7

Making electrical provision for the heater

For each Warmup® Heater you install, you will have 1 unheated lead running from the floor to

the thermostat's electric connection. The joint connecting the unheated lead to the space

heating cable must be at least 2 inches from the wall and placed in a position to be covered by

tile and thin set mortar.

It may be necessary to chisel out short channels in the subfloor to minimize the increased

height presented by the floor probe and the unheated lead.

All electrical connections should be done by a qualified technician.

Install to NEC and local BOCA codes.

Separate conduit will be required to run the unheated lead and the sensor wire back up to the

thermostat. Please note that they cannot be placed within the same conduit. Neither the

unheated lead or sensor wire must cross, or come into contact with, the heating element. Bear

in mind that you will need to make provision for drawing the unheated lead and sensor

wire up through the conduit to the control box.

Electrical Requirements

Please refer to the table on page 6 to calculate the amperage load for your particular

system. For smaller areas, you may be able to utilize an existing circuit. In most cases,

however, you will need a separate circuit to power the Warmup heaters.

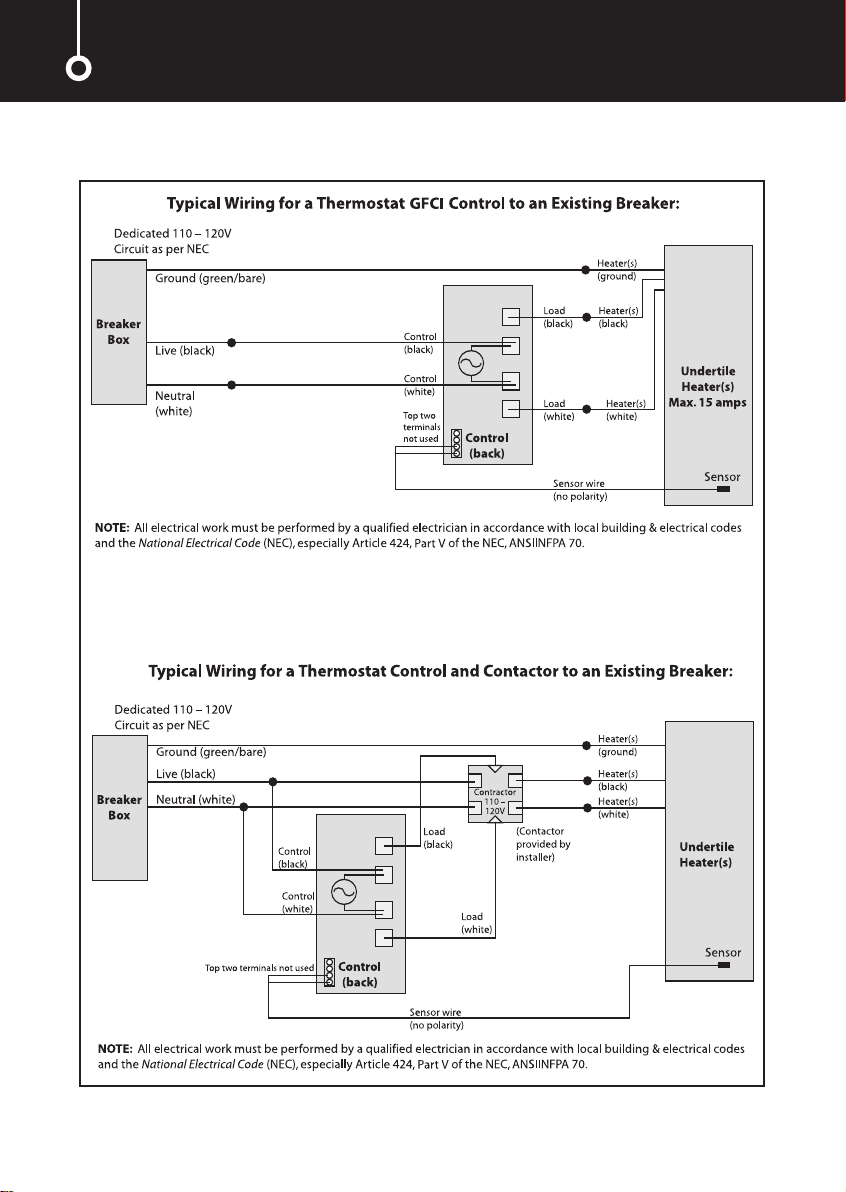

The Warmup thermostat has a maximum resistive load of 15 amps (i.e. a maximum of 2 x

USDW800). It also includes a built-in GFCI. If you want to control more than 15 amps worth of

