5

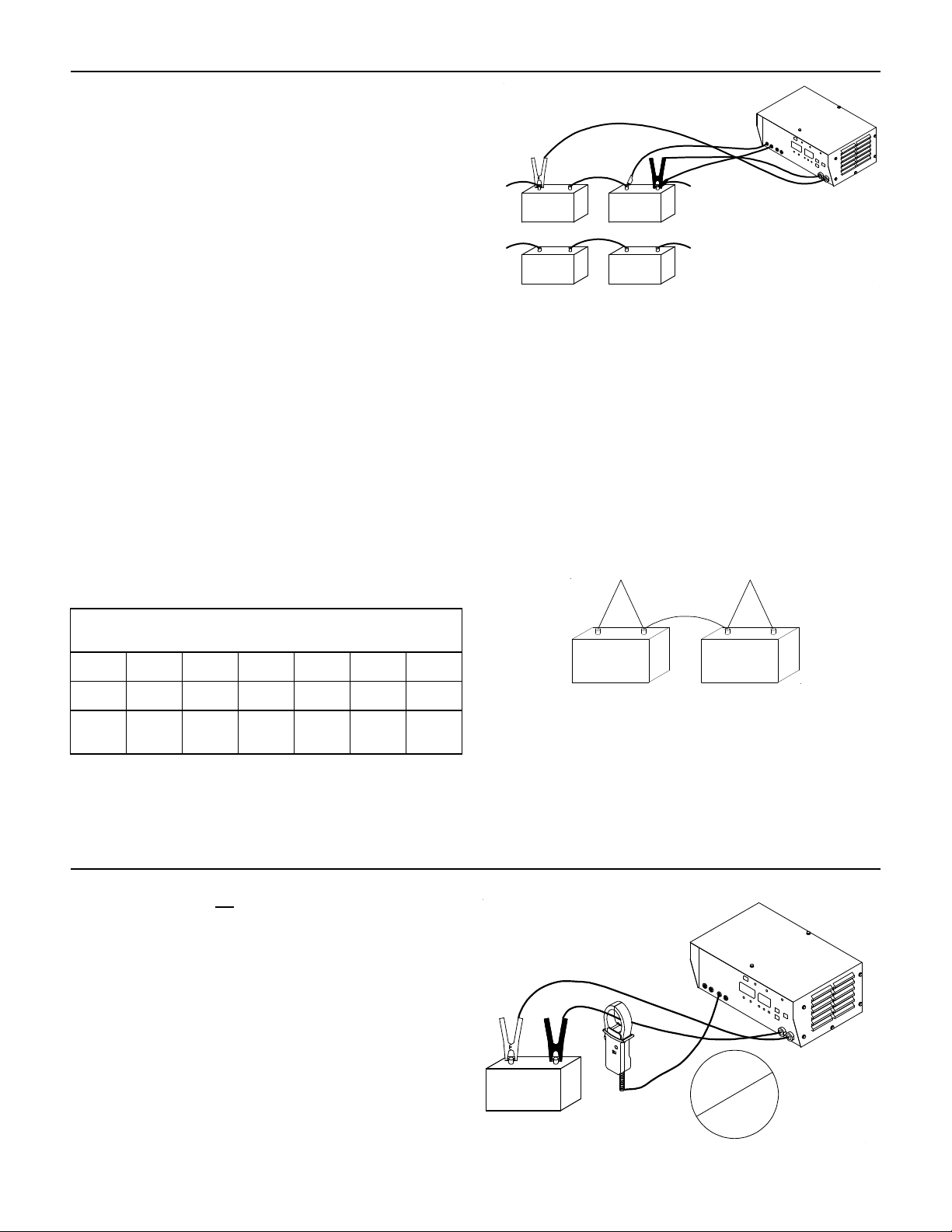

STARTER TESTS

Current draw of the starter, battery voltage, and voltage drop of

leads can be measured when connected as shown (See figure

8).

This unit is designed to capture the maximum (peak) starting

current , the running starting current and the minimum battery

voltage when the vehicle is started.

