Deye GE-F60 User manual

Installation and Operation Installations

High Voltage Battery

GE-F60

Version: V1.0

1

Table of contents

All Rights Reserved:..................................................................................................4

About This Manual ....................................................................................................4

1 Safety Precautions.................................................................................................5

1.1 Personal Requirements ...................................................................................5

1.2 Electrical Safety...............................................................................................6

1.3 Battery Safety..................................................................................................7

1.4 Hoisting and Transportation.............................................................................7

1.5 Installation and Wiring...................................................................................... 7

1.6 Operation and Maintenance.............................................................................7

1.7 Disposal of Waste............................................................................................ 8

2 Product Description................................................................................................8

2.1 Product Introduction.........................................................................................8

2.2 External Design ...............................................................................................9

2.3 Air-conditioner Design.................................................................................... 10

2.4 Internal Design............................................................................................... 11

2.4.1 Internal Equipment ................................................................................................11

2.4.2 Battery Introduction...............................................................................................13

2.4.3 Indicator light Design .............................................................................................16

3 Transport and storage.......................................................................................... 19

3.1 Transportation................................................................................................ 19

3.2 Transportation Requirement .......................................................................... 19

3.3 Storage requirement...................................................................................... 20

4 Mechanical Installation......................................................................................... 21

4.1 Inspection Before Installation......................................................................... 21

4.1.1 Deliverables Inspection ..........................................................................................21

4.1.2 Product Inspection .................................................................................................22

4.2 Installation Environment................................................................................. 22

4.3 Installation Spacing Requirement................................................................... 23

4.4 Installation of inverters and BESS.................................................................. 24

4.5 Transportation and lifting ............................................................................... 25

4.5.1 Transportation........................................................................................................25

4.5.2 Hoisting Equipment................................................................................................26

2

4.5.3 Hoisting ..................................................................................................................27

