Dexon OWMDH Series User manual

DEXON CANADA AIR SYSTEMS INC.

Dexon Canada Air Systems Inc., 5018 80th Ave, SE, Calgary AB T2C 2X3, www.dexoncanada.com

Phone: 403-272-0562, Fax: 403-235-0149, Email: dexoncan@dexoncanada.com

BLOWER HEATER OWNERS MANUAL

OWMDH SERIES

PROVIDING SAFETY VENTILATION TO THE WATER, WASTER WATER INDUSTRY

SINCE 1986

Dexon Canada Air Systems Inc OWMDH Series Use Manual Version 07.2019

Page 1

1. GENERAL COMMENTS ........................................................................................................................................................2

1.1. INTRODUCTION ..........................................................................................................................................................2

1.2. PURPOSE ....................................................................................................................................................................2

2. OPERATOR AND EQUIPEMENT SAFETY ..........................................................................................................................3

2.1. OPERATOR SAFETY ..................................................................................................................................................3

2.2. EQUIPMENT SAFETY .................................................................................................................................................3

3. CONTROL PRINCIPALS .......................................................................................................................................................4

3.1. SEQUENCE OF OPERATIONS ..................................................................................................................................4

3.2. FEATURES ……………………………………………………………………………….…………………………….…...…..5

3.3. OPTIONS ……………………………………….………………………..………………………………………..…………….5

3.4. STATUS INDICATION ............................................................................................................................................6, 7

4. INSTALLATIONS ..................................................................................................................................................................8

4.1. INSTALLATION REQUIREMENTS .............................................................................................................................8

4.2. INSTALLATION INSTRUCTIONS ..........................................................................................................................8, 9

4.3. PERFORMANCE CHECK. ……………………………………………………………………………………..…..…..9,10,11

5. MAINTENANCE ..................................................................................................................................................................11

5.1. MAINTENANCE INSTRUCTIONS ......................................................................................................................11, 12

6. TROUBLE SHOOTING GUIDES ……………………………………………………….....……………………………………….13

6.1. TROUBLE SHOOTING GUIDE .................................................................................................................................13

6.2. MAIN CONTROL BOARD - 95DH ………………………...…………………………….……..…………………....…14, 15

6.3. STATUS BOARD –95STS ……………………………………………………………………....……….……..….16, 17, 18

7. WARRANTY………………………………………………………………………………………..…….…………….………………19

8. DRAWINGS………………………………………………………………………………..…………………….………….…………20

8.1. DIMENSIONS………………………………………………………………………………………….………………………..20

8.2. BOTTOM FOOTPRIN.…………………………………………………………………………………………..………….…..21

8.3. INTERNAL WIRING…………………………………………………………….………………………………………………22

8.4. FIELD WIRING……………………………….……………………………………………………………………………….…23

8.5. OPTIONAL 95ALM ALARM MODULE ( IF APPLICABLE)………………………………………………………………...24

9. APPENDICES:

Spare Parts List, Specs Sheet, Fan Curve, Control Section Removal, Quality Control Test Report

CONTENT

Dexon Canada Air Systems Inc OWMDH Series Use Manual Version 07.2019

Page 2

1.1INTRODUCTION

Dexon blower heaters are CSA Certified and designed to meet the requirements of the Canadian

Electrical Code. The OWMDH series is suitable for outdoor wall mounted applications.

1.2 PURPOSE

To provide continuous positive pressure safety ventilation to pumping station wet wells, dry wells,

buildings, vaults and chambers for the safety of the operator and to provide a less corrosive

environment for equipment.

A function of the blower heater is to temper the ventilating air in order to mitigate the risk of freezing the

ventilated space. They will maintain a preset discharge temperature of between +6°C to +18°C with an

adjustable 5°range. If the discharge temperature drops below 0°C (typically) the blower heater will shut

down to prevent the ventilated space from freezing.

This equipment is suitable for use in Class 1, Division 2, Gas Groups C and D, Temp Code T2C or for

Non-Hazardous Locations only.

FEATURES

Overheat Protection

Low Temperature Shut Down

Discharge Temperature Sensor

Adjustable Fan Speed in Auto

Mode

Full Fan Speed in Manual Mode

Auto Reset

Fan Boost Start

Proof of Fan Rotation

Staged Heating for Larger Units

CSA Certified

1. GENERAL COMMENTS

OPTIONS

Various Installation Configurations; outdoor

freestanding –SMDH series, indoor inline

–IMDH Series, indoor wall mounted-

WMDH series and outdoor wall mounted –

OWMDH series

Voltages from 120-600VAC, 1 or 3 phase

Class 1 Div. 2, Gas Groups C & D and

Ordinary Location Certified

External Alarm Interfacing

Manual Mode Interface for Hatch/Lid

Switch or PLC etc.

Dexon Canada Air Systems Inc OWMDH Series Use Manual Version 07.2019

Page 3

2.1 OPERATOR SAFETY

The installation, operation and maintenance of this unit must be carried out by qualified

personnel only and in accordance with national and local electrical codes.

For your safety read the supplied Owner’s Manual and Installation Instructions before installing.

Ensure all required lock-out procedures are followed.

Take note of all the safety labels on the unit.

If entering a confined space always follow confined space entry procedures.

Switch the blower heater into “Manual” mode to purge the space before entering. NEVER leave

the unit in “Manual”mode unattended.

