DeWils Industries, Inc.- July, 2008

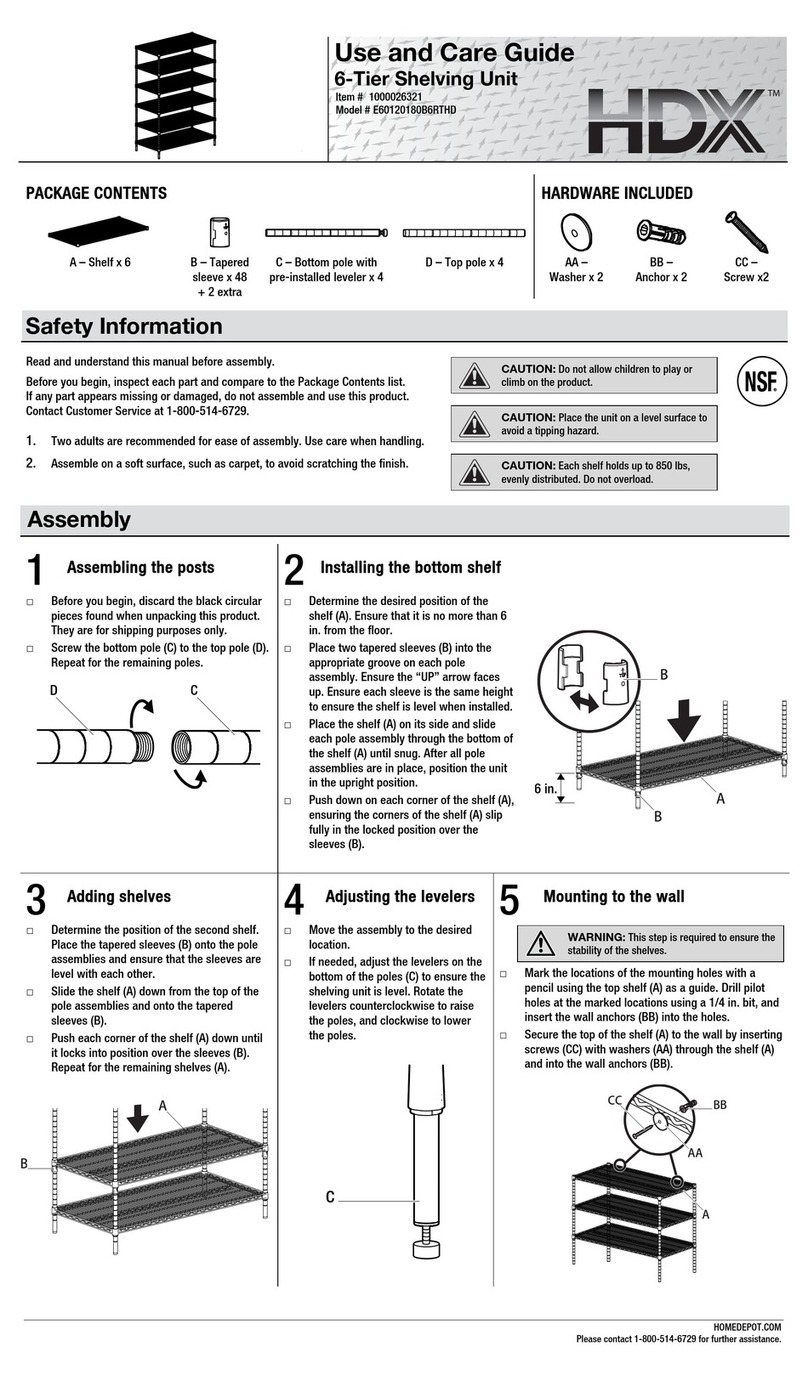

The first step in the cabinetry installation process is to prepare both yourself and the

work areas for the new cabinets. Begin by familiarizing yourself with the kitchen

drawings. Make sure you know where each cabinet will be placed in your new

kitchen and check them against your list to ensure you have each item. If you are

remodeling your kitchen, prepare the work space by removing all existing

appliances, cabinets, sinks, and anything else which may be attached to the walls or

floor. Be sure to turn off the water and electricity before removing the sinks and

appliances. If you are planning on replacing the flooring, electrical or plumbing, or

repairing and painting the walls, this work will be much easier if it is done prior to

the cabinet installation. It is also important to protect the new floor with tarps or

cardboard during installation of the cabinetry.