4.6 Fixing Methods .............................................................................................. 27

5. Electrical connection ........................................................................................... 28

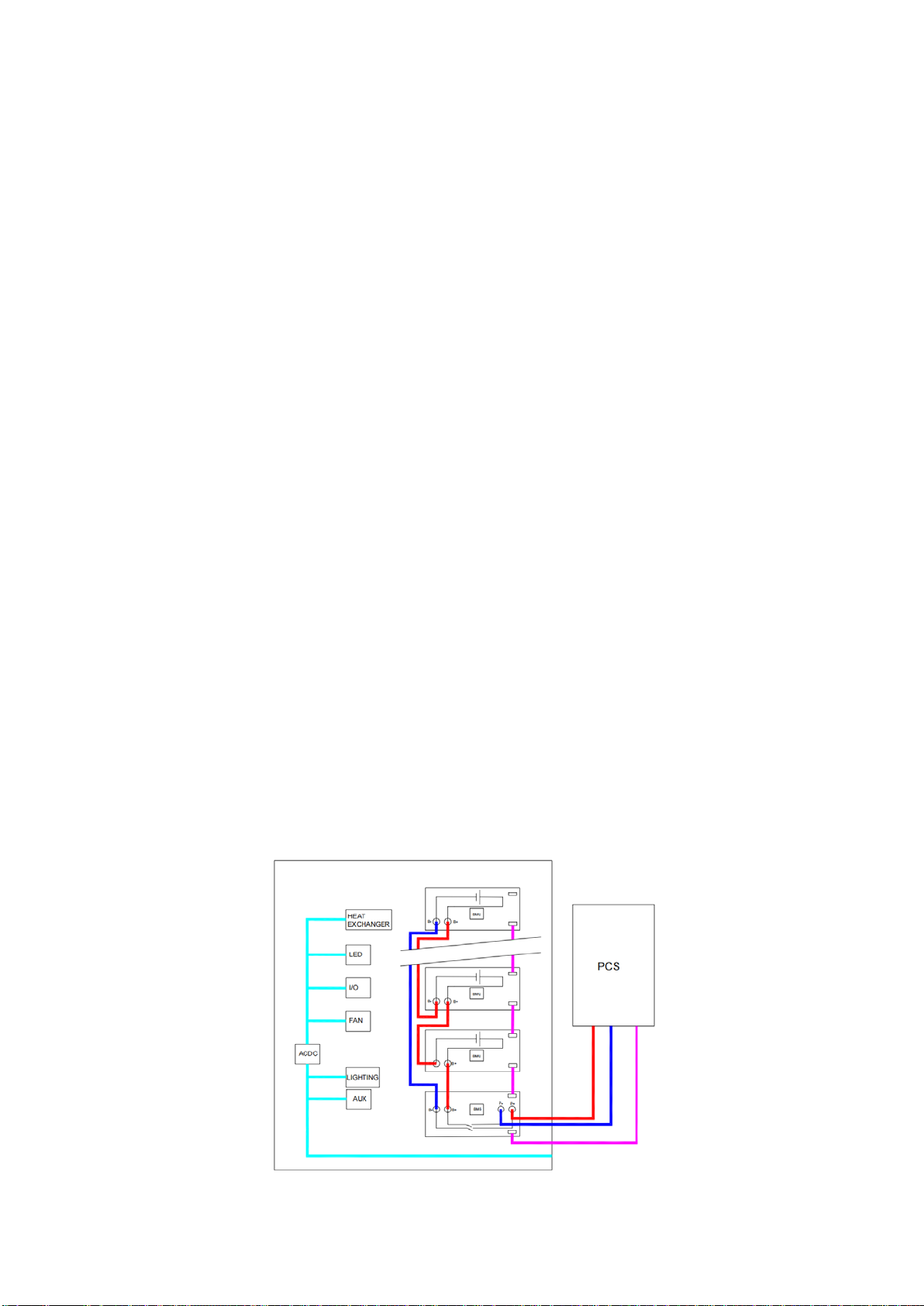

5.1 Electrical connection Overview ...................................................................... 29

5.2 Preparation before connection....................................................................... 29

5.4 Cable connection........................................................................................... 30

5.4.1 Cable connections inside BESS ...............................................................................30

5.4.3 Cable connection between BESS............................................................................32

5.4.2 Cable connection between the inverter and BESS .................................................34

5.5 Operation after cable connection................................................................... 35

5.6 Battery Connection........................................................................................ 35

6 Activate BESS...................................................................................................... 35

Power on and off ................................................................................................. 35

6.1 Power-on procedure...................................................................................... 36

6.2 Power-off procedure ...................................................................................... 36

6.3 Unplanned (emergency) shut down ............................................................... 37

7 Fire Suppression system...................................................................................... 37

7.1 Fire Suppression equipment.......................................................................... 37

7.2 Exhaust system ............................................................................................. 38

8 Troubleshooting ................................................................................................... 39

9. Inspection, cleaning and maintenance................................................................. 40

9.1 Basic Information........................................................................................... 40

9.2 Maintenance item and period......................................................................... 40

9.3 Battery Maintenance...................................................................................... 42

10 Upgrade............................................................................................................. 44

10.1 USB Upgrade............................................................................................... 44

10.2 PC Upgrade................................................................................................. 44

10.3 PCS Upgrade............................................................................................... 47

11. Battery recycling................................................................................................ 49

11.1 Recovery process and steps of cathode materials....................................... 49

11.2 Recovery of anode materials ....................................................................... 50

11.3 List of recycling equipment........................................................................... 50

12 Contact Information............................................................................................ 50

4

All Rights Reserved:

No part of this document can be reproduced in any form or by any means without the prior

written permission of NINGBO DEYE ESS TECHNOLOGY CO., LTD (-hereinafter "Deye ESS").

Trademarks

Deye and other Deye trademarks used in this manual are owned by Deye ESS.

All other trademarks or registered trademarks mentioned in this manual are owned by their

respective owners.

Software Licenses

•It is prohibited to use data contained in firmware or software developed by Deye ESS, in part

or in full, for commercial purposes by any means.

•It is prohibited to perform reverse engineering, cracking, or any other operations that

compromise the original program design of the software developed by Deye ESS.

About This Manual

This manual describes the transportation and storage, mechanical installation, electrical

connection, power-on and power-off operation, troubleshooting, and maintenance of the BESS.

How to Use This Manual

Please read this manual carefully before using the product and keep it properly at a place for

easy access.

In order to provide the best customer experience, contents of the manual may be updated and

amended continuously, so it is possible that there may be some errors or slight inconsistency

with the actual product. Please refer to the actual product purchased, and the latest manual can

be obtained from service-ess@deye.com.cn (www.deyeess.com) or sales channels.

The figures in this manual are for reference only. The actual product received may differ.

Symbol Explanations

To ensure the safety of the users and their properties when they use the product and to make

sure that the product is used in an optimal and efficient manner, this manual provides users with

the relevant safety information highlighted by the following symbols.

Below is a list of symbols used in this manual. Please read it carefully to make better use of this

manual.

Danger!

Failure to follow the instructions bearing this sign may result in a serious

accident resulting in death or serious injury.

5

Warning!

Failure to follow the instructions of this sign may result in a serious accident

resulting in serious personal injury.

Caution!

Failure to follow the instructions of this sign may result in minor or

moderate injury.

Notice!

Provide information that is considered important but not relevant to the

danger. The information relates to property damage.

This product is designed to an integrated system, which must be performed by a qualified person

trained in electrical engineering and familiar with the characteristics and safety requirements of

lithium batteries. Do not use this product if you are unsure if you possess the necessary skills to

complete this integration.

