Deye Spring Series User manual

User Manual

Spring series LFP Battery

SE-G5.3

Version:V1.2

~ 1 ~

About This Manual

The manual mainly describes the product information, guidelines for installation, operation, and

maintenance. The manual cannot include complete information about the solar photovoltaic-energy

storage hybrid system.

How to Use This Manual

Read the manual and other related documents before performing any operation on the battery.

Documents must be stored carefully and be always available.

Contents may be updated or modified periodically due to product update iterations. The

manual is subject to change without prior notice. The latest manual can be acquired via service

1.Safety Introductions

Reminding

1)

It is very important and necessary to read the user manual carefully (in the accessories) before

installing or using battery. Failure to do so or to follow any of the instructions or warnings in this

document can result in electrical shock, serious injury, or death, or can damage battery,

potentially rendering it inoperable.

2)

If the battery is stored for long time, it is required to charge them every six months, and the SOC

should be no less than 50%.

3)

Battery needs to be recharged within 48 hours after fully discharged.

4)

Do not expose cable outside.

5)

All the battery terminals must be disconnected for maintenance.

6)

Please contact the supplier within 24 hours if there is something abnormal.

7)

Do not use cleaning solvents to clean battery.

8)

Do not expose battery to flammable or harsh chemicals or vapors.

9)

Do not paint any part of Battery, include any internal or external components.

10)

Do not connect battery with PV solar wiring directly.

11)

The warranty claims are excluded for direct or indirect damage due to above items.

12)

Any foreign object is prohibited to insert into any part of battery.

~ 2 ~

Warning

1.1 Before Connecting

1)

After unpacking, please check product and packing list first, if product is damaged or lack of

parts, please contact with the local retailer.

2)

Before installation, be sure to cut off the grid power and make sure the battery is in the turned-

off mode.

3)

Wiring must be correct, do not mistake the positive and negative cables, and ensure no short

circuit with the external device.

4)

It is prohibited to connect the battery and AC power directly.

5)

Battery system must be well grounded and the resistance must be less than 1Ω.

6)

Please ensured the electrical parameters of battery system are compatible to related equipment.

7)

Keep the battery away from water and fire.

1.2 In Using

If the battery system needs to be moved or repaired, the power must be cut off and the

battery is completely shut down.

It is prohibited to connect the battery with different type of Battery.

It is prohibited to put the batteries working with faulty or incompatible inverter.

It is prohibited to disassemble the battery.

In case of fire, only dry fire extinguishers can be used. Liquid fire extinguishers are

forbidden.

Please do not open, repair, or disassemble the battery except staffs from DEYE or

authorized by DEYE. We do not undertake any consequences or related responsibility

which because of violation of safety operation or violating of design, production, and

equipment safety standards.

2. Product Introduction

This lithium iron phosphate battery is one of new energy storage products developed and

produced by DEYE, it can be used to support reliable power for various types of equipment

and systems.

This battery is especially suitable for application scene of high power, limited installation

space and long cycle life.

This battery has built-in BMS battery management system, which can manage and monitor

cells information including voltage, current and temperature. What’s more, BMS can balance

cells charging and discharging to extend cycle life.

Multiple batteries can connect in parallel for larger capacity and longer power supporting

duration requirements

2.1 Front Panel Function Introduction

In order to operate the product correctly, please carefully view the function of the front panel of the

battery.