2.2 EQUIPMENT SAFETY

Store the blower heater in a safe dry environment prior to installation.

Ensure that the factory preset continuous airflow meets the onsite requirements.

We strongly recommend providing surge protection.

When installing/servicing ensure all latches are used to secure the door.

We do not recommend installing on a down pipe smaller than the discharge outlet.

Ensure there is adequate distance between intake louvers and pressure relief vent/gooseneck.

Follow regular maintenance procedures as outlined in section 5.1 of this manual.

Locations with higher debris accumulation such as vegetation, construction, road dust or salt

may require more monitoring and maintenance.

Do not leave the blower heater in “Manual”mode unattended.

2. OPERATOR AND EQUIPMENT SAFETY

IMPORTANT: The blower heater must run continuous. NOT all components in the unit are

corrosive resistant and rely on the continuous positive pressure of the unit to keep the

damaging moist and corrosive gases from entering the blower heater. If the blower heater

cannot be immediately started or run continuously, on site actions must be taken to

prevent corrosive gases and moisture from entering the blower heater.

WARNING: EXPLOSION HAZARD; SUBSTITUTION OF COMPONENTS MAY IMPAIR

SUITABILTY FOR CLASS 1, DIV. 2.

Dexon Canada Air Systems Inc OWMDH Series Use Manual Version 07.2019

Page 4

3.1 SEQUENCE OF OPERATION

The main PCB inside the unit controls the blower heater functions, the fan and powers the

status board.

A temperature sensor at the discharge of the unit regulates the heating elements to maintain a

preset temperature that is based on airflow requirements and location.

In this series the heating elements are staged to reduce power consumption. Stages 2 and 3 will

only be activated and only remain on when stage 1 cannot meet the demand. Stage 2 and 3

LEDs will not blink but remain constant.

In “Auto” mode the fan will run continuous at an adjustable preset speed based on airflow

requirements and heating capacity of the unit; in “Manual” mode the fan will run at full speed.

When the discharge temperature drops below 0°C (typically) the unit will go into a “Low Temp.”

shut down condition, shutting down the fan to prevent freezing of the ventilated space.

The unit will automatically restart when the discharge temperature reaches +2°C (typically) or

more.

A built-in timer overrides this shut down for 7-8 minutes when the unit is manually reset or

power is cycled to allow the elements to warm up the discharge temperature. This override does

not apply when the unit automatically restarts after a “Low Temp.” shut down.

If the discharge temperature rises above the normal operating range the unit will go into an

“Overheat” condition cutting power to the heating elements. After cooling down, the heating

elements will automatically restart.

Power to the heating elements will also be cut in the event of a fan failure or a “Low Temp.” shut

down condition that caused the fan to shut down.

A fan failure will indicate a “Fan Stopped” status on the status board. If the optional alarm

module is used it will initiate a remote alarm even if there is no power to the status board.

3. CONTROL PRINCIPALS

CAUTION: Leaving the blower heater in “Manual” mode will drive the fan at full speed

and will override the “Low Temp.” shut down feature. The unit should never be left in

“Manual” mode since the heating capacity of the unit is based on preset airflow rate

and continuous duty in “AUTO” mode.

Dexon Canada Air Systems Inc OWMDH Series Use Manual Version 07.2019

Page 5

3.2 FEATURES:

Overheat protection: For Ordinary Location rated units one Klixon thermostat located at the

top of the element mounting panel will shut down the heating elements if temperature at the top

of the heat exchanger rises above approx. 65°C. For Hazardous Location rated units additional

thermostats on each element will cut power when the skin temperature of the elements reaches

approx. 107°C.

Low Temperature Shut Down: When the sensor at the discharge of the blower heater senses

temperature lower than 0°C (typically) the unit will go into a “Low Temp.”shut down condition to

prevent freezing of the space. See sequence of operations for more information.

Discharge Temperature Sensor: Monitors the discharge temperature to regulate the heating

elements to maintain a preset discharge temperature of between +6°C to +18°C with an

adjustable 5° range (Example: A +6°C preset discharge temperature would be adjustable from

+5°C to +10°C and +15°C preset temp. would be adjustable from +13°c to +18°C).

Auto Reset: The blower heater will automatically reset when temperatures reach +2°C

(typically) after a “Low Temp.” shut down has occurred and after the elements have sufficiently

cooled from an “Overheat” condition.

Fan Boost Start: Provides a momentary full output voltage to the fan for cold start-up etc.

Proof of Fan Rotation: Provides an indication when the fan is no longer running and activates

remote alarms when the optional alarm module is included.

Staged Heating: Staged heating is only provided for the larger SMDH/IMDH/WMDH/OWMDH

series and the SRVDH/IRVDH/WRVDH/OWRVDH series blower heaters to prevent high current

draw and reduce power consumption when not required. Stage 2 and Stage 3 heating elements

will only be used if Stage 1 is not able to maintain the preset discharge temperature setting and

only as required to maintain this discharge temperature.

CSA Certified: Dexon blower heaters are CSA certified for Class 1, Div. 2, Gas Groups C & D,

Temp. Code T2C Locations and for Ordinary Locations. Any modifications to existing certified

units will require special CSA approvals/certification.

3.3 OPTIONS:

Various Installation Configurations: The OWMDH series blower heaters are for outdoor,

through the wall applications with either back or bottom air outlets (See SMDH for outdoor

freestanding, WMDH series for indoor wall mounted and IMDH Series for indoor inline

applications).

