DeZurik MO User manual

Other DeZurik Controllers manuals

DeZurik

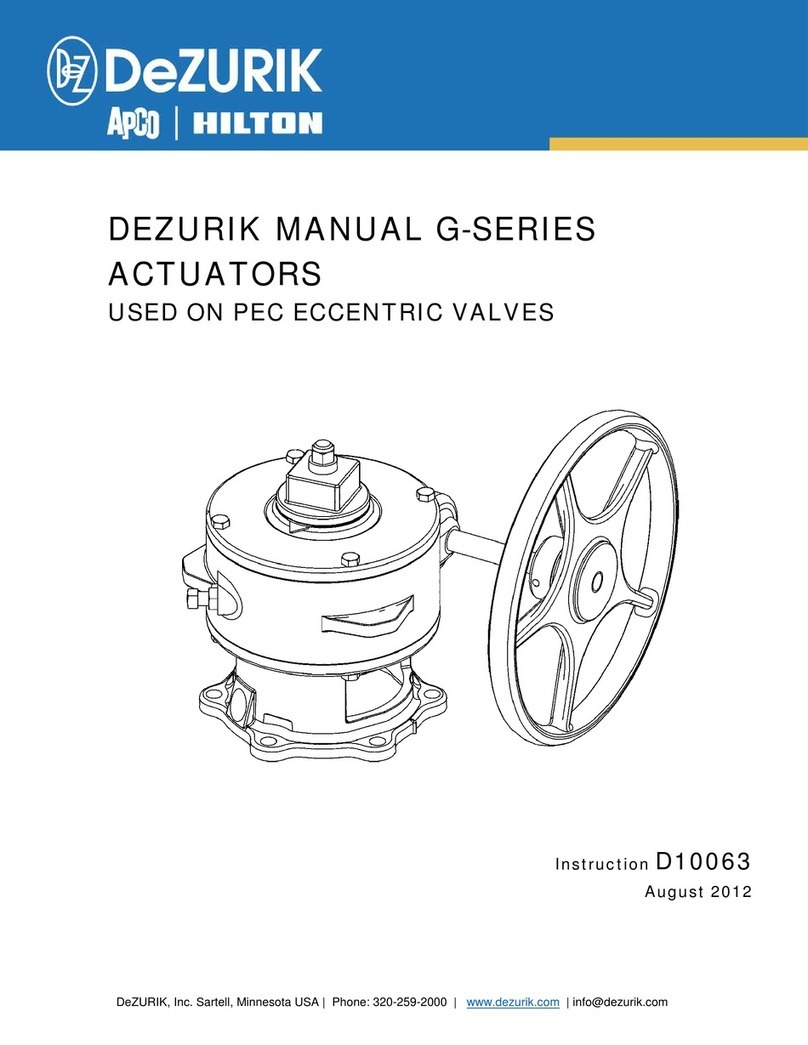

DeZurik G-SERIES User manual

DeZurik

DeZurik M Series User manual

DeZurik

DeZurik G-SERIES User manual

DeZurik

DeZurik POWERRAC R3 User manual

DeZurik

DeZurik APCO DAT User manual

DeZurik

DeZurik T Series User manual

DeZurik

DeZurik AFR3 User manual

DeZurik

DeZurik G-SERIES User manual

DeZurik

DeZurik 145 User manual

DeZurik

DeZurik G-SERIES User manual

DeZurik

DeZurik POWERRAC R1 User manual

DeZurik

DeZurik KSL User manual

DeZurik

DeZurik G-SERIES User manual

DeZurik

DeZurik LA Series User manual

DeZurik

DeZurik G-SERIES User manual

DeZurik

