DEWESOFT VIBRO KIT V20-2 Product manual

VIBRO KIT

TECHNICAL REFERENCE MANUAL

VIBRO KIT V20-2

VIBRO KIT

TECHNICAL REFERENCE MANUAL

1 Table of contents

1 Table of contents 2

2 About this document 4

2.1 Legend 4

3 Technical data 5

3.1 Introduction 5

3.2 Scope of supply 5

3.3 Vibro-kit parts description 6

3.3.1 Encoders 6

3.3.2 Optical sensor below taped disk 7

3.3.3 Front panel 8

3.3.4 Back panel 9

3.3.5 Couplings 11

4 Possibilities of use 12

4.1 Super-counters 12

4.2 FFT analyzer 15

4.3 Order tracking 17

4.4 Balancing 18

4.5 Torsional vibration 20

5 Specifications HW v1.3 22

6 User interface FW v1.9 22

6.1 Manual mode 22

6.2 Ramp mode 23

6.3 Analog in mode 24

6.4 PWM in mode 24

7 Warranty information 25

7.1 Calibration 25

7.2 Support 25

7.3 Service/repair 25

7.4 Restricted Rights 25

7.5 Printing History 26

7.6 Copyright 26

7.7 Trademarks 26

8 Safety instructions 26

8.1 Safety symbols in the manual 26

8.2 General Safety Instructions 26

8.2.1 Environmental Considerations 27

8.2.2 Product End-of-Life Handling 27

8.2.3 System and Components Recycling 27

8.2.4 General safety and hazard warnings for all Dewesoft systems 27

VIBRO KIT V20-1 2/29

VIBRO KIT

TECHNICAL REFERENCE MANUAL

2 About this document

2.1 Legend

The following symbols and formats will be used throughout the document.

Important

It gives you important information about the subject.

Please read carefully!

Hint

It gives you a hint or provides additional information about a subject.

Example

Gives you an example of a specific subject.

VIBRO KIT V20-1 4/29

VIBRO KIT

TECHNICAL REFERENCE MANUAL

3 Technical data

3.1 Introduction

The new VIBRO-KIT is a compact tool for simulating rotating machinery measurements. It is meant for

demonstrations or educational purposes such as in a lab or university. It provides a playground for

almost unlimited experiments.

It's made of solid aluminum. It’s built of a small electric motor with a simple control panel, two bearings,

two optical strip-tape angle sensors, two encoders and two different couplings on each side. One is rigid

and the other is made of spring.

The RPM can be controlled manually by a turn knob, or you can completely define ramps, cycles, etc.

with the built-in display.

Furthermore, an external analog voltage (or even PWM signal) can be used to control the RPM.

Functionalities:

●Manual RPM control (turn knob, display)

●Definable ramps (runup, coast down, hold time and multiple cycles)

●RPM control by external voltage (e.g. step curve)

●External PWM input

●Different angle sensors (2 optical strip tape, 2 Encoders)

3.2 Scope of supply

Type

Quantity

Description

Vibro-kit

1

Vibro-kit unit

BNC-BNC

1

BNC to BNC connector cable of 1,2 m

L1B7m-BNC

2

7 pin LEMO to BNC connector cable of 0,6 m

BALANCING SCREWS

kit

Screws 10pcs M3x4, 10pcs M3x6, 10 pcs M3x8, 10pcs M3x10

Nuts 20pcs M3x2.3

** Power supply adapter is not included

VIBRO KIT V20-1 5/29

VIBRO KIT

TECHNICAL REFERENCE MANUAL

3.3 Vibro-kit parts description

3.3.1 Encoders

Using projection below the left side refers to the Tacho 1 output signal and right side refers to the Tacho

2 output signal.