Discharge outlet configurations: Can be round or rectangular and out the back or bottom.

Available Voltages: All Dexon blower heaters require two circuits; one for controls and one for

heating elements. Controls require 120VAC and heating elements can be 120,208,240,480 or

600 Volt and can be 1 phase or 3 phase.

External Alarm Interfacing: An optional “95ALM” three alarm status output relay module is

available for interfacing with external alarms or PLC. The alarm module can be easily added

after installation if required.

Manual Mode Interfacing: A set of manual mode interfacing terminals is available for dry

contact only, input from PLC, Hatch/Lid Switch, Gas Detector etc. dry contacts to temporarily

initiate “Manual” mode (full fan speed) for added safety.

Dexon Canada Air Systems Inc OWMDH Series Use Manual Version 07.2019

Page 6

3.4 STATUS INDICATION

Alarm

Module

Status

Board

Status Board with Optional Alarm Module

Status Board - 95STS

The blower heater is equipped with a status board to provide the following status indications:

Power On –indicates there is power to the unit.

Fan Stopped –indicates a fan failure or “Low Temp.” shut down.

Low Temp. –indicates the unit has gone into a “Low Temp.” shut down condition.

Overheat –indicates the unit has gone into an “Overheat”condition.

Element 1 –indicates there is a heat demand and the LED can be either blinking or

constant.

Element 2 & 3 –indicate stage 2 or 3 are required to maintain the desired temperature.

These LEDs will not blink they will remain constant.

WARNING: The remote manual mode interface feature is intended to temporarily turn on “Manual”

mode (full fan speed) for added safety regardless of the position of the “Auto/Manual” toggle switch

on the status board. If the unit was previously in “Auto” mode it will return to “Auto” mode when the

remote dry contact opens. If it was in “Manual” mode the blower heater will remain in “Manual” and

should be switched back to “Auto”. The unit should never be left in “Manual” mode since the heating

capacity of the unit is based on preset airflow rate and continuous duty in “AUTO” mode.

Dexon Canada Air Systems Inc OWMDH Series Use Manual Version 07.2019

Page 7

The status board also has two switches:

1. “Man. Fan Auto” to switch unit from “Auto”mode to “Manual”mode.

2. “Reset” switch that will restart the unit after a “Low Temp.” shut down has occurred.

Optional features that can be added to the status board:

1. An optional Alarm Module is available to interface with external alarms or PLC to provide

three status output alarms; “Fan Stopped”, “Low Temp.” and “Overheat”. Optional

Alarm Module sold separately.

2. A Manual Mode Interface Terminal is available for input from PLC, Lid Switch etc. dry

contact, to initiate “Manual” mode (full fan speed).

Standard Cable length –3 meters with the status board and 8 meters with the blower heater unless

requested otherwise.

Please see status board Trouble Shooting Guide for more information.

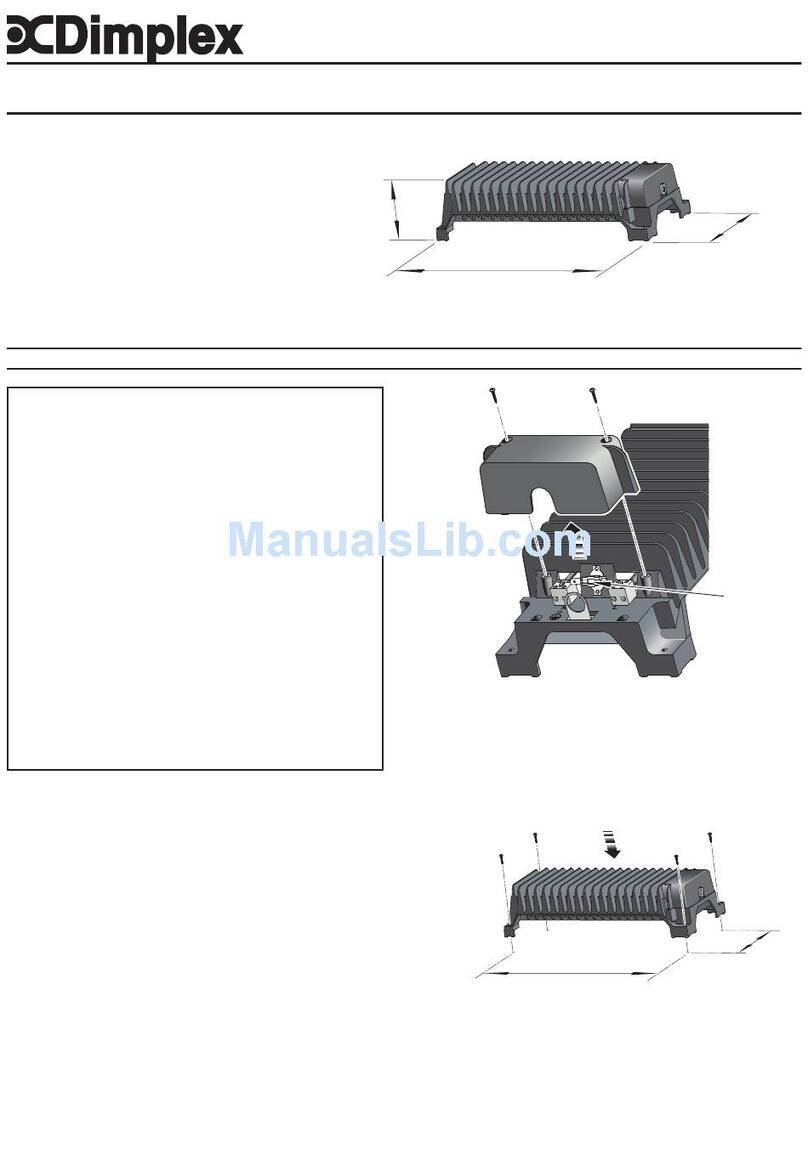

Status Board Dimensions

The status board is not weather resistant and must be installed in an

appropriate enclosure, remote from hazardous or corrosive locations in

accordance with local electrical codes.