~ 3 ~

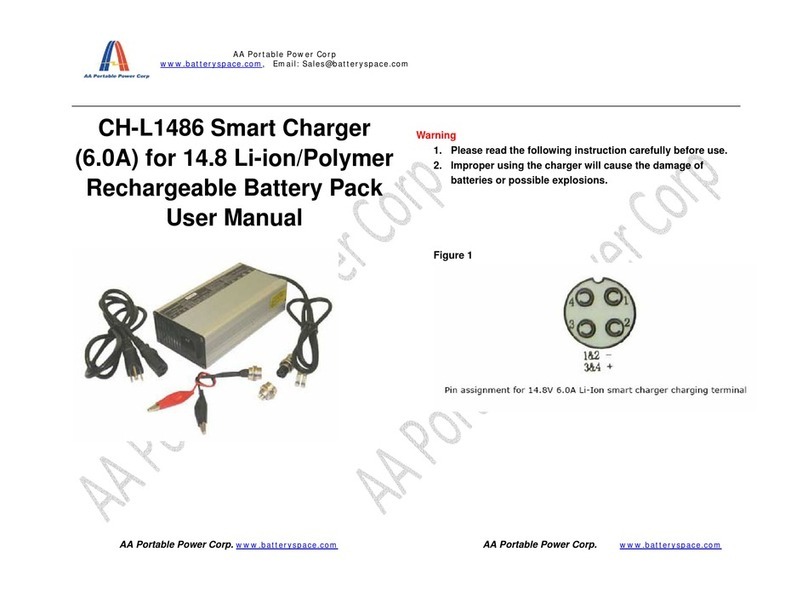

Figure 2-1: Front Panel Function Introduction

1. Power button: to turn ON/OFF the whole battery BMS standby, no power output.

2. DRY CONTACT output.

3. PCS:Inverter communication terminal: (RJ45 port) follow the CAN protocol (baud rate:

500kbps), and RS-485(baud rate: 9600bps), used to output battery information to the inverter.

4. IN: parallel Communication Terminal: (RJ45 port) Connect "out" Terminal of Previous battery, for

communication between multiple parallel batteries.

5. SOC: These 5 LEDs are used to display the pack SOC. The lightning of these LEDs indicates the

SOC of 20%, 40%, 60%,80% and 100%.

6. RUN light: green LED lighting to show the battery running status

Alarm light: yellow and red LED lighting to show the battery has been alarmed or protected.

7. OUT: parallel Communication Terminal: (RJ45 port) Connect "IN" Terminal of Next battery, for

communication between multiple parallel batteries.

8. USB: (USB port) Used to insert USB flash drive for battery upgrade.

9. Negative output terminal.

10.Grounding bolt.

11.Handle: It was used to carry/move the battery.

12.Positive output terminal.

13.Used for fixing with cabinet.

~ 4 ~

2.2 Communication Port

(1) PCS Port Definition

(2) IN Port Definition

(3) OUT Port Definition

~ 5 ~

2.3 Product Specifications

Table 2-1: Product Specifications

Main Parameter

SE-G5.3

Battery Chemistry

LiFePO4

Capacity (Ah)

104

Scalability

Max. 64 pcs pack (340kWh) in parallel (Max. 32 pcs no external setup)

Nominal Voltage (V)

51.2

Operating Voltage(V)

43.2~57.6

Energy (kWh)

5.32

Usable Energy (kWh)[1]

4.79

Charge/Discharge

Current (A) [2]

Recommend

50

Max.

100

Peak

150 (2mins,25℃)

Other Parameter

Recommend Depth of Discharge

90%

Dimension (W/H/D, mm)

440*133*560

Weight Approximate(kg)

44

Master LED indicator

5LED(SOC:20%~100%)

3LED (working, alarming, protecting)

IP Rating of enclosure

IP20

Working Temperature

Charge:0℃~55℃

Discharge:-20℃~55℃

Storage Temperature

0℃~35℃

Humidity

5%~95%

Altitude

≤2000m

Cycle Life

≥6000(25℃±2℃,0.3C/0.3C 90%DOD,70%EOL)

Installation

19-inch standard rack (depth≥600mm), Floor-Mounted

Communication Port

CAN2.0, RS485

Certification

CE, IEC62619, UN38.3

Energy Throughput

16MWh@70%EOL

[1] DC Usable Energy, test conditions: 90% DOD, 0.3C charge & discharge at 25°C. System usable energy may vary due

to system configuration parameters.

[2] The current is affected by temperature and SOC.

2.4 State Indicator

Condition

RUN

ALM

ERROR

SOC1

SOC2

SOC3

SOC4

SOC5

Power Off

Off

Discharge or

Idle

Blink

Blink if

Alarm

Exists

Off

e.g., Soc67%:

Off

On

On

On

On

Charge

Off

e.g., Soc47%:

Off

Off

Blink

On

On

Alarm

Blink

Off

Same as 'Discharge or Idle'

System

Error/Protection

On

Upgrade

Blink Fastly

Critical Error

Blink Slowly

~ 6 ~

3. Unpack the Battery

The battery and the related accessories are packed in the carton box. Use tools to open the packing

box. After open the packing box, confirm the product components according to the parts list.

Warning

Violent unpacking is strictly prohibited. If the battery system is found to be broken, deformed

or other abnormal conditions, the user shall immediately stop using the battery and contact

us.

3.1 Parts List

Check the parts during unpacking.

