3

English

Definitions: Safety Guidelines

The definitions below describe the level of severity

for each signal word. Please read the manual and pay attention

to these symbols.

DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury.

CAUTION: Used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may result

in property damage.

Important Safety Instructions

SAVE THESE INSTRUCTIONS – This manual contains important

instructions for models DW650LAG, DW90LAG, DW13LAG that

should be followed during installation and maintenance of the

engine.

DANGER: Carbon Monoxide. Using an engine indoors will

kill you in minutes. Engine exhaust contains high levels of

carbon monoxide (CO), a poisonous gas you cannot see or

smell. You may be breathing CO even if you DO NOT smell

engine exhaust.

• NEVER use an engine inside homes, garages, crawlspaces, or

other partly enclosed areas. Deadly levels of carbon monoxide

can build up in these areas. Using a fan or opening windows and

doors does NOT supply enough fresh air.

• ONLY use outdoors and far away from open windows, doors

and vents. These openings can pull in engine exhaust.

• Even when the engine is used correctly, CO may leak into your

home. ALWAYS use a battery-powered or battery backup CO

alarm (not supplied) in the home. Read and follow all direc-

tions for CO alarm before using. If you start to feel sick,

dizzy or weak at anytime, move to fresh air immediately. See a

doctor. You could have carbon monoxide poisoning.

WARNING: Do not operate this unit until you read and understand

this instruction manual and the tool instruction manual for safety,

operation and maintenance instructions.

SAVE THESE INSTRUCTIONS

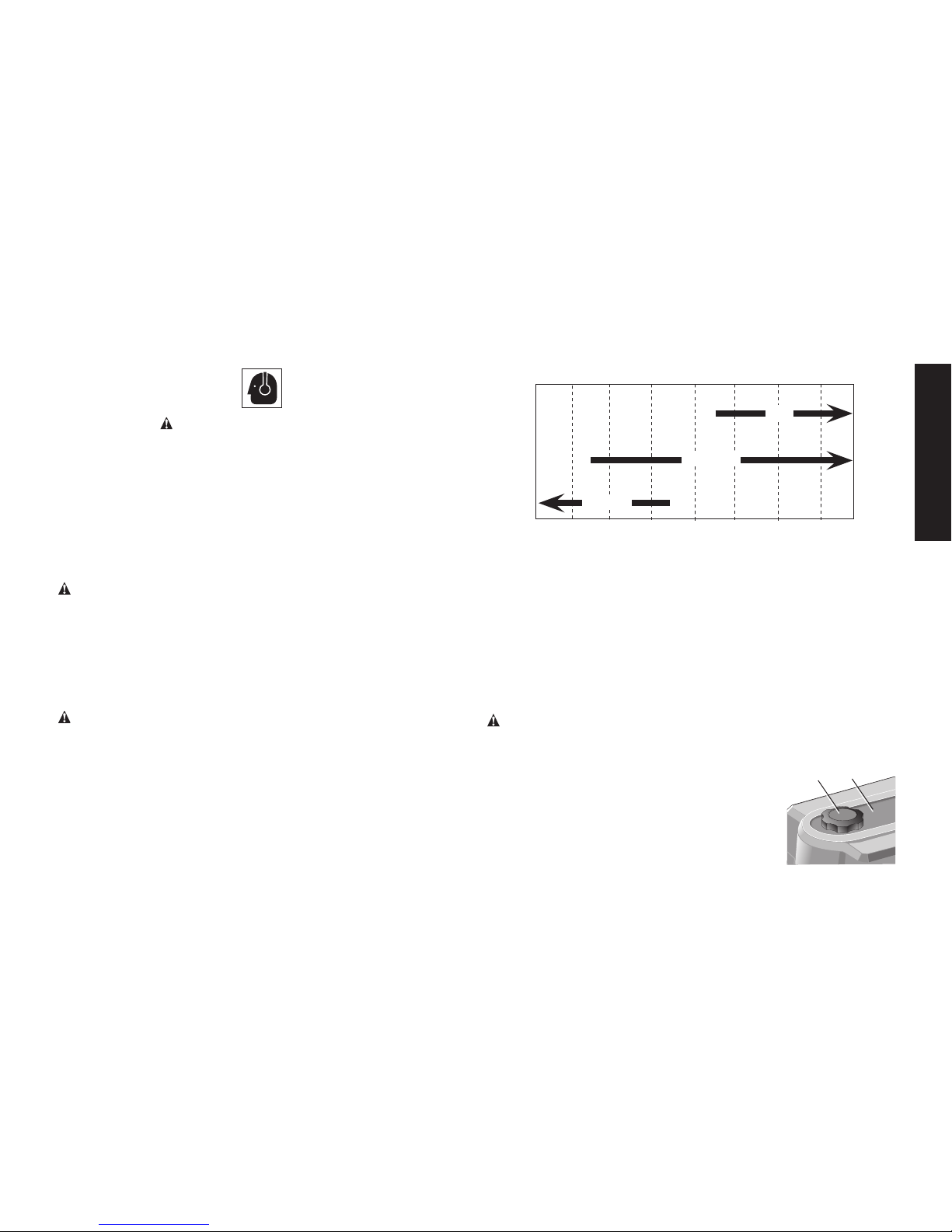

DANGER: RISK OF EXPLOSION OR FIRE

WHAT CAN HAPPEN HOW TO PREVENT IT

• Spilledgasolineandit’s

vapors can become ignited

from sparks from smoking

products, electrical arcing,

exhaust, flame, gases and

hot engine components such

as the muffler.

