DHC BT2400 Pro User manual

1

BT2400 Pro

Cloud Ready Battery

and Electrical System Tester

Owner’s Manual

Read entire manual before using this product.

2

MAIN FEATURES

1. 6V and 12V Starter Battery Test. (including Start-Stop Batteries)

2. 12V and 24V Cranking & Charging System Test.

3. Built-in Wi-Fi for test report upload to mybatteryexpert.com and OTA firmware

update.

4. Built-in barcode scanner, supports 1D and 2D barcodes.

5. Precise temperature compensation.

6. Print out test results.

7. Optional amp clamp and voltage probe.

IMPORTANT

1. Suggested operation range 0濎 (32ʲ) to 50濎 (122ʲ) in ambient

temperature.

2. Radio frequency range: 2400 ~ 2483.5 MHZ

3. Maximum radio frequency transmitted power: 20.5 dBm

4. FCC ID: 2AC7Z-ESPWROOM02D

WARNING

WARNING: This product can expose you to chemicals including arsenic, which is

known to the State of California to cause cancer.

For more information, go to www.P65Warnings.ca.gov.

1. Working in the vicinity of a lead acid battery is dangerous. Batteries generate

explosive gases during normal battery operation. For this reason, it is of

utmost importance, if you have any doubt, that each time before using your

tester, you read these instructions very carefully.

2. To reduce risk of battery explosion, follow these instructions and those

published by the battery manufacturer and manufacturer of any equipment

English

3

you intend to use in the vicinity of the battery. Observe cautionary markings

on these items.

3. Do not expose the tester to rain or snow.

PERSONAL SAFETY PRECAUTIONS

1. Someone should be within range of your voice or close enough to come to

your aid when you work near a lead acid battery.

2. Have plenty of fresh water and soap nearby in case battery acid contacts skin,

clothing, or eyes.

3. Wear safety glasses and protective clothing.

4. If battery acid contacts skin or clothing, wash immediately with soap and

water. If acid enters eye, immediately flood eye with running cold water for at

least ten minutes and get medical attention immediately.

5. NEVER smoke or allow a spark or flame in vicinity of battery or engine.

6. Be extra cautious to reduce risk of dropping a metal tool onto the battery. It

could spark or short-circuit the battery or other electrical parts and could

cause an explosion.

7. Remove personal metal items such as rings, bracelets, necklaces, and

watches when working with a lead acid battery. It can produce a short circuit

current high enough to weld a ring or the like to metal causing a severe burn.

PREPARING TO TEST

1. Be sure area around battery is well ventilated while battery is being tested.

2. Clean battery terminals. Be careful to keep corrosion from contacting with

eyes.

3. Inspect the battery for cracked or broken case or cover. If battery is damaged,

do not use tester.

English

4

4. If the battery is not sealed maintenance free, add distilled water in each cell

until battery acid reaches level specified by the manufacturer. This helps

purge excessive gas from cells. Do not overfill.

5. If it is necessary to remove battery from vehicle to test, always remove ground

terminal from battery first. Make sure all accessories in the vehicle are off to

ensure you do not cause any arcing.

OPERATION AND USE

Each time you connect the tester to a battery, the tester will run a quick cable

verification to ensure a proper connection through the output cables to sensors in

the clamp jaws. If the connection checks out OK, the tester will proceed to the

Home Screen. If the connection is poor, the display will show “CHECK CABLE”.

In this case, check cable connections for visible signs of damage, as you may

need to re-connect the clamps to the battery or replace the cable end.

PAPER REPLACEMENT

1. Open the paper roll cover.

2. Place a new paper roll in the compartment. Make sure the thermal side is

upside placed as below.

3. Pull a short length of paper from the compartment and press down the cover

to close.

English

5

PRECAUTIONS FOR USING THE INTEGRATED PRINTER

To prevent overheating the integrated printer, it is not recommended to operate

the printer continuously without short breaks. The printer should be rested for at

least 1 minute for every 2 minutes of continuous use.