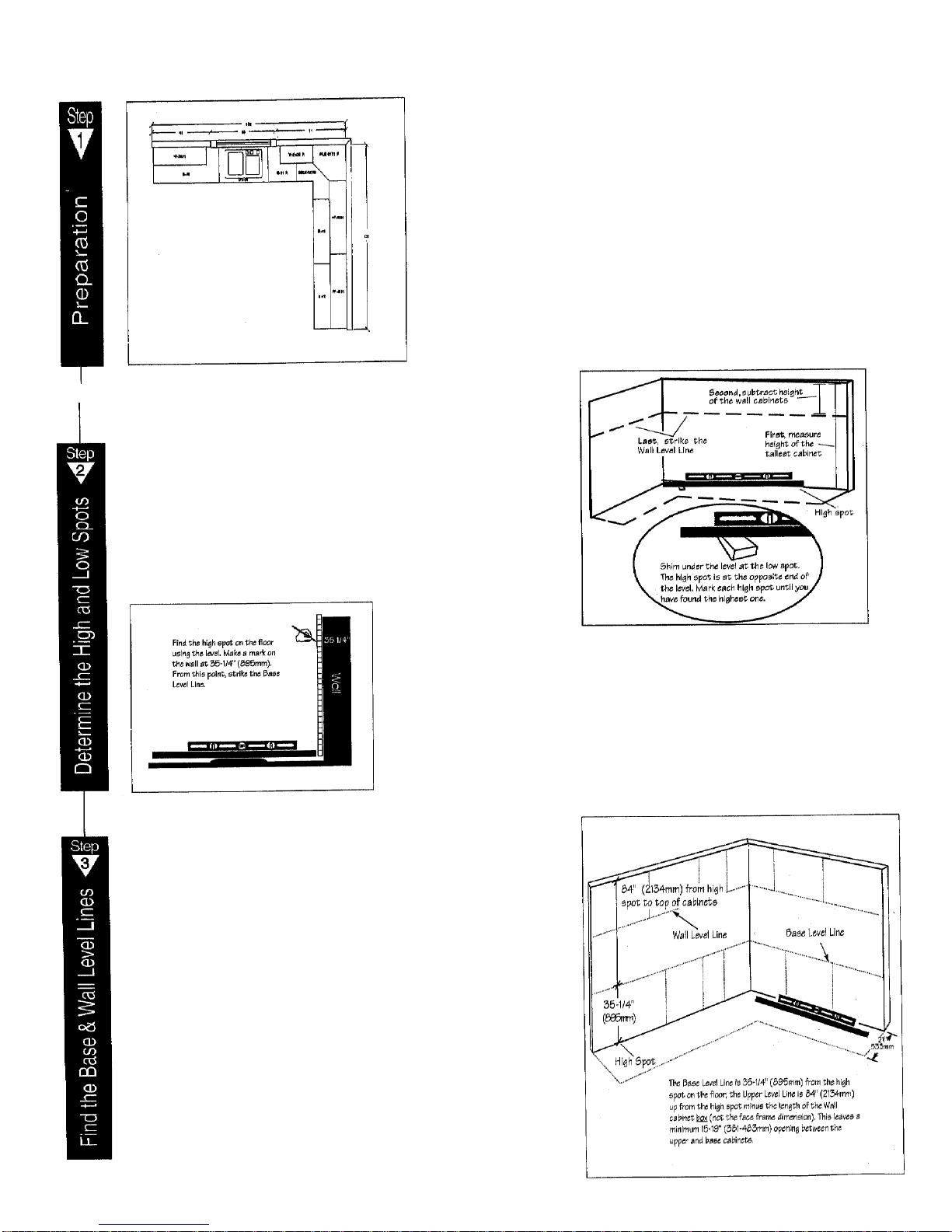

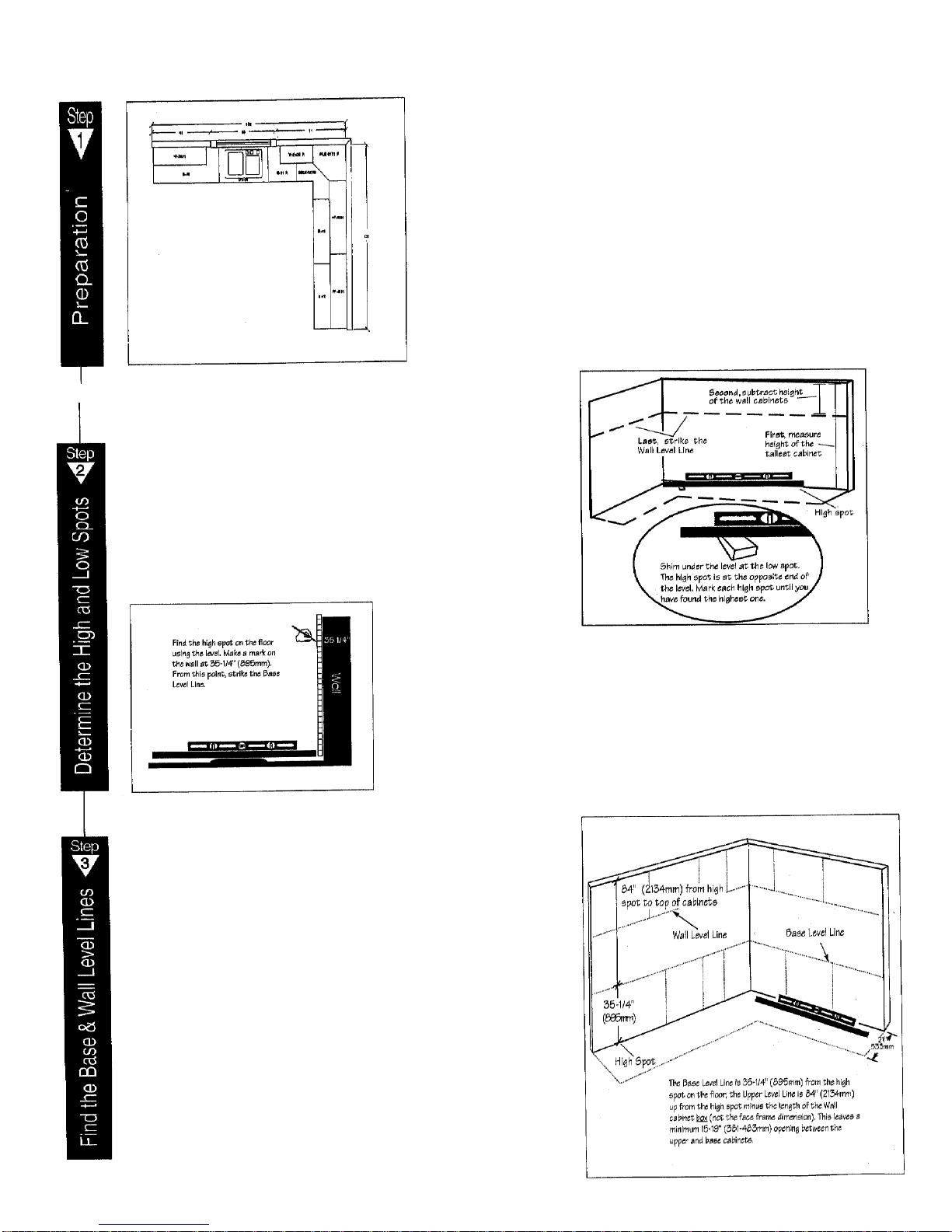

One of the most important steps in cabinetry installation is to begin with a

level foundation for the cabinets. Since not all floors and walls were

created with smooth, plumb surfaces, it is critical to locate the high spots.

Once found, you may either level the spots to the low areas or shim the

cabinets to make the installation plumb and square. To determine

locations of high spots, place a carpenter’s level on top of a 4’to 6’long

straight edge. Beginning in a corner, move the straight edge and level

around the room on the floor along the wall, marking where the bubble in

the level indicates high areas. Repeat the procedure 21”out from the walls

until you have found the highest spot.

For wall cabinetry, it is also imperative to ensure a smooth base. Utilizing the same

method as you used for finding the high spot on the floor, check for unevenness in

the walls and soffits. The low spots should be shimmed even with the high point to

obtain a smooth, even wall.

If the walls and floors are straight and level to begin with, it will eliminate

misalignment of doors and drawers due to racking (twisting) the cabinets.

This is a critical step!

From the high spot, measure up the wall 34 ½” or 35 ¼” if installing base

height cabinets; 30 ¼” if installing vanity height cabinets. With the chalk line,

strike a level line, called the “Base Level Line”, around the room on the walls

using the highest spot as the starting point. This is the point to which the

tops of the base cabinets should be level. Because DeWils customizes cabinet

heights, it is best to unwrap one of the cabinets and measure from the

bottom of the toe kick to the top of the cabinet to determine how far up

from the high spot you should strike the Base Level line.

Measure 84”, 90”, 96”, or the height of the tallest cabinet according to the

finished height of the cabinetry from the original high spot. Subtract the

height of the wall cabinets and make a mark on the wall. Move up the wall 1”

from this mark and strike a line on the walls parallel to the Base Level line.

This is called the Wall Level line and it is the line along which the bottoms of

the wall cabinets should be level. Please note that the recommended

clearance between the top of the base cabinets and the bottom of the wall

cabinets is a minimum distance of 16”and a maximum of 19”. Please be sure

the distance between your installed wall and base cabinets fall within this

range.