Table 3-1: Parts List

~ 7 ~

Table 3-2: Recommended Tools and Instruments

3.2 Visual Inspection of the Modules

After transporting the modules to the installation location, check for:

▪Physical damage to the exterior.

▪Damaged or protruding screws.

4. Battery Installation

This system must be installed by qualified, trained workers familiar with the required instruments.

Warning

▪Be sure to use insulated tools (torque wrench, extension, socket, etc.).

▪All the instruments must be insulated and no metal articles (e.g., watch, ring) should be present

in the installation area.

▪All power switches must be turned off in advance.

▪Prepare a CO2fire extinguisher, a first aid kit, and an AED (automated external defibrillator)

before installation.

▪Arc Flash and Shock Hazard: Insulated tools are required for any work on this energized

equipment.

▪Sharp Edges: Wear gloves and other protective gear to prevent injury.

▪Pinch Point: Use caution when working in the enclosure to prevent injury.

▪Heavy Object: Can cause muscle strain or back injury. Use lifting aids and proper lifting

techniques when moving trays, batteries, and other heavy objects.

~ 8 ~

4.1 General requirements for installation

(1) Transport battery modules to the installation location.

(2) Place the battery modules on the bracket or rack or cabinet.

(3) Fix the battery on the bracket or rack. Using the bracket or cabinet bolt to fix the battery into the

bracket or rack.

(4) After installation, tighten all bolts.

4.2 Installation method 1:

With simple bracket installation

4.3 Installation method 2:

With standard 19 inches cabinet or rack installation

~ 9 ~

4.4 Installation method 3:

Wall-mounted method

The installation location description should meet the size requirements of the figure below:

Figure 4-1

a) Use the 6 screws of M4*8 to fix the battery pack Fixed Ears the both sides battery, as show

in Figure 4-2.

Figure 4-2

~ 10 ~

b) Choose the recommend drill head (as shown in Figure 4-3) to drill 4 holes on the

wall,100mm-110mm deep.

c)

Use a hammer to secure the support to the wall, and install the expansion bolt in the hole, as

shown in Figure 4-3.

Figure 4-3

d) Fasten the screw head of the expansion bolt to finish the mounting.

e) Carry the battery and hold it. Fix the battery to the support after fixing it to the wall. Ensure

that battery mounting ears are aligned with the left and right holes on the support, as shown in

Figure 4-4.

Figure 4-4

~ 11 ~

▪The battery can be mounted on a standard 19 inches cabinet or rack.

▪Battery modules can be inserted into a rack frame according to the customer battery

configuration scheme.

Warning

Note the allowable installation modes.

5. Cable Connection

5.1Single Battery Connection

Warning

▪Before connect the cable with the inverter, the worker must confirm the output switch of the

inverter has been turn off, to prevent the risk of fire or electric shock.

▪Before connection, make sure to close the battery.

▪Please follow the instructions to protect the module BMS against damage.

▪DO NOT deviate from the sequence of steps below.

▪Exercise extreme caution prevent the terminals from contacting anything except their intended

mounting points.

▪Terminals and their connected wires have either positive or negative polarity (Positive: +; Negative-).

The polarity of a terminal or a wire connected to the terminal is on the front of each module.

Exercise extreme caution to prevent the terminals and/or wires with opposite polarity from

contacting with each other.

~ 12 ~

▪The maximum voltage of the battery is no more than 60V, which is higher than the safe voltage of

36V. Therefore, we still recommend that the battery terminals or other exposed parts should not be

directly touched during the installation.

▪When tightening the screws, make sure they are at a straight angle from the battery module

terminals to avoid damage to the nuts inside.

▪The power terminals, such as “+,” “-,” of the module are covered with the protecting cover to

guard against a short circuit (Shown in Figure 5-1).

▪You must remove the insulation cover prior to connecting.

Figure 5-1: Install the Grounding Wire

(Using a Phillips-head within the fastening torque of less than 3.0 N.m)

Step 1: Wear the protective gloves.

Step 2: Install the battery ground cable.

Step 3: Install negative and positive power cables for the battery.

1) Remove the protective cover from the battery power wiring terminal.

2) Connect the negative power cable to the battery.

3) Connect the positive power cable to the battery.

4) Install the other end of the battery power cables at a battery route and the corresponding busbar

in the power system.

~ 13 ~

Connect the inverter:

1) Remove the protecting cover.