There is no need to be worried under normal operation, where one test only

requires one printout and continuous printing is highly unlikely. However, if the

integrated printer does start to get warm, please allow it to cool down by

temporarily halting any printing actions.

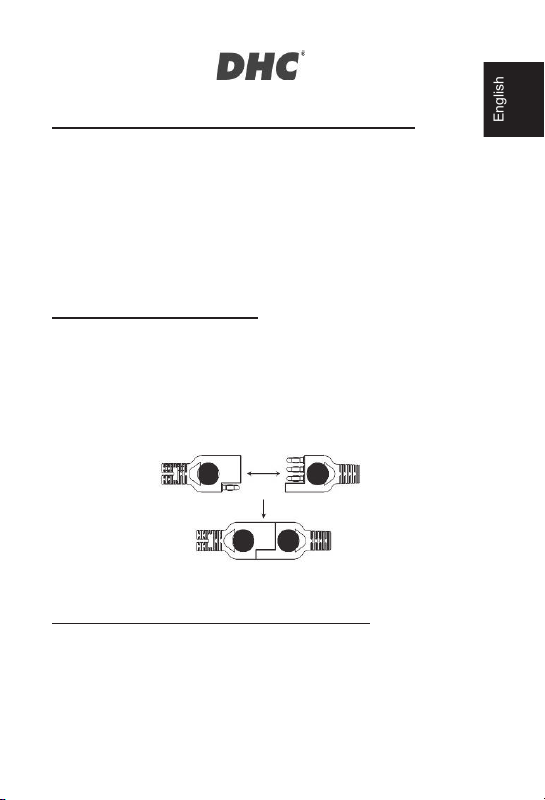

HOW TO REPLACE CLAMP SET

1. Detach the clamp set when in need of replacement.

2. Make sure the new clamp set is properly connected.

*Do not detach the cables unless necessary to ensure the pins are not exposed to

the moisture and acidic liquids which could cause rusting and corrosion.

INSTALL / REPLACE THE INTERNAL BATTERIES

The tester offers two different options for its internal batteries.

A. 6pcs AA batteries.

B. 2pcs 18650 rechargeable lithium batteries.

English

6

Important

It is recommended that the user to apply protected type 18650 lithium batteries

instead of unprotected type 18650 batteries.

Because the circuit of the protected type 18650 battery is embedded in the cell

packaging (battery casing) which protects the cell from “over charge”, heat or

“over discharge”, over current and short circuit and less likely to overheat, burst or

start on fire.

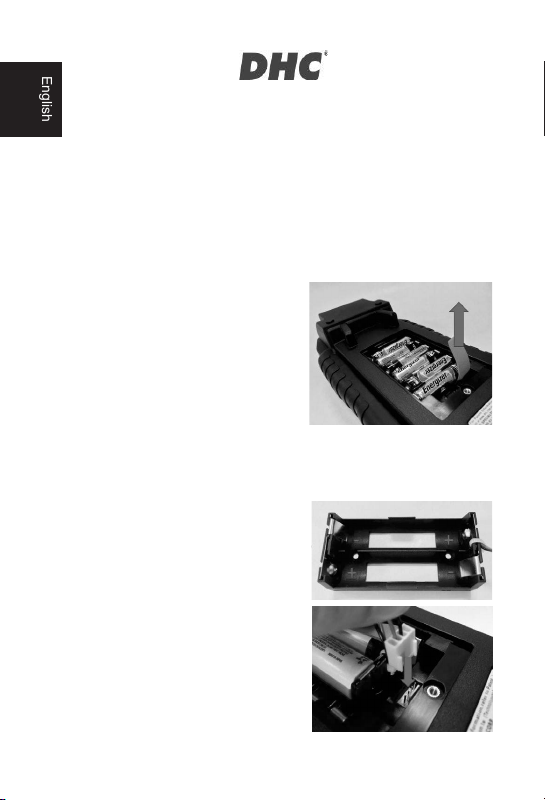

Replace / Install the AA batteries

1. Unscrew the battery cover to access

the battery compartment.