Review the Safety section in the front of this manual.

1) Attach the heavy duty leads to the battery as shown.

2) Press Test Selection [2] button until the starter LED is lit.

3) Press Start Test [4] button Starter LED will start to flash.

Attach the Amp Probe around the lead from the positive

battery terminal to the starter. If that cable is not

accessible, it may be placed around the ground cable that

runs from the frame or engine block to the negative battery

terminal.

4) Be sure that all the lights and accessories are turned off.

3) Start the engine. Under no condition should you crank

more than 10 seconds at a time. The tester will alternate

the amps display showing the maximum cranking current

with the “MAX. AMPs” LED lit and the

starter running

current

at this time in the amps display. It will also display

the minimum battery voltage with the “MIN. VOLTS” LED lit

alternating with the actual battery voltage in the voltage

display.

4) Minimum acceptable voltage for most vehicles while

cranking is 9.6 volts. Typical

starter running currents

(this would be the smaller current displayed) for vehicles

are:

4 cylinder gas engine--up to 175 amps

6 cylinder gas engine--up to 225 amps

8 cylinder gas engine--up to 250 amps

8 cylinder diesel engine--up to 650 amps

The vehicle service manual should be consulted for more

detailed information. While the vehicle is starting, you should

listen for high pitch or low growling sounds that may indicate

bearing or other problems.

Connections between the battery and starter and between the

battery and frame can also be checked at this time.

STARTER

MOTOR

STARTER

SOLENOID

FRAME

FRAME

+ -

BLACK

LEAD

RED

LEAD

1

2

3

4

5

6

Excessive voltage drop in either cable caused by loose or corroded

connections, undersized, or broken wires may be the problem, not

the starter.

Testing procedure using the Eternal Voltage leads: Review safety

section in the front of the manual. (see figure 8)

1) Attach tester to battery as shown. Press Test Selection [2]

button until the Starter LED is lit: press Start Test [4] button.

2) Attach positive external lead to positive battery terminal (1).

Attach negative (light gauge) external lead to starter solenoid

where the lead from the battery terminates (2).

3) Start the vehicle, press the up arrow this will display the

maximum differential (external) voltage reading during the

starter test.

4) Repeat the same procedure, checking the voltage drop across

the solenoid, (negative lead to starter side of solenoid), (2 to 3).

5) Repeat again, checking the voltage drop between the solenoid

and the starter. (Positive lead at solenoid, negative lead at

starter.) (3 & 4).

6) Repeat again, checking the ground cable from the battery to the

engine block. (Positive lead to engine block, negative lead to

battery negative terminal.) (5 & 6).

7) Acceptable voltage drop on any wire lead should be 0.2 volts or

less. Voltage drop across the starter solenoid should 0.3 volts

or less. Check vehicle service manual for further details.