Abbreviation:

Complete designation Abbreviations

Battery Module Module

Battery Pack Pack

Power Distribution Unit PDU

Accessory box /

Energy Storage System

BESS

Battery Base

Base

1 Safety Precautions

1.1 Personal Requirements

The hoisting, transportation, installation, wiring, operation, and maintenance of the BESS must

be carried out by professional electrical technicians in accordance with local regulations. The

professional technician is required to meet the following requirements:

•Should know electronic, electrical wiring and mechanical expertise, and be familiar with

electrical and mechanical schematics.

•Should be familiar with the composition and working principles of the BESS and its corollary

equipment.

•Be able to quickly respond to hazards and emergencies that occur during installation and

commissioning.

•Be familiar with the relevant standards and specifications of the country/region where the

project is located.

6

1.2 Electrical Safety

Danger!

•Touching the power grid or the contact points and terminals in the devices connected to the

power grid may lead to electric shock! All circuit connectors must be disconnected during

maintenance.

•The battery side or the power grid side may generate voltage. Always use a standard

voltmeter to ensure that there is no voltage before touching.

Danger!

•Lethal voltages are present inside the product!

•Note and observe the warnings on the product.

•Respect all safety precautions listed in this manual and other pertinent document.

•Respect the protection requirements and precautions of the lithium battery

Danger!

When the power supply is disconnected, there may still be electricity in the battery. Wait for 10

minutes and ensure that the device has no voltage before performing any operation.

Warning!

•All hoisting, transportation, installation, wiring, operation, and maintenance must be carried

out complying with the relevant codes and regulations of the country where the project is

located.

•Always use the product in accordance with the requirements described in this manual.

Otherwise, equipment damage may occur.

Notice!

To prevent accidents caused by misuse or unrelated persons, place necessary warning signs or

barriers near the product.

7

1.3 Battery Safety

It is very important to read the owner's manual carefully before installing or using the battery.

Follow any instructions or warnings in this document, otherwise it may result in electric shock,

serious injury, or death, or may damage the battery and render it inoperable.

After the battery is fully discharged, it needs to be charged within 48 hours. The battery is not

charged as required, resulting in loss of battery capacity or irreversible damage. If the battery is

stored for a long time, it is required to be charged every six months, and the SOC should not be

less than 50%.

•Do not use cleaning solvents to clean batteries. Do not expose the battery to flammable or

irritating chemicals or vapors.

•Do not connect the battery directly to the photovoltaic solar power wire.

•Do not paint any part of the battery, including any internal or external components.

•Please do not use batteries provided by the company with other batteries, including but not

limited to batteries of other brands or batteries with different rated capacities.

•Do not insert any foreign matter into any part of the battery.

•Handle or handle with care to avoid battery damage, drop, or leakage.

•Do not store batteries with inflammable and explosive materials. This may cause product

damage or property loss.

Maintain the battery according to this manual. Deye ESS is not responsible for insurance and

claims if maintenance is not performed in accordance with this manual.

1.4 Hoisting and Transportation

Follow the procedure of work of heights when walking on the top of the container.

1.5 Installation and Wiring

In the whole process of mechanical installation, the relevant standards and requirements of the

project location must be strictly observed.

Please refer to the wiring method recommended by Deye ESS.

1.6 Operation and Maintenance

Personal protective equipment must be equipped when maintaining and maintaining the BESS.

Maintenance personnel must wear protective equipment such as goggles, helmets, insulating

8

shoes, and gloves.

Users are not allowed to perform battery maintenance without guidance. Warning Except the

maintenance operations described in this manual, do not perform other maintenance operations

to avoid electric shock. If necessary, please contact Deye ESS Customer Service center for

maintenance.

Removing or repairing the battery may cause the battery to catch fire. The replacement of

internal parts must be carried out by professionals. Do not spray paint internal or external parts

of the product. Do not use cleaning agents to clean products or expose them to harsh chemicals.

1.7 Disposal of Waste

When the equipment is at the end of its service life, it cannot be disposed of together with

domestic waste. Some parts can be recycled, and some parts will cause environmental pollution.

2 Product Description

2.1 Product Introduction

GE-F60 lithium iron phosphate battery the new energy storage products developed and

produced by DEYE ESS, which can be used to support the reliable power supply of various

equipment and systems. The GE-F60 is particularly suitable for high-rate cyclic charging and

discharging scenarios.

GE-F60 has built-in local management system, it can manage and monitor, voltage, current,

temperature, humidity, smoke, etc. In addition, BMS also balances the capacity of the battery

and extends the cycle life of the system. Meanwhile, support black start function, Off grid

operation, and built-in aerosol fire suppression device and combustible gas detection exhaust

system. Multiple battery systems can be expanded in parallel for greater capacity and longer

power support duration requirements.