2. Pull the strap up to remove the AA

batteries and install new ones (Always

keep the strap under the batteries.)

3. Close the battery cover and tighten

the screw.

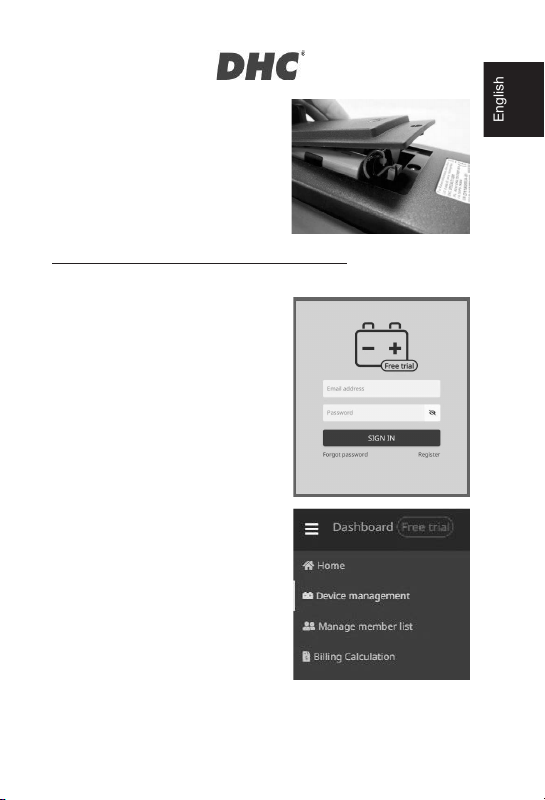

Replace / Install the rechargeable 18650 lithium batteries

1. Unscrew the battery cover to access

the battery compartment.

2. Install / Replace the 18650 lithium

batteries from the battery holder.

3. Plug in the connector of the 18650

lithium battery holder.

4. Place the 18650 lithium battery holder

in position. (Always keep the strap

under the battery holder.)

5. Close the battery cover and tighten the

screw. (Make sure the battery cover

doesn’t clip on the cables of the battery

English

7

holder when closing.)

6. Tighten the srew of the battery cover.

*18650 lithium batteries are not

included in the package.

mybatteryexpert.com (DHC CLOUD SERVICE)

z REGISTER AN ACCOUNT

1. Go to mybatteryexpert.com

2. Click on the “Register” link.

3. Enter your email address and

password, then click “SUBMIT”.

4. Go to your email inbox to complete

account validation.

5. Once completed, you can now start

using mybatteryexpert.com

z LINKING A DEVICE TO YOUR

ACCOUNT

1. Sign into mybatteryexpert.com

2. Expand the menu bar on the top

right corner.

3. Click on “Device management”.

4. Click on “ADD A DEVICE”.

5. Select how would you like to

register y

6. our device, either through scanning

1D/2D barcode or input the

registration code manually.

7. Once completed, you will be able to see the device in the device table.

English

8

6V AND 12V BATTERY TEST

1. Select “Battery Test” from the

main menu.

2. Enter VIN via the barcode

scanner or manually.

z Scan:

Select the QR code icon.

Point the scanner at the

barcode or QR code, VIN

will be automatically

entered.

Select “NEXT” to proceed.

z Manual input:

Press ENTER when the

input area is highlighted to

initiate the virtual keyboard.

Type in the VIN and select

“ аġ” to close the virtual

keyboard.

Select “NEXT” to proceed.

z Note:

Highlight the “X” icon and press ENTER to clear the input area.

Skip the process by directly selecting “NEXT”.

Invalid VIN warning will pop up if the VIN does not meet requirements in

terms of length or character. Select “Yes” to continue without modifying

the VIN. Select “No” to return and reenter the VIN.

3. Select “SETUP” to edit the battery testing criteria. (Testing criteria will be

stored after each test, select “START” to reuse previous settings.)

4. Select battery type. (available types: FLOODED, AGM FLAT, AGM SPIRAL,

VRLA/GEL, EFB.)