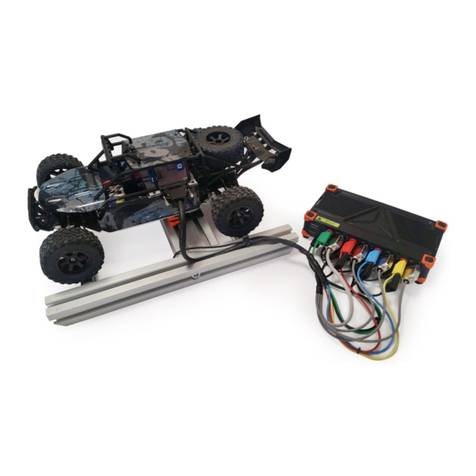

Image 1: Vibro-kit unit

Counter input connectors on cable

Pin

Name

Description

1

IN0/A

Output A

2

IN1/B

Output B

3

IN2/Z

Output Z

4

GND

Ground

5

+5V

5V supply

6

+12V

12V supply

7

GND

Ground

VIBRO KIT V20-1 6/29

VIBRO KIT

TECHNICAL REFERENCE MANUAL

3.3.2 Optical sensor below taped disk

Integrated optical sensor on the bottom side of the chassis for measuring signal of the striped tape on

the rotating disc which is affixed on the shaft of the motor.

Please see chapter 3.3.1. Encoders to define which sensor has Tacho 1 output and which has Tacho 2

output.

Image 2: Vibro-kit unit

VIBRO KIT V20-1 7/29

VIBRO KIT

TECHNICAL REFERENCE MANUAL

3.3.3 Front panel

Button on the top serves as a ON/OFF start button for the motor. The front knob serves as a navigation

knob for the Menu. Display shows general values and motor options when Vibro-kit is turned on.

