52

ELECTROMAGNETIC COMPATIBILITY INFORMATION...................54

3

LT-2023

GENERAL INFORMATION

INTRODUCTION

This service manual was designed to provide DeVilbiss Healthcare qualied service technicians and homecare providers with the proper maintenance, service, safety,

and repair procedures for the DeVilbiss Oxygen Concentrator.

Read and understand all the information contained in this service manual before attempting to operate or perform any maintenance on the concentrator.

An oxygen concentrator is a device that delivers highly concentrated oxygen for therapeutic applications.

Room air is a mixture of 78% nitrogen, 21% oxygen, 1% argon and other gases. The concentrator draws in room air, separates the nitrogen from the oxygen, and

delivers concentrated oxygen to the patient through an oxygen port.

For more in-depth classroom type training, contact the Respiratory Technical Service Department at 1-800-338-1988 (814-443-4881).

NOTE– DeVilbiss reserves the right to alter or change the design of the DeVilbiss Oxygen Concentrator series. Hence, slight differences in construction or

components may exist between the unit in hand and what is described in this manual.

SYMBOL DEFINITIONS

It is mandatory to read and

understand the operating instructions

prior to use.

This symbol has a blue

background on the product label.

O

I

Off

On LOT Number Manufacturer

Electric Shock Hazard. Cabinet to be

removed by authorized personnel

only.

This symbol has a yellow

background on the product label.

Reset Catalog Number European Representative

Danger - No smoking near patient or

device.

This symbol has a red circle and

diagonal bar on the product label.

Alternating Current Serial Number European Rep CE mark

Use no Oil, Grease or Lubricants

This symbol has a red circle and

diagonal bar on the product label.

Type B applied part Normal Oxygen Keep unit dry.

Do not use near heat or open ames

This symbol has a red circle and

diagonal bar on the product label.

Double Insulated Low Oxygen

Maximum recommended

ow rate: 5LPM

General Warning

This symbol is used throughout

this manual to indicate hazardous

situations to avoid.

Hour Meter Service Required

Important Information

This symbol is used throughout

this manual to indicate important

information you should know.

+5˚C

+35˚C Operating Temperature

Range +5 to +35˚C (+41 to

+95˚F)

C

US

TUV Rheinland C-US

approval mark

Note and Information Symbol

This symbol is used throughout

this manual to indicate notes, useful

tips, recommendations and

information.

Atmospheric Pressure

Range 840 to 1010 hPa

(Approximate sea level to

5000 ft)

TUV Rheinland Certied

approval mark Inmetro approval mark

Federal (U.S.A.) law restricts this device to sale by or on the order of a

physician.

IP21

Ingress Protection - Protected against nger access to hazardous

parts; protected against vertically falling water drops.

This device contains electrical and/or electronic equipment that must be recycled per EU Directive 2012/19/EU- Waste Electrical and Electronic Equipment

(WEEE)

LT-2023

4

GENERAL INFORMATION

IMPORTANT SAFEGUARDS

Read this entire guide before using your DeVilbiss concentrator. Important safeguards are indicated throughout this guide. Pay special attention to all safety information.

Imminently and potentially hazardous information is highlighted by these terms:

DANGER

Indicates an imminently hazardous situation which could result in death or serious injury to the user or operator if not avoided.

WARNING

Indicates a potentially hazardous situation which could result in death or serious injury to the user or operator if not avoided.

CAUTION

Indicates a potentially hazardous situation which could result in property damage, injury, or device damage if not avoided.

IMPORTANT

Indicates important information you should know.

NOTE

Indicates notes, useful tips, recommendations, and information.

DANGER

• Oxygen causes rapid burning. Do not smoke while your oxygen concentrator is operating, or when you are near a person utilizing oxygen therapy.

• Smoking during oxygen therapy is dangerous and is likely to result in facial burns or death. Do not allow smoking within the same room where the

oxygen concentrator or any oxygen carrying accessories are located.

• If you intend to smoke, you must always turn the oxygen concentrator off, remove the cannula and leave the room where either the cannula or mask

or the oxygen concentrator is located. If unable to leave the room, you must wait 10 minutes after you have turned off the oxygen concentrator

before smoking.

• Oxygen makes it easier for a re to start and spread. Do not leave the nasal cannula or mask on bed coverings or chair cushions if the oxygen

concentrator is turned on but not in use. The oxygen will make the materials ammable. Turn the oxygen concentrator off when not in use to prevent

oxygen enrichment.

• Keep the oxygen concentrator and cannula at least 2 m (6.5 feet) from hot, sparking objects or naked sources of ame.

• Open ames during oxygen therapy are dangerous and are likely to result in re or death. Do not allow open ames within 2 m (6.5 feet) of the oxygen

concentrator or any oxygen carrying accessories.

• DeVilbiss oxygen concentrators are equipped with a re mitigating outlet tting that prevents propagation of re into the unit.

WARNING

• To avoid electric shock, do not plug the concentrator into an AC outlet if the concentrator cabinet is broken. Do not remove the concentrator cabinet. The

cabinet should only be removed by a qualied DeVilbiss technician. Do not apply liquid directly to the cabinet or utilize any petroleum-based solvents or

cleaning agents.

• Improper use of the power cord and plugs can cause a burn, re or other electric shock hazards. Do not use the unit if the power cord is damaged.

• Ensure the mains power cord is fully inserted into the concentrator connector (230 volt units) and the power cord plug is completely inserted into a fully

functioning AC wall outlet. Failure to do so may cause an electrical safety hazard.

• See instructions for use regarding re propagation prevention.

• Locate oxygen tubing and power supply cords to prevent tripping hazards and reduce the possibility of entanglement or strangulation.

• Do not lubricate ttings, connections, tubing or other accessories of the oxygen concentrator to avoid the risk of re and burns.

• Do NOT use lubricants, oils or grease.

• Before attempting any cleaning procedures, turn the unit “Off.”

• Use only water-based lotions or salves that are oxygen-compatible before and during oxygen therapy. Never use petroleum or oil-based lotions or

salves to avoid the risk of re and burns.

• Use only spare parts recommended by the manufacturer to ensure proper function and to avoid the risk of re and burns.

• When using the Transller Caddy with a Transll device, always keep the system on a at surface. Disassemble the system prior to moving.

5

LT-2023

GENERAL INFORMATION

WARNING

• If you feel discomfort or are experiencing a medical emergency while undergoing oxygen therapy, seek medical assistance immediately to avoid harm.

• Geriatric, pediatric or any other patient unable to communicate discomfort can require additional monitoring and/or a distributed alarm system to convey

the information about the discomfort and/or the medical urgency to the responsible caregiver to avoid harm.

• Use of this device at an altitude above 13,123 feet (4000 meters) or above a temperature of 95°F (35°C) or greater than 93% relative humidity may

affect the ow rate and the percentage of oxygen and consequently the quality of the therapy. Refer to specications for details regarding parameters

tested.

• To ensure you receive the therapeutic amount of oxygen delivery according to your medical condition, the Oxygen Concentrator must:

• be used only after one or more settings have been individually determined or prescribed for you at your specic activity levels.

• be used with the specic combination of parts and accessories that are in line with the specication of the concentrator manufacturer and that were

used while your settings were determined.

• Your delivery settings of the oxygen concentrator should be periodically reassessed for the effectiveness of therapy.

• For your safety, the oxygen concentrator must be used according to the prescription determined by your physician.

• Under certain circumstances, oxygen therapy can be hazardous. Seek medical advice before using an oxygen concentrator.