5. Select rating. (available ratings: CCA/SAE, DIN, EN, EN2, IEC, JIS, CA/MCA)

English

9

6. Select capacity. Available capacity range:

z 25 to 3000 CCA/SAE

z 25 to 2830 EN

z 25 to 2710 EN2

z 25 to 1985 IEC

z JIS (by battery type)

z 25 to 1685 DIN

z 25 to 3600 CA/MCA

7. Confirm battery position by

selecting the YES/NO option of

“TEST IN VEHICLE?”.

8. The tester will then check if the

user would like to proceed to an

In-Vehicle Test.

z If YES, the tester will

automatically proceed to

the system test after the

battery test is completed.

z If NO, the tester will perform only the battery test.

9. Temperature compensation. Aim the temperature sensor at the battery and

press ENTER.

10. Test result will be presented after test is completed, use directional keys to

review the test result. Select “PRINT” to print test result. Select “DONE” to

return to the main menu.

SURFACE CHARGE

If the tester detects a surface charge, a pop-up notification will ask the user to turn

on loads/headlights for 15 seconds to eliminate the surface charge.

Please note that vehicles with LED headlights and modern vehicle control

modules might not be able to eliminate surface charge within 15 seconds and the

English

10

pop-up may continue. Turn on more loads and repeat the process if this problem

persists.

BATTERY TEST RESULTS

z GOOD & PASS

The battery is good and capable of holding a charge.

z GOOD & RECHARGE

The battery is good but needs to be recharged.

z CAUTION

The battery may be serviced but performance will decline gradually. The

battery may fail under extreme weather conditions and should be closely

monitored, replacement might be necessary. Check battery connection and

charging system to ensure the battery is properly charged.

z RECHARGE & RETEST

Battery is discharged, the battery condition cannot be determined until it is

fully charged. Recharge and retest the battery.

z BAD & REPLACE

The battery will not hold a charge. It should be replaced immediately.

z BAD CELL & REPLACE

The battery has at least one cell short circuit. It should be replaced

immediately.

z LOAD ERROR

Failed to measure battery condition, please make sure the battery is not over

3000CCA/SAE, clamps are properly connected to the battery, and

clamps/cables are in a good state. Clamp/cable condition can be determined

with the “Cable Diagnosis” tool. If the problem persists or clamp/cable need

replacing, ask your dealer for replacement parts or further diagnostics.

English

11

12V AND 24V SYSTEM TEST

1. Select “SYSTEM TEST” from the main

menu.

2. Enter the VIN of the vehicle. (same

input method as BATTERY TEST)

3. Turn off loads and start engine.

4. Use directional keys to review

cranking test result.

5. Select “NEXT” to proceed to charging

test.

6. “Is it a diesel engine?”

z If YES, the tester will ask the

user to rev the engine for 40

seconds before proceeding

to idle & load on test.

z If NO, the tester will proceed with

the idle and load on test

directly.

7. Select “NEXT” when idle test is

completed and move on to the ripple &

load on test.

8. Turn on loads and rev engine for 15

seconds.

(The tester will countdown 15

seconds)

9. Once completed, the ripple & load test

results are displayed.

10. Select NEXT to review the complete

system test results including the

cranking, idle, ripple, and load on test

results.

English

12

11. Use directional keys to switch between 4 different pages of the system test

results.

12. Select PRINT if you would like to print out the system test result.

CRANKING TEST RESULTS

z CRANKING VOLTS NORMAL

The system is showing normal draw.

z CRANKING VOLTS LOW

The cranking voltage is below normal limits, troubleshoot the starter with

manufacturers recommended procedure.

z CRANKING VOLTS NOT DETECTED

The cranking voltage is not detected.