9

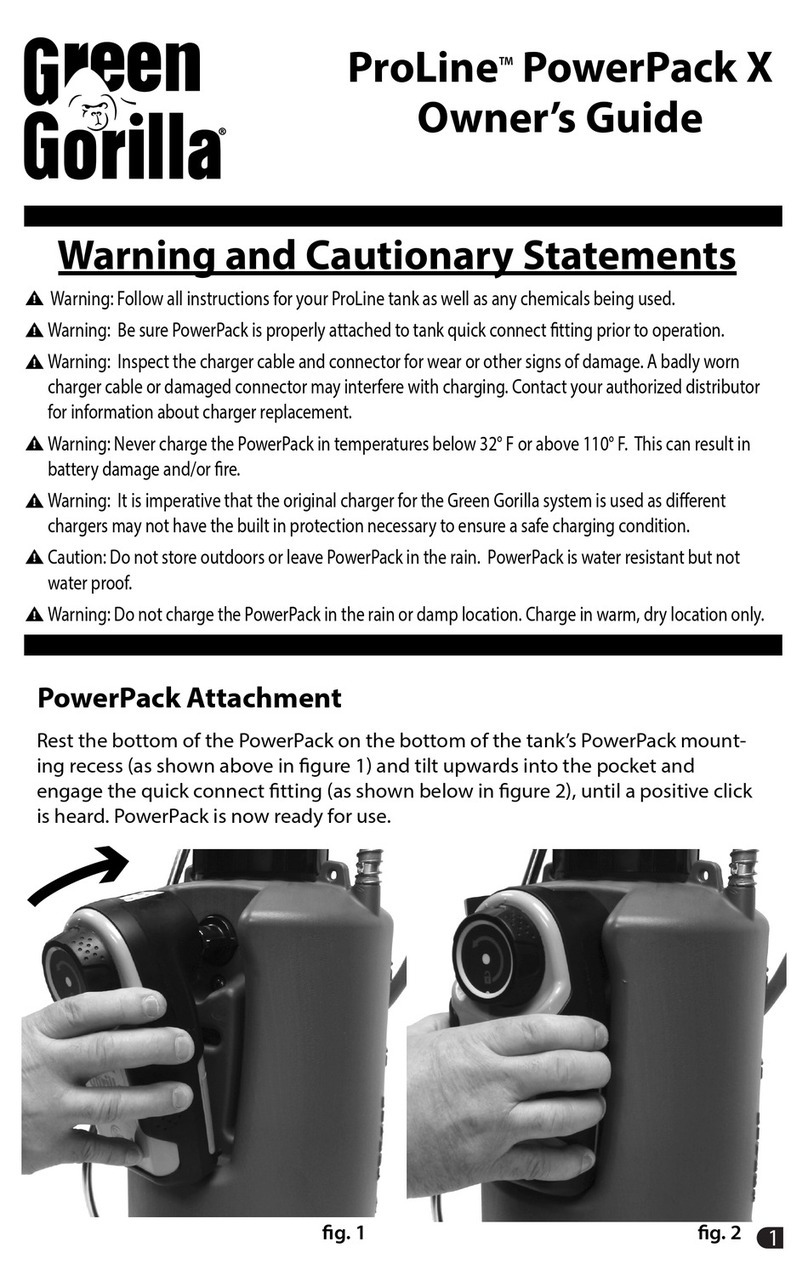

2.2 External Design

Cabinet Appearance

①Indicator light: When the green light

comes on, the BESS is Run. When the red

light comes on, the BESS gives an alarm.

⑤Flammable gas outlet: When flammable gas

appears in the BESS, it can be discharged

through this outlet.

②Air inlet: Outdoor air enters air conditioner

through this opening.

⑥Door switch: Insert the key to open the ESS.

③Emergency stop switch: When the air

conditioner out of order, activate this

switch to stop the BESS.

⑦Cable outlet:The cable outlet during parallel

operation or connected to the inverter.

④Water outlet: External incoming water and

air conditioning condensed water.

10

2.3 Air-conditioner Design

System built-in air conditioner cooling

The air conditioning system uses steam compression refrigeration, so that it becomes cold air,

and then sends it to the internal air duct of the energy storage cabinet to cool the battery.