WARNING

• Medical Electrical Equipment needs special precautions regarding EMC and needs to be installed and put into service according to the Electromagnetic

Compatibility [EMC] information provided in the accompanying documents.

• Portable and Mobile RF Communications Equipment can affect Medical Electrical Equipment.

MR Unsafe

• Do not bring the device or accessories into a Magnetic Resonance (MR) environment as it may cause unacceptable risk to the patient or damage to the

oxygen concentrator or MR medical devices. The device and accessories have not been evaluated for safety in an MR environment.

• Do not use the device or accessories in an environment with electromagnetic equipment such as CT scanners, Diathermy, RFID and electromagnetic

security systems (metal detectors) as it may cause unacceptable risk to the patient or damage to the oxygen concentrator. Some electromagnetic

sources may not be apparent, if you notice any unexplained changes in the performance of this device, if it is making unusual or harsh sounds,

disconnect the power cord and discontinue use. Contact your home care provider.

• This device is suitable for use in home and healthcare environments except for near active HF SURGICAL EQUIPMENT and the RF shielded room of

an ME SYSTEM for magnetic resonance imaging, where the intensity of Electromagnetic DISTURBANCES is high.

• Use of this equipment adjacent to or stacked with other equipment should be avoided because it could result in improper operation. If such use is

necessary, this equipment and the other equipment should be observed to verify that they are operating normally.

• Portable RF communications equipment (including peripherals such as antenna cables and external antennas) should be used no closer than 30 cm (12

inches) to any part of the oxygen concentrator, including cables specied by the manufacturer. Otherwise, degradation of the performance of this

equipment could result.

CAUTION

• It is very important to follow your oxygen prescription. Do not increase or decrease the ow of oxygen – consult your physician.

• The surface temperature of the exhaust vents on the bottom of the unit may exceed 105.8˚F (41˚C) under certain conditions.

• When device is used under extreme operating conditions, the temperature near the exhaust vents on the bottom of the unit may reach 145˚F (63˚C).

Keep body parts a minimum of 32” (81.2 cm) away from this area.

• Use of harsh chemicals (including alcohol) is not recommended. If bactericidal cleaning is required, a non-alcohol based product should be used to

avoid inadvertent damage.

IMPORTANT

• It is recommended that the homecare provider lock the ow control knob to prevent inadvertent adjustment. A ow setting other than prescribed may

affect the patient therapy.

• Do not service or clean this device while in use with a Patient.

• Installation of 515LF-607 low output ow meter package will cause the low ow alarm to not work and will prevent the device from meeting the

requirements of ISO-80601-2-69:2014 Section 201.13.2.101.

• The Device is classied as IP21 which means it is protected against nger access to hazardous parts and protected against vertically falling water

drops.

• Equipment not suitable for use in the presence of a ammable anesthetic mixture with air or with oxygen or nitrous oxide.

• This device contains electrical and/or electronic equipment. Follow local governing ordinances and recycling plans regarding disposal of device

components.

LT-2023

6

UNPACKING AND SETUP

INITIAL INSPECTION

It is suggested that an initial inspection be performed upon receiving the oxygen

concentrator.

1. After removing the DeVilbiss Oxygen Concentrator from the carton,

examine it for any external damage. If shipping damage has occurred,

contact the DeVilbiss Customer Service Department at 1-800-338-1988

(814-443-4881) for specic instructions. Save the carton for possible later

return; note the position of the unit and placement of the packing material.

2. Check to be sure the intake bacteria lter is in place.

3. Plug the unit into an electrical outlet, turn the unit “On,” and check the

audible and visible alerts.

4. Set the ow meter to maximum recommended liter ow and let the unit

run for at least 20 minutes. Also record the number of hours on the hour

meter.

5. Use an oxygen analyzer to check the concentration.

6. With unit still running, unplug to test the power fail alarm.

NOTE–If the unit fails to operate properly (oxygen concentration not within

specication) or if internal damage is found, contact the DeVilbiss Customer

Service Department at 1-800-338-1988 (814-443-4881).

PATIENT SETUP

1. Position the unit near an electrical outlet in the room where the patient

spends most of his or her time.

NOTE–Do not connect to an electrical outlet controlled by a wall

switch.

2. Position the unit at least 6 inches (16 cm) from walls, draperies, or any

other objects that might prevent the proper ow of air in and out of the

oxygen concentrator.

3. Locate the unit a minimum of 6.5 feet (2 m) from replaces, radiators,

heaters, and hot-air registers.

WARNING

Oxygen causes rapid burning. Do not smoke while your oxygen

concentrator is operating, or when you are near a person utilizing

oxygen therapy. Keep the oxygen concentrator and cannula at least

6.5 feet (2 m) from hot, sparking objects or naked sources of ame.

Electric Shock Hazard. Only qualied DeVilbiss Healthcare homecare

providers may remove the cabinet.

4. Attach the appropriate oxygen accessories (oxygen tubing or humidier)

to the oxygen outlet port.

NOTE–The bubble humidier should be supplied with a permanent re stop

device. If a bubble humidier needs to be used without a permanent re stop

device, a secondary re stop device must be used and placed as close to the

humidier as possible. Failing to do so could increase the risk of re.

NOTE–A maximum of 50 feet (15 meters) of tubing plus 7 feet (2.1 meters)

of cannula plus a bubble humidier is allowed between the concentrator and the

patient.

NOTE– The oxygen supply accessory (patient tubing)

shall be equipped with a means that in case of re stops the

delivery of oxygen to the patient. This means of protection

should be located as close to the patient as practicable.

Oxygen Tubing Only Connection

1. Thread the cannula tting onto the oxygen outlet port.

2. Attach the 5/32” (4 mm) I.D. oxygen tubing.

Oxygen Tubing with Humidification

Connection

If the physician has prescribed an oxygen humidier as part of the patient’s

therapy, follow these steps (If using a prell, go to Step 3.):

1. Fill the humidier bottle with distilled, demineralized, or boiled water. Do

not overll.

2. Thread the wing nut located on the top of the humidier bottle to the

oxygen outlet port so that it is suspended. Make sure it is securely

tightened.

3. Attach the 5/32" (4 mm) I.D. oxygen tubing, not to exceed 50 feet (15

meters), directly to the humidier bottle outlet tting.

NOTE–For optimum performance, the DeVilbiss Oxygen Concentrator has

a preset nominal output pressure of 8.5 psi (58.6 kPa). Use only “bubble-type”

humidiers. Do not use “jet-type” humidiers.

NOTE–Condensation from the humidier may occur in longer lengths of

tubing or if the tubing is laying on a cold oor.

When ready for operation

1. Attach the nasal cannula to the oxygen tubing (per the manufacturer’s

directions).

2. Follow the Operating Instructions.

OPERATING INSTRUCTIONS

1. Remove the power cord completely from the strap. Make sure the power

switch is in the “Off” position.

2. 115 Volt Units– Insert the plug into an electrical outlet. The DeVilbiss

Oxygen Concentrator uses a two-prong polarized plug and is double-

insulated to protect against electric shock.

220/230/240 Volt Units – Ensure cord is connected to the unit before

inserting plug into an appropriate electrical outlet.

WARNING

The plug on the DeVilbiss 525DS concentrators has one blade wider

than the other. To reduce the risk of electric shock, this plug is

intended to t in a wall outlet only one way. Do not attempt to defeat

this safety feature.

Improper use of the power cord and plugs can cause a burn, re, or

other electric shock hazards. Do not use the unit if the power cord is

damaged.