IDLE TEST RESULTS

z CHARGING SYSTEM NORMAL WHEN TESTING AT IDLE

The system is showing normal output from the alternator. No problem is

detected.

z HIGH CHARGING VOLTS WHEN TESTING AT IDLE

The voltage output from the alternator to the battery exceeds the normal limits

of a functioning regulator. Check to ensure there is no loose connection and

the ground connection is normal

If there is no connection issue, replace the regulator. Since most alternators

have the regulator built-in, this will require you to replace the alternator. The

normal high limit of a typical automotive regulator is 14.7 volts +/- 0.05. Check

manufacturer specifications for the correct limit, as it will vary by vehicle type

and manufacturer.

z LOW CHARGING VOLTS WHEN TESTING AT IDLE

The alternator is not providing sufficient current to the battery. Check the belts

to ensure the alternator is rotating with engine running.

English

13

If the belts are slipping or broken, replace the belts and retest. Check the

connections from the alternator to the battery. If the connection is loose or

heavily corroded, clean or replace the cable and retest. If the belts and

connections are in good condition, replace the alternator.

RIPPLE TEST RESULTS

z NORMAL RIPPLE DETECTED

Diodes function well in the alternator / starter.

z NO RIPPLE DETECTED

Ripple is not detected.

z EXCESS RIPPLE DETECTED

One or more diodes in the alternator are not functioning or there is stator

damage. Check to ensure the alternator mounting is sturdy and that the belts

are in good shape and functioning properly. If the mounting and belts are

good, replace the alternator.

LOAD ON TEST RESULTS

z CHARGING SYSTEM NORMAL WHEN LOAD ON TESTING

The system is showing normal output from the alternator. No problem

detected.

z CHARGING SYSTEM HIGH WHEN LOAD ON TESTING

The voltage output from the alternator to the battery exceeds the normal limits

of a functioning regulator.

Check to ensure there are no loose connections and that the ground

connection is normal. If there are no connection issues, replace the regulator.

Since most alternators have the regulator built-in, this will require you to

replace the alternator.

z CHARGING SYSTEM LOW WHEN LOAD ON TESTING

The alternator is not providing sufficient current for the system’s electrical

loads and the charging current for the battery. Check the belts to ensure the

English

14

alternator is rotating with the engine running. If the belts are slipping or broken,

replace the belts and retest.

Check the connections from the alternator to the battery. If the connection is

loose or heavily corroded, clean or replace the cable and retest. If the belts

and connections are in good working condition, replace the alternator.

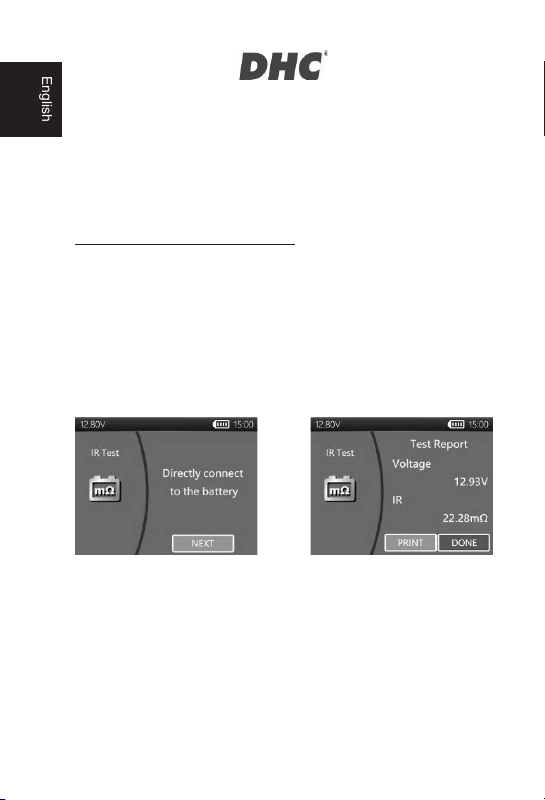

IR TEST (Internal Resistance Test)

1. Select IR TEST from the main menu.

2. Use the clamps to connect with the battery directly.

3. Measure the battery temperature by aiming the temperature sensor at the

battery.

4. Once the IR test is completed, the tester will display the voltage & internal

resistance value on the result page.

5. Select DONE to return to main menu or select PRINT to print out the IR test

result.

