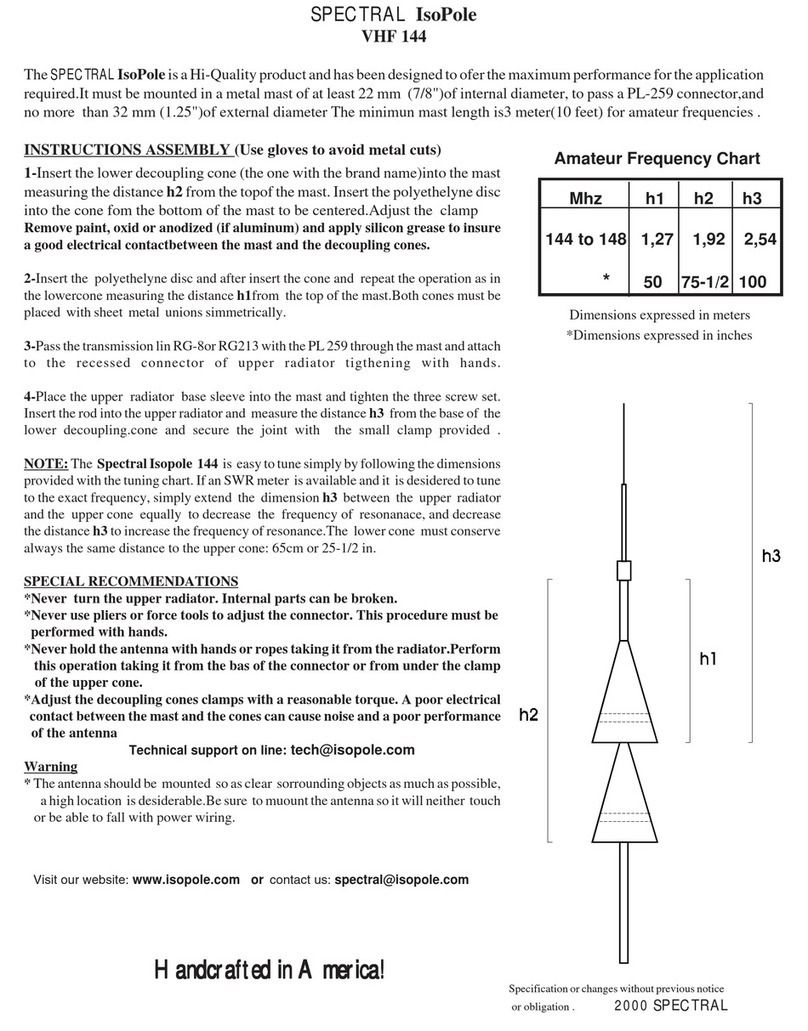

DH Antenna GIBRALTER GE-MINI User manual

CRITICAL FACTORS

INSTALLING A DH ANTENNA

1. READ INSTRUCTIONS before disassembling the crate.

2. RIBS: Look for color coded dot on the rib. Dots indicate correct order

to assemble panels. Number is stamped in the lip of the antenna too.

3. PILOT HOLE: Locate pilot hole on the ring and antenna. THIS IS

YOUR STARTING POINT! Pilot hole is located on the 2nd block from

the left of the weld on the ring from the back view of the antenna.

MATCH mount pilot hole to panel with pilot hole.

4. FINGER TIGHT: Installing the panels to the ring and installing the

ribs on the panel sections. DO NOT OVERTIGHTEN.

5. TIGHTEN DOWN all ribs to become a solid antenna. (Once all panels installed)

6. STRING THE ANTENNA. Strings should just touch. Adjust the

braces so front surface is exactly flat.

7. TIGHTEN DOWN ALL BOLTS: Ring to antenna.

8. SET FEEDHORN TO EXACT FOCAL LENGTH & TO EXACT

CENTER OF THE ANTENNA. Use a laser tool or cut a piece of wood

to the focal length of your antenna. Feedhorn must be flat to antenna

surface. Please consider feedhorn manufacturer’s recommendation. See

“Preparing the Feed Assembly” in manual.

CALL 1-608-326-8406 WITH QUESTIONS

Congratulations! You have now purchased the finest Dual Powered Azimuth-Elevation Mount

available. This unit will not only track the geosynchronous arc, but will work equally well for

satellites that are in inclined orbit, or elliptical orbit. Please follow these instructions. You may

call us at 608/326-8406 for help, Monday – Friday 7AM to 5 PM CST. Please review the

shipping warranty for missing parts immediately upon arrival (see back page).

The Ge-mini is designed to go with the 2.4m, 2.7m, and 3m antenna from DH. The 2.4m and the

3m are identical in theory with the exception of the 3m having a 48” ring with eight back braces.

We will cover the basic installation first and address each individually as the installation

requires.

PLEASE READ COMPLETE INSTRUCTIONS BEFORE BEGINNING INSTALLATION!!

www.dhsatellite.com

4PC Sectional Antenna Gibralter GE-MINI

Installation Instructions

PO BOX 239

600 N MARQUETTE RD

PRAIRIE DU CHIEN WI 53821

PHONE: 1 (608) 326-8406

FAX: 1 (608) 326-4233

EMAIL: [email protected]

CAUTION: Your 3m antenna will have 8 back braces.

Please be sure to string your antenna at time of installation.

Sectional antennas must be handled with care not to twist

or distort sections while handling for installation. 12/18/2017

*Galvanizedbackbracespleaseimmediately

readspecialnoteonboltbagpage2.