Oxygen causes rapid burning. Do not smoke while your oxygen

concentrator is operating, or when you are near a person utilizing

oxygen therapy. Keep the oxygen concentrator and cannula at least

6.5 feet (2 m) from hot, sparking objects or naked sources of ame.

3. Press the power switch to the “On” position. When the unit is turned “On,”

all three lights (Service Required, Low Oxygen, and Normal Oxygen) on

the front panel will briey illuminate and an audible signal will sound

momentarily. The unit will then operate in "start up" mode with the Low

Oxygen light lit until a normal oxygen level is achieved at which time the

Normal Oxygen light will remain lit. The "start up" may take up to 15

minutes.

NOTE–DeVilbiss recommends for optimal service life that the

DeVilbiss Oxygen Concentrator to be operated for at least 30 minutes

after it is powered on. Shorter periods of operation, operating in extreme

7

LT-2023

UNPACKING AND SETUP

temperature/humidity conditions or in the presence of contaminates, and/

or handling and storage conditions outside those specied, may affect the

long term reliable operation of the product.

4. Slowly turn the ow meter knob until the ow meter ball is centered on the

line next to the appropriate ow rate.

NOTE–When the ow meter knob is turned clockwise, the ow

decreases (and eventually will shut off the oxygen ow). When the knob is

turned counter-clockwise, the ow increases.

NOTE–For prescriptions of 5 LPM, be sure the ball is centered on the

5 liter line; the ball should not touch the red line. Setting the ow higher

than 5 may cause the oxygen purity level to drop.

NOTE–Use low output ow meter (part #515LF-607) for ow rates

under 1 lpm.

NOTE–Installation of 515LF-607 low output ow meter package will

cause the low ow alarm to not work and will prevent the device from

meeting the requirements of ISO-80601-2-69:2014 Section 201.13.2.101.

NOTE–The low-ow alarm may activate if the ow meter ball is set at

or below .5 lpm. The unit will continue to run; however, the Service

Required light will come on accompanied by an audible alarm. Adjust the

ow meter to your prescribed ow.

NOTE–The unit may require up to 20 minutes for the oxygen

concentration and ow rate to stabilize. The ow rate should be monitored

and readjusted if necessary.

5. The ow meter has a locking device. If it is necessary to preset and lock in

the prescribed ow rate, tighten the set screw located on the hex nut just

below the control knob using a 1/16" Allen bit. No adjustment can be made

without loosening the set screw.

6. The DeVilbiss oxygen concentrator is now ready for use.

LT-2023

8

MAINTENANCE

PATIENT ALERT SYSTEM

The DeVilbiss Oxygen Concentrator patient alert system will detect unit

component failure. This system is comprised of both visible and audible alerts

which signal the patient if a malfunction should occur.

DeVilbiss OSD®Operation

The OSD is a device within DeVilbiss concentrators that monitors the oxygen

produced by the unit. The OSD operates as follows:

• Normal Oxygen (green light) - oxygen purity normal

• Low Oxygen (yellow light) - oxygen purity low–requires servicing

If the oxygen purity continues to fall, an audible signal will sound intermittently. If

the oxygen purity continues to fall to a low enough level, the yellow “Low

Oxygen” light will turn off and the red “Service” light will turn on.

NOTE–Refer to the Alerts section below for specic alert settings.

After Power On, the OSD conducts a continuous diagnostic evaluation to check

for a fault in the piezo electronics. If this condition is detected by the OSD

electronics at any time during concentrator operation, the green “Normal

Oxygen” OSD light will turn off and the beeping audible alert and blinking red

“Service” light will activate. Otherwise for the rst fteen minutes of operation,

the green “Normal Oxygen” light will remain illuminated during the oxygen

stabilization process. After that time, the OSD will begin monitoring the oxygen

purity every second.

For units with Serial Numbers

starting with B

After power on, the electronics continuously monitor the oxygen sensor. If a

fault is detected, the green "Normal Oxygen" light will turn off and the beeping

audible alert and blinking red "Service Required" light will activate.

During the rst 15 minutes, the unit will be in “Start Up” mode. The oxygen

purity is continuously monitored and the green "Normal Oxygen" light will turn

on as soon as the therapeutic oxygen levels are obtained. After 15 minutes

stabilization time, if the O2is less than 85% the yellow Low O2LED will be on

and a beeping audible alarm will occur. If the level is below 60% (after

startup) then the yellow and red LEDs will be lit along with a beeping audible

alarm. The audible low O2alarms are blocked during the 15 minute

stabilization delay, and also during the 10 minute stabilization delay that

occurs during turn-down mode enter/exit.

Alerts:

There are two visible service alerts located on the front panel.

For serial numbers starting with

B, J, N or R For serial numbers starting with F

Low O2%Service Low O2%Service

The audible alert system is internally powered; no batteries are required. If the

indicator lights illuminate or the audible alert sounds other than during start-up, a

problem has occurred

• Power Failure (Blinking red “Service” light and pulsing audible alert)

• Low Flow (Below 0.5 lpm) (Continuous red “Service” light and audible alert)

• Below Normal Oxygen (84% to 75%, yellow “Low Oxygen” light. 75% to

60%, yellow “Low Oxygen” light and beeping audible alert. Less than 60%,

red “Service” light and beeping audible alert.)

The visible and audible alerts will activate for approximately 15 minutes in a no

power situation. If the unit is turned “On” without power or power is removed

later, no alert will sound for the rst 10 seconds. After that time, the alert will

produce an audible pulse every few seconds while the visible alert blinks. Power

for this alert is provided by a capacitor on the PC board.

For units with Serial Numbers

starting with B

The audible alert system is internally powered; no batteries are required. If

the indicator lights illuminate or the audible alert sounds other than during

start-up, a problem has occurred

• Power Failure (Pulsing audible alert)

• Low Flow (Below .5 lpm) (Continuous red “Service” light and audible

alert)

Below normal O2:

• The yellow Low Oxygen light will illuminate with an audible alarm at

<85%.

• The yellow Low Oxygen and red Service Required lights will illuminate

with an audible alarm at <60%.

The audible alert will activate for a minimum of two minutes in a no power

situation. There is no visual indicator for this alarm. If the unit is turned “On”

without power or power is removed later, the alert will sound within 10

seconds. After that time, the alert will produce an audible pulse every few

seconds. Power for this alert is provided by a capacitor on the PC board.

NOTE–If the concentrator has been unused for an extended period, the unit

must run several minutes before the power fail alert will activate.

The PC (printed circuit) board is responsible for controlling the system and

alerts.

NOTE–A high pressure condition is indicated by the audible (a “popping”

sound) release of pressure from a pressure relief valve located on the

compressor head.

NOTE–Installation of 515LF-607 low output ow meter package will cause

the low ow alarm not to work and will prevent the device from meeting the

requirements of ISO-80601-2-69:2014 Section 201.13.2.101.

ALARM FUNCTION TESTING

The 525 series is designed to activate alarms when certain conditions or failures

occur. The alarm functions may be tested following the procedures below:

1. Overheating:

a. Remove the front and rear covers from the concentrator; then

disconnect the cooling fan from the printed circuit board.

b. Replace the front and rear covers.

c. Place the concentrator in a location that has an ambient temperature

of approximately 70° F. Then plug the unit into the appropriate mains

voltage and turn it on.

d. Allow the unit to operate until the Service Required Alarm activates,

which should be within approximately two hours.