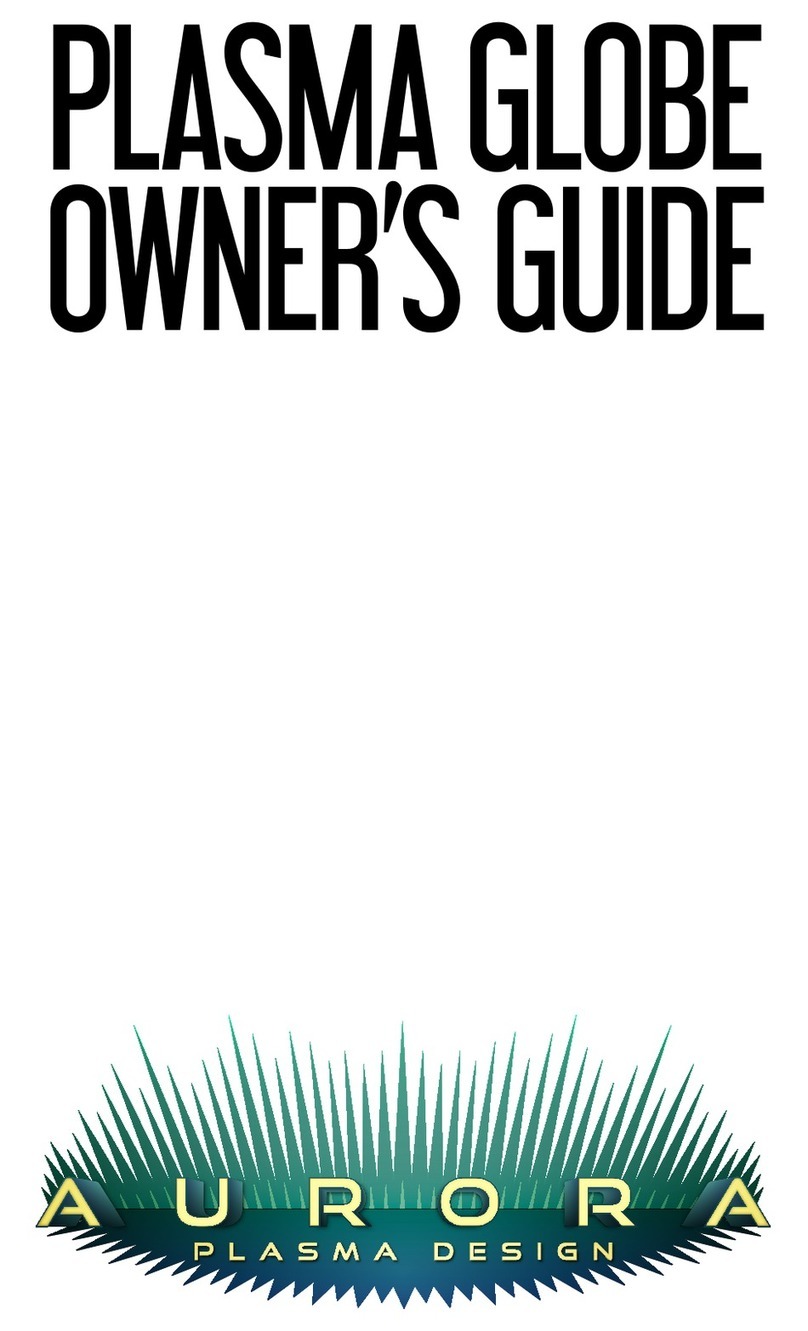

Image 3: Front panel of drive part

VIBRO KIT V20-1 8/29

VIBRO KIT

TECHNICAL REFERENCE MANUAL

3.3.4 Back panel

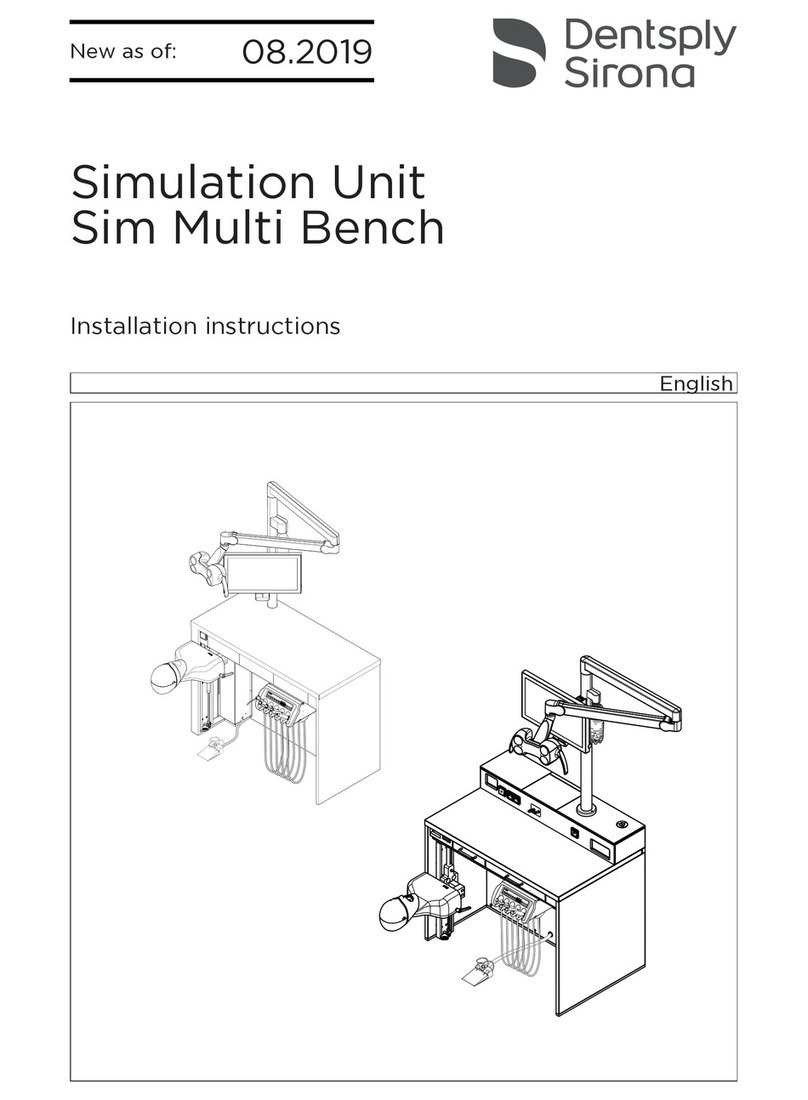

Image 4: Back panel of drive part

Power supply connector

Pin

Name

Description

1

V +

Power supply 12V...36V

2

V -

Ground

VIBRO KIT V20-1 9/29

VIBRO KIT

TECHNICAL REFERENCE MANUAL

Control IN connector

BNC female connector

Using an input signal if you want to control the

RPM of an internal motor with voltage signal.

Tacho 1 Out

BNC female connector

Measuring an output signal from an optical

sensor that is integrated below the rotating disk.

Tacho 2 Out

BNC female connector

Measuring an output signal from an optical

sensor that is integrated below the rotating disk.

VIBRO KIT V20-1 10/29

VIBRO KIT

TECHNICAL REFERENCE MANUAL

3.3.5 Couplings

The right encoder is connected to the spring coupling which damps high accelerations but may cause

an oscillation until the moving parts are equalized.

Black round plate has a white dotted strap on it which you can read with the tacho sensor.

Image 5: Flexible coupling on the right side

The left encoder is connected to the rigid coupling which eliminates any oscillations in regard to the

accelerating.

Image 6: Rigid coupling on the left side

VIBRO KIT V20-1 11/29

VIBRO KIT

TECHNICAL REFERENCE MANUAL

4 Possibilities of use

4.1 Super-counters

Additional equipment: SIRIUS with at least one CNT module (ACC+, …).

DewesoftX’s super-counters work on a 102.4 MHz internal time base, always, independent of the current

sample rate. In comparison to standard counters, which only output whole numbers like 1,1,2,2,3,4, … one

sample later, DewesoftX ® is able to extract the accurate values like 1.37, 1.87, 2.37, … fully time- and

amplitude-synchronized. This is done by measuring the exact time of the rising edge of the signal with