2) Connect the positive output cable between the battery positive terminal of the battery and the

inverter. The plug must be firmly inserted to ensure a reliable connection.

3) Connect the negative output cable between the battery negative terminal of the battery and the

inverter. The plug must be firmly inserted to ensure a reliable connection.

4) Sort the cables and fasten the battery cables to the perforated bracket with cable ties.

5) Communication line connection as shown in Figure 5-2.

Figure 5-2: Single Battery Connection

6) If you need to debug the battery, connect the communication line between battery and computer

with USB converter (USB to RS485 or CAN2.0).

Figure 5-3: Communication Connections between Battery and Computer

~ 14 ~

5.2 Multiple Batteries in Parallel

When multiple batteries in parallel, the cable connecting procedures are follows.

5.2.1. As shown in Figure 5-4, following the cable connection method of the single battery, connect

the positive and negative cables between the Battery 1 and the busbar, Battery 2 and the busbar,

and Battery N and the busbar respectively.

Note: To ensure the current balance, please use cables with the same diameter and length for each

battery.

Figure 5-4: Multiple Batteries Connections

5.2.2. As shown in Figure 5-4, connect the communication line (a standard RJ45 network cable)

between the adjacent batteries.

Note: The PCS Port of the first battery must be connected to the inverter's battery communication

interface, otherwise the inverter cannot communicate with the batteries.

Note: The OUT Port of the first battery is connected to the IN Port of the next battery, and so on,

connecting the communication of multiple batteries together, otherwise multiple batteries will not be

able to communicate correctly.

~ 15 ~

5.3 Visual Inspection of the Connection

After connecting the battery, check for:

Usage of positive and negative cables.

Connection of the positive and negative terminals. Terminals must be securely inserted to

ensure reliability

All the bolts are tightened.

Cables fixation and the appearance.

The communication cable is connected correctly.

The installation of the protecting cover.

6. Activate the Product

6.1 Start the Battery

After installation, wiring, and configuration are completed, you must check all the connection. When

the connections are correctly, and then press power button to activate the battery. The green

working light on the front panel of the battery flashes, indicating that the battery system is normal.

7. Inspection, Cleaning and Maintenance

7.1 General Information

The battery product is not fully charged. It is recommended that the installation be completed

within 3 months after arrival;

During the maintenance process, do not re-install the battery in the battery product.

Otherwise, the performance of the battery will be reduced;

It is forbidden to dismantle any battery in the battery product, and it is forbidden to dissect the

battery;

After the battery product is over-discharged, it is recommended to charge the battery within

48 hours. The battery product can also be charged in parallel. After the battery product is

connected in parallel, the charger only needs to connect the output port of any product

battery.

Never attempt to open or dismantle the battery! The inside of the battery does not contain

serviceable parts.

Disconnect the Li-Ion battery from all loads and charging devices before performing cleaning

and maintenance activities

Place the enclosed protective caps over the terminals before cleaning and maintenance

activities to avoid the risk of contacting the terminals.

~ 16 ~

7.2 Inspection

Inspect for loose and/or damaged wiring and contacts, cracks, deformations, leakage, or

damage of any other kind. If damage to the battery is found, it must be replaced. Do not

attempt to charge or use a damaged battery. Do not touch the liquid from a ruptured battery.

Regularly check the battery’s state of charge. Lithium Iron Phosphate batteries will slowly

self-discharge when not in use or whilst in storage.

Consider replacing the battery with a new one if you note either of the following conditions:

- The battery run time drops below 70% of the original run time.

- The battery charge time increases significantly.

7.3 Cleaning

If necessary, clean the Li-Ion battery with a soft, dry cloth. Never use liquids, solvents, or abrasives

to clean the Li-Ion battery.

7.4 Maintenance

The Li-Ion battery is maintenance free. Charge the battery to approximately > 80% of its capacity at

least once every year to preserve the battery’s capacity.

7.5 Storage

The battery product should be stored in a dry, cool, and cool environment.

Generally, the maximum storage period at room temperature is 6 months. When the battery

is stored over 6 months, it is recommended to check the battery voltage. If the voltage is

higher than 51.2V, it can continue to store the battery. In addition, it is needed to check the

voltage at least once a month until the voltage is lower than 51.2V. When the voltage of the

battery is lower than 51.2V, it must to be charged according to the charging strategy.

The charging strategy is as follows: discharge the battery to the cutoff voltage with 0.2C10A

current, and then charge with 0.2C10A current for about 3 hours. Keep the SOC of the battery

at 40-70% when stored.