2. Compressor Failure:

a. Remove the rear cover from the concentrator; then disconnect the

compressor electrical connector from the main wire harness.

b. Plug the unit into the appropriate Mains voltage and turn it on.

c. Allow the unit to operate until the Service Required Alarm activates,

which should be within approximately two minutes.

3. Low Flow / Obstruction of Gas Pathway:

a. Plug the concentrator into the appropriate mains voltage and turn it

on.

b. Allow the device to run for several minutes.

c. Turn the ow meter off so that there is no oxygen owing out of the

unit.

d. Allow the unit to operate until the alarm condition occurs (red light

and audible beep).

9

LT-2023

MAINTENANCE

e. Increase the ow to 1 LPM and conrm that the alarm condition ends.

4. High Flow

a. Connect the oxygen concentrator to AC power and turn the power

switch on.

b. Allow the device to run for several minutes.

c. Adjust the output ow to more than 6.0 LPM using the ow meter

knob (turn counter clockwise until ball goes above 6.0 LPM).

d. The alarm condition (yellow light) should occur.

e. Decrease the ow to 5 LPM and conrm that the alarm condition

ends.

5. Oxygen Generation Mains Failure:

a. Plug the concentrator into the appropriate mains voltage and turn it

on.

b. Turn the ow meter to 5 LPM.

c. Attach another ow meter to the auxiliary oxygen port which is located

on the rear of the concentrator and then adjust the ow to 3 LPM.

d. Allow the unit to operate until the Service Required Alarm is activated,

which should be within approximately thirty minutes.

6. Pressure Failure:

a. Remove the front and rear covers from the concentrator.

b. Disconnect the tubing from the top of one of the sieve beds.

c. Plug the unit into the appropriate mains voltage and turn it on.

d. Turn the ow meter to 5 LPM.

e. Allow the unit to operate until the Service Required Alarm is activated,

which should be within approximately thirty minutes.

7. Power Supply Failure

a. Connect the oxygen concentrator to AC power and turn the power

switch on. Allow the device to run for several minutes.

b. With the power switch in the on position, unplug the AC power cord

from the outlet.

c. The alarm condition (audible beep) should occur and continue for a

minimum of 120 seconds. There is no visual indicator for this alarm

condition.

d. Reconnect the AC power cord and conrm that the alarm condition

ends.

8. Malfunction – O2S Gas Temperature High

a. This alarm condition is tested automatically during start-up.

9. Malfunction – Corrupted Settings

a. This alarm condition is tested automatically during start-up.

10. Malfunction – Non-Recoverable Valve Error

a. This alarm condition is tested automatically during start-up.

11. Malfunction – O2S Oxygen Sensor Communication Failure

a. This alarm condition is tested automatically during start-up.

12. Low Oxygen Concentration – Startup Period

a. Connect the oxygen concentrator to AC power and turn the power

switch off.

b. Leave the device off for several minutes until the outlet ow is zero

(ow meter ball at zero).

c. Turn the power switch to the on position. The alarm condition (yellow

light) occurs during startup until the oxygen concentration reaches

85%.

13. Low Oxygen Concentration – Startup Period Over

a. This alarm condition is tested automatically during start-up. Once the

oxygen concentration reaches 85% the green light comes on.

Service Life

The expected service life of the 525 is 5 years of operation, when used in

accordance with all manufacturer guidance for safe use, maintenance, storage,

handling and general operation. Expected service life of the unit, and in particular

the sieve beds and compressor, may vary based on the operating environment,

storage, handling and the frequency and intensity of use.

ROUTINE PATIENT MAINTENANCE

DeVilbiss recommends using only original DeVilbiss parts and lters in order to

guarantee a reliable operation of the product.

The oxygen patient should perform the following maintenance:

Cannula, Tubing, and Humidifier Bottle

The patient should clean and replace the cannula, tubing, and humidier bottle

according to the manufacturer’s instructions.

Air Filter

NOTE– Recent updates made to the oxygen-generating / ow systems within

the concentrator have eliminated the need for the gross particle lter to be

included on future production units. The lter door has been recongured to allow

for increased air ow through horizontal slots without the ltration material

included.

The redesigned lter door is standard on all 525 models as of October, 2020.

Although the lter is no longer required when using the new lter door, a recess

inside the door has been created, should a provider still desire to have a gross

particle lter included.

The new lter door is backwards compatible with older 525 models.

The maintenance guidelines below should still be followed for those

concentrators that have the gross particle lter.

The air lter should be inspected periodically and cleaned as needed by the user

or caregiver. Replace if torn or damaged. To clean, follow these steps:

NOTE–Frequency of inspection and cleaning of lter may be dependent

upon environmental conditons like dust and lint.

1. Remove the air lter located in the door on the back of the unit.

2. Wash in a solution of warm water and dishwashing detergent.

3. Rinse thoroughly with warm tap water and towel dry. The lter should be

completely dry before reinstalling.

WARNING

Do not attempt to operate the unit without the air lter or while the

lter is still damp.

NOTE–The air lter should be monitored more closely in environments with

abnormal amounts of dust and lint.

CAUTION

Operation of the DeVilbiss Oxygen Concentrator in extreme

environments or without the air lter will prematurely occlude the

intake bacteria lter and cause a decrease in the unit performance.

Exterior Cabinet

The patient should clean the concentrator exterior cabinet weekly by using a

damp cloth or sponge with a mild household cleaner and wiping it dry.

WARNING

Do not apply liquids directly to the cabinet or utilize any petroleum-

based solvents or cleaning agents.

LT-2023

10

MAINTENANCE

PERIODIC HOMECARE PROVIDER

PREVENTATIVE MAINTENANCE

Use only DeVilbiss concentrator replacement parts and accessories.

Every DeVilbiss Oxygen Concentrator is tested at the factory. To assure

continued trouble-free performance, the following preventative maintenance

should be performed by the homecare provider during periodic oxygen patient

visits not to exceed 3 years. Failure to properly maintain the unit will void the

warranty.

1. Check the oxygen concentration with an oxygen analyzer (part #R217P62)

every 3 years.

a. Calibrate the oxygen analyzer prior to checking the oxygen

concentration. The analyzer should be properly calibrated using the

manufacturer’s recommended procedure.

NOTE–Changes in temperature, altitude, or humidity may affect

the analyzer’s oxygen concentration reading. The analyzer should be

calibrated in similar conditions to the location of the concentrator.

b. Power the unit, set the ow meter to 5 LPM and connect the analyzer

to the unit’s oxygen outlet port.

c. Wait 20 minutes for the display to stabilize. The concentrator must

operate for a minimum of 20 minutes before checking the oxygen

concentration.

d. Record the reading.

2. Check the audible alert and indicator lights during every service. When the

power switch is turned “On,” listen for the audible alert and check to see if

the front panel indicator lights are operating.

3. Inspect cabinet air lter (part #303DZ-605) every PM check. Replace if lter

is torn or damaged. Units manufactured since October, 2020 do not have a

gross particle or cabinet air lter. See note under Air Filter on page 9.

4. Inspect intake bacteria lter (part #MC44D-605) during every PM Check.

Replace as necessary.

a. Open the lter door and replace lter as required.

5. Inspect the nal bacteria lter (part #PV5LD-651) during every compressor

service. Replace as necessary.

a. Use the Cabinet Removal instructions found under CABINET

REMOVAL in this manual to remove and attach the cabinets.

b. Remove the hose from each end of the lter and discard the lter.

c. Install the new nal bacteria lter with the “IN” tting toward the ow

meter.