an additional counter.

Image 7: Super-counter

Frequency/super-counter mode has many advantages over traditional counter measurements.

The problem with traditional counters is that the value of the counter is latched only at a sample rate

interval. Therefore, we only have discrete values on each sample. Since the counters can measure exactly

where the position of the pulse is between two samples, we can calculate two things out of this: the

exact interpolated position of the counter at the sample point, as well as the exact frequency of the

pulses.

We connect the encoder to the CNT module. In DewesoftX ® software, we add the Counters.

VIBRO KIT V20-1 12/29

VIBRO KIT

TECHNICAL REFERENCE MANUAL

Image 8: Counters

In the Counter menu, you will see all the available counter channels. Enter the setup of the channel

where your encoder is connected.

Change the Basic application to the Sensor and choose the correct sensor from the dropdown list. If

your sensor is not on the list, you can add it in the counter sensor editor.

Select the output channels that you want to show (angle, frequency, raw count).

VIBRO KIT V20-1 13/29

VIBRO KIT

TECHNICAL REFERENCE MANUAL

Image 9: Counter menu

Enter the Measure mode and add a recorder visual control. Display the Angle and Raw count on the

same recorder. When the Vibro Kit is running, press Freeze and zoom into the signal. You can see how

DewesoftX ® interpolates the angle values and is not updated only when a new pulse comes from the

angle sensor. The raw count value is increased every time a new pulse comes from the sensor.

VIBRO KIT V20-1 14/29

VIBRO KIT

TECHNICAL REFERENCE MANUAL

Image 10: Signals on recorder

For more detailed explanation of the parameters, please visit:

https://training.dewesoft.com/online/course/digital-counters

4.2 FFT analyzer

Additional needed equipment: SIRIUS with one ACC, accelerometer.