Parts List for: The “Dual Powered Ge-mini”

Elevation Assembly

1- 18" Actuator w/HD Clamp

1- 1/2" x 4 1/2" Bolt

1- 1/2" x 2" Bolt

2- 1/2" Lock Washers

2- 1/2" Nuts

Back Braces

3.0m w/48” Ring

(Optional on 2.4m & 2.7m w/39” Ring)

8- Back Braces

8- Brace Clips

8- Bent Tabs

8- ½” x 1 ½” Bolts

24- ½” Nuts

8- ½” Lock Washers

8-3/8" x 1 ½” Bolts

8-3/8" Nuts

8- 3/8” Lock Washers

16- ¼”x ¾” Bolts

16- ¼” Nuts

16- ¼” Lock Washers

PAGE 2

Base Plate Template Kit

(Optional)

4- 3/4" x 18" J-bolts

4- 3/4" Nuts

1- Wood Template

Antenna to Ring

39” & 48” Ring 8 Block

8- ½” x 3” Bolts

8- ½” Lock Washers

8- ½” Nuts

8- ½” Flat Washers

16- ½” Rubber Washers

C14F

Chaparral

Feed Assembly

1- Set of 4 Struts

1- Collar (C, Ku)

8- ¼” x 1 ½” Bolts

8- ¼” Lock Washers & Nuts

Ku4FL: 3PC

Add to C14F

3- Section to 3pc collar

3- 8-32 x 1” Bolts

3PC Collar for Ku4FL

(Use to Attach to Horseshoe of C14F)

3- 8-32 x ¾” Bolts

3- #8 Fender Washers

3- 8-32 Nuts

Mount to Ring

2- 1/2" Lock Washers

2- 1/2" x 2 1/2" Bolts

2- 1/2" Nuts

2- 1/2" x 3/4"x 1/2" Long Brass Bushings

NOTE:

Stainless steel or DURA-CON® hardware provided.

*DURA-CON® is a corrosion resistant coating.

DURA-CON®: Problem of thread-galling is eliminated.

NOTE: SECTIONAL ANTENNAS INCLUDE ADDITIONAL

HARDWARE, SEE TABLES BELOW

Template Rib Hardware: Sectional

Antenna Size ¼” x ¾” Bolts ¼” Lock Washers ¼” Nuts

2.4M 36 36 36

2.7M 40 40 40

3.0M 44 44 44

Splice Straps: Sectional

Antenna Size Splice Straps ¼” x ¾” Bolts ¼” Lock Washers ¼” Nuts

2.4M 4 8 8 8

2.7M 4 8 8 8

3.0M 4 8 8 8

Heavy Duty Feed

Struts

C14F or C24

1- Set of 4 Struts

1- Collar (C, Ku)

12 - 5/16” Lock Washers & Nuts

4- 2' x 2' Angle Brackets

4- 5/16” x 1 ½” Bolts

*Highly Recommended On Systems With Galvanized Back Braces*

Please use a rubberized spray or silicon sealant to coat the threaded rods on

the end of back braces to help prevent corrosion. When doing annual

maintenance on your antenna system please make sure to check as it may

need to be reapplied.

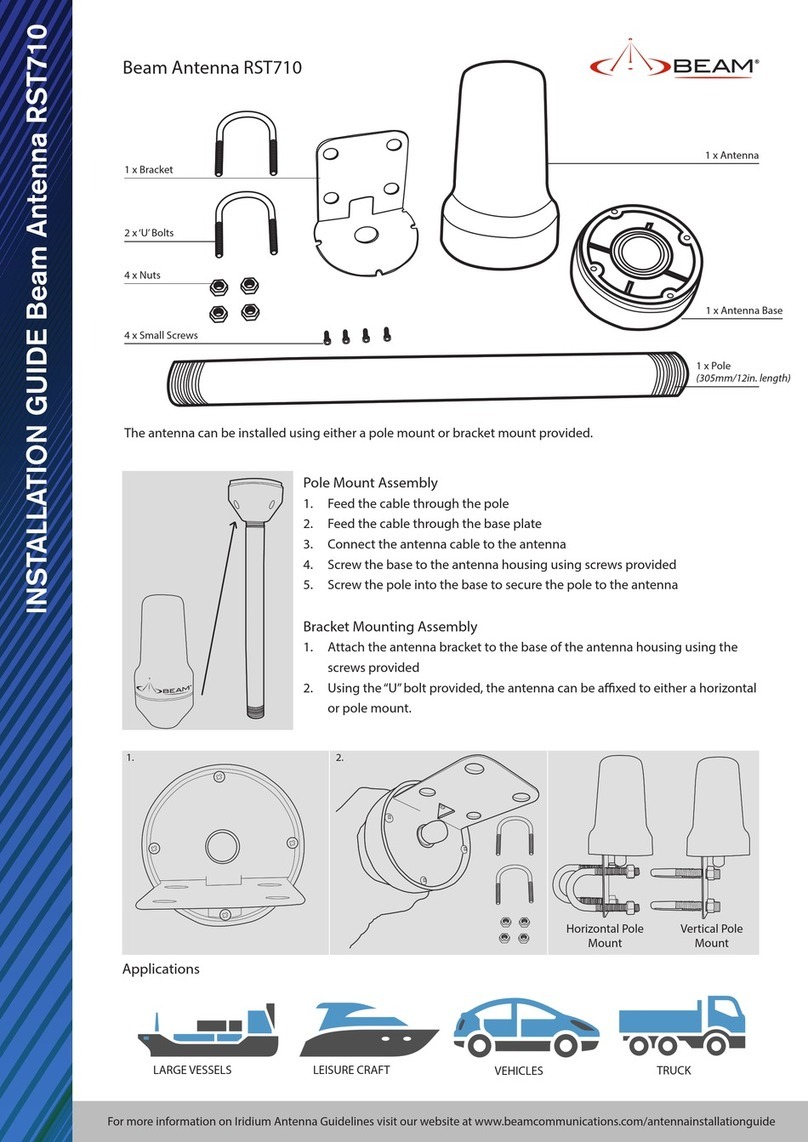

3/8" x 39" Ring

Gemini 39" Azel Mount & Fixed Mount

DH SATELLITE

PRAIRIE DU CHIEN, WISCONSIN 53821

PHONE (608) 326-8406

P.O. BOX 239

DESCRIPTION:

DRWN BY: DATE;

SCALE: REVISED:

DRWG#:

GILBERTS 1-27-15

NOT TO SCALE

39AZELMT wblocks

weld

22.5°

45.0° 45.0°

2" 1/2"

1 1/2"

2"

17/32" Hole

End Side

Top

Tabs

14 1/2"

3/4"

38 1/2"

1/4" x 3" Fins

1/2" x 18" x 18" Plate

3/16" x 2" Dust Shroud

Motivario Gearbox

Chain Drive

16" 20"

12"

6 1/2"

4"

1 1/2"

3/4"

2"

2"

1/8" x 2" x 2" x 40" Square Tube

1/8" x 2" x 2" x 32 1/2" Square Tube

1/8" x 2" x 2" Square Tube

2"

5 3/4"

5 1/4"