DeZurik G-SERIES User manual

DeZurik

DeZurik G-SERIES User manual

DeZurik

DeZurik AFR3 User manual

DeZurik

DeZurik G-SERIES User manual

DeZurik

DeZurik POWERRAC R1 User manual

Popular Controllers manuals by other brands

Pilz

Pilz PNOZ mmc7p CC operating manual

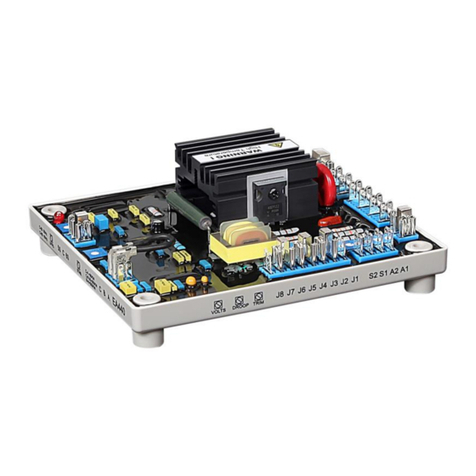

Moore Industries

Moore Industries 545 user manual

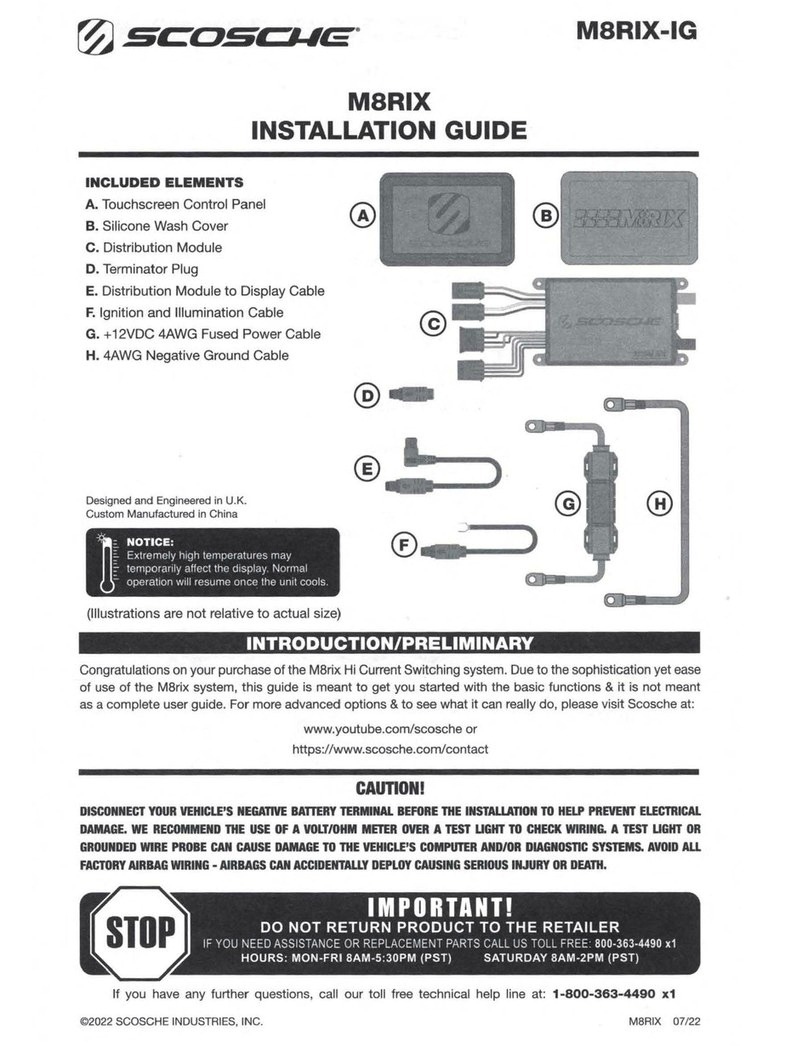

MicroNova

MicroNova O026 Technical Manual for Installers

LSI

LSI MegaRAID SATA150-2 Quick Hardware Setup Guide

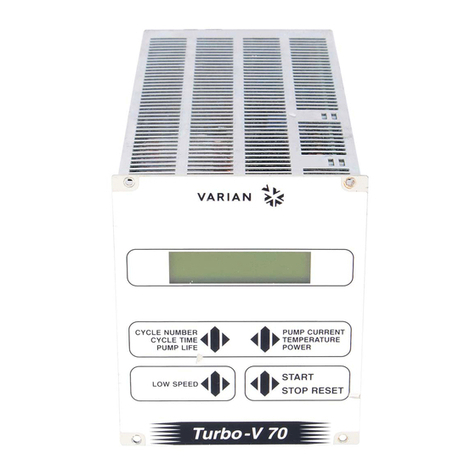

Metso

Metso VALVCON QX Series Installation maintenance and operating instructions

Tridonic

Tridonic luxCONTROL DaLI Msensor 5DPI 14 product manual