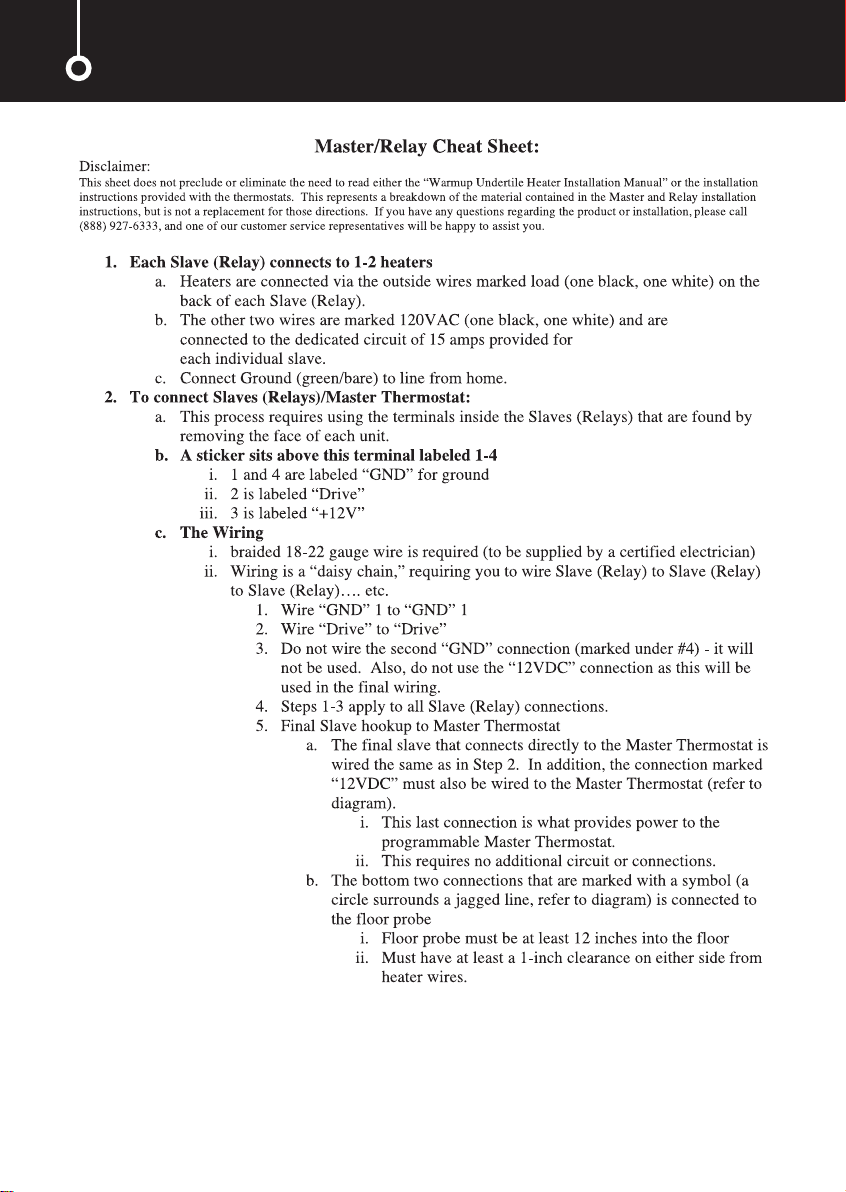

heating via a single thermostat you will need to use Warmup’s master / relay configuration.

Instead of using the thermostat, a different model of master thermostat is used to control

individual switching units (each capable of switching up to a 15 amp load, and each containing

its own GFCI). The relay units requiretheir own separate electrical feed, and up to 10 relay

units can be daisy chained to a single master unit via low voltage cabling. For further

information please call the Warmup Helpline or visit www.warmup.com.

The thermostat should be connected to the main electrical supply via a fuse or circuit in

accordance with the National Electrical Code. If the thermostat used does not include a built-in

Ground Fault Circuit Interrupter (GFCI), then one must be added to the circuit between the

main power supply and the thermostat. If the thermostat does include a GFCI, it is NOT

recommended to include another in the circuit, as this may cause accidental tripping of the

control unit.

Ensuring Safety

Install the Warmup thermostat within thesameroom as the heater. In order to ensure the

efficient running of the system within bathrooms, we recommend that the controls are located

at least 36 inches away from shower openings or basin back splash areas so you minimize the

possibility of exposureto water.

The rating label in this manual must be attached to the circuit breaker box for referral by the

homeowner or electrical inspector. An additional smaller label is attached to the manual to be

fixed adjacent to or on the thermostatic control.