1 1/4" Hole

1/8" x 2" x 2"x 30 1/2" Square Tube

1/4" x 2" x 2" x 19" Square Tube

Galvanized Tin Shroud

10 1/2" x 17 3/4"

Front Shroud 5 1/4" deep x 20 1/4" Long

4"

1 3/4"

3/8"

17/32" Hole

31 1/4"

1/8" x 2" x 2" Square Tube

T- Top

Tab

Top Plate

Wear Plate

Bottom Plate 1/2" x 23 1/2"

Bottom of T-

Top

Side

19"

5 1/4"

17/32" Hole

1/4" 2" x 2" Square Tube

3/4"

5 1/2" x 48" Sch. 40

Gibralter Gemini Dual Az-El Mount

3/4"

1/2"

3/4" Hole

2" 2"

18"

18"

1 1/4" Holes

Gemini Base Plate

1/4 x 3" Fins full length

12"

3"

3"

6" O.D. Pipe

3/16" Wall

3/4" x 1 1/2" Set Screws (4)

8 1/2"

8 1/2"

Stow Bar End Tab

5/8"

2"

1/2"

17/32" Hole

Stow Bar End Cap

2 1/4"

30"

1 7/8" x 30" Tube

1/2"

1"

1/4"

2"

17/32" Hole

1"

17/32" Hole

1/2"

1 3/4"

3"

1/2"

Gibralter Gemini Fixed

6"

4"

10"

Fins made from 1/4 x 4"

39" Ring w/blocks

PAGE 3

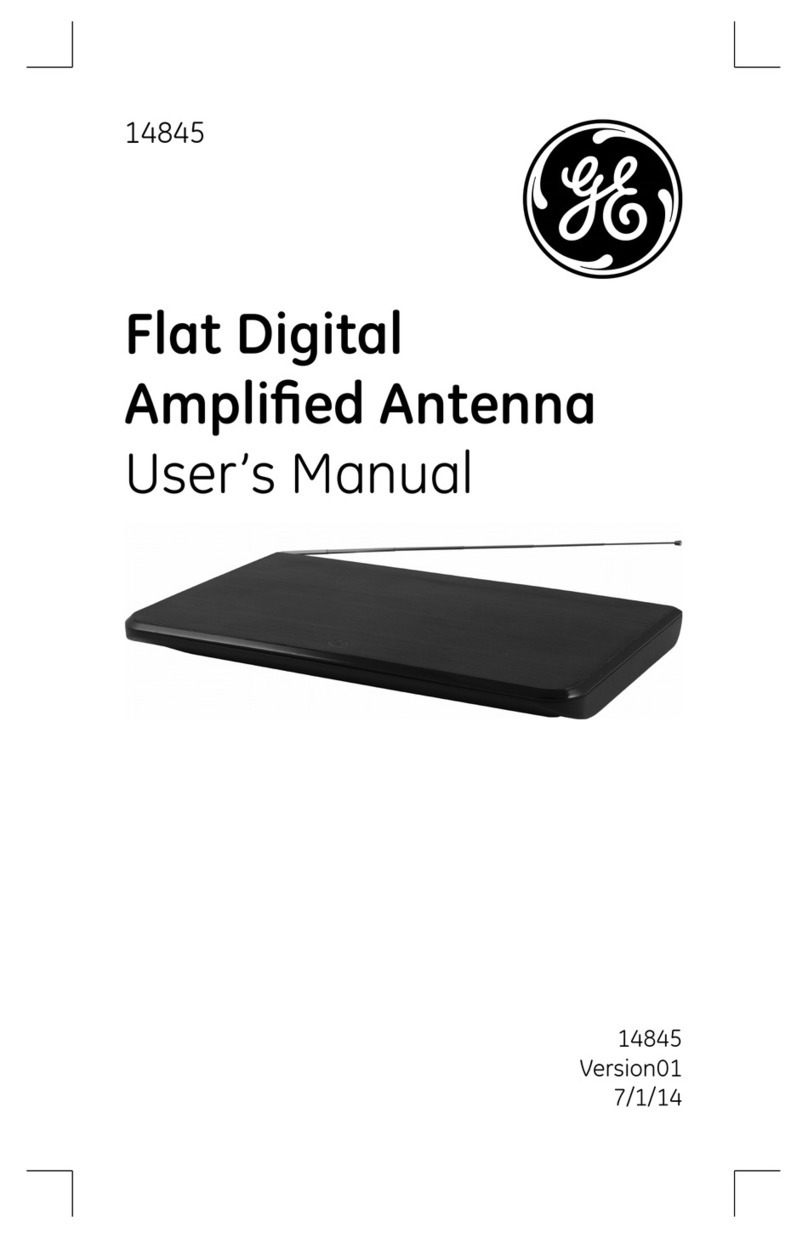

INSTALLATION OF BASE

Look at the drawings below. Figure #1 shows a typical recommended concrete base. This base

should be a minimum of 3’0”x3’0”x 3’0” deep for 2.4m antenna. In areas of frost, we

recommend that this base go below frost levels. You can (depending on soil type) opt to use ½”

rebar to reinforce this structure. Contact your local concrete dealer or a local engineer to give

you an idea if you should use rebar for your locality. WE RECOMMEND THAT YOU CHECK

WITH A LOCAL ENGINEER TO DETERMINE SOIL TYPE AND BEARING TO VERIFY THAT THIS

BASE WILL WORK FOR YOUR LOCALE.

When pouring the concrete, be sure to have the base template ready and insert the J-bolts as per

Figure #2. Leave approximately 2” of the bolt out of the concrete. These bolts can be installed

after the mount is delivered; by drilling the holes in the concrete and using either lead heads or

Garonite, (A resin mortar) to secure the bolts. If you decide to put the bolts in after the concrete

has set, you must install regular hardened bolts or cut the bottom of the J-bolts. (We recommend

the bolts be installed prior to the delivery of the mount). Our people have installed both lead

heads and Garonite, we recommend the Garonite.

When installing the Gibralter Gemini stand, carefully lower it over the bolts and tighten the

nuts in place. (The gearbox should be on the North side of the mount in the Northern Hemisphere and on the

South side of the mount for the Southern Hemisphere.) Be sure to install a lock washer. It is always a

good idea to get the base plumb, although this is not critical with this Azimuth-Elevation mount

as it would be a polar mount. The front of the mount should be facing south in the Northern

Hemisphere. (The rear of the mount will have the gearbox). With the Gibralter Gemini mount,

you will have over 250 degrees of travel, but you do not have a full 360 degrees of azimuth. I

mention this for those of you who are installing the Gibralter Gemini to track things other than

the Geosynchronous Satellite belt.