English

15

AMP CLAMP AND VOLT PROBE

(DC/AC Current and DC Voltage measurement)

z Optional voltage probe烉MAX 40VDC (Base on the black clamp)

z Optional current clamp烉MAX 600A (1A/1mV)

Note: Please use only the AMP clamp & Volt probe provided by DHC Specialty

Corp.

z DC/AC CURRENT MEASUREMENT

1. Install the 9V battery.

2. Connect Clamp Meter to the jack A

on the tester.

3. Press the button ZERO. Make sure

the display reads zero.

4. Press the trigger to open the

transformer jaws and clamp one

electrical wire.

5. Make sure the clamp jaw is perfectly

closed.

6. Select “V/A METERS” from the main

menu.

7. Read the displayed value.

8. Select “Record Max” and then select “Stop Recording”, the tester will display

the max current recorded during the recording period.

z DC VOLTAGE MEASUREMENTS

*Do not test more than 60V, it may damage the tester.

1. Connect red test lead to the jack V on the tester.

2. Select “V/A METERS” from the main menu.

3. Use the test lead to touch a point within the network of the battery.

4. Read the displayed value.

English

16

5. Select “Record Max” and then select “Stop Recording”, the tester will display

the max voltage recorded during the recording period.

SETTINGS

Enter SETTING from the main menu and then select the item you would like to

adjust or proceed. Such as backlight, language, date & time, customized

information, and cable diagnosis. Or simply check the version of tester.

z BRIGHTNESS

1. Select “BRIGHTNESS” and use directional keys to adjust the brightness of

the display.

2. Press ENTER to confirm the setting and return to settings menu. Or press

BACK key to discard the change and return to the settings menu.

z LANGUAGE

1. Select “LANGUAGE” to choose the language wanted.

2. Press ENTER to confirm the setting and return to setting menu. Or press

BACK key to discard the change and return to the setting menu.

z DATE & TIME

Adjust date and time settings.

1. Use directional keys to adjust and press ENTER to proceed to the next item.

2. Once completed, press BACK to return to the setting menu.

z INFORMATION

1. Select “INFORMATION” to enable / disable, edit or erase the customized print

out info.

2. Press BACK to return to the setting menu.

English

17

z VERISON

1. Select “VERSION” to check the current firmware version and serial number of

the tester.

z CABLE DIAGNOSIS

1. Select “CABLE DIAGNOSIS” to perform self diagnosis of the cable set.

2. Follow on screen instructions.

1. Clamp on a battery that the voltage is above 12.4V. And make sure its

posts are clean.

2. Press ENTER to start.

3. Select START to start the cable diagnosis.

4. Result will be shown on the Test Report, use left and right key to switch

between positive/negative cable test result explanation.

HISTORY

z TEST RESULT

1. Select “HISTORY” and then enter “TEST RESULT” to review the test results

within the last 7 days.

2. Select between test types & days for reviewing.

3. Select “ERASE” will clear all the test records that saved in the tester.

z TEST COUNTER

1. If the “TEST COUNTER” is selected. The user may review the number of the

tests that have been performed. Or print out the counter if needed.

English

18

TEST CODE DECODER

DHC test code decoder can be found at the following sources:

1. On the disc included in the box. (selected models only)

2. At our website, www.dhc.com.tw.

Navigation instruction: DHC website ɦ Support ɦ Download

GLOSSARY

What is a GEL battery?

A gel battery is a lead-acid electric storage battery that:

Ɏ is sealed using special pressure valves and should never be opened.

Ɏ is completely maintenance-free.

Ɏ uses thixotropic gelled electrolyte.

Ɏ uses a recombination reaction to prevent the escape of hydrogen and oxygen

gases normally lost in a flooded lead-acid battery (particularly in deep cycle

applications).

Ɏ is non-spillable, and therefore can be operated in virtually any position.

However, upside-down installation is not recommend-ed.

Ɏ Connections must be retorqued and the batteries should be cleaned

periodically.

What is an AGM battery?

An AGM battery is a lead-acid electric storage battery that:

Ɏ is sealed using special pressure valves and should never be opened.

Ɏ is completely maintenance-free.*

Ɏ has all of its electrolyte absorbed in separators consisting of a sponge-like

mass of matted glass fibers.

Ɏ uses a recombination reaction to prevent the escape of hydrogen and oxygen

gases normally lost in a flooded lead-acid battery (particularly in deep cycle

applications).

English

19

Ɏ is non-spillable, and therefore can be operated in virtually any position.

However, upside-down installation is not recommended.

Ɏ Connections must be retorqued and the batteries should be cleaned

periodically.

What is a VRLA battery?

Valve Regulated Lead Acid Battery – This type of battery is sealed Maintenance

Free with a bounce valve or valves in the top of them that opens when a preset

pressure is realized inside the battery and let’s the excess gas pressure out.

Then the valve resets itself.

What is a SLI battery?

These initials stand for Starting, Lighting and Ignition, which are the three basic

functions which a battery has to perform on all normal vehicles. Batteries given

this description will have been specifically designed for service on cars and trucks

within a voltage controlled electrical system. Those SLI batteries which are

intended for heavy haulage vehicles fitted with large diesel motors may often be

called COMMERCIAL batteries. They have to be much more powerful and more

robust than batteries intended for cars.

What is STATE OF HEALTH?

It means how much battery capacity is left (%) comparing with the marked original

battery capacity.

What is STATE OF CHARGE?

It means how many percent of the battery is actually charged.

What is CCA (COLD CRANKING AMPS)?

The current in amperes which a new fully charged battery can deliver for 30

seconds continuously without the terminal voltage falling below 1.2volts per cell,

after it has been cooled to 0OF and held at that temperature. This rating reflects

the ability of the battery to deliver engine starting currents under winter conditions.

English

20

What is AMPERE-HOUR?

The unit of measurement of electrical capacity. A current of one ampere for one

hour implies the delivery or receipt of one ampere-hour of electricity. Current

multiplied by time in hours equals ampere-hours.

TERMS AND CONDITIONS OF WARRANTY

Any battery tester defective in material or workmanship will be repaired or

replaced according to published defective return test repair procedures. The

existence of a defect shall be determined by the seller in accordance with

published procedures. The published test procedures are available upon request.

This warranty does not cover any unit that has been damaged due to accident,

abuse, alternation, use for a purpose other than that for which it was intended, or

failure to follow operating instructions. This warranty is expressly limited to

original retail buyers. This warranty is not assignable or transferable. Proof of

purchase is required for all alleged claims. Warranty cannot be authorized without

proof of purchase. Warranty claims must be sent pre-paid with dated proof of

purchase. Damage incurred during shipment is the responsibility of the shipper

(customer returning unit) If the returned unit qualifies for warranty, the shipper will

only incur shipping cost. The seller reserves the right to substitute or offer

alternative warranty options at its discretion.

The sole and exclusive remedy for any unit found to be defective is repair or

replacement, at the option of the seller. In no event shall the seller be liable for

any direct, indirect, special, incidental, or consequential damages (including lost

profit) whether based on warranty, contract, tort, or any other legal theory.

RETURN GOODS

Pack with sufficient over-pack to prevent damage during shipment. Damage

incurred during return shipment is not covered under this warranty. Repair costs

for such damages will be charged back to shipper.

REMARK

WHEN RETURNING GOODS, PLEASE SHOW “RETURN GOODS” ON ALL

INVOICES & RELATED SHIPPING DOCUMENTS TO PREVENT ANY EXTRA

CHARGE.”

English

Table of contents

Languages:

Other DHC Test Equipment manuals

Popular Test Equipment manuals by other brands

Bosch

Bosch FSA 500 instructions

Saluki

Saluki S2108 Series user manual

Associated Equipment

Associated Equipment BEST 6044 Owner/operator and safety manual

Transforming Technologies

Transforming Technologies Ohm Metrics WST200 instruction manual

Flintec

Flintec LCT-11 Quick user guide

Rohde & Schwarz

Rohde & Schwarz RTO64 Getting started