Glue the accelerometer on the Vibro Kit. Connect the accelerometer to the SIRIUS ACC module, and

enter the channel setup. Select the IEPE mode – if the sensor has a TEDS chip, the sensitivity will be

recognized. Otherwise, enter the setup and change the sensitivity of the sensor manually.

Image 11: Channel setup

Add the FFT analyzer math module (with the click on the plus button More). Select the input channel

(accelerometer) and set up the math.

VIBRO KIT V20-1 15/29

VIBRO KIT

TECHNICAL REFERENCE MANUAL

Image 12: FFT analyser settings

Enter the measure mode and add the FFT channel on a 2D graph. Run the machine and observe the

FFT.

Image 13: FFT math on 2D graph

VIBRO KIT V20-1 16/29

VIBRO KIT

TECHNICAL REFERENCE MANUAL

On the FFT graph, you can show the markers and how FFT behaves with different parameters in the

setup. For an explanation of all the parameter visit:

https://training.dewesoft.com/online/course/fft-spectral-analysis

4.3 Order tracking

Additional needed equipment: SIRIUS with one ACC and one CNT module, accelerometer.

Glue the accelerometer on the Vibro Kit and connect it to the ACC module. Connect encoder to the CNT

module. Open channel setup and set the acceleration sensor to IEPE mode and enter the correct

sensitivity. Add an Order tracking module.

Image 14: Order tracking settings

Select the vibration and the frequency input channel. Detailed description of all the parameters can be

found here: https://training.dewesoft.com/online/course/order-tracking

Enter the measure mode, and run the machine slowly from 0 RPM to 3000 RPM.

VIBRO KIT V20-1 17/29

VIBRO KIT

TECHNICAL REFERENCE MANUAL

The order tracking module creates a display with two 3D graphs to show order and FFT waterfalls, two

2D graphs to show the order harmonics and phase of the harmonics and a digital meter to monitor the

RPMs of the machine.

Image 15: Order tracking screen

4.4 Balancing

Additional needed equipment: SIRIUS with one ACC (single plane balancing) or two ACC modules (dual

plane balancing), accelerometer (single plane balancing) or two accelerometers (dual plane balancing),

additional screws for balancing the rotor.

Select the input channel (vibration) and define the frequency source (counters, analog sensor, RPM

channel). Balancing procedures should be done at constant RPMs.

VIBRO KIT V20-1 18/29

VIBRO KIT

TECHNICAL REFERENCE MANUAL

Image 16: Balancing settings

Balancing is a step-by-step procedure. First, you need to perform the initial run, to get the initial

unbalance vector. After that, you attach a trial weight, perform a trial run to get another unbalance

vector. From those two unbalanced vectors, we calculate the correction mass that has to be added and

the angle at which this should be added. You can perform as many steps as you wish.

Image 17: Rotor balancer screen

For more detailed explanation of balancing parameters and settings, please visit:

https://training.dewesoft.com/online/course/balancing

VIBRO KIT V20-1 19/29

VIBRO KIT

TECHNICAL REFERENCE MANUAL

4.5 Torsional vibration

Additional needed equipment: SIRIUS with 2 CNT modules and accelerometer.

Connect two angle sensors to SIRIUS. Add a torsional vibration module. Select the first (reference) and

second angle sensor input and assign sensors to the counter channels.

Select the wanted output channel from the module. Detailed description of the parameters and setting

can be found here: https://training.dewesoft.com/online/course/rotational-and-torsional-vibration

Image 18: Torsional vibration settings

Enter the measure mode. The plugin creates a new display with 2 XY recorders for displaying the

rotational angles and torsional angle against the reference angle sensor.

On the time recorder, you can see the behavior of the rotational angle and observe how the vibrations

change with the RPM.

VIBRO KIT V20-1 20/29

Table of contents

Other DEWESOFT Science Education Product manuals