Fig. #1

Fig. #2

PAGE 4

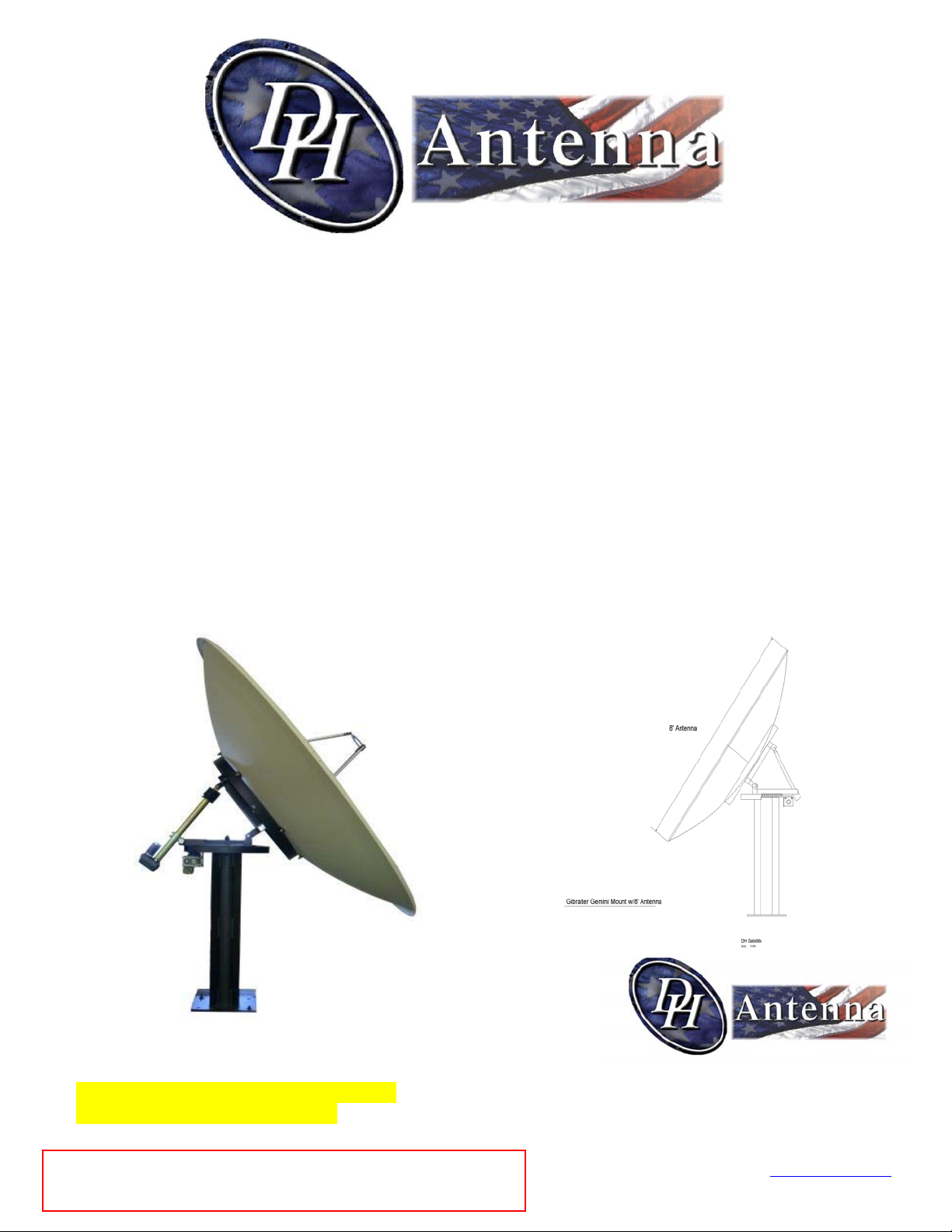

Assemble Ring to Base Stand (for the 2.4m & 2.7m)

You will have to assemble the 39” ring to the Ge-Mini base. Look at the photo of

the mount in Fig. #3, you will notice that the top of the mount has a bracket to

attach the elevation arm. The bottom of the 2” framework has two tabs. Insert a

½”x ¾” x ½” long brass bushing (found in the bolt bag) into each of the tabs.

Place the ring on the base stand, inserting the tabs (with the bushing) into the

double ear tabs. Secure with ½” x 2 ½” bolt, ½” lock washer & nut. Next install

the elevation actuator. Attach the gimball actuator clamp to the right side rear of

the 2” square tube with a ½” x 4 ½” bolt. Then take the eyebolt on the end of the

actuator and put it in between the top bracket of the frame work of the ring. Use a

½” x 2” bolt and use a lock washer and nut to secure it in place. This elevation

actuator will be used to precisely aim the dish to the satellite you are using.

PAGE 5

Please see the parts listed supplied to

help identify all parts for both the

Dual Powered Ge-Mini and the Fixed

Az-El Ge-mini. You will find these

drawings on the previous pages of

this instruction manual. Note the

Fixed Az-El Ge-Mini does not

include the motors or gears and

drives. These parts are only used for

the Dual Powered Ge-mini.