Energy storage Air Conditioning

Model:DY-CNA20-BP

Rated Voltage: 220V ~

Rated Frequency 50Hz

Rated Cooling Capacity: 2100W

Rated Heating Capacity: 1650W

Rated Cooling Power Input: 900W

Rated Heating Power Input: 1650W

Rated Cooling Current: 4.15A

Max.Power: 1800W

Max.Current: 8.3A

Max Operating Pressure 2.7Mpa

Max.Suction Pressure 1.6Mpa

Max.Discharge Pressure 2.7Mpa

Air Flow Volume 630m³/h

Electric Shock Prevention I

Water-proof Class IP55

Dimension(W╳H╳D)478╳798╳304mm

Net Weight 47kg

11

2.4 Internal Design

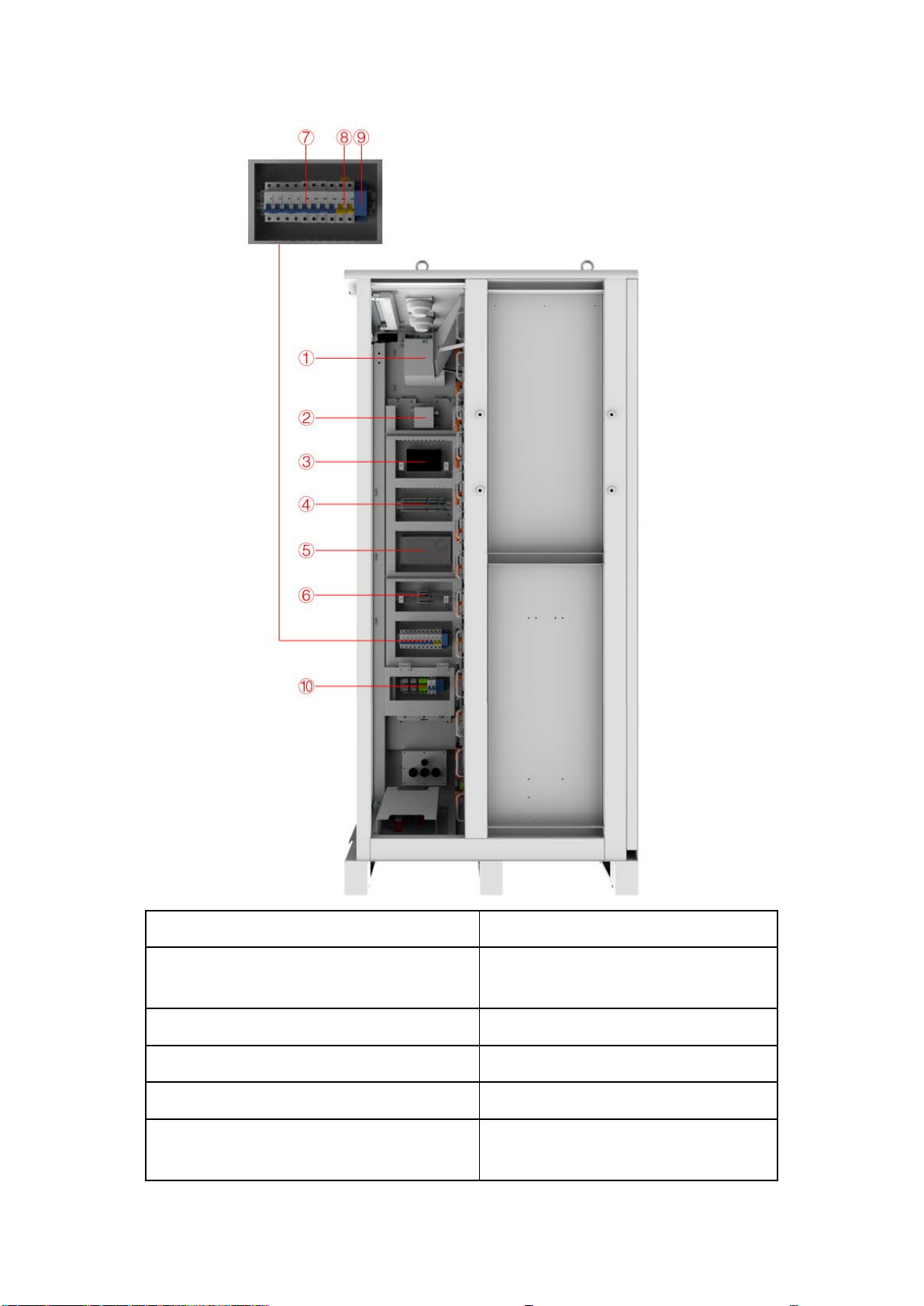

2.4.1 Internal Equipment

①Air conditioner Cooling the BESS.

②Aerosol Fire Suppression Device

When the BESS is detected to be on fire, aerosol

is emitted to extinguish the fire.

③Travel switch Check whether the BESS’s door is closed.

④Smoke detector A device used to detect smoke in a fire and sound

an alarm when smoke is detected.

⑤Heat detector

A device used to measure temperature and

sound an alarm if it detects excessive

temperature.