6. Inspect the compressor lter during every compressor service. Replace as

necessary.

NOTE–A change was made to the type of compressor lter used in the 525

series concentrator. The unit may have one of two different types of compressor

lters depending on when the concentrator was manufactured. The original one

is a white plastic lter that is located near the compressor. The newer style is a

sintered bronze lter (525DD-626) that is installed in one end of the compressor

exhaust hose near the rotary valve. All models of the 525 series are now being

manufactured with the sintered bronze compressor lter. See gure below.

Sintered Bronze Compressor Filter

(525DD-626)

NOTE– This PM Schedule reects:

• 5000 hour usage equal to one year

• a normal, clean operating environment.

The homecare provider is responsible for:

• determining the condition of the concentrator operating environment.

• determining a preventative maintenance interval frequency* which takes

into consideration the specic operating environment.

* Standard intervals are noted below. Service interval may be more or

less frequent than stated below provided that the Home Care

Provider establishes and documents appropriate protocols.

7. Inspect AC power cord, power switch and circuit breaker every PM check

or between patients. Replace as necessary.

PROVIDER’S NOTES - Cleaning and

Disinfection When There is a Patient Change

DeVilbiss Healthcare recommends that at least the following procedures be

carried out by the manufacturer or a qualied third party between uses by

different patients.

NOTE – If the following described complete processing of the concentrator by

an appropriately trained individual is not possible, the device should not be used

by another patient.

NOTE – If preventive maintenance is due at this time, these procedures

should be carried out in addition to the servicing procedures.

1. Use disinfectants safely. Always read the label and product information

before use.

2. Always wear personal protective equipment when performing this

procedure. Use suitable gloves and safety glasses. Cover exposed skin on

arms to prevent accidental contact with bleach solution that has been

applied to the concentrator.

3. Dispose of all accessories that are not suitable for reuse. This includes but

may not be limited to the oxygen tubing, tubing connectors, nasal cannula

and/or mask, oxygen outlet connector, and humidier bottle.

4. Clean the exterior of the concentrator with a clean lint-free cloth. Heavy soil

should be removed with a clean lint-free cloth dampened with water. A soft

bristled brush dampened with water can be used to remove stubborn soil.

Dry the concentrator using a clean lint-free cloth if water was used to

remove soil.

5. Use 5.25% chlorine bleach (Clorox Regular Liquid Bleach or equivalent).

Mix one (1) part bleach with four (4) parts water in an appropriate clean

container. This ratio produces a one (1) part bleach to ve (5) total parts

solution (1:5). The total volume (amount) of solution required is determined

by the number of concentrators in need of disinfection. NOTE– An

alternate suitable disinfecting agent (e.g. Mikrobac® forte or Terralin®

Protect) may also be used. Follow disinfectant manufacturer’s instructions.

6. Apply the bleach solution in an even manner to the cabinet and power cord

using a clean lint-free cloth. The cloth should be dampened only and not

dripping of solution. Do not use a spray bottle to apply the solution. Do not

saturate the device with the solution. Take care that no solution enters the

vent areas on the concentrator base or the Auxiliary O2 tting area on the

back of the unit. Avoid over-saturating the cabinet seams so that no

solution residue builds up in these areas. Avoid the caster wells located on

the bottom of the unit.

7. Exposure time of the disinfectant solution should be 10 minutes minimum

to 15 minutes maximum.

8. After the recommended exposure time, all surfaces of the concentrator

should be wiped with a clean lint-free cloth dampened with drinking quality

water no warmer than room temperature. Dry the unit with a dry, clean lint-

free cloth. This is to remove residue that may stain or leave a lm on the

unit, especially after repeated disinfections.

9. Check the cord, the plug on the back of the device, the power switch, the

fuse holder, and the indicator lights for possible damage. Replace all

damaged or worn components.

10. Replace the cabinet air lter on the back of the device.

11. Check the oxygen concentration. If the device is within specication, the

extended life intake bacteria lter does not need to be replaced between

patients. If the oxygen concentration is not within specication, the provider

should refer to the service manual section on Troubleshooting.

12. OPTIONAL INSIDE CLEANING: The concentrator must be disconnected

from the power supply for this step: Open the concentrator and remove all

11

LT-2023

MAINTENANCE

dust deposits inside the cabinet with an appropriate vacuum cleaner. Close

the concentrator.

NOTE – There is no portion of the gas pathways through the concentrator

that could be contaminated with body uids under normal conditions.

The device patient connection may unintentionally become contaminated with

expired gases for a single fault condition i.e., a hose internal to the device

becomes disconnected. This condition will cause no ow out of the device and/or

an alarm condition. Should this occur, refer to the service manual section on

Troubleshooting.

Cleaning

Recommended

cleaning interval

Number of

cleaning cycles *

Compatible cleaning

method

Outer Cabinet 7 days 260 Water, use only a damp

cloth

Air Filter

Units manufactured

since October, 2020

do not have a gross

particle or cabinet air

lter. See note under

Air Filter on page 9.

7 days 104 Mild dish soap (2 tbsp)

and warm water (2

cups)

Oxygen Outlet

Connector

7 days 104 Mild dish soap (2 tbsp)

and warm water (2

cups)

Filter Door Vents 7 days 260 Wipe with dry cloth, or a

cloth dampened with

water to remove dust

* number of cleaning cycles determined by recommended cleaning interval and

expected service life

Disinfection

NOTE–The disinfection process can only be completed by the manufacturer

or by a qualied DeVilbiss provider/service technician.

Recommended

disinfection

interval

Number of

disinfection

cycles

Compatible

disinfection method

Cabinet parts, power cord Between patients 20 1:5 chlorine bleach

(5.25%) and water

solution, Mikrobac

forte, Terralin Protect

Oxygen tubing, tubing

connectors, nasal cannula/

mask, oxygen outlet

connector, humidier bottle,

cabinet air lter

Do not clean,

replace between

patients

N/A N/A

Optional - Inside cabinet Between patients N/A Remove dust with a

vacuum cleaner

RETURN AND DISPOSAL

This device may not be disposed of with household waste. After use of the

device, please return the device to the provider for disposal. This device contains

electrical and/or electronic components that must be recycled per EU Directive

2012/19/EU-Waste Electrical and Electronic Equipment (WEEE). Non-infectious

used accessories (e.g. nasal cannula) can be disposed of as residential waste.

The disposal of infectious accessories (e.g. nasal cannula from an infected user)

must be made via an approved waste disposal company. Names and addresses

can be obtained from the local municipality.

PREVENTATIVE MAINTENANCE SUMMARY

Patient / Caregiver

Clean and replace oxygen tubing, cannula / mask, and humidier bottle (if used)

according to manufacturer’s instructions.

Homecare Provider

During each inspection

• Wash/Replace cabinet lter if applicable.

• Check audible alert and indicator lights.

• Clean lter door vents if applicable.

During each PM check – not to exceed 3 years for the 525 series

• Inspect/Replace intake bacteria lter as necessary.

• Check oxygen purity.

During compressor service

• Inspect/ Replace nal bacteria lter.

• Inspect/ Replace the compressor lter

NOTE– There is no portion of the gas pathways through the concentrator that

could be contaminated with body uids under normal conditions.

The device patient connection may unintentionally become contaminated with

expired gases if a hose internal to the device becomes disconnected. This

condition will cause no ow out of the device and/or an alarm condition. Should

this occur, remove the front cabinet in order to determine where the

disconnection occurred.