Dexon Canada Air Systems Inc OWMDH Series Use Manual Version 07.2019

Page 8

4.1 INSTALLATION REQUIREMENTS

Status board must be installed in a suitable enclosure remote from hazardous locations in

accordance with local electrical codes.

Class 1, Div. 2 units must be fused remote from hazardous locations.

We recommend a pressure relief vent/gooseneck at least equal in cross section to the

discharge outlet.

Ensure the pressure relief vent/gooseneck is not in close proximity to the blower heater louvers.

Maintain 205mm (12”) clearance to the bottom of the intake louvers for accumulating debris or

drifting snow.

Maintain a minimum of 1 meter (3’3”) clearance on control access side of the blower heater for

maintenance and servicing.

4.2 INSTALLATION INSTRUCTIONS

All installations must be done by qualified personnel and in accordance with local electrical codes.

1. If through the wall (back air outlet) is used cut a rough opening for air outlet as per dimensions

diagram provided allowing enough space between the ground and the unit for ducting,

transitions or off sets. Through-wall lining and insulation supplied by others and installed by

others as required.

2. The unit may be secured to the wall with the four wall mount brackets supplied.

3. If not pre- mounted, install the status board in a suitable enclosure in a non-hazardous dry

location.

4. Run separate conduits; one for the status board cable and one for the appropriate heating and

control power circuits.

4. INSTALLATION

IMPORTANT: The blower heater must run continuously. NOT all components in the unit

are corrosive resistant and rely on the continuous positive pressure of the unit to keep

the damaging moist and corrosive gases from entering the blower heater. If the blower

heater cannot be immediately started or run continuously, on site actions must be

taken to prevent corrosive gases and moisture from entering the blower heater.

.

CAUTION: Do NOT install status board cable in the conduit intended for heating element and

power circuits. Doing so will put the extra low voltage circuits in close proximity to low voltage

circuits which may cause signal interference.

Dexon Canada Air Systems Inc OWMDH Series Use Manual Version 07.2019

Page 9

5. Connect the status board cable at TB3 inside blower heater as per field wiring diagrams in

section 8.

6. Supply appropriate heating element and control power circuits to TB7 and TB8 as shown in the

field wiring diagram. Note: status and power entry is generally at the base of the unit but may

also be on the side with the use of liquid tight fittings.

7. Power up the heating element circuit at TB8 first so the elements have power available if there

is a heat demand.

8. Power up the control circuit. The green “Power On” LED on the status board and on the main

controller PCB should light up. A yellow LED on the 95DH Main Controller will also light up to

indicate that a delay timer which overrides the “Low Temp.” shut down feature has been

activated. This LED will continue to flash for the duration of the timed delay, approx. 7-8 minutes

(See Trouble Shooting Guide 6.1 for more information). This allows the blower heater to start in

cold conditions and will occur every time the unit is reset or powered up.

9. If there is a heat demand the “Element 1” LED on the status board should light up and should

only remain constant momentarily, then blink as it meets the demand. The element LED will go

out every time the demand is met, whether it be long intervals or short blinks. If there is no heat

demand then only the “Power On” LED should be lit.

10.If required perform function test as described below.

4.3 PERFORMANCE CHECK

NOTE: You will require a means of cooling the temperature sensor to check the heating, “Low Temp.”

and the “Fan Stopped” functions. We would suggest using ice water or a Dexon Temperature Simulator

(sold separately).

To create a demand with ice water; remove the temp. sensor from tubing (Fig.1) and place the sensor

in the ice water to create a heating demand and then place the sensor directly on ice to lower the

temperature to 0°C to create the “Low Temp.” shut down condition.

Temperature Sensor Tubing

Fig. 1

Dexon Canada Air Systems Inc OWMDH Series Use Manual Version 07.2019

Page

10

To create the required demands using the Dexon Temperature Simulator (Fig.2), unplug the temp

sensor from the main 95DH Main Controller and plug the simulator in its place as shown in Fig.3.

Temp. Sensor Jack

with Dexon Simulator

Connection

Temp, Sensor

Disconnected

Fig. 2: Temperature Simulator

Fig. 3: Temperature Simulator Connections

1. Start the unit and let it run for APPROX. 8-10 minutes to allow the “Low Temp.” override timer to

time out.

2. Create a heating demand by placing the temperature sensor in ice water or using the Dexon

Temp. Simulator as described above. Once the heat demand has been created the “Element 1”

LED should light up and there should be current draw at TB8.

3. Create a low temperature condition as described above with ice water or with the Dexon Temp.

Simulator to drop the discharge temperature to 0°C. The “Low Temp.” LED should light up and

the fan should shut down followed by a “Fan Stopped” indication.