Fig. #3

ASSEMBLING THE ANTENNA TO THE RING

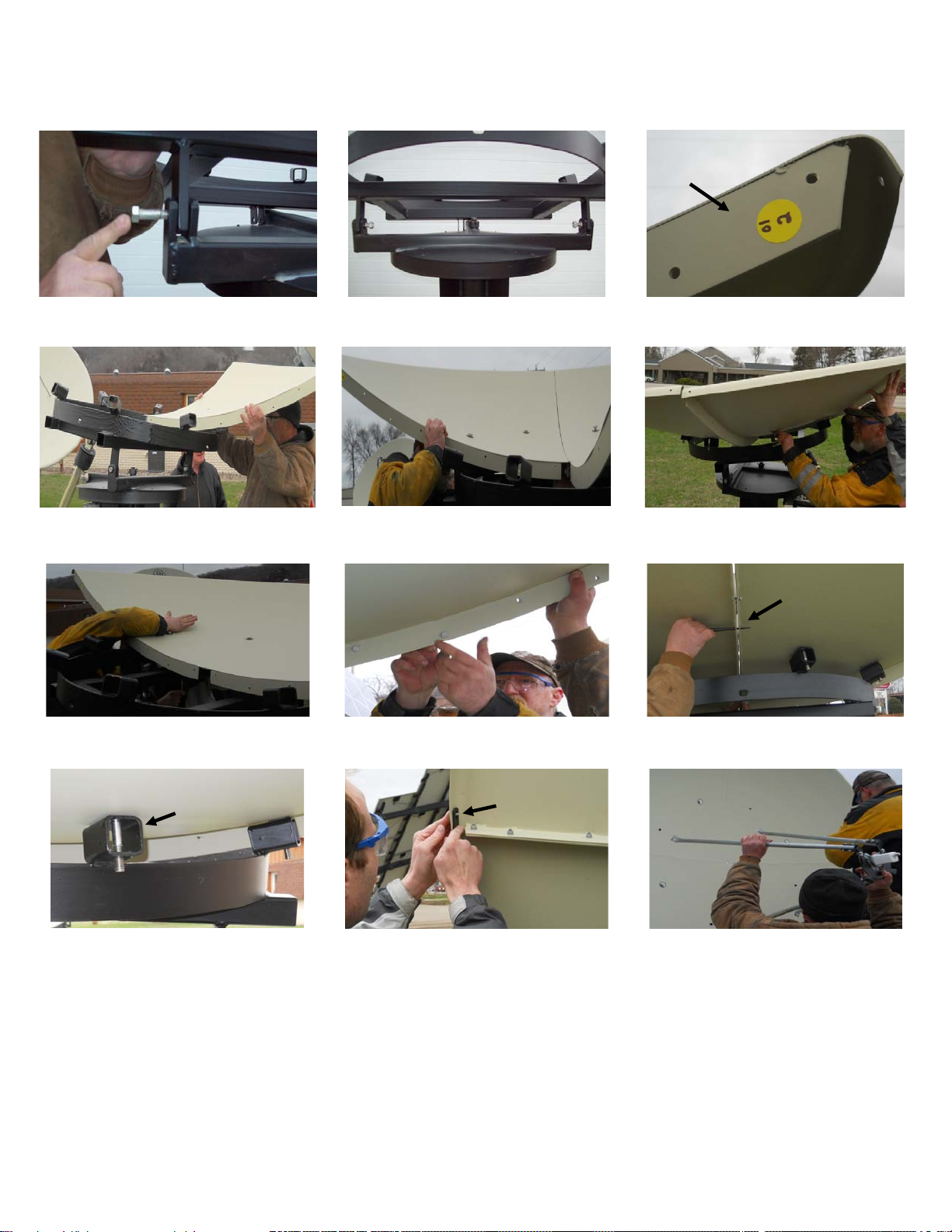

The mount should be assembled and now it is time to install the antenna. We recommend two methods of lifting the

antenna onto the post. SPECIAL NOTE: A 2.4m and 2.7m use a 39” ring and a 3.0m uses a 48” ring.

1st Option: (On Ground: Lifting the Antenna as One Piece)

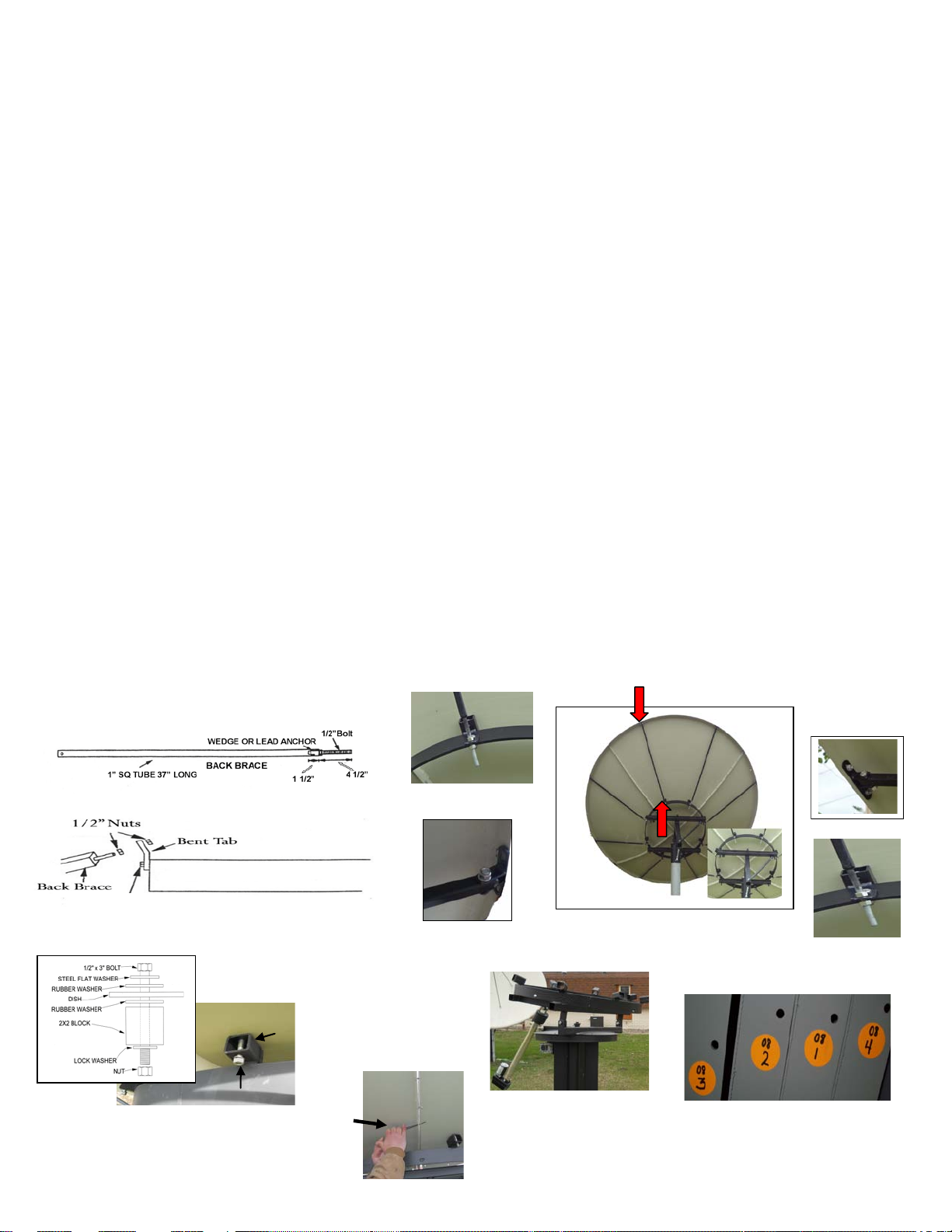

The antenna will come in 4 pieces each having a color coded dot on the rib (see FIG. #9). NOTE: After complete

