DC-CT

TECHNICAL REFERENCE MANUAL

1. About this document

This is the Technical Reference Manual for DC-CT Sensors Version V23-1

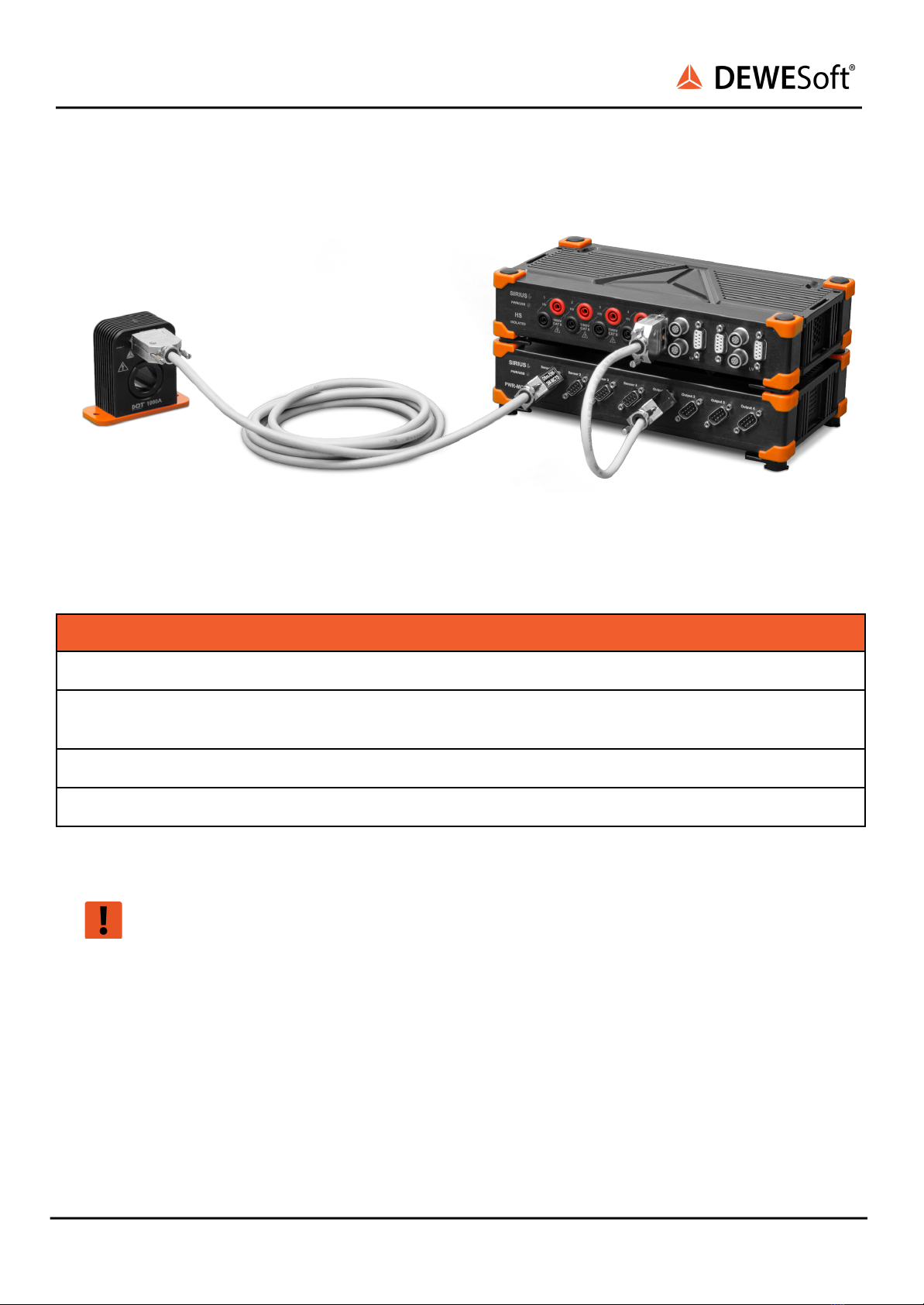

DC-CT is a high-performance, low-power consumption current transducer, specially designed in a

smaller housing than usual for easier mounting in E-mobility applications where enough space is usually

an issue. Together with our measurement devices and power supply, it represents a high-speed,

accurate and precise solution for current measurements of your choice.