Replace all components from the free end of the disconnect through the outlet

port. Reference the pneumatic diagram and replacement part numbers/

instructions.

SYSTEM OPERATION

The DeVilbiss Oxygen Concentrator uses a pressure swing adsorption system.

The air is drawn into the unit through air lters and into a double-head

compressor.

A pneumatic diagram of the system is shown on page 48.

The compressed air passes through a rotary valve, which is cycled at a pre-

determined rate, and is directed into one of two sieve beds. The sieve beds

contain molecular sieve material which is a synthetically-produced inorganic

silicate. It is very porous and has the unique ability to selectively adsorb nitrogen

from the air as it passes through the sieve bed.

As one bed is being pressurized, the other bed is quickly depressurized. This

allows the nitrogen that was adsorbed during its pressurization cycle to be

exhausted from the sieve material.

The nitrogen is released through exhaust ports located on the rotary valve

assembly. The ports are connected to a single piece of hose running from the

valve to the exhaust mufer.

Also during each bed pressurization, a small amount of oxygen ows through an

orice from the pressurized bed into the depressurizing bed. This helps purge the

nitrogen from the depressurizing bed.

The beds will continue to be alternately pressurized and depressurized as the

unit operates.

Oxygen leaving the sieve beds is directed through a check valve to the

accumulator tank. A pressure regulator on the tank controls the oxygen pressure

as it leaves the accumulator and enters the ow meter. The ow meter allows the

oxygen ow to be controlled and adjusted to the level prescribed by the patient’s

physician. From the ow meter the oxygen passes through the nal bacteria lter

and nally the oxygen outlet port to the patient.

LT-2023

12

MAINTENANCE

The DeVilbiss Oxygen Concentrator operates on a timed cycle (3.6 sec. @

5LPM) that is controlled by the PC board. The PC board will send voltage to the

valve causing it to shift and alternately pressurize the sieve beds.

The PC board also activates the electronic alert system. Low ow, system

abnormality, and power failure are indicated by audible and visible alerts. A high

pressure condition will be indicated with a “popping” type sound produced by

release of pressure from a pressure relief valve on the compressor head.

The 525 operating system incorporates “turn-down” technology. The PC board

constantly monitors the ow rate and will decrease the cycle time whenever the

ow rate is less than 1.2 LPM. Therefore it “turns-down” the cycle based on lower

oxygen demand. As a result, the unit runs cooler and less power is consumed.

NORMAL OPERATING SEQUENCE

When the concentrator is turned “On,” the following cycling sequence can be

observed by attaching a pressure gauge to the manifold or accumulator tank test

point.

1. The rotary valve is quickly cycled several times to relieve residual bed

pressure preventing a static condition in the compressor. This rapid cycling

only happens on start-up and is clearly heard as pressure is being quickly

exhausted several times. The pressure exhausts through an exhaust

mufer that is connected to the valve.

2. The PC board applies a short DC voltage signal to the valve. The valve will

stop for several seconds causing the right bed to pressurize rst while the

left bed depressurizes.

3. Voltage is again applied to the valve for a short time. The valve will stop for

approximately a second. During this time the sieve bed pressures are

equalized.

4. A short DC voltage signal is again applied to the valve. The valve will stop

for several seconds causing the left bed to pressurize while the right bed

depressurizes.

5. A short DC voltage signal is again applied to the valve. The valve will stop

for approximately a second. During this time, the sieve bed pressures are

equalized.

6. The cycle then repeats with step 2.

NOTE–In the “turn-down” mode, the xed cycle time is decreased to less

than 2 seconds.

LOW PRESSURE SYSTEM

Changes were made to the 525 series that reduced the internal system pressure

approximately 4 to 5 psi. These changes were implemented in production for all

525 models starting in December, 2019. The change to a lower pressure system

reduces internal temperatures and increases component life.

Starting serial numbers for units with the low pressure system:

• 525DS .............B19C060100DS

• 525DS-Q .........B201130001DQ

• 525KS .............B201020001KS

• 525KS-LT ........Not available at this time.

• 525PS .............B203040001PS

Changes include:

1. PC board was reprogrammed to shorten the cycle time from 3.6 to 2.9

seconds. The shorter cycle time results in lower accumulator tank

pressures as compared to previous units. Therefore it is important to

reference the accumulator tank pressure range chart when measuring tank

pressures. See revised pressure range chart below. Note that pressures

are slightly lower for units that have the low pressure system.

2. A new purge manifold is being used. Internal dimensional changes were

made for the low pressure system. The new manifold has a white top

making it easy to recognize.

3. An orice was added to the tubing connected to the auxiliary oxygen port

on all units having the lower pressure system.

The changes to the parts above require different part numbers. The part numbers

listed below are used only in low pressure system units. Always refer to the parts

list in this manual when ordering service parts.

• 525DD-638 PC board

• 525DD-618 Purge manifold w/white top

• 525DD-645 Auxiliary oxygen port tubing w/orice

NOTE – When servicing 525 models, low pressure system units can be

identied by serial number and manifold color.

TYPICAL PEAK ACCUMULATOR TANK PRESSURE RANGE @ 5LPM

Original System Low Pressure System

Altitude PSI kPa PSI kPa

0 to 457 m

0 to 1500 ft. 23-32 159-221 18-27 124-186

457 to 914 m

1500 to 3000 ft. 21-29 145-200 16-25 110-172

914 to 1524 m

3000 to 5000 ft. 20-27 138-186 13-24 90-165

There will be a pressure swing during each cycle.

• 4 – 5 psi on original system

• 3 – 4 psi on low pressure system

13

LT-2023

TROUBLESHOOTING

SIMPLIFIED TROUBLESHOOTING

The key to simple troubleshooting is to recognize which type of problem exists

and select the most effective approach to solving the problem. The different

types of problems and the approaches for solutions are as follows:

Type I—Purity Issues (Low Oxygen Indicator Light and/or

an audible alert is activated or the Pressure Relief Valve releases

pressure with a ‘popping’ sound).

WARNING

Electric Shock Hazard. Extra care should be taken if it is necessary

to operate the unit with the cabinet removed.

WARNING

Mechanical Hazard. Keep ngers, loose clothing, etc. away when

working on compressor.

Observe the pressure cycle at the oxygen tank.

1. Connect a calibrated pressure gauge to the unit’s oxygen tank test point or

manifold. See accumulator pressure test on page 18.

2. Set the unit’s ow meter to 5 LPM.

3. Power the unit and allow it to operate for a minimum of 5 minutes before

observing the pressure cycle.

4. Compare the high pressures and low pressures to those expected for the

current elevation and use the following chart to nd the appropriate action.

All consecutive high pressures should be within 2 psi of each other and all

consecutive low pressures should be within 2 psi of each other.

NOTE–For normal system pressures refer to Specications.

NOTE–Check for leaks using a certied leak detection solution such as

Snoop® or equivalent (must not contain ethylene glycol). Apply leak test solution

to all ttings and hose connections with unit running. If an air leak is present, the

solution will bubble. All leaks should be repaired before putting the unit back in

service.

CAUTION

Do not apply leak test solution to any part of the rotary valve or the

main PC Board assembly.