When the battery product is stored, the source of ignition or high temperature should be

avoided and it should be kept away from explosive and flammable areas.

~ 17 ~

8. Troubleshooting

To determine the status of the battery system, users must use additional battery status monitoring

software to examine the protection mode. Refer to the installation manual about using the

monitoring software. Once the user knows the protection mode, refer to the following sections for

solutions.

Table 8-1: Troubleshooting

Fault Type

Fault Generation

condition

Possible Causes

Troubleshooting

BMS fault

The cell voltage sampling

circuit is faulty.

The cell temperature

sampling circuit is faulty

The welding point for cell voltage

sampling is loose or disconnected.

The voltage sampling terminal is

disconnected.

The fuse in the voltage sampling circuit

is blown.

The cell temperature sensor has failed.

Replace the battery.

Electrochemical

cell fault

The voltage of the cell is low

or unbalanced.

Due to large self- discharge, the cell

over discharges to below 2.0V after

long term storage.

The cell is damaged by external

factors, and short circuits, pinpricks, or

crushing occur.

Replace the battery.

Overvoltage

protection

The cell voltage is greater

than 3.65 V in charging state.

The battery voltage is greater

than 58.4 V.

The busbar input voltage exceeds the

normal value.

Cells are not consistent. The capacity

of some cells deteriorates too fast or

the internal resistance of some cells is

too high.

If the battery cannot

be recovered due to

protection against

abnormality contact

local engineers to

rectify the fault.

Under voltage

protection

The battery voltage is less

than 40V.

The minimum cell voltage is

less than 2.5V

The mains power failure has lasted for

a long time.

Cells are not consistent. The capacity

of some cells deteriorates too fast or

the internal resistance of some cells is

too high.

Same as above.

Charge or dis-

charge high

temperature

protection

The maximum cell

temperature is greater than

60◦C

The battery ambient temperature is too

high.

There are abnormal heat sources

around

Same as above.

Charge low

temperature

protection

The minimum cell

temperature is less than 0◦C

The battery ambient temperature is too

low.

Same as above.

Discharge low

temperature

protection

The minimum cell

temperature is less than

-20◦C

The battery ambient temperature is too

low.

Same as above.

By checking the above data and sending the data to the service personnel of our company, the

service personnel of our company will reply the corresponding solution after receiving the data.

~ 18 ~

9. Battery recovery

Aluminum, copper, lithium, iron and other metal materials are recovered from discarded LiFePO4

batteries by advanced hydrometallurgical process, and the comprehensive recovery efficiency can

reach 80%. The specific process steps are as follows:

9.1 Recovery process and steps of cathode materials

Aluminum foil as collector is amphoteric metal. Firstly, it is dissolved in NaOH alkali solution to make

aluminum enter the solution in the form of NaAlO2. After filtration, the filtrate is neutralized with

sulfuric acid solution and precipitated to obtain Al (OH)3. When the pH value is above 9.0, most of

the aluminum precipitates, and the obtained Al (OH)3can reach the level of chemical purity after

analysis.

The filter residue is dissolved with sulfuric acid and hydrogen peroxide, so that lithium iron

phosphate enters the solution in the form of Fe2(SO4)3 and Li2SO4, and is separated from carbon

black and carbon coated on the surface of lithium iron phosphate. After filtration and separation, the

pH value of the filtrate is adjusted with NaOH and ammonia water. First, iron is precipitated with Fe

(OH) 3, and the remaining solution is precipitated with saturated Na2CO3solution at 90 ℃.

Since FePO4is slightly dissolved in nitric acid, the filter residue is dissolved with nitric acid and

hydrogen peroxide, which directly precipitates FePO4, separates impurities such as carbon black

from acid solution, leaches Fe (OH) 3 from filter residue respectively, and precipitates Li2CO3with

saturated Na2CO3solution at 90 ℃.

9.2 Recovery of anode materials

The recovery process of anode materials is relatively simple. After the separation of anode plates,

the purity of copper can be more than 99%, which can be used for further refining electrolytic copper.

9.3 Recovery of diaphragm

The diaphragm material is mainly harmless, and has no recycling value.

9.4 List of recycling equipment:

Automatic dismantling machine, pulverizes, wet gold pool, etc.

Other manuals for Spring Series

2

This manual suits for next models

1

Table of contents

Other Deye Batteries Pack manuals