12

①Fan Emission of combustible gas

②Combustible gas sensor

Detect combustible gases and notify

aerosol fire suppression systems

③Serial relay Control system

④Terminal line For connecting cables

⑤Switching Mode Power Supply

Power source

⑥Temperature and humidity sensor

Used to measure ambient temperature

and humidity

13

⑦Miniature circuit breaker Controlled power-on and power-off

⑧Lightning protection backup protector Automatic regulation, safety protection,

conversion circuit

⑨Water immersion sensor Check the BESS for water leakage

⑩Terminal line Connect external cables

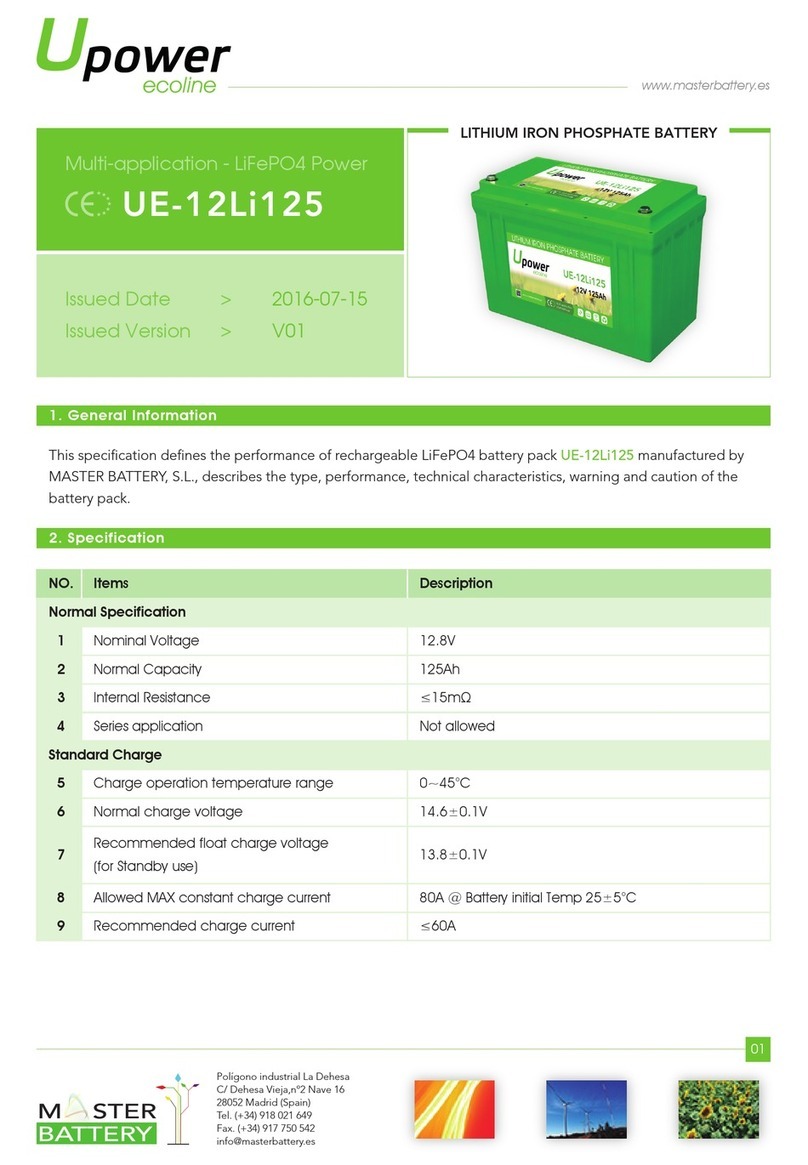

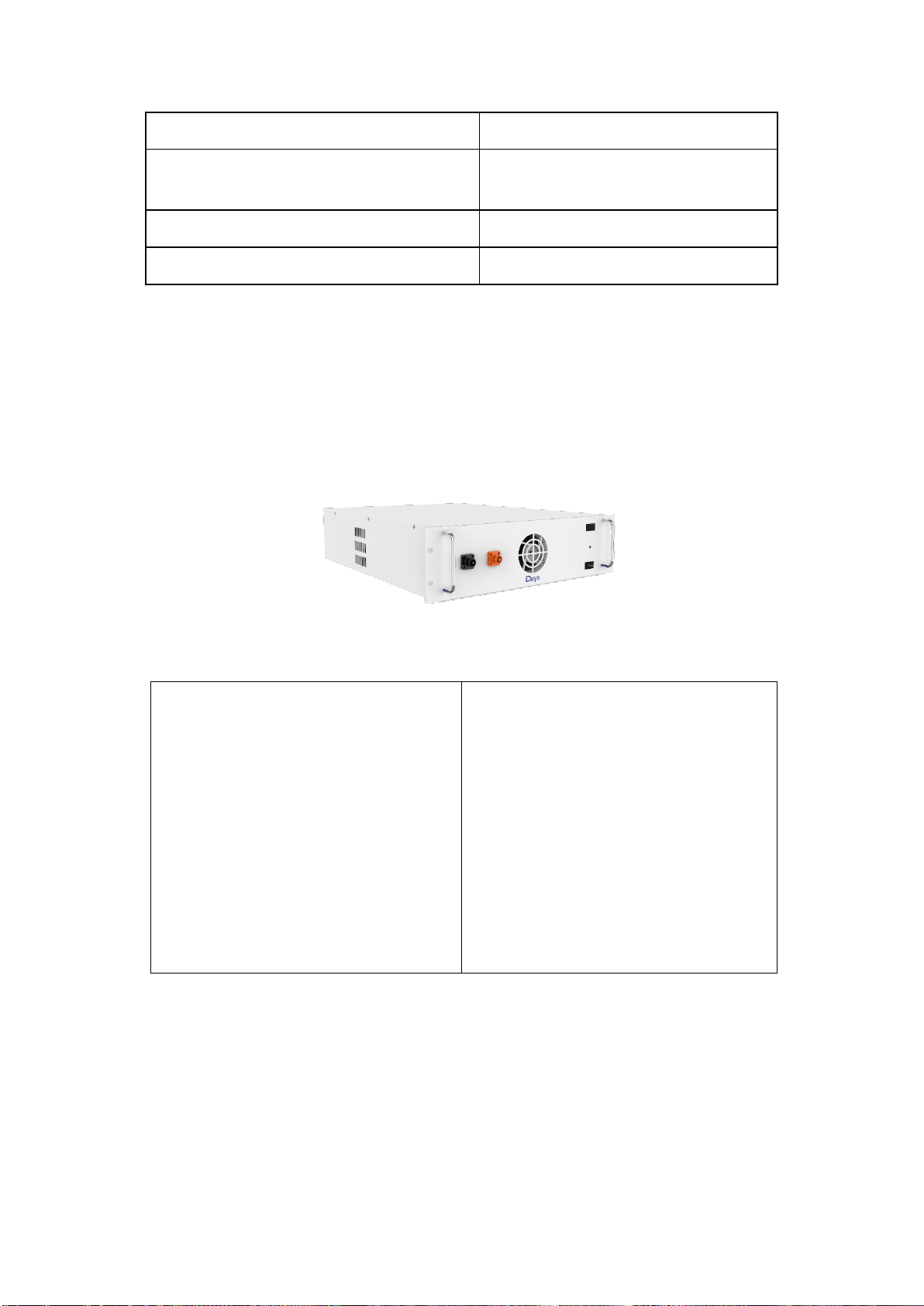

2.4.2 Battery Introduction

Battery Module

Battery Type

Nominal Voltage

Rated Capacity

Rated Energy

Nominal

Charge/Discharge Current

Peak. Discharge Current

Charge Temperature

Discharge Temperature

Storage Temperature

Ingress Protection

Dimension (W/D/H)

Weight Approximate

LiFePO4(LFP)

51.2Vdc

100Ah

5.12kWh

100A

125A

0~55°C

-20℃~55°C

0℃~35°C

IP20

440*570*133mm

44kg

14

①Aerosol sensor Detection of aerosol concentrations in the

air

②Battery module

Provides electrical energy storage and

output

③CCS Cells Contact System

④Vent hole

Heat dissipation

⑤Battery Negative-

/

⑥Battery Positive+ /

⑦Fan Promote internal and external air flow

⑧BMU Battery monitoring

Power Distribution Unit

15

Operating Voltage

Nominal Charge/Discharge Current

Max. Charge/Discharge Current