Pressure Diagnostic Chart

If Pressure Reading Is Do This To This

Higher than expected and/

or pressure relief valve

has a ‘popping’ noise

Replace Sieve beds (2)

Lower than expected

Inspect and replace, as

needed Filters

Inspect and correct or replace,

as needed Tubing connections

Troubleshoot

Compressor

See Component Testing,

Repair and Replacement

As expected Inspect and correct, as

needed

Leaks from sieve beds to

oxygen outlet port

Dropping too low during

cycle change Replace Check valves or manifold

Uneven - high pressures

& low pressures are not

consistent during cycle

Inspect and replace, as

needed Rotary valve wire harness

Troubleshoot or replace

Rotary valve or PC board.

See Component Testing,

Repair and Replacement

Type II—Operation Issues (Service Indicator Light and/

or an audible alert is activated or the Pressure Relief Valve releases

pressure with a ‘popping’ sound)

WARNING

Electric Shock Hazard. Extra care should be taken if it is necessary

to operate the unit with the cabinet removed.

WARNING

Mechanical Hazard. Keep ngers, loose clothing, etc. away when

working on compressor.

NOTE–Check for leaks using a certied leak detection solution such as

Snoop® or equivalent (must not contain ethylene glycol). Apply leak test solution

to all ttings and hose connections with unit running. If an air leak is present, the

solution will bubble. All leaks should be repaired before putting the unit back in

service.

CAUTION

Do not apply leak test solution to any part of the rotary valve or the

main PC Board assembly.

Operation Alarm Chart

If this is happening It’s because of this Do this to resolve

Pressure relief valve has a

‘popping’ noise with

possible uneven tank

pressure.

Rotary valve not cycling

properly.

Test rotary valve. Refer to page

25.

Defective sieve beds. Replace sieve beds.

Continuous red light with a

pulsing audible alert while

compressor is operating.

Low ow alert – ow setting

below 0.5 lpm.

Correct setting and educate

user and / or install low ow

meter if prescription is below 1

lpm. See section on the ow

meter.

Continuous red light with a

continuous audible alert

and unit is warm to touch.

Internal temperature is too

high.

Move unit to cooler location.

Ensure unit vents are clear.

Ensure unit lters are clean.

Ensure cooling fan is operating,

replace as needed.

Ensure there is proper voltage

to the unit. If voltage is correct,

replace capacitor or

compressor.

Continuous red light with a

pulsing audible alert and

fan is operating but

compressor is not.

Internal power failure to

compressor.

Test voltage at compressor

connector. If no voltage,

replace main wire harness. If

voltage present, replace

capacitor or compressor.

Blinking red light with a

pulsing audible alert and

compressor and fan not

operating.

NOTE–Serial

numbers starting with B

will have audible only.

External OR Internal power

failure.

Ensure voltage is correct and /

or the part is functional for the

following: AC outlet, power

cord, IEC connector or cord

connection, main wire harness,

circuit breaker; correct as

needed. If issue persists,

replace power switch.

Blinking red light with a

pulsing audible alert and

compressor and fan are

operating. Pressure relief

valve has a ‘popping’

noise.

Internal power failure at

valve wire harness or PC

board.

Inspect wire harness and

replace as needed.

Inspect fuse, if blown, replace

PC board. NOTE–Serial

numbers starting with B,

replace PC board.

Type III—The concentrator runs and continues

to cycle but has low oxygen concentrations and

no alarms are activated.

This problem is similar to Type I in the way it is diagnosed/resolved. Observe

pressure cycle at oxygen tank as recommended in Type I.

LT-2023

14

TROUBLESHOOTING

OTHER SYMPTOMS POSSIBLE CAUSE POSSIBLE REMEDY

Pulsating air noise Intake filter not in place or defective Check filter and replace if necessary

Compressor intake hose disconnected Reconnect hose

Excessive noise Loose or defective motor mounts Replace motor mounts

Defective compressor Replace compressor

Defective cooling fan Replace cooling fan

Fluctuating oxygen ow Occluded humidier Clean or replace humidier

Use of improper humidier Use only a bubble-type humidier

Occluded filters Clean or replace filters

Occluded or defective cannula and tubing Detach cannula from oxygen delivery tubing. If proper flow is not

attained, check tubing for kinks or other obstructions. Clean or straighten

as required or replace tubing if necessary

Use of excess oxygen tubing The unit is designed to deliver 5 lpm with a cannula on 50 feet (15

meters) of approximately 5/32” (4 mm) inside diameter tubing. Smaller

diameter tubing or the addition of any other ow restriction may prevent

obtaining the desired ow rate.

Defective ow meter Replace ow meter

Leak in system Check for leaks in all hoses and ttings

Defective compressor Replace compressor

Defective compressor reed valve Replace compressor reed valve

Defective check valve Replace check valve or manifold

Pressure regulator not adjusted properly or defective Adjust or replace pressure regulator

Little or no oxygen ow Flow meter not adjusted properly Adjust ow meter

Hose disconnected to ow meter Reconnect hose

Oxygen delivery tubing is kinked or blocked Straighten tubing or remove obstruction

Occluded humidier Clean or replace humidier

Low oxygen concentration Leak in system Check for leaks in all hoses and ttings

Defective sieve bed check valve Replace check valve or manifold

Defective compressor reed valve Replace compressor reed valve

Defective compressor Replace compressor

Rotary valve not operating correctly Replace valve

Occluded lters Clean or replace lters

Contaminated sieve beds Replace sieve beds

Audible alarm does not sound during power

failure

Unit has not been used for an extended period of time.

NOTE– If the concentrator has been unused for an

extended period, the unit must run several minutes before

the power fail alarm will activate.

Allow unit to run for 20 minutes and retry

Defective PC board Replace PC board

Defective power switch Replace power switch

Defective wire harness Replace wire harness

Audible alarm does not sound when unit is

turned “On”

Defective PC board Replace PC board

Pressure relief valve activated – “popping”

sound

PC board connectors not properly latched Be sure tabs are pushed completely into place

Defective PC board Replace PC board

Defective rotary valve Replace valve

Service Required light does not illuminate when

unit is turned “On”

PC board connectors not properly latched Be sure tabs are pushed completely into place

Defective PC board Replace PC board

Defective light panel Replace light panel (N/A for serial numbers starting with B)

Visible Alarm Audible Alarm Compressor

OFF OFF ON

TROUBLESHOOTING CHART A

15

LT-2023

TROUBLESHOOTING

TROUBLESHOOTING CHART B

Visible Alarm Audible Alarm Compressor

BLINKING PULSING OFF

OTHER SYMPTOMS POSSIBLE CAUSE POSSIBLE REMEDY

Fan off Line cord not properly installed or defective Insert plug in receptacle or replace line cord. On 220/230/240

Volt units, check that the IEC connector on the back of the unit is

attached.

No power at receptacle Check building circuit breaker or fuse, or have house wiring

checked by qualified electrician Circuit may be fully loaded with

other appliances and another receptacle may be required.

Oxygen concentrator circuit breaker activated Press the circuit breaker reset button. If unit circuit breaker opens again,

check internal wiring.