4. After the unit has shut down turn the fan switch on the status board to “Manual” (this overrides

the “Low Temp.” shut down feature). The fan will come on at full speed and the “Fan Stopped”

LED will then go out and the heating elements will come on.

5. With the unit still in a low temperature condition move the fan switch back to “Auto”. This will

cause the fan and heating elements to shut down again and the “Low Temp.” LED and “Fan

Stopped” LED to light up again.

6. With the unit back in “Auto”mode and still in “Low Temp.” condition press the “Reset” switch to

initiate the 7-8 minute override timer. This will allow the fan and heating elements to operate

regardless of the “Low Temp.” condition and the “Low Temp.” LED should go out when the

discharge temperature is above 2°C (typically).

Dexon Canada Air Systems Inc OWMDH Series Use Manual Version 07.2019

Page

11

7. After the override has timed out remove the created heat demand. If using ice water replace the

sensor in the tubing being sure to insert it all the way to the stopper and if using the Temp.

Simulator, unplug from the jack and reconnect the temp sensor. This confirms that the Heating

Demand, “Fan Stopped”, “Low Temp.”shut down, “Manual”mode and “Reset”features and

indications are functioning as intended.

8. Replace the cable ties and duct seal on the sensor tubing and other conduits as required; check

all components and ensure they are secured. Secure the door using all the latches.

9. If desired a DC voltage representation of the discharge temperature can be monitored during

these procedures at test pin “DP” (discharge temperature test pin) as described in section 6.1

95DH Main Controller.

5.1 MAINTENANCE INSTRUCTIONS

MAINTENANCE SHOULD ONLY BE PERFORMED BY QUALIFIED PERSONNEL

ONCE A YEAR, PREFERABLY BEFORE THE COLD WEATHER SETS IN, PERFORM THE

FOLLOWING MAINTENANCE PROCEDURES.

1. Check the status board for the following indications;

a. The “Power On”LED should be on.

b. The fan switch should be in “Auto” mode.

c. The “Element 1” LED may be off, steady on or blinking. An off LED would indicate there

is no heat demand; a steady on LED would indicate there is a heat demand requiring full

element capacity; a blinking LED would indicate the heat demand is being met by

intermittent pulses of energy.

2. If the “Power On” and “Element”LEDs are the only ones on and if the fan switch is in “Auto”

mode and you’ve confirmed that it is actually running, then the unit should be functioning as

intended. You may now proceed with the following steps;

a. Power down the heating element and control circuits and lock out power as required.

b. Open the latched door to expose the controls.

c. Clear air intake louver section and discharge ducts of any debris.

d. Clear pressure relief vent/gooseneck of any debris.

5. MAINTENANCE

Dexon Canada Air Systems Inc OWMDH Series Use Manual Version 07.2019

Page

12

e. Check all connections to the control section for loose or damaged wires and ensure they

are secure.

f. Check for any signs of moisture or corrosion in the control section and on the 95DH

Main Control Board.

3. Disconnect wires to heating element and controls circuit at TB7 and TB8 and cap-off.

Disconnect the status board wires at TB3 on the main controller and cut any cable ties. Remove

screws at the top of the control panel and gently pull the top of control panel towards you and up

off the mounting pins (See appendices –Control Section Removal). This allows the complete

control section to be removed including the fan, heating elements, thermostats and sensors.

Proceed with the following;

a. Remove any accumulated debris from the fan, heating elements, thermostats and

sensors.

b. Check the fan, heating elements, thermostats and sensor connections for signs of

moisture or corrosion and ensure they are secure.

c. Ensure the temperature sensor is inserted all the way to the bottom of the tubing.

4. Replace any damaged or corroded parts. When complete reinstall the control section and

reconnect all wiring.

5. Power up the unit and complete the performance check as described under section 4.3.

6. Ensure all conduit holes are completely sealed with duct seal and secure door with using all the

latches.

Please note that if the blower heater is installed in a high debris location, in forests or parks the

blower heater may require more frequent cleaning and maintenance.

WARNING: Never leave the blower heater in “Manual” mode unattended. Leaving it in

“Manual” mode will drive the fan at full speed and will override the “Low Temp.” shut

down feature. The unit should never be left in “Manual” mode since the heating

capacity of the unit is based on preset airflow rate and continuous duty in “AUTO”

mode.

CONTACT INFORMATION:

Email: techsu[email protected], Website: www.dexoncanada.com

Tech Support Phone: 403-930-1284, Admin Phone: 403-272-0562

WARNING: EXPLOSION HAZARD; SUBSTITUTION OF COMPONENTS MAY IMPAIR

SUITABILTY FOR CLASS 1, DIV. 2.

Dexon Canada Air Systems Inc OWMDH Series Use Manual Version 07.2019

Page

13

6.1 STATUS INDICATION TROUBLE SHOOTING GUIDE

“Power On”

LED is NOT on

1. Check control power to TB7 in blower heater.

2. Check control power fuse and for short circuits.

3. Check fuse on 95DH Main Controller.

4. Check 95DH Main Control Board for damage or

for short circuit.

5. Check that the transformer on 95DH Main

Controller hasn’t come lose or is damaged.

6. Check for 12VDC between brown and grey wires

to the status board at TB3 on 95DH Main

Controller and the same wires on the status

board.