DC Input Rating

Operating Temperature Range

Ingress Protection

Dimension (W/D/H)

Weight Approximate

120~750Vdc

100A

125A

12±2%V/4.15A

-20~65°C

IP20

440*570*150mm

17kg

①B-

Connection position of the common negative pole of the

battery

②B+ Connection position of the common positive pole of the battery

③Air switch

Used to manually control the connection between the battery

rack and external devices

④ALRM light indicator Battery system fault alarm indicator

⑤

HV light indicator

High-voltage hazard indicator

⑥PCS- Connection position of PCS negative pole

⑦PCS+ Connection position of PCS positive pole

⑧USB

BMS upgrade interface and storage expansion interface

⑨OUT COM

Connection position with next GE-F-PDU communication

output

⑩IN COM

Connection position with previous GE-F-PDU communication

input

⑪PCS COM Communication interface with charging and discharging

equipment

⑫START A start switch of 12VDC power inside the high-voltage control

box

⑬COMM1

Communicative connection with the cabinet

⑭COMM2

Communicative connection with the first battery module; and

providing 12VDC power for the first battery module.

16

2.4.3 Indicator light Design

Indicator light: When the green light comes on, the BESS is Run. When the red light comes on,

the BESS gives an alarm.

1. The following faults trigger either level 2 fault. The cabinet ALARM red light is on, the external

ALARM light is on, and the RUN indicator is off.