Line cord quick-connect terminal inside unit is

disconnected Reconnect quick-connect terminal

Defective power switch Replace power switch

Defective circuit breaker Replace circuit breaker

TROUBLESHOOTING CHART C

Visible Alarm Audible Alarm Compressor

BLINKING PULSING ON

OTHER SYMPTOMS POSSIBLE CAUSE POSSIBLE REMEDY

Fan and compressor operating

Pressure relief valve activated – “popping”

sound

Connector on PC board not connected Connect connector

Blown fuse on PC board Replace PC board (N/A for serial numbers starting with B)

Defective PC board Replace PC board

Defective valve or valve wire harness. Replace valve or valve wire harness

TROUBLESHOOTING CHART D

Visible Alarm Audible Alarm Compressor

ON ON OFF

OTHER SYMPTOMS POSSIBLE CAUSE POSSIBLE REMEDY

Fan operating Main wiring harness disconnected/defective Reconnect/replace wiring harness

Loose compressor wire Tighten or attach wire

Defective capacitor Replace capacitor

Defective compressor Replace compressor

Unit warm to the touch and cannot be

restarted for several minutes

Compressor overheated due to:

1. Occluded lters 1. Clean or replace lters

2. Restricted input or output air passage 2. Remove obstruction

3. Low or high line voltage 3. Check line voltage; use alternate circuit independent of other

appliances

Defective cooling fan Replace cooling fan

Defective compressor Replace compressor

LT-2023

16

TROUBLESHOOTING

TROUBLESHOOTING CHART E

Visible Alarm Audible Alarm Compressor

ON ON ON

OTHER SYMPTOMS POSSIBLE CAUSE POSSIBLE REMEDY

Fluctuating or no ow System pressure below 9 psi (62.1 kPa) due to:

1. Leak in system 1. Check for leaks in all hoses and ttings

2. Defective compressor 2. Replace compressor

TROUBLESHOOTING CHART F

Visible Alarm Audible Alarm Compressor

SEE BELOW SEE BELOW ON

OTHER SYMPTOMS POSSIBLE CAUSE POSSIBLE REMEDY

No OSD lights are illuminated. Defective OSD. Check concentration with an oxygen analyzer. If the concentration is

within specification, replace the PC board.

Red “Service Required” light is illuminated

accompanied by a beeping audible alarm

Oxygen level is low* Check concentration with an oxygen analyzer. If the concentration is

within specication, replace the PC board. If the concentration is low,

refer to low oxygen concentration symptom in Troubleshooting Chart A.

Defective OSD (for serial numbers starting with

B)

Replace PC board.

Yellow Low Oxygen Light and the Red

Service Required Light are illuminated

accompanied by a beeping audible alarm.

Defective OSD Replace PC board.

Oxygen level is low* (for serial numbers starting

with B)

Check concentration with an oxygen analyzer. If the concentration is

within specication, replace the PC Board. If the concentration is

low, refer to low oxygen concentration symptom in Troubleshooting

Chart A.

Yellow Low Oxygen light is illuminated. Oxygen level is low* Check concentration with an oxygen analyzer. If the concentration is

within specication, replace the PC board. If the concentration is low,

refer to low oxygen concentration symptom in Troubleshooting Chart A.

Yellow Low Oxygen light is illuminated and

an intermittent audible alarm sounds every

few seconds.

Oxygen level is low* Check concentration with an oxygen analyzer. If the concentration is

within specication, replace the PC board. If the concentration is low,

refer to low oxygen concentration symptom in Troubleshooting Chart A.

*Refer to Alerts page for oxygen purity levels.

NOTE–If unit does not run or perform to specication, verify the proper AC input voltage and frequency are being used.

17

LT-2023

COMPONENT TESTING, REPAIR AND REPLACEMENT

PROPER REPAIR PROCEDURES

WARNING

When servicing the DeVilbiss Oxygen Concentrator, be absolutely

certain that the correct tools are used and that the parts are free of

oil and grease or any material not compatible with oxygen. Teon®

tape is recommended and must be applied to the male threads

omitting the rst thread to eliminate the possibility of tape particles

entering the oxygen system.

Electric shock hazard. Do not remove cabinet. The cabinet should

only be removed by a qualied DeVilbiss homecare provider.

Disconnect the power cord from the wall outlet before attempting

repairs on the unit. Extra care should be taken if it is necessary to

operate the unit with the cabinet removed.

NOTE–Be sure to read all of the steps involved before beginning any of the

procedures in this manual.

NOTE–After repairing or replacing a component, run the unit for 20 minutes,

check the oxygen concentration and test for leaks.

The DeVilbiss Oxygen Concentrator is designed for ease of service. To aid

service personnel a Service Kit (part #444-501) is available which contains the

necessary gauges, tools, and testing instruments to properly service the oxygen

concentrator. See list below.

In addition, you will also need an oxygen analyzer (part #R217P62) to

periodically check oxygen concentration levels and leak test solution.

WARNING

A certied leak detection solution, such as SWAGELOK #MS-Snoop®

or equivalent, is needed to test for system leaks. The solution must

not contain ethylene glycol.

CAUTION

Do not apply leak test solution to any part of the rotary valve or the

main PC Board assembly.

NOTE–Apply leak test solution to all ttings and hose connections with the

unit running. If an air leak is present, the solution will bubble. All leaks should be

repaired before putting the concentrator back in service.

The following parts are included in the Service Kit:

1Slotted bit

1#1 Phillips bit

1#2 Phillips bit

1Crescent wrench

18” Duckbill pliers

1 Voltmeter

2Pressure/Vacuum gauge

1Tool box

2Test ttings

1Torx screwdriver w/bits

1Channel Lock pliers

11/4” Ratchet wrench

110mm Socket 1/4 Drive

11/4” Drive extension

1Plastic storage case

CABINET REMOVAL

For units with Serial Numbers starting with B,

J, N or R

To remove back cabinet:

The majority of all the servicing and repairs can be done without removing the

front cabinet completely. However, it may be loosened or removed to gain access

to the components behind it.

1. Unplug the unit from the wall outlet.

2. Remove the six screws that secure the back cabinet – 2 behind handle, 2

near the bottom, and 1 on each side.

NOTE–All six screws are the same size.

3. Remove the back cabinet by sliding it toward the rear until clear.

4. To reassemble, reverse steps 2-3.

To loosen the front cabinet:

5. Remove the two screws (located directly above the hour meter) that hold

the front cabinet to the unit’s internal structure.

6. Remove the screw located near the bottom of the recessed humidier

compartment on the front of the unit. The top of the front cabinet can now

be tilted forward to allow access to the components behind it.

To remove the front cabinet completely:

7. Tilt cabinet forward and disconnect the ribbon connector from the PC

board. Units with serial numbers starting with B do not have a ribbon

connector.

8. Before disconnecting the wires from the power switch and circuit breaker

note their positions in order to reconnect them properly; then disconnect

the wires.

9. Disconnect the hose at the bottom of the ow meter and remove cabinet.

10. To reassemble reverse steps 5 – 9 making sure bottom of cabinet is

inserted securely in base of unit.

NOTE–Two types of cabinet screws have been used in the 525 models

during the past several years, thread-forming screws and machine screws. Take

care not to overtighten the thread-forming screws; they should be torqued to 18 –

20 in-lbs. The machine screws have much ner threads and are used in

conjunction with brass inserts that are molded into the cabinet part; they should

be torqued to 20 – 25 in-lbs.

When replacing a cabinet part such as the front cover, base or compressor box

be sure to use the correct screw. The ne threaded machine screws should

always be used if there is a brass insert. Thread-forming screws should be used

if there is no brass insert molded into the cabinet part.

These screws are not interchangeable, so be sure to order the correct part

number. See gure below.

Thread-forming

Cabinet Screw

(525DD-636)

Machine Cabinet

Screw (525DD-628)

For units with Serial Numbers starting with F

To remove front and back cabinets:

1. Ensure the unit is unplugged from the wall outlet.

2. Remove the six screws that secure the back cabinet – 2 behind handle, 2

near the bottom, and 1 on each side.

NOTE–All six screws are the same size.

3. Remove the back cabinet by sliding it toward the rear until clear.