1. Restore power.

2. Replace fuse if required.

3. Replace fuse if required.

4. Replace or have 95DH Main

Controller repaired.

5. Send 95DH Main Controller in for

repairs if required.

6. If 12VDC is not present check

connections, for short circuit or

controller damage and send in for

repair if required.

“Fan Stopped”

LED is on

1. Check the “Low Temp.” LED for indication of a

“Low Temp.”shut down condition.

2. Check fan; if it’s not running check fan terminals

for corrosion, frost build up or impeller

restrictions.

3. Check for fan power at TB5 on 95DH Main

Controller; if no power, check connections, for

short circuit or controller damage.

1. If shut down press the “Reset”

switch.

2. Remove restrictions and replace

fan if required.

3. If damaged replace or send 95DH

Main Controller in for repairs.

“Low Temp.”

LED is on

1. Check for element power at TB8 in blower

heater.

2. Visually inspect all Klixon thermostat(s) on the

elements and on the Heat Sink above the

elements for damage

3. Ensure the unit is not in “Manual”mode.

4. Check that the fan voltage is set as per

specifications (see quality control test report).

5. Check if the “Overheat” LED is on.

1. Restore power.

2. Replace damaged Klixon

thermostat(s) if required.

3. Set to “Auto” and press “Reset”

switch.

4. Adjust as required.

5. If on see “Overheat”LED below.

“Overheat”

LED is on

1. Check overheat thermostat for continuity

between the leads at TB4 on 95DH Main Control

Board. It should be in a closed circuit condition.

2. Check element relay(s) for current leakage by

disconnecting control power to eliminate any

demand and check for a current draw on the

element power supply leads.

1. If in open circuit condition check

the thermostat for damaged leads

and replace as required.

2. If there is current draw and there is

no demand replace the relay(s).

“Element”

LED is off or

inactive

1. Check that the ambient outdoor temperature is

not above the discharge set point as indicated on

the quality control test report in appendices.

2. If the ambient temp. is below the set point check

if unit is in “Low Temp.” shut down condition or

“Overheat” due to corroded overheat thermostat.

3. Check that there is power to the status board and

TB7 on the 95DH Main Controller.

1. If the ambient temperature is

above the set point then there is

no demand; unit is working as

intended.

2. Refer the “Low Temp.” shut down

and “Overheat” conditions above.

3. Refer to status board “Power On”

condition above.

If the above recommendations do not solve the problem please contact Dexon Canada Air

6. TROUBLE SHOOTING GUIDES

Dexon Canada Air Systems Inc OWMDH Series Use Manual Version 07.2019

Page

14

6.2 MAIN 95DH CONTROL BOARD

12VDC output to

Crydom SS Heating

Relays. May be

Pulsing or Steady

24VDC stg1 stg2 stg3

Fan Adjustment

Potentiometer

To normally closed

overheat thermostat

in heat exchanger

TachOP PCB Jack

“SP4” – Low Temp Restart Test Pin. Positive

Lead on DC Volt Meter 0-20V Range

“SP1” – Stage 1 Temp. Set Point Test Pin.

Positive Lead on DC Volt Meter 0-20V Range

“DP” – Discharge Temperature Test Pin.

Positive Lead on DC Volt Meter 0-20V Range

“COM” Common Test Pin. Negative Lead on

DC Volt Meter 0-20V Range

“SP” –Set Point Potentiometer for Discharge

Temperature Adjustments

Temperature Sensor Jack

0 to 10VDC should be

present here. Fan volts

are variable with Fan

Adjustment Pot

0-10VDC 24VDC n/c com

120Volt Power

120VAC should be

present here

“Low Temp.” shut down bypass timer

LED: The LED will blink until the timed

delay has ended. Note: In order to

allow time for the heat sensor to reach

its set point temperature a 7-8 minute

bypass is built into the controller for

cold starts. If the discharge

temperature is below 0°C and the set

point is not reached in the allotted

time the blower heater will go into a

“Low Temp.” shut down condition.

Controller Fuse Brackets –

500MA - Type AGC Fuse

IMPORTANT: Please contact

Dexon Canada Air Systems

Inc. before adjusting any

potentiometers (pots). There

are only 2 pots that can be

adjusted onsite and this

should only be done when

absolutely necessary and by

qualified personnel only.

“SP3” – Stage 3 Temp. Set Point Test Pin.

Positive Lead on DC Volt Meter 0-20V Range

“SP2” – Stage 2 Temp. Set Point Test Pin.

Positive Lead on DC Volt Meter 0-20V Range

Heat 2

Heat 3

Common

Manual Reset

Heat 1

Fan

Overheat

Low Temp.

Fan Stopped

12VDC Power

TO STATUS BOARD

Dexon Canada Air Systems Inc OWMDH Series Use Manual Version 07.2019

Page

15

DEXON 95DH MAIN CONTROLLER TEST PINS DESCRIPTION

NOTE: We recommend using “Minigrabber” type test leads that clip/hook on to the test pin holes for

measurements on the main controller to prevent accidentally shorting out test pins to components in

close proximity. IMPORTANT: When taking measurements the voltage does not equate exactly to

temperature, there is a 0.1VDC offset; for example (0.7VDC = 6°C), (1.1VDC = 10°C), (0.9VDC = 8°C).