installation you will no longer see the colored dots. You must take two sections of the antenna and place them on a flat

surface face down allowing for an installer to work on attaching the numbered ribs. The antenna must always stay in the

crate until assembled. (see FIG. #10). Take panel one labeled 08/1 and 08/2 and attach it to panel 2 which is labeled 08/2

on one rib and 08/3 on the other rib. Connect panel 1 with rib #2 (labeled 08/2) to panel 2 with rib #2 (labeled 08/2),

matching the #2 on each rib of the two panels (See photos below). Install 1/4" x 3/4" bolts in all holes, finger tight. To

allow for greater ease in aligning the templates we recommend using an alignment punch tool (See Figure #11).

IMPORTANT: Do not force or drill any ribs to make them fit. Doing so will void your warranty and the dish will

not perform. Once you have the bolts inserted into the template holes, attach the splice straps to the inside lip of the

antenna (See FIG. #12 ). Continue on to the next panel in the same manner until finished with all panels. Now tighten all

hardware.

Next lift up the antenna and have the smallest worker go underneath the dish. You will then place the ring on the

antenna, making sure that the two pilot holes correspond. One is located next to one of the 8- ½” holes in the dish and

other is found on one of the 8 blocks on the mount next to the ½” holes. The pilot holes are just locators for aligning the

holes on the dish with those on the mount. The weld on the antenna is lined up with the boom on the mount. Have the

worker underneath the antenna insert the bolts up through the dish. On the other side have another worker attach the

rubber washer, lock washer and nut. Please do not tighten nuts at this point. After all bolts have been inserted have

the worker underneath come out from under the dish. If you purchased an antenna with back braces attach them now and

tighten down all bolts. You can now lift the antenna and ring by a crane, forklift or a boom truck. This insures that no

pressure will be put on the antenna.

FIG. #9

FIG. #10

Match 2 with 2

Rib

The top number represents the serial number of the antenna. *Example: In FIG. #9 you will see 4 sections with the

top number 08. You will take all four pieces of 08 to make one complete antenna.

Rib number. *Example: On a 4 piece 3.0m antenna the dot will have a 08 on the upper part of the dot

(serial number) and the lower number of 1, 2, 3, 4 are the rib numbers.

FIG. #11

Splice Strap

FIG. #12

Alignment

Punch

PAGE 6

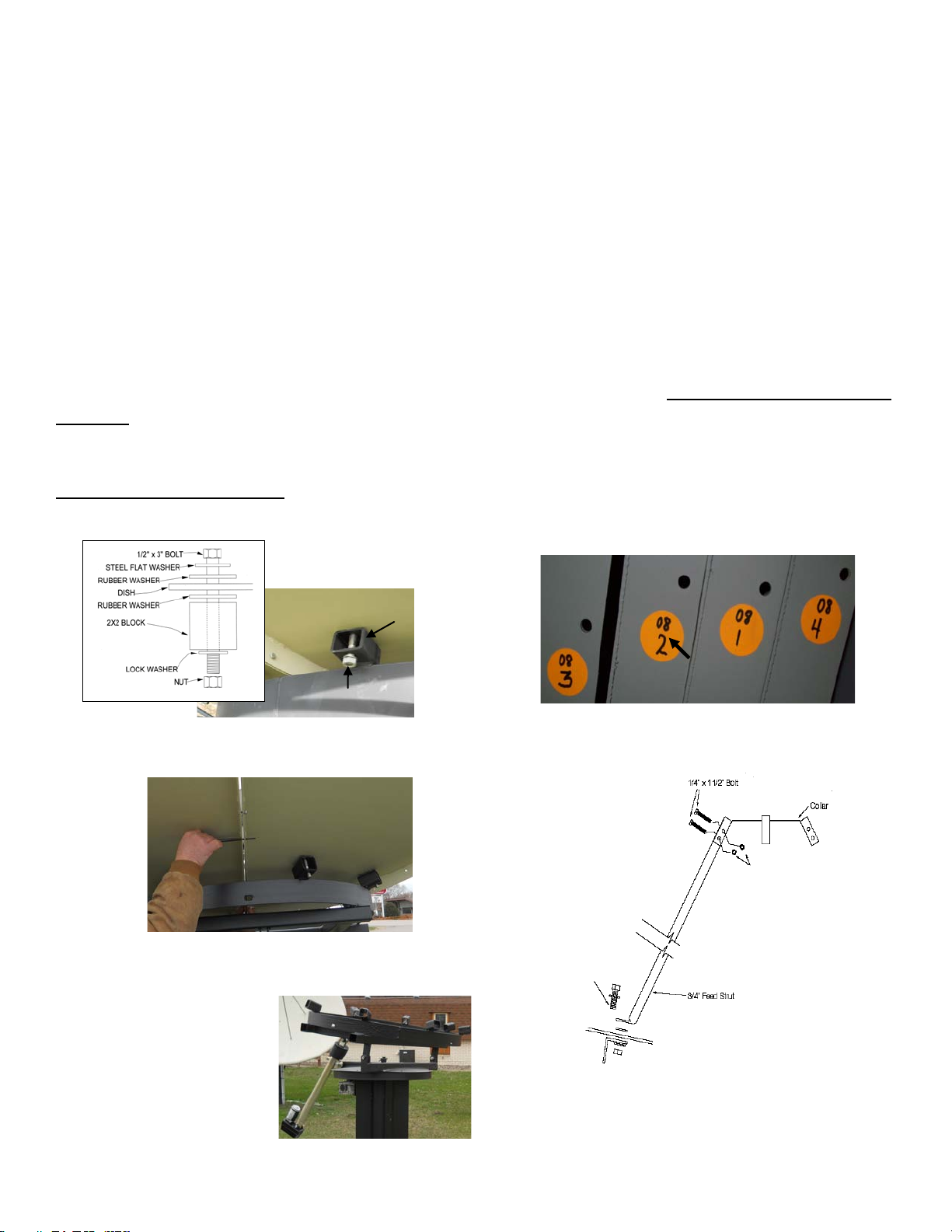

NOTE:

The aluminum antenna is also stamped in the lip. This number

reflects the position of the panel.