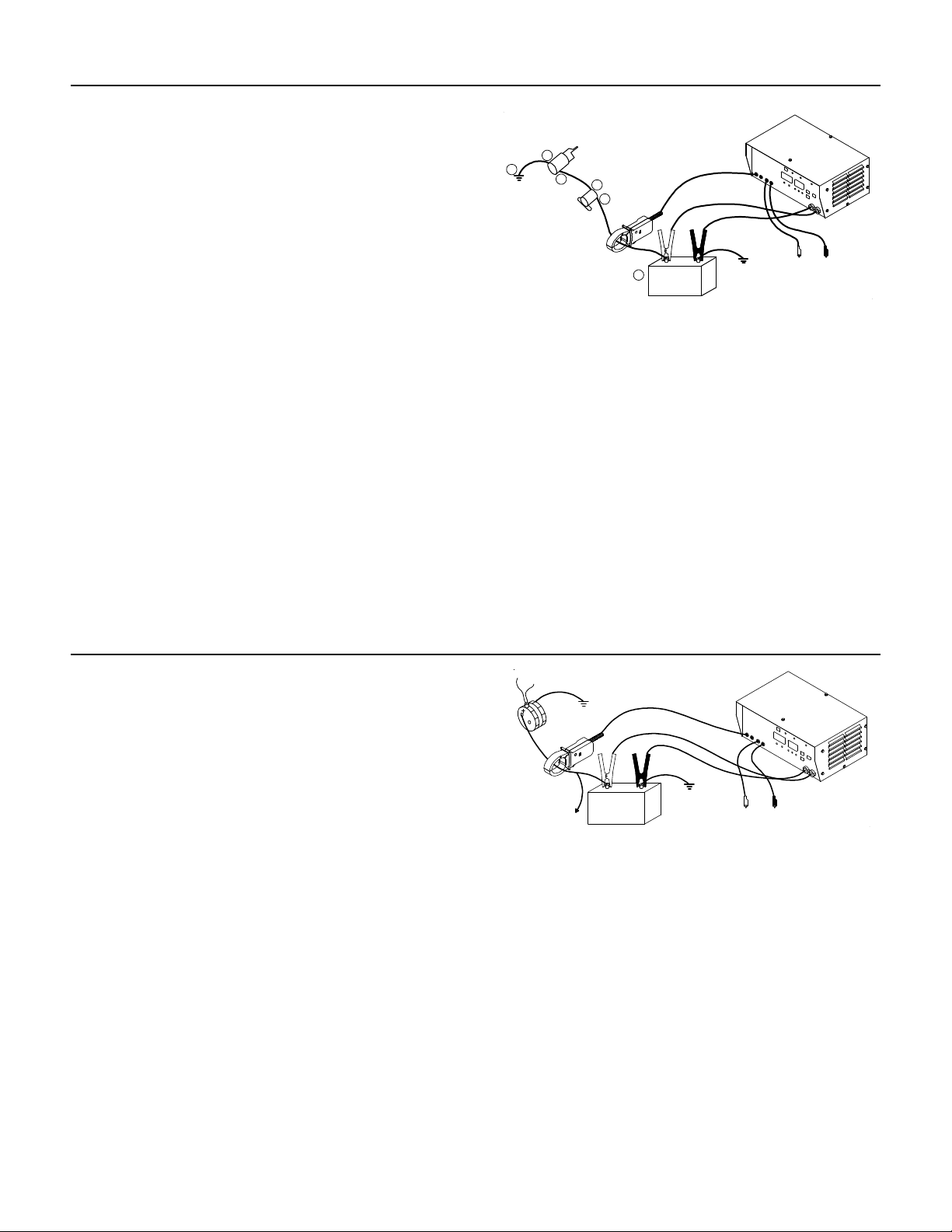

CHARGING SYSTEM TESTS

Please review all the safety instructions in the front of this

manual before running these tests.

Charging problems can be caused by a number of different

things. These can include loose belts, defective diodes or

stators, defective regulators, corroded or loose connections or

defective diode trios (GM cars).

Undercharging will shorten battery life and may not provide the

proper charge to start the vehicle. Overcharging will cause

excess water usage in the battery and shorten battery life.

Proper charging voltage and current from the charging system

to the battery is important for the longest life and maximum

performance.

The proper end of charge voltage will depend on the type of

battery installed by the manufacturer and ambient temperature

of the charging system.

●

A conventional battery (lead-antimony ) will require

charging voltages up to about 14.5 volts.

●

A recombination battery or low maintenance battery may

require charging voltages up to about 14.8 volts.

Voltage specifications will vary from manufacturer to

manufacturer. The service manual for the vehicle should be

consulted for exact charging specifications.

TO

ACCESSORIES

FRAME

+ -

BLACK

LEAD

RED

LEAD

ALTERNATOR

FRAME

It is also important that the charging system be capable of putting out

it's rated current. If the electrical load, (lights, blower, power

accessories, etc.) in the vehicle is more than the output of the

alternator, the battery will discharge to provide the needed current.

The battery may become discharged and will not recharge until some

of the load is turned off. This type of discharge/charge cycle will

greatly shorten the life of the battery. Therefore, output current as

well as output voltage of the charging system should be checked.

NOTE:

A check of the charging system should include a check of the

battery cables to ground and to the alternator to determine bad

connections.