• Shutoffengineandallowitto

cool before removing cap and

adding fuel to the tank.

• Usecareinfillingtanktoavoid

spilling fuel. Make sure the

cap is secure and move unit

away from fueling area before

starting engine.

• Heatwillexpandfuelinthe

tank which could result in

spillage and possible fire

explosion.

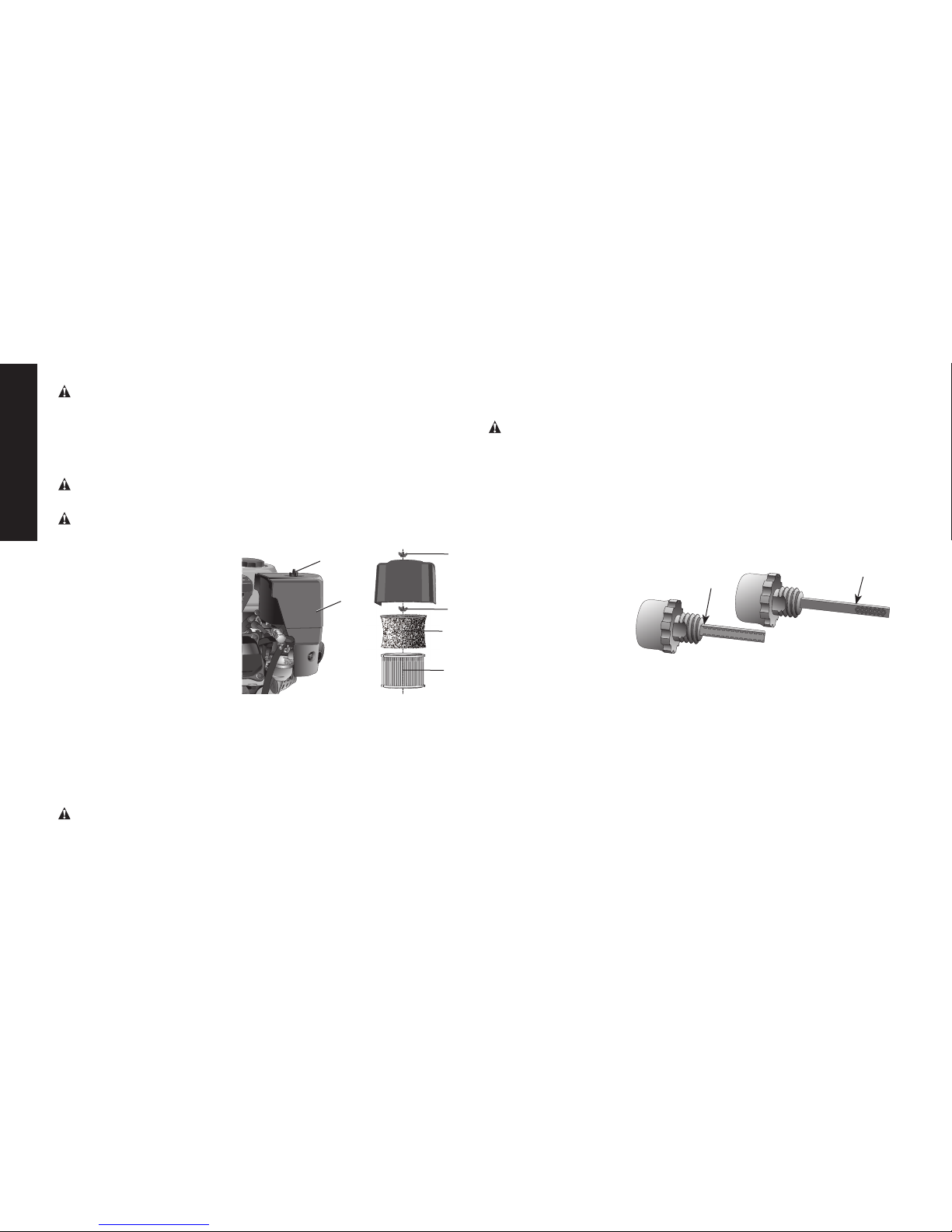

• Keepmaximumfuellevel

below the shoulders on the

debris screen

to allow for

expansion.