TEST PIN

DESCRIPTION

COM

- Is the common pin for all 95DH Main Controller and Airflow Circuit Board voltage

tests (0-24VDC Range). The negative from a DC Volt Meter goes here for each

sampling.

DP

- Is the Discharge actual temperature as per the temperature sensor located near

the bottom of the blower heater in a small aluminum tube (See Dexon 95DH Main

Controller for Temperature Sensor Jack).

SP1

- Is the set point temperature that will be maintained at the blower heater

discharge at the bottom of the blower heater. The desired temperature may be

adjusted by turning “SP” (Set Point discharge temperature adjustment

potentiometer) clockwise to increase or counter clockwise to decrease. Typical

range is +5°C to +10°C (0.6VDC to 1.1VDC). IMPORTANT: Please contact Dexon

Canada Air Systems Inc. (403-272-0562) before making any adjustments to any

potentiometers. Note: the airflow in “Auto”mode is preset by Dexon based on

airflow requirements and heating capacity. Increasing the airflow should only be

done if airflow is inadequate due to unforeseen on-site piping/ducting friction.

Adjustments should only be made when absolutely necessary and by qualified

personnel.

SP2

- Is the set point at which the stage 2 element will engage in order to maintain SP1

set point. As the outdoor temperature drops the stage 2 elements are called upon

to provide heat when the DP (down pipe) temperature sensor drops to where the

SP2 set point is set. Typically 0.5VDC = +4°C.

SP3

- Is the set point at which the stage 3 element will engage in order to maintain SP1

set point. As the outdoor temperature drops the stage 3 elements are called upon

to provide heat when the DP (down pipe) temperature sensor drops to where the

SP3 set point is set. Typically 0.35VDC = +4.5°C.

SP4

- Is the low temperature automatic restart set point. This is the temperature at

which the blower heater will automatically restart after a “Low Temp.” shut down

has occurred.

A “Low Temp.” shut down occurs when the discharge temperature drops below

0°C and the fan shuts down to prevent freezing of the space. As the outdoor

temperature warms up the fan will automatically reset and start up based on the

SP4 temperature set point. Typically 0.2VDC = +1°C.

CONTACT INFORMATION:

Email: techsu[email protected], Website: www.dexoncanada.com

Tech Support Phone: 403-930-1284, Admin Phone: 403-272-0562

Dexon Canada Air Systems Inc OWMDH Series Use Manual Version 07.2019

Page

16

6.3 STATUS BOARD –95STS

The information provided on these pages assumes there IS a problem and there are no issues with the

95DH Main Controller, the 95STS Status Board or wiring problems.

“Power On” LED: When lit indicates that the status board is receiving

power from the 95DH Main Controller located inside the blower heater.

If it is not lit - check to ensure the control power circuit is energized

inside the blower heater. If the circuit is energized check the fuses

leading up to and on the main controller then check the wiring between

the blower heater and the status board.

“Element 1” LED: When this LED is blinking/pulsing it’s an indication

that the outdoor temperature is such that the main controller is calling

for heat. The continuous blinking/pulsing indicates that the blower

heater is easily maintaining the pre-set discharge temperature.

Please Note: “Element 2”and “Element 3”LEDs will only be active

when stage 1 cannot maintain the preset discharge temperature on its

own and stage 2 and/or stage 3 elements are required. These LEDs will

not blink/pulse.

“Overheat” LED: When lit indicates that an “Overheat”condition has

occurred. This condition may be the result of either the Crydom Solid

State Relay failing, the overheat thermostat at the top of the heat

exchanger has had its wiring corrode off or has opened its internal

contact (normally closed contact becomes open).

Relay Fail test: Turn off the control power and check for current in the

heating circuit. If a current is measured the relays could be leaking

across their voltage barrier, have found a current path to ground or

have completely shorted out.

Overheat Sensor test: If the relays are fine check the continuity of the

overheat thermostat, it should be in a normally closed state to allow

heating. See Dexon 95DH Main Controller page for location of the

overheat thermostat wires.

Figure 2: “Overheat” Indication

Figure 1: Normal Operations

Dexon Canada Air Systems Inc OWMDH Series Use Manual Version 07.2019

Page

17

Figure 3: Fan Stopped Indication

“Power On” LED and “Fan Stopped” LEDs are both lit: Is an indication

that there has be a fan failure or if there is confirmation of the fan

running then possibly issues with the 95DH Main Controller, status

board or TachOP PCB. If fan is not running confirm that there is power

output from the 95DH Main Controller to the fan. If you confirmed the

fan is running and there is still a “Fan Stopped” indication then there is

an issue with one or more of the control boards.

IMPORTANT: When the “Fan Stopped” LED is lit the heating elements

are disabled for safety. If the outdoor temperature is below 0°C this will

lead to a “Low Temp.” shut down condition; if this does occur the “Low

Temp.” LED will also light up.

“Power On”, “Fan Stopped”and “Low Temp.” LEDs are all lit: In cold

temperatures this is the most common failure indication. This can be

due to a “Low Temp.” shut down condition which causes the “Fan

Stopped” indication or a “Fan Stopped” indication which activates the

“Low Temp.” shut down feature since the “Fan Stopped” condition will

disable the heating elements. This occurs at temperatures below 0°C.

The “Low Temp” LED can light up due to a lack of heating, the heating

circuit is off or one or more heat sensors are “open”. This is most

commonly due to corroded wire leads in the heat exchanger. It could

also be caused by a temperature sensor failure, a sensor out of

calibration or the 95DH main controller has failed.