1 System fault 18 Discharge relay

adhesion 35

Sensor second alarm

(Temperature sensor and

smoke sensor)

2 Charging current fault 19 Charge relay

adhesion 36 Emergency stop press fault

3 Charging current fault 20 Heating relay

adhesion 37 Detected combustible gas

fault

4

Charging

overtemperature fault 21 Extreme protection 38

Detected water sensor

fault

5 Discharging

overtemperature fault 22 Abnormal supply

voltage 39 Detected smoke sensor

fault

17

6 Charging low

temperature fault 23 Main positive relay

adhesion 40 Pre-charge failed fault

7

Discharging low

temperature fault 24 blown fuse 41

The Charging voltage is too

low

8 Pressure difference

too large fault 25 BMU repeat fault 42 BMU communication fault

9

Temperature

difference too large

fault

26 BMU repeat fault 43 BMU number anomaly

10 High SOC fault 27 Internal CAN

communication fails 44 Abnormal Mot total

pressure collection

11 Cell temperature low

voltage fault 28 PCS CAN

Communication fails 45

Abnormal Temperature

collection of the BMS

connector

12 Pre-charge resistance

temperature too high 29 Abnormal PCS RS485

communication 46

Abnormal Temperature

collection of the BMU

connector

13 Insulation fault 30

Abnormal external

total pressure

collection

47 EEPROM storage fault

14 Heating film is too

high fault 31

Abnormal internal

total pressure

collection

48 RTC clock fault

15 SOC too low fault 32 Abnormal SCHG total

pressure collection 49 Current module fault

16 Total voltage too high

fault 33 Voltage acquisition

fault 50 Current acquisition fault

17 Total voltage too high

fault 34

Temperature

acquisition fault 51 Detect temperature

exceedance fault

2. When the emergency stop press fault, flammable gas fault, water flooding fault, temperature

exceeding fault and smoke fault are detected, the BESS external ALARM light is on and the RUN

light is off.

3. The air conditioner is offline, the BESS external ALARM light is on, and the RUN light is off.

4. The following faults occur in the air conditioner. The BESS external ALARM light is on and the

RUN light is off.

1 High temperature alarm 9 Internal ambient

temperature 1 fault

17 Inner coil temperature

protection

2 Low temperature alarm 10 Internal ambient

temperature 2 fault

18 Internal fan failure

3

High humidity alarm

11

Internal ambient

19

Internal fan

18

humidity 1 fault communication fault

4 Low humidity alarm 12 Internal ambient

humidity 2 fault

20 Internal fan overloaded

fault

5

Electric heating

protection

13

Inner coil temperature

fault

21

External fan failure

6

Outdoor ambient

temperature fault

14

Pressure sensor failure

22

External fan

communication fault

7 Outer coil temperature

fault

15 High exhaust

temperature protection

23 External fan

overloaded fault

8 Exhaust temperature

fault

16 Outer coil temperature

protection

24 Compressor startup

failure

25

Compressor

communication failure

Indicator: Steady yellow indicates that PDU is working properly and the battery power circuit is

closed. When the red light is on, PDU gives an alarm.

The following faults trigger any level 2 fault, the battery ALARM red light is on, the PDU ALARM

light is on, and the HV indicator is off.

1 System fault 18 Discharge relay

adhesion 35

Sensor second alarm

(Temperature sensor and

smoke sensor)

2 Charging current fault 19 Charge relay

adhesion

36 Emergency stop press fault

3 Charging current fault 20

Heating relay

adhesion 37

Detected combustible gas

fault

4

Charging

overtemperature fault 21 Extreme protection 38

Detected water sensor

fault

5 Discharging

overtemperature fault

22 Abnormal supply

voltage

39 Detected smoke sensor

fault

6 Charging low

temperature fault 23 Main positive relay

adhesion 40 Pre-charge failed fault

7

Discharging low

temperature fault 24 blown fuse 41

The Charging voltage is too

low

8 Pressure difference 25 BMU repeat fault 42 BMU communication fault

19

too large fault

9

Temperature

difference too large

fault

26 BMU repeat fault 43 BMU number anomaly

10 High SOC fault 27 Internal CAN

communication fails 44 Abnormal Mot total

pressure collection

11 Cell temperature low

voltage fault 28 PCS CAN

Communication fails 45

Abnormal Temperature

collection of the BMS

connector

12 Pre-charge resistance

temperature too high 29 Abnormal PCS RS485

communication 46

Abnormal Temperature

collection of the BMU

connector

13 Insulation fault 30

Abnormal external

total pressure

collection

47 EEPROM storage fault

14 Heating film is too

high fault 31

Abnormal internal

total pressure

collection

48 RTC clock fault

15 SOC too low fault 32 Abnormal SCHG total

pressure collection 49 Current module fault

16 Total voltage too high

fault 33 Voltage acquisition

fault 50 Current acquisition fault

17 Total voltage too high

fault 34

Temperature

acquisition fault 51 Detect temperature

exceedance fault

3 Transport and storage

3.1 Transportation

1 Preventive Measures

Failure to ship and store products in accordance with the requirements of this manual may void

the warranty.

2 Mode of Transportation

It can be transported by cars, trains and ships.

3.2 Transportation Requirement

The following conditions should be met for the transportation of BESS:

Ensure that the door is locked.

Select appropriate crane or lifting tool according to the site conditions. The lifting tool used

shall have a sufficient load bearing capacity, boom length and radius of rotation.

Table of contents

Other Deye Batteries Pack manuals