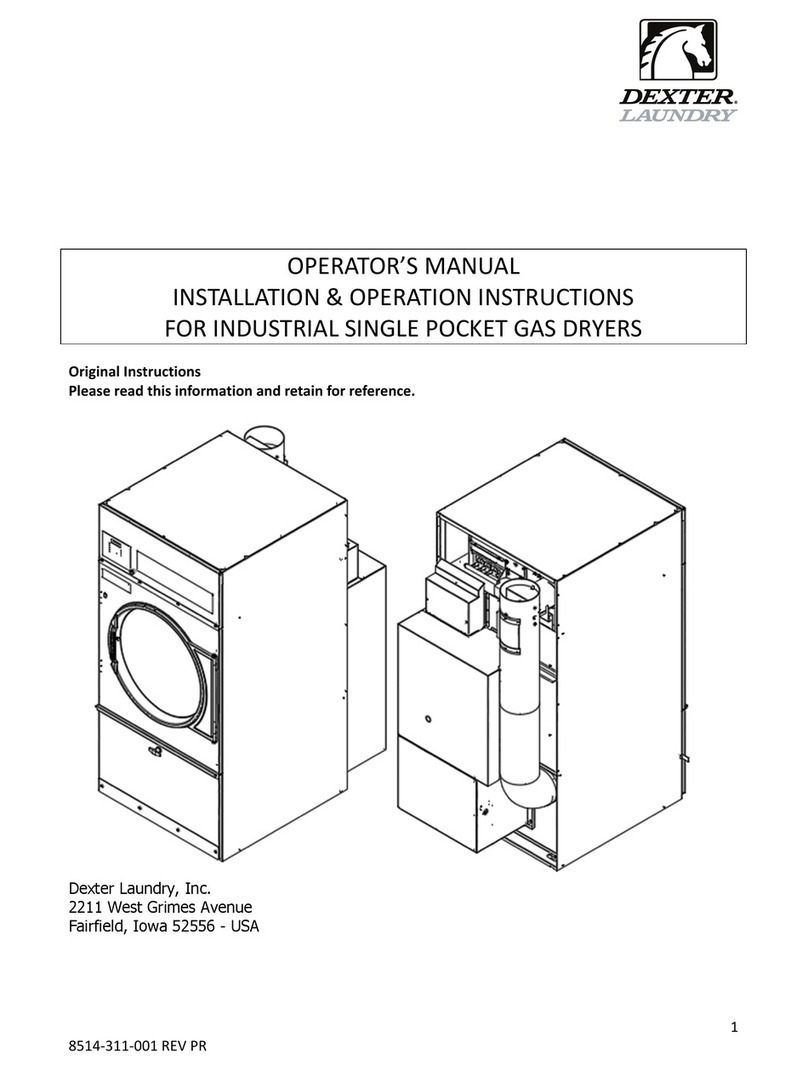

Dexter Laundry C Series User manual

Other Dexter Laundry Dryer manuals

Dexter Laundry

Dexter Laundry T-20SWD Installation instructions

Dexter Laundry

Dexter Laundry T-30X2 Installation instructions

Dexter Laundry

Dexter Laundry T-80 User manual

Dexter Laundry

Dexter Laundry DC50X2 User manual

Dexter Laundry

Dexter Laundry DC30X2 Series Building instructions

Dexter Laundry

Dexter Laundry T-30 User manual

Dexter Laundry

Dexter Laundry T-50X2 User manual

Dexter Laundry

Dexter Laundry C Series Quick start guide

Dexter Laundry

Dexter Laundry T-20 SWD User manual

Dexter Laundry

Dexter Laundry T-50X2 Administrator guide

Dexter Laundry

Dexter Laundry DTCH 80 V Manual

Dexter Laundry

Dexter Laundry DDAD50KC Series User manual

Dexter Laundry

Dexter Laundry DL2X30Q Manual

Dexter Laundry

Dexter Laundry T-20 SWD User manual

Dexter Laundry

Dexter Laundry DDAD30HC-11 Series User manual

Dexter Laundry

Dexter Laundry DDAD30KC Series User manual

Dexter Laundry

Dexter Laundry DTCH30 series User manual

Dexter Laundry

Dexter Laundry V Series Manual

Dexter Laundry

Dexter Laundry T-30 Administrator guide

Dexter Laundry

Dexter Laundry DCBD 30 Series User manual

Popular Dryer manuals by other brands

Alliance Laundry Systems

Alliance Laundry Systems TMB795C Installation

Asko

Asko T793C operating instructions

Kenmore

Kenmore 8041 - 5.8 cu. Ft. Capacity Electric Dryer installation instructions

Frigidaire

Frigidaire CAQE7077KW0 use & care

Bosch

Bosch WTX8HKM9SN User manual and installation instructions

Sharp

Sharp KD-NHH9S7GW2-PL user manual