The manual is divided into several chapters. You will find:

●A detailed description of the DC-CT current transducers

●A detailed description of the DC-CT accessories

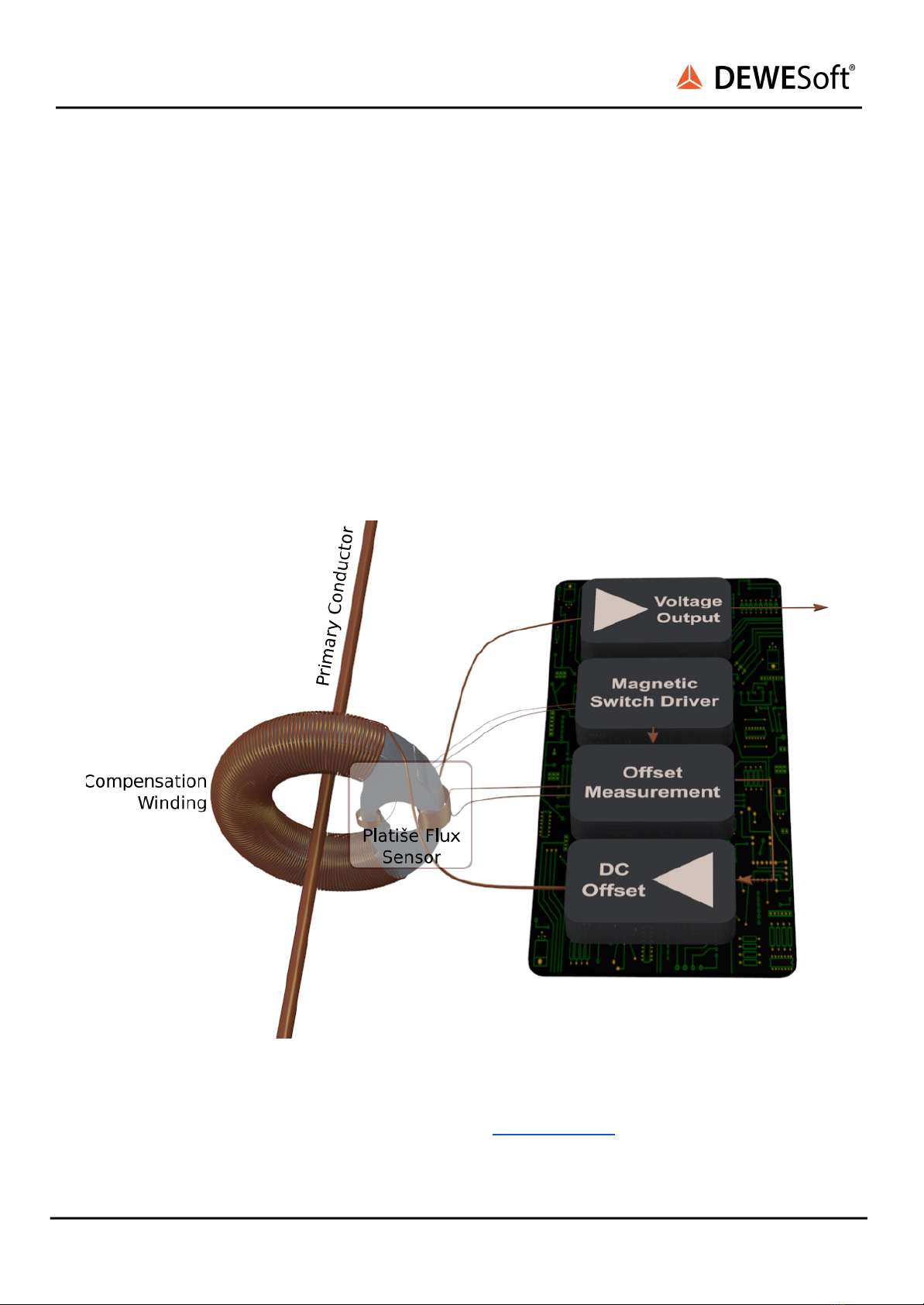

●A description of the patented technology used for measurement

●A comprehensive introduction to the configuration of the modules using DewesoftX®

●Detailed technical data and electrical characteristics

1.1. Legend

The following symbols and formats will be used throughout the document.

Important

It gives you important information about the subject.

Please read carefully!

Hint

It gives you a hint or provides additional information about a subject.

Example

Gives you an example of a specific subject.

1.2. Online versions

1.2.1. Device Technical Reference Manual

The most recent version of this manual can be downloaded from our homepage:

https://dewesoft.com/download/manuals

In the Hardware Manuals section click the download link for the Device® technical reference manual.

1.2.2. DEWESoft® User Manual

The DEWESoft® User Manual document provides basics and additional information and examples for

working with DEWESoft® and certain parts of the program.

The latest version of the DEWESoft® tutorials can be found here:

https://dewesoft.com/download/manuals

In the Software Manuals section click the download link of the DEWESoft X User Manual entry.