The “Fan Stopped” LED: Will light up in the event of a fan failure or if a

“Low Temp.” condition occurred as described above. Check the fan for

operation and check to ensure the heating circuit is energized (breaker

is on).

The “Low Temp.” LED: Will light up due to a lack of heating; the

heating circuit is off or one or more heat sensors are open. This is most

commonly due to corroded wire leads in the heat exchanger. It could

also be caused by a temperature sensor failure, a sensor out of

calibration or the 95DH Main Controller has failed.

Note: A “Low Temp.” condition can also occur in Class 1, Div. 2 blower

heaters as they have overheat thermostats mounted directly on each of

the heating elements. These normally closed thermostats shut down

the heating if the heating element skin temperature reaches close to

ignition temperature of the gases in the Gas Groups C & D. There is no

status indication for this condition; check for open contact, corroded

wires etc.

Figure 4: “Fan Stopped” with

“Low Temp.” Indication

Figure 3: “Fan Stopped”

Indication

Dexon Canada Air Systems Inc OWMDH Series Use Manual Version 07.2019

Page

18

“Manual/Auto” Toggle Switch:

DO NOT LEAVE UNIT IN MANUAL MODE UNATTENDED

This switch is primarily used to purge/flush/ventilate a confined

space prior to entry.

In “Auto”mode the blower heater runs at a pre-set level based on

the required airflow rate; generally based on the area of the space

and the safety ventilation requirements of the location. For

continuous airflow in “Auto” mode all safety features of the unit

are active.

In “Manual” mode the blower is put into full speed; this is to

purge/flush/ventilate the space only. This is not meant for

continuous operation since the heating capacity of the unit is

sized for only the continuous airflow rate.

It is important to note that in “Manual” mode the “Low Temp.” shut

down feature is bypassed/disabled to ensure the unit does not

shut down while the confined space is occupied. This bypass can

be used to allow heating even in a “Low Temp.” shut down in

order to defrost the fan if frosted up. The fan will often restart

once thawed.

“Reset” Switch:

This switch is used in order to start a bypass timer built into the 95DH

Main Controller that will allow heating for roughly 7-8 minutes

regardless of the “Low Temp.” shut down condition. This is done in an

attempt to warm the temperature sensor above freezing and remove

the “Low Temp.” shut down. This is provided the heating elements

have power and the “Fan Stopped” LED is not lit.

Figure 5: “Manual/Auto”

Toggle Switch

Figure 6: “Reset” Switch

CONTACT INFORMATION:

Email: techsu[email protected], Website: www.dexoncanada.com

Tech Support Phone: 403-930-1284, Admin Phone: 403-272-0562

Dexon Canada Air Systems Inc OWMDH Series Use Manual Version 07.2019

Page

19

Limited Warranty

Dexon Canada Air Systems Inc. warrants its Blower Heater and Vent Fans to be free of defects in

material and workmanship for a period of one (1) year from start up or eighteen (18) months from

shipment, whichever comes first.

This warranty does not extend to abnormal or abusive wear and tear or improper installations and

operations. All units and components of the unit must be installed according to Dexon’s installation

instructions provided with each unit. Responsibility for proper installation and operations must rest on

the purchaser. Once properly installed all units must be operated as intended and maintained as

outlined in owners and operators manuals supplied with each unit, and as per tags on each unit.

If the unit is shut down for any reason the unit must be completely sealed off to prevent any gases from

entering the inside of the unit. This includes ducting/discharge, conduit and bolt holes, or any holes

that would allow air to migrate into the unit. When removing the inside panels for repair or service, the

discharge duct and any holes must still be covered in such a way as to prevent moisture from entering

the body of the Blower Heater or Vent Fan.

Dexon’s sole obligation under this warranty shall be to replace or repair defective parts or

workmanship if upon evaluation it has been determined that they are defective and not a result of

abnormal or abusive wear and tear or improper installations and operations.

Warranty services will only be extended to the original purchaser. In order to obtain warranty service

the owner must ship the product prepaid to Dexon for evaluation. Dexon will ship the replaced or

repaired product back prepaid if evaluation has determined that they are defective.

Dexon Canada Air Systems Inc.

5018 80th Ave. SE

Calgary, AB T2C 2X3

Phone: (403) 272-0562, Fax: (403) 235-0149

Email: dexoncan@dexoncanada.com, techsupport@dexoncanada.com

7. WARRANTY

Table of contents

Popular Heater manuals by other brands

Zibro

Zibro Kamin R 616 C operating manual

welltherm

welltherm BP 550 Series Installation and operating instructions

EUROM

EUROM WALL DESIGNHEAT 2000R instruction manual

Timberk

Timberk TOR 22.2512 AXX I instruction manual

Desa

Desa SH10E owner's manual

Robur

Robur Supercromo Installation, use and maintenance manual

STIEBEL ELTRON

STIEBEL ELTRON BHE 75 Classic Operation and installation

THERMOBILE

THERMOBILE Bio Energy 2 user manual

Runtal

Runtal EWP series Owner's manual & operating instructions

Swim & Fun

Swim & Fun XP2 manual

Royal Sovereign

Royal Sovereign HCE-190 owner's manual

Comfort Glow

Comfort Glow CGR18P OWNER'S OPERATION AND INSTALLATION MANUAL