-3-

Dexter Sway Control Mounting

CAUTION

This is the safety alert symbol. It is used to alert you to

potential injury hazards. Obey all safety messages that

follow this symbol to avoid possible injury or death.

CAUTION

The Dexter Sway Control should only be installed by a

qualified technician.

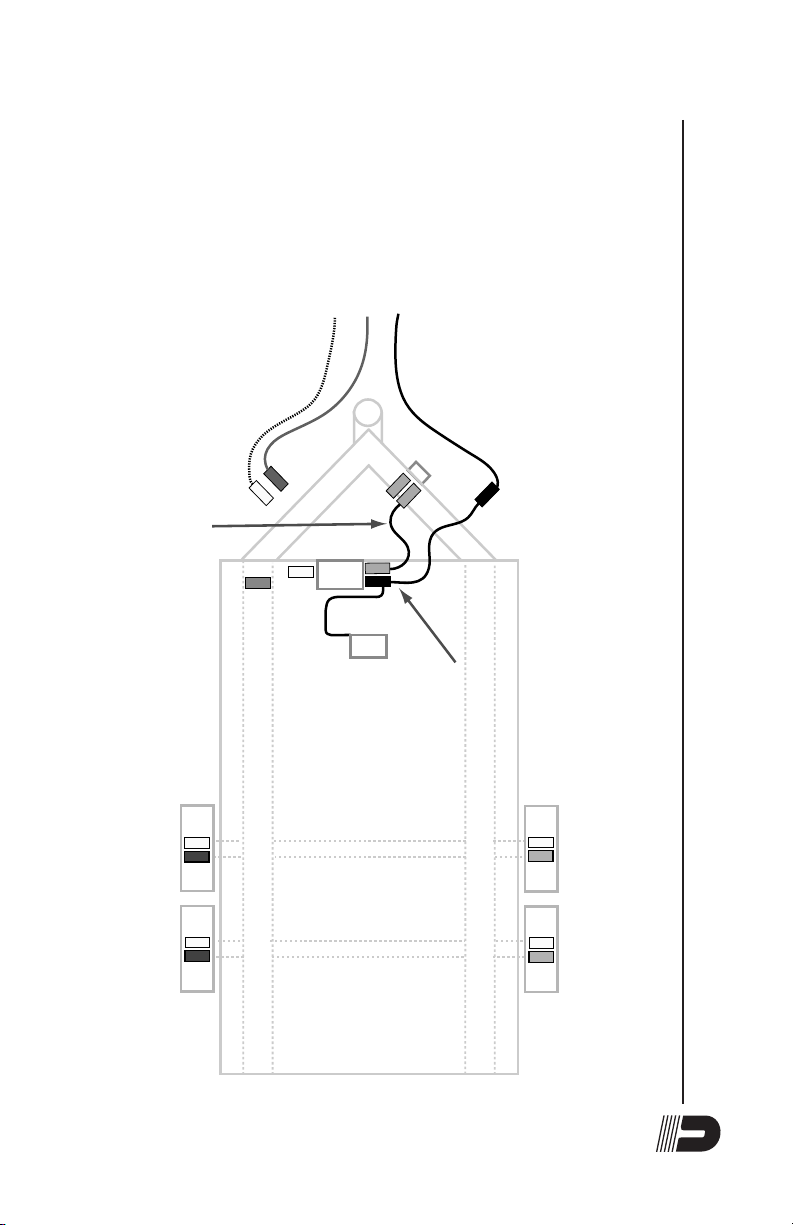

DSC Trailer Mounting

DSC Mounting Location

Select a location on the trailer to mount the DSC. The location

must be 5 to 10 feet behind the trailer bumper hitch ball and

shielded from road debris. The DSC must be securely fastened

onto a vertical surface that does not flex or move from wind, such

as plastic covers or plastic walls. The center of the DSC (marked

by a red dot on the DSC label shown below) must be positioned

on the “center line” of the trailer and the DSC must be mounted

with the correct side in the UP direction as indicated on the label.

The longest edge of the DSC (as indicated by a red line on the

label) must be mounted parallel to the trailer axle beam(s). See

Figure 1.

www.dexteraxle.com

Phone: 574-295-7888

Part No. 058-010-00

MOUNT THIS EDGE UP

Mount this edge parallel with the trailer axle beams 5 to 10 feet back

from trailer bumper hitch ball on a vertical frame surface

Module will not function if

positioned and/or oriented

improperly. Read and

follow all Installation Instructions

to ensure proper operation.

WARNING

Wires Trailer Wire Function

Purple Left side electric brakes output

Pink Right side electric brakes output

White Trailer battery/frame ground point

Blue Electric brake controller signal from tow vehicle

Black 12VDC from tow vehicle trailer harness

MOUNT THIS POINT ON TRAILER CENTER LINE

MODULE WIRING

CONNECTOR

ON THIS SIDE

Label No. 059-898-00 Rev C

Assembled in the USA by Tuson RV Brakes, LLC.