The number stamped on the rib reflects the antenna as a whole for

bulk shipping. Each section has one rib stamped. The number will

be the same on all ribs making it one complete antenna.

2nd Option: Bird Bath Method, installing by sections with BACK BRACES.

(Using 2-3 People)

*IMPORTANT: If you purchased an antenna without back braces continue to page 8.

Assemble mount and put mount in birdbath position (See picture C below).

Step 1: Install the brace clips to the back braces before placing on the antenna lip and ring. Have all 4 brace

clips installed on the brace before going to the next step. See brace clip and back brace photos below.

Step 2: Install brace clips to the ends of the 4 back braces and install the ½” nut on the threaded rod end of the

back brace, threading it down approximately 4 to 4 ½” down the threaded rod (see FIG. #13).

Step 3: Take the first panel and install it to the ring of the mount finger tight. Be sure to find the pilot hole on

the mount and on the antenna. Take the back brace that is ready and put the threaded rod through the tab on the

ring (see photo A). Take the other end of the rod with the clip and attach the brace and clip to the lip of the

antenna section (see picture B).

Step 4: Insert ½” x 3” bolt (see FIG. #17 for washers and rubber placement) from the antenna to the mount.

Have one person continue holding the panel in place while the second person attaches the back brace.

(Remember the threaded end of the back brace should already have the ½” nut on the threaded end about 4-4 ½”

on the threaded rod and the bent tab already installed on the ring, see FIG. #15). Insert the threaded rod of the

back brace into the bent tab and bolt brace clip on the edge of the antenna with 3/8” x 1 ½” bolt, 3/8” nut and

3/8” lock washer. Make sure everything is finger tight.

Step 5: Pick up the second antenna panel and be sure the numbers line up and bolt in place just like the first

panel. (see FIG. #9) Once secure you can begin bolting the two units together by placing the ¼” x ¾” bolts

through the templates. Again only finger tight. Continue for the next 2 panels. To allow for greater ease in

aligning the templates we recommend that you use an alignment punch tool. (see FIG. #10).

STEP 6: You will notice all 8 bolts in the face of the antenna have been installed from the antenna to the ring at

this point. You now remove every other bolt from the face of the antenna and replace them with a feed strut.

(See preparing the feed assembly on page 10)

FIG. #13

PICTURE A

PICTURE B

FIG. #17

FIG. #15

Back braces are measured by tube length only.

PAGE 7

FIG. # 9

Brace Clip

Brace Tab Threaded

PICTURE C

PICTURE AA

1/2” x 1 1/2" Bolt

Match 2 with 2

FIG. # 10

Alignment

Punch

Block

1/2” x 3” Bolt

Bird Bath Method, installing by sections NO BACK BRACES.

(Using 2-3 People)

Assemble mount and put mount in birdbath position (See picture C below).

Step 1: Take the first panel and install the ½” x 3” bolt from the antenna to the mount finger tight (see FIG. #9

for washer and rubber placement). Be sure to find the pilot hole on the mount and on the antenna.

Step 2: Pick up the second antenna panel and be sure the numbers line up and bolt in place just like the first

panel (see FIG. #10). Once secure you can begin bolting the two units together by placing the ¼” x ¾” bolts

through the templates. Again only finger tight. Continue for the next 2 panels. To allow for greater ease in

aligning the templates we recommend that you use an alignment punch tool (see FIG. #11).

Step 3: You will notice all 8 bolts in the face of the antenna have been installed from the antenna to the ring at

this point. You now remove every other bolt from the face of the antenna and replace them with a feed strut.

Use this sequence: bolt, metal washer, feed strut, rubber washer. On the backside of the dish, insert a rubber

washer between the dish and the ring block, followed by a lock washer and a nut. Please do not tighten nuts at

this time.

Step 4: Next install the feed collar (C14F collar) into the feed struts. Secure with 8- ¼” x 1 ½” bolts and ¼”

lock washers and nuts. (see FIG. #12). Your next step is to tighten the 8 bolts that secure the dish to the ring.

DO NOT OVER TIGHTEN. This is also addressed in Preparing the Feed Assembly on page 10.

FIG. #10

Match 2 with 2

FIG. #9

FIG. #12

PICTURE C

FIG. #11

PAGE 8

¼” Lock Washers & Nuts

Block

1/2” x 3” Bolt

½” x 3” Bolt

½” Steel Washer

½” Rubber Washer

Antenna Surface

½” Rubber Washer

½” Lock Washer

½” Nut

Installation Photos:

Additional Help for Installing by Sections to the Ring

Template Rib

Block

Splice Strap

Alignment Punch

PAGE 9

Preparing the Feed Assembly

If the feedhorn you have selected has an adjustable scalar ring, move it to the proper wave-guide setting.

The 2.4M, 2.7M, and 3M antennas all have the same f/l. The F/D ratio is listed below for each. Be

sure to measure from the center of the dish to the throat of the feedhorn when using a Chaparral

style feed. You should be measuring 35 ¾” from the center of the dish to the throat of the feedhorn

for C band. Ku band is more critical so please if using a C/Ku band feedhorn to error on setting it up

for measuring the Ku which would be 35 7/8” from the center of the dish to the throat of the

feedhorn. Major adjustments for Ku band can be made by placing the three-piece collar on

either side of the horseshoe collar.

Special note: Seavey feeds are measured to the scalar ring and not the throat.

Unless you have specified what brand name and frequency your feedhorn is, you will have received by

default the C14F collar. It is best if you have discussed with your sales rep the feedhorn you are using prior

to shipping so that DH Satellite can make sure you have the proper collar to mate to your feedhorn. You do

need to make sure your feedhorn and collar are the correct combination.

Take the scalar ring of the feedhorn and place it under the collar with rings pointing toward the dish. Turn

it until all three holes line up between the two and insert the ¼” x ¾” bolts through the scalar ring and then

through the collar; fasten with the ¼” nuts. Most C-band and dual feeds have a 3-bolt pattern on the scalar

ring just for this. Tighten all nuts and bolts. Figure #7 is the final assembly for the Ku band showing a Ku

straight through feedhorn being used.

Check to see that the feed is at the focal length, the actual focal length should be ¼”

inside the wave-guide, for C-band and 1/8” for Ku band.

8' 35 ¾” Focal Length - .375 F/D - Wave Guide 9/16”

9’ 35 ¾” Focal Length - .33 F/D -Wave Guide 5/8”

10’ 35 ¾” Focal Length - .3 F/D -Wave Guide 7/8”

KU4FL

FIG. #6

PAGE 10

FIG #7

C14F COLLAR AND STRUTS

Strut Local on Ring Face of 4PC Sectional

Antenna 8 Block Ring

HeavyDutyFeedStrut________________________

Wehavedevelopedanewfeedstrutandcollarforthe

heavier4PortSeaveyfeedassembly.Thisutilizesthe

rectangularaluminumtubeforthefeedstrut.Figure

#12rightshowsthesketchofthisfeedassembly;itis

verysimpletoinstall.Eachstruthas2‐5/16x21/4”

boltstoattachtothefeedcollar.Nowattachoneof

theanglebrackets(2"x2")totheantennawiththe

1/2"x3"bolts.Noticethatanglebrackethastwo

holes.Youwillusethebottomhole.Thetopholeis

foranoptionalChaparraltypefeed.Next,attachthebase

ofthestruttotheanglebracketswiththe5/16x11/2"

boltssupplied.Alignthefeedtopointdirectlyatthecenter

oftheantenna.Nowmeasurethefocallengthtothefront

ofthescalarrings.(Seaveyrecommendsf/lismeasuredto

frontofscalarring.)

KuBandFeedAssembly-----------------------------

WhenusingtheKuonlyfeeds,youwillbeusingtheC14Ffeedplateandtri‐collar.SeeFigure#13.First,attachtheflat

tri‐collartothefeedhornasfollows:attachthefirsttwopiecesbyusingthe8‐32x1"screwsprovided.Nowslidethe

collarontothefeedhornandaddthethirdpiece;tightenevenly.Attachthetri‐collartothelargerhorseshoecollarby

the8‐32x¾”boltsandnuts;tightendown.Youcanadjustpolaritybylooseningthesenutsandrotatingfeed.Finishby

assemblingthestrutstothefeedcollarasshowninFigure14.(Fig#14showssingleKufeedinsertedincollar)

Figure#13Figure#14

FineTuningtheAntenna--------------------------------

Aftertheassemblyiscomplete,werecommendyou"stringtheantenna."Simplyrunastringfromabackbraceacross

thefrontoftheantennatothebrace180degreesapart.Nowdothiswitheachbrace.Ifthestringsallmeetinthe

middleandnopressureisonanyofthem,theantennaisperfectandnofurtherworkneedsbedone.Ifoneofthe

stringsisnotclosetotheothers,thenstepbackandsightacrossthedishandseewhereyouwillhavetopushwiththe

backbraces.Onlymakesmalladjustmentsatatimeandremembertostartwithallbracesloose.Afteryouaresure

theantennasurfaceisflat,youshoulddoublechecktoseethatthefeedhornissetattheproperdistance,then

check

toseethatitispointedatthecenteroftheantenna.Inouryearsofsettingupantennas,these

threeitems

seemtocoverover98%ofallproblemsofpicturequality.

PAGE11

FeedStrutLength

2.4m&2.7mwitha39”mountis365/8”

3.0mwitha48”mountis413/4”

Figure#12

½” x 3” Bolts

Final Inspection of the Antenna

After the assembly is complete, we recommend that you visually

look at the dish for FOUR things. 1. Make sure that both edges

are symmetrical. To accomplish this you should stand approx.

3M(10ft) away from the side of the dish. Eye ball the two edges to

confirm that they are even. This will confirm your dish is in

perfect shape. 2. Check to make sure that your feed is set to the

right focal distance. 3. Check that the feed is pointed precisely to

the center of the dish. 4. Look at all the nuts & bolts to confirm

that they are tight. After this final inspection you should be able to

install all your electronics and complete the wiring.

Technical Service: 1-608-326-8406

M-F 7:30AM to 5PM CST

www.dhsatellite.com

PAGE 12

MISSING PARTS WARRANTY

You have obtained one of the best antennas on the market today!

We hope that you will be happy with your new DH Antenna.

To better acquaint you with our system, we ask that you read the

instruction manual and verify that all of the equipment has been

supplied in your shipment. Please check the hardware as well as the

parts list and compare to what you have received. It is our policy to

make every effort to assure you that you have received all parts

necessary to make this a pleasant experience.

While checking over your parts it is possible to find that you are

missing pieces that are necessary to complete the installation. You

will find below our shipping policy and charges if any.

Notify Factory within 5 days ARO (Delivery): Red / no charge

Notify Factory 5 to 30 days ARO: Regular / no charge

Notify Factory 31 days ARO: Your cost for parts and shipping.

Please note we are only able to ship out from our location if notified by 12:00

PM CST. Calls received after this time will ship the following business day.

International shipping will need to be discussed prior to shipping.

Call us M-F 7:30 am to 5 pm 608-326-8406

PHONE: 1 (608) 326-8406

FAX: 1 (608) 326-4233

EMAIL: [email protected]

Size of antenna: _________________ Date: ______________________

Feedhorn make: _________________ Model: ______________________

LNB Make: _____________________ Model: ______________________

Please make notes below to help in future years with replacement needs.

Table of contents

Popular Antenna manuals by other brands

Channel Master

Channel Master 2016 installation instructions

Deger

Deger D25H Assembly and operating manual

HUSTLER

HUSTLER 6-BTV installation instructions

Trantec

Trantec S4.5 Series operating instructions

Cisco

Cisco Aironet AIR-ANT2568VG-N quick start guide

PRO.SIS.TEL.

PRO.SIS.TEL. PST-DDR5 Assembly instructions

VideoComm Technologies

VideoComm Technologies EAT-002 (PARA-5829) owner's manual

RCA

RCA ANT1650 - Flat Digital Amplified Indoor TV... user guide

M2 Antenna Systems

M2 Antenna Systems 403CP20 Assembly manual

Hama

Hama 121703 operating instructions

RF Elements

RF Elements UltraDish TP 400 user guide

Shure

